Welding defects can compromise structural integrity, lead to catastrophic failures, and cost thousands in repairs. Without proper inspection, these hidden flaws remain ticking time bombs in critical components.

Non-destructive testing (NDT) allows thorough examination of welded components without damaging them. These techniques use various physical principles to detect surface and subsurface defects, ensuring structural integrity while preserving the functionality of the tested parts. NDT is essential for quality control in industries where component failure isn't an option.

Non-destructive testing of welded components

In our machining operations, we've seen firsthand how proper testing protocols can make the difference between component success and failure. Let's explore the world of non-destructive testing and how it can transform your manufacturing quality assurance.

What Is Non-Destructive Testing?

Manufacturers face increasing pressure to deliver flawless components while maintaining tight production schedules. Traditional destructive testing means sacrificing valuable parts, driving up costs, and creating waste.

Non-destructive testing encompasses a range of inspection methods that evaluate material properties and component integrity without causing damage. These techniques use principles like sound waves, electromagnetic fields, or radiation to detect defects invisible to the naked eye. NDT provides crucial quality assurance while preserving the tested component for its intended use.

Different non-destructive testing equipment

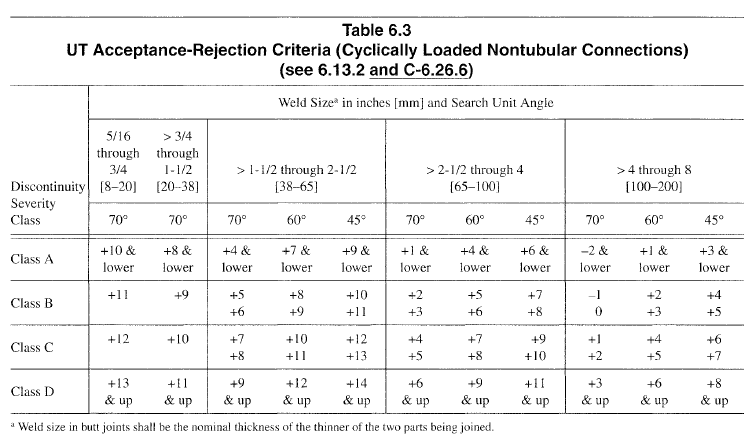

NDT techniques have evolved significantly over recent decades, becoming more sophisticated and accessible for manufacturing applications. The core NDT methods include ultrasonic testing (UT), radiographic testing (RT), magnetic particle inspection (MPI), liquid penetrant testing (PT), and visual inspection. Each method has specific strengths and applications depending on the material being tested and the types of defects being sought.

Ultrasonic testing uses high-frequency sound waves to detect internal flaws by measuring reflected signals. It's particularly effective for thick metal sections and can locate cracks, inclusions, and other discontinuities with high precision. Radiographic testing employs X-rays or gamma rays to create an image of internal structures, making it ideal for detecting voids, inclusions, and incorrect internal geometry.

Magnetic particle inspection works by inducing a magnetic field in ferromagnetic materials – when the field encounters discontinuities, magnetic particles applied to the surface concentrate at these locations, making defects visible. Liquid penetrant testing relies on capillary action to draw a visible dye into surface-breaking defects, highlighting cracks and porosity that might otherwise be invisible. Visual inspection, though seemingly basic, remains fundamental and is often enhanced with tools like borescopes and high-definition cameras.

The selection of the appropriate NDT method depends on factors like material composition, component geometry, defect types being investigated, and accessibility of the inspection area.

How Do Different NDT Methods Apply to Precision Metal Components?

Precision components face increasingly strict tolerances, with even microscopic defects potentially causing catastrophic failures. Customers demand perfection, but traditional inspection methods can miss critical hidden flaws.

Different NDT methods serve specific purposes when examining precision metal components. Ultrasonic testing excels at finding internal defects in thick metal parts without radiation hazards, while X-ray inspection creates detailed images of internal structures for complex geometries. Magnetic particle inspection quickly identifies surface and near-surface cracks in ferromagnetic materials, making it ideal for steel components.

Ultrasonic testing on a precision metal component

In our precision machining operations, we've implemented a multi-method approach to NDT that addresses the unique challenges presented by various metal components. For critical aerospace parts made from titanium alloys, we typically employ a combination of ultrasonic testing and liquid penetrant inspection. The ultrasonic method allows us to scan the internal structure for any anomalies like inclusions or voids, which could lead to failure under high stress, while the penetrant testing reveals any surface-breaking defects that might serve as stress concentration points.

For vacuum chamber components, where leak-free integrity is paramount, we utilize both helium leak testing and radiographic inspection. The helium test can detect even the smallest leak paths that would compromise vacuum performance, while radiography confirms proper weld penetration and absence of porosity throughout critical seam welds.

Advanced CNC-machined components often benefit from eddy current testing, which is particularly sensitive to surface and near-surface defects in conductive materials. This method has proven invaluable for thin-walled components where traditional methods might be too invasive or insensitive to minor but critical defects.

The effectiveness of each method varies by material – aluminum components may require different approaches than steel or titanium parts. For instance, magnetic particle inspection works excellently on our steel automotive components but is ineffective on non-ferromagnetic materials like aluminum or titanium. Understanding these material-specific considerations is essential when developing a comprehensive NDT strategy for diverse precision machining operations.

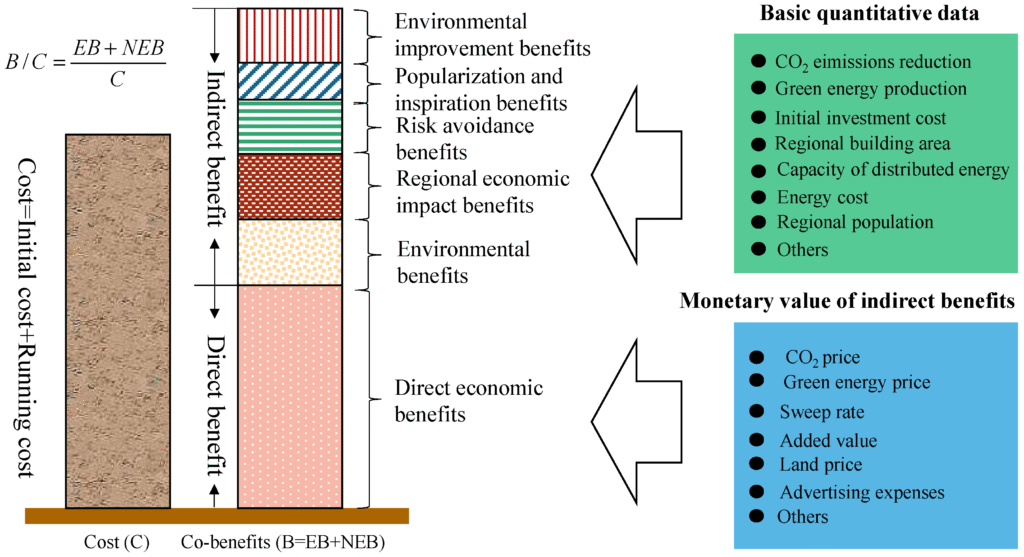

What Are the Cost Implications of Implementing NDT in Machining Operations?

Implementing NDT methods requires significant upfront investment in equipment and training, while production schedules face potential delays from additional testing procedures. Many manufacturers worry about balancing quality assurance with operational efficiency.

While initial NDT implementation involves costs for equipment, training, and certification, the long-term financial benefits typically outweigh these investments. Early defect detection prevents expensive rework, reduces warranty claims, and protects brand reputation. For critical components, NDT can be the difference between reliable performance and catastrophic failure.

Cost-benefit analysis of NDT implementation

The financial aspects of implementing NDT in precision machining operations require careful consideration across multiple dimensions. In our experience establishing comprehensive NDT capabilities at our facility, we found the initial capital expenditure ranged from $50,000 for basic equipment to over $300,000 for advanced systems like industrial CT scanning. However, this investment must be evaluated against the potential costs of quality failures.

Personnel considerations represent another significant cost factor. Proper NDT requires certified technicians – we've invested in Level II certification for key team members across multiple NDT methods, which required both training investments and temporary productivity reductions during the learning process. Annual salary premiums for NDT-certified personnel typically range from 15-30% above standard machinist compensation.

The operational impact varies by NDT method and integration approach. In-line testing generally adds minimal cycle time but requires careful production line integration, while batch testing creates less disruption but may delay defect discovery. We've found that strategic implementation of automated NDT systems at critical control points offers the best balance, particularly for high-volume production.

For small to medium batch manufacturing, we've developed a risk-based testing approach where critical features receive 100% inspection while less critical elements undergo statistical sampling. This optimizes the cost-benefit ratio while maintaining quality standards. Additionally, properly documented NDT procedures have reduced our insurance premiums by demonstrating comprehensive quality control measures.

A particularly valuable metric has been our calculation of "cost of quality" before and after NDT implementation. While inspection costs increased by approximately 3-5% of production value, our failure costs (scrap, rework, warranty claims) decreased by over 60%, yielding a net positive impact on profitability.

When Should You Implement Non-Destructive Testing in Your Manufacturing Process?

Manufacturing managers often struggle to determine the right timing for NDT implementation – too early wastes resources on stable processes, too late means discovering defects after significant value has been added. This timing dilemma creates uncertainty in quality planning.

Non-destructive testing should be implemented at critical control points where defects would cause significant downstream issues or where rework becomes exponentially more expensive. Key implementation stages include material verification before machining begins, after critical operations that could introduce defects, and final verification before shipping high-value or safety-critical components.

Strategic NDT implementation points in manufacturing

The strategic timing of NDT implementation throughout the manufacturing process significantly impacts both quality outcomes and operational efficiency. Based on our experience with precision components for demanding industries, we've developed a framework for NDT integration that optimizes defect detection while minimizing production disruption.

At the incoming materials stage, we conduct initial NDT screening to verify material integrity before value-adding operations begin. For critical materials like high-grade titanium and specialty alloys, this typically involves ultrasonic testing to detect internal laminations or inclusions that could compromise finished component integrity. This early screening has prevented numerous manufacturing failures by identifying substandard materials before machining even begins.

During the manufacturing process, we implement in-process NDT after operations that have high defect potential. For example, after complex welding operations, we perform immediate magnetic particle inspection (for ferromagnetic materials) or liquid penetrant testing to identify any weld defects. This allows for prompt correction before additional machining operations that would make repairs more difficult or impossible.

For critical features with tight tolerances, we utilize coordinate measuring machine (CMM) verification integrated with non-contact optical measurement systems. While primarily dimensional, these systems also detect surface anomalies that might indicate deeper issues requiring follow-up NDT investigation.

Final verification represents another crucial implementation point. For aerospace components, we conduct comprehensive NDT as the final quality assurance step using methods appropriate to the material and potential defect types. This serves as the last line of defense before components enter service in critical applications.

We've found that the most effective approach involves designing NDT requirements during the initial process planning rather than adding them later. This forward-thinking approach allows for optimal test point selection, appropriate method selection, and efficient production flow that accommodates inspection requirements without creating bottlenecks.

How Can NDT Reduce Rejection Rates in Precision Manufacturing?

High rejection rates in precision manufacturing waste materials, labor, and machine time, while delaying customer deliveries and eroding profit margins. Without effective detection methods, quality issues compound throughout production.

NDT significantly reduces rejection rates by identifying defects early in the manufacturing process before additional value is added. By implementing appropriate testing at critical stages, manufacturers can correct issues immediately, refine processes based on real-time feedback, and establish statistical process control that maintains consistent quality.

Rejection rate reduction through NDT implementation

Our manufacturing facility has experienced dramatic quality improvements through strategic NDT implementation. When we began producing high-pressure hydraulic components for marine applications, our initial rejection rate approached 8% – an unsustainable level that threatened customer relationships and profitability. By implementing a comprehensive NDT program, we reduced this to under 1% within six months while simultaneously increasing production volume.

The key to this improvement was our multi-layered NDT approach. For raw materials, we instituted ultrasonic testing to verify material integrity before machining. After initial welding operations, we implemented both visual inspection with enhanced lighting and magnetic particle testing to catch surface and near-surface defects when they were still easily repairable.

For critical internal passages and pressure boundaries, we developed a custom acoustic emission testing protocol that could verify wall thickness and detect potential leak paths without requiring destructive testing. This allowed 100% testing rather than statistical sampling, dramatically improving our confidence in component integrity.

Beyond the direct detection of defects, our NDT program generated valuable data that allowed us to identify and address the root causes of recurring issues. For instance, pattern analysis of magnetic particle inspection results revealed that certain weld defects consistently occurred during specific ambient humidity conditions, allowing us to implement environmental controls that eliminated these defects entirely.

We also established correlations between specific machine parameters and defect patterns, creating a feedback loop where NDT results informed process adjustments. This continuous improvement cycle transformed our quality metrics and created a competitive advantage in securing contracts for high-precision, safety-critical components.

The financial impact extended beyond reduced scrap and rework. Customer confidence increased, leading to expanded orders and reduced inspection requirements on their end. Our warranty claims dropped to near-zero levels, and we qualified for preferred supplier status with several key customers based on our demonstrated quality control capabilities.

Conclusion

Non-destructive testing represents a critical investment for precision manufacturers seeking to ensure component integrity without sacrificing production efficiency. By implementing appropriate NDT methods at strategic points in the manufacturing process, we can detect defects early, refine procedures continuously, and deliver components that perform flawlessly in the most demanding applications.