In fact, CNC machining center is CNC milling machine. Many people who live in Guangzhou, Jiangsu, Zhejiang and Shanghai areas call it CNC machining center, which is a automated machine tool with the automatic control system. CNC machine tool, also known as Computer Numerical Control, is a automatic machine tool controlled by the system, and this automatic control system can handle logically the procedure which manipulates codes or other tag commands, decode these procedures according to computer, and then control CNC machine tools to machine components.

G codes

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. CNC refers to CNC milling machines controlled by programming language, which are G codes.

G code tells the computer that controls the motors of the manufacturing equipment how far to move and at what speed.

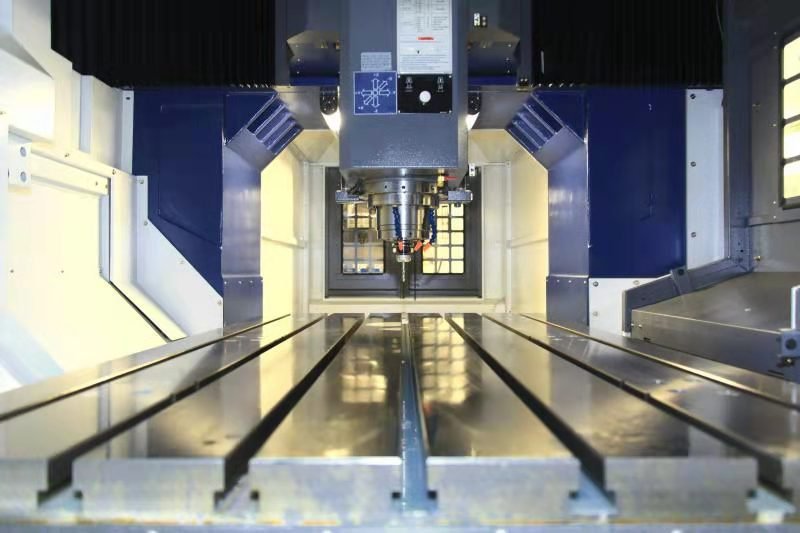

A mill has a spinning tip that carves a metal block, for example, into an intricately machined part.

Code can provide the instructions to the computer-controlled equipment to move the head through 3D maneuvers at differing speeds to create a camshaft, which, as an example, may be used to control valve timing in a gasoline-powered engine.

CNC machining's advantages

The parts produced through CNC machining are of high accuracy and precision,

CNC machining can machine extremely complicated parts which manual machining are not able to handle.

CNC machining technologies have been widely promoted, and most of CNC machine shops are capable of handling machining process.

The most common machining methods are CNC machining centers, CNC machine tools and wire cut EDM in the representative machine shops.

The special tools conducting CNC machining centers are called CNC milling machines or CNC Machining centers. CNC lathes conducting milling processing are called CNC turning centers. G codes for CNC machining can be written by manual procedure, but CNC machine shops usually load CAD files automatically through mobile software named CAM and convert them into G codes programming, and then handle CNC machine tools.

Kunshan Baichuan Precision Parts Co., Ltd,

Kunshan Baichuan Precision Parts Co., Ltd, equipped with more than 20 CNC machining centers and perfect inspection equipment to meet customers' accuracy requirements for machining components, relies on its professional skills in R&D, design, production and assembling to provide one-stop service for a wide range of industries, ranging from the vessel, automation equipment, semiconductor and automotive industries to wind power, medical equipment, aeronautical and aerospace industries, etc.

Call us at 86-13451780566 for consulting.