How Does Ultrasonic Leak Detection Improve CNC Machining Precision?

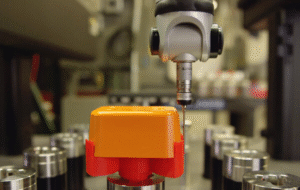

Ultrasonic leak detection has transformed our CNC machining precision, catching invisible problems before they impact quality.

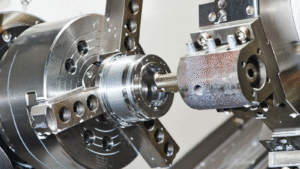

Drawing from our 20+ years of precision machining experience, we share practical insights to help you overcome technical challenges in complex parts manufacturing. From material selection to process optimization, we empower your procurement decisions with professional expertise and confidence.

Ultrasonic leak detection has transformed our CNC machining precision, catching invisible problems before they impact quality.

By integrating best practices, planning inspections early, training personnel, relying on calibrated tools, and reviewing results promptly, manufacturers transform FAI into a strategic advantage.

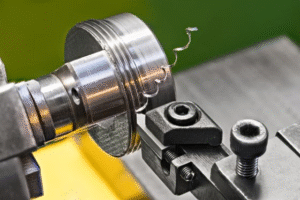

Tracer gas testing provides unmatched precision for verifying leak-free machined components. By implementing this testing method with the appropriate standards, gases, and procedures, manufacturers can significantly improve quality assurance while meeting strict industry requirements.

Ultrasonic leak detection represents a game-changing quality control advancement for precision CNC manufacturing. By implementing this technology, we’ve reduced defects, won new business, and established ourselves as a trusted partner for demanding industries.

Steering is one of the most critical aspects of a vessel, yet most sailors rarely think about the hidden hardware that makes it possible. Behind the wheel or tiller lies a system of components working in unison, and at the very core of that system are the tiller head and the quadrant.

Magnetic finishing is also referred to as magnetic field-assisted finishing, and is a precision surface treatment technique that applies a controlled magnetic field to induce abrasives to strike a workpiece.

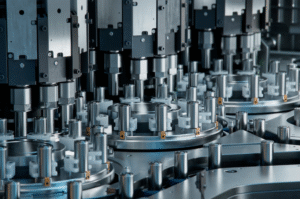

Vacuum attenuation testing is not just a quality check—it’s essential insurance for high-precision components. By investing in proper testing equipment and protocols, you’ll prevent costly failures, ensure component reliability, and maintain your reputation for excellence.

Non-destructive testing represents a critical investment for precision manufacturers seeking to ensure component integrity without sacrificing production efficiency.

Titanium CNC fasteners are more than just an upgrade; they’re a strategic choice for sailors serious about performance, reliability, and longevity.

The genuine solution is that it depends on your objectives, available resources, and developmental stage. Each technology has unique benefits that make it more appropriate for a certain circumstance.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.