Finding the right manufacturing process can make or break your project's success. Many engineers struggle with this decision, wasting time and money on inappropriate methods. CNC turning might be your solution.

CNC turning is ideal for cylindrical parts requiring high precision and efficiency. This process rotates the workpiece while a cutting tool removes material to create the desired shape, offering excellent surface finish and dimensional accuracy while reducing production times and material waste.

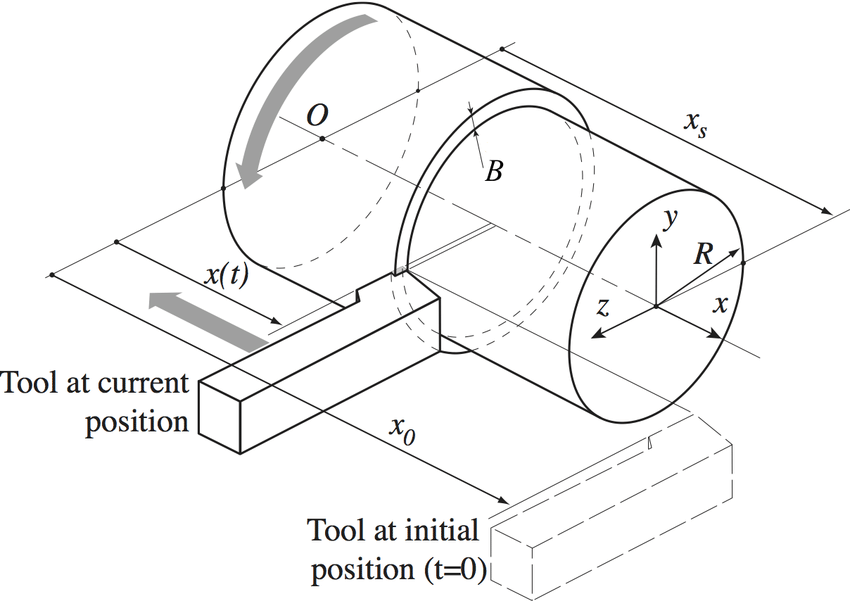

CNC turning process showing the creation of a precision cylindrical component

CNC turning process showing the creation of a precision cylindrical componentBefore diving deeper into CNC turning1, let's establish a clear understanding of what it is and when it makes the most sense for your projects. I've spent over 20 years working with various manufacturing methods, and I can tell you that choosing the right process at the beginning can save you significant headaches later on.

What is turning?

Choosing the wrong manufacturing process can lead to cost overruns, quality issues, and missed deadlines. Many engineers overlook turning as a solution when it could be the perfect fit.

Turning is a machining process where a cutting tool removes material from a rotating workpiece to create cylindrical shapes. The workpiece rotates on its axis while stationary cutting tools move linearly to create the desired features, allowing for precise dimensional control and superior surface finishes.

Diagram showing the basic principles of turning with labeled components

Turning operations fall into several categories, each serving specific purposes in manufacturing. External turning creates outer diameters, while internal turning (boring) produces internal features. Facing operations create flat surfaces perpendicular to the rotation axis, essential for part squareness. Thread turning generates precise threads, and grooving creates recessed features.

Modern CNC turning centers have revolutionized this traditional process. These machines follow programmed instructions to perform complex operations automatically, maintaining tight tolerances consistently. Multi-axis turning centers can perform milling operations without removing the workpiece, significantly reducing setup time and improving accuracy. The evolution from manual lathes to sophisticated CNC turning centers represents one of manufacturing's most significant technological leaps, enabling the production of complex components that would be impossible to create manually.

Key Factors That Make CNC Turning the Right Choice

Project managers often struggle with manufacturing decisions that can impact deadlines, budgets, and quality. Choosing the wrong process can lead to costly rework or scrapped parts.

CNC turning becomes the optimal choice when your project involves cylindrical components with rotational symmetry. Its ability to produce round parts with high precision, excellent surface finish, and cost efficiency makes it ideal for many applications where dimensional accuracy2 is critical.

Various complex components are manufactured using CNC turning

The decision to use CNC turning should be guided by several critical factors that I've learned to evaluate during my years in manufacturing. Part geometry is the primary consideration - turning excels with rotationally symmetric parts like shafts, bushings, and cylindrical components. Production volume also matters significantly; CNC turning offers excellent scalability from prototyping to high-volume production runs.

Material considerations play an equally important role. Turning can handle a wide range of materials including metals (steel, aluminum, copper, titanium), plastics, and even some ceramics. However, the machinability of these materials varies greatly. For example, free-cutting steels machine easily while super alloys require specialized tooling and optimized cutting parameters. Dimensional requirements are another crucial factor - turning can achieve tolerances as tight as ±0.0005" on diameter, making it perfect for precision components in industries like aerospace, medical, and automotive.

Cost efficiency should always be considered as well. While the hourly rate for CNC turning might seem high compared to some alternatives, the overall project cost often ends up lower due to faster cycle times, less material waste, and fewer secondary operations. For instance, a complex shaft that might require multiple setups on a mill can often be completed in a single operation on a CNC lathe with live tooling.

CNC Turning vs. Other Manufacturing Methods

Making the wrong manufacturing choice can dramatically increase production costs and lead times. Many project managers overlook critical process differences, resulting in inefficient production paths.

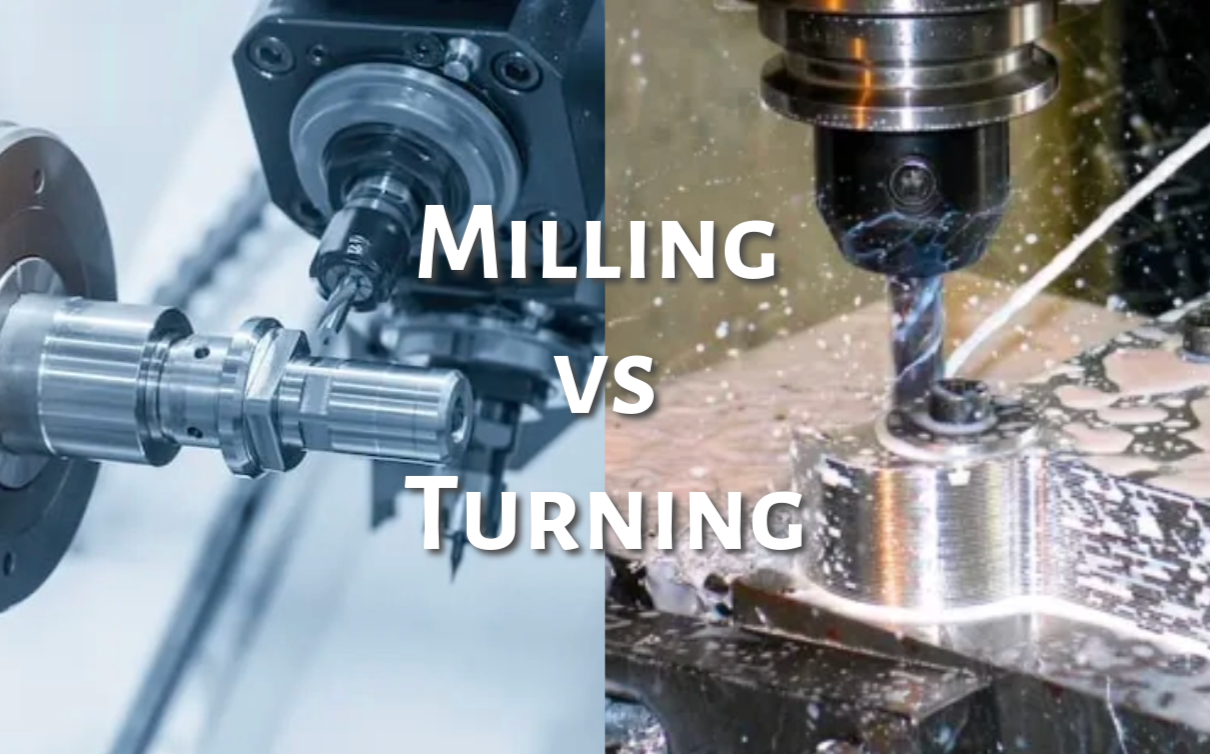

CNC turning offers distinct advantages over alternative manufacturing methods for specific applications. While milling excels at non-cylindrical parts with complex features, turning provides superior efficiency, surface finish, and cost-effectiveness when producing cylindrical components with rotational symmetry.

Side-by-side comparison of parts made by turning and milling

When comparing manufacturing processes, I always consider the specific requirements of each project. CNC turning1 and CNC milling represent two fundamental machining approaches with distinct capabilities. Turning produces cylindrical parts by rotating the workpiece while a cutting tool removes material. In contrast, milling uses rotating cutting tools on a stationary workpiece to create various features. While milling offers versatility for complex geometries, turning provides superior efficiency for round parts.

For high-volume production, manufacturing engineers must consider injection molding and die casting as alternatives. These processes offer exceptional efficiency for very large quantities but require significant upfront investment in tooling. CNC turning provides a more economical solution for low to medium production runs and offers greater flexibility for design changes. Unlike additive manufacturing methods that build parts layer by layer, turning is a subtractive process that can achieve better mechanical properties and surface finishes for cylindrical components.

The economics of each process vary significantly based on production volume. At low quantities (1-100 parts), CNC turning often provides the most cost-effective solution for cylindrical components due to minimal setup time and tooling costs. In the mid-range (100-10,000), the per-part cost of turning decreases significantly due to automated production and optimized processes. Only at very high volumes do processes like injection molding become more economical when amortizing the high initial tooling costs over many parts.

How does material selection impact CNC turning performance?

Choosing incompatible materials for turning operations can lead to poor surface finish, tool failure, and dimensional inaccuracy. Engineers often underestimate how dramatically material properties affect the turning process.

Material selection significantly impacts CNC turning performance3, affecting tool life, surface finish, and dimensional stability. Different materials require specific cutting speeds, feed rates, tool geometries, and coolant strategies to achieve optimal results, making material-specific expertise essential for successful turning operations.

Different material types commonly used in CNC turning applications

Material selection is perhaps the most critical factor influencing turning operations in my experience. Each material category presents unique machining characteristics4 that fundamentally change the approach to turning. Ferrous metals like carbon steels and stainless steels are common in turning operations but vary widely in machinability. Carbon steels typically turn well with standard carbide tools, while stainless steels—particularly austenitic grades like 304 and 316—tend to work harden during machining, requiring lower cutting speeds and rigid setups.

Non-ferrous metals present their own challenges and opportunities. Aluminum alloys generally turn easily at high speeds but can produce problematic chips without proper tool geometry. Copper alloys vary significantly—brass machines excellently, while some bronze alloys can be abrasive to cutting tools. Titanium, increasingly common in aerospace and medical applications, requires specialized techniques due to its poor thermal conductivity and chemical reactivity with cutting tools at elevated temperatures.

The hardness and internal structure of materials directly impact turning parameters. Harder materials generally require slower speeds, more rigid setups, and more frequent tool changes. Materials with inconsistent hardness or inclusions can cause unpredictable tool wear or breakage. Each material class demands specific optimizations:

| Material Type | Optimal Cutting Speed | Tool Material | Special Considerations |

|---|---|---|---|

| Carbon Steel | Moderate | Carbide | Good general machinability |

| Stainless Steel | Low to Moderate | Coated Carbide | Tendency to work harden |

| Aluminum | High | Diamond/PCD | Heat buildup, chip control |

| Titanium | Very Low | Carbide with special coatings | Heat management critical |

| Plastics | Moderate to High | Sharp HSS or Carbide | Melting concerns, specific rake angles |

Understanding these material-specific parameters has allowed our facility to specialize in difficult-to-machine materials that many competitors struggle with.

Design Considerations for CNC Turning

Poor design for manufacturability causes manufacturing delays, cost overruns, and quality issues. Engineers often create designs that look perfect in CAD but prove unnecessarily difficult to produce.

When designing parts for CNC turning, engineers should consider feature proportions, tolerance requirements, and surface finish specifications. Optimizing designs for turning processes can significantly reduce manufacturing costs while maintaining or enhancing component functionality through careful attention to features like undercuts, threads, and transitions.

Before and after examples of part designs optimized for CNC turning

Designing specifically for turning operations fundamentally improves manufacturing outcomes. I've seen countless projects saved by thoughtful design adjustments that maintained functionality while dramatically improving manufacturability. Length-to-diameter ratio is one of the most critical design considerations—parts with ratios exceeding 4:1 typically require additional support during machining to prevent deflection. Without proper support, long, thin components can vibrate during machining, causing poor surface finish and dimensional inaccuracy.

Feature accessibility represents another critical design consideration. External features are generally easier and more economical to machine than internal ones. Deep bores and internal features present challenges for tool reach and chip evacuation. When designing internal features, consider the length-to-diameter ratio5 of the bore—ratios exceeding 3:1 typically require special tooling and processes. Wherever possible, standard tool geometries should be accommodated in the design. For example, specifying standard internal corner radii that match available tool sizes reduces the need for special tooling.

Tolerance specifications dramatically impact manufacturing cost, following an exponential rather than linear relationship. Twice as tight tolerances might quadruple production costs. I recommend applying tolerances selectively—only critical features should receive tight tolerances, while non-functional features can have more relaxed specifications. Consider this breakdown of tolerance impacts:

| Tolerance Level | Typical Value Range | Cost Impact | Application Examples |

|---|---|---|---|

| Standard | ±0.005" (±0.127mm) | Baseline cost | Non-critical dimensions |

| Precision | ±0.001" (±0.0254mm) | 2-3× cost increase | Bearing seats, mating surfaces |

| High Precision | ±0.0005" (±0.0127mm) | 4-10× cost increase | Precision shafts, medical devices |

| Ultra Precision | <±0.0001" (<±0.00254mm) | >10× cost increase | Optical components, gauge parts |

Surface finish requirements similarly impact machining time and cost. Specifying only the necessary surface finish for each feature optimizes production efficiency while maintaining functionality.

Which industries benefit most from precision CNC turning services?

Companies often miss opportunities to leverage CNC turning's advantages for their specific industry applications. This oversight can result in higher production costs and compromised component quality.

Precision CNC turning6 delivers critical benefits to aerospace, automotive, medical, oil & gas, and defense industries. These sectors rely on turned components for applications requiring high accuracy, excellent surface finish, material certification, and complex geometrical features that ensure safety, performance, and regulatory compliance.

High-precision turned components used in critical industrial applications

Each industry benefits from precision turning in unique ways based on its specific requirements and challenges. In the aerospace sector, where I've done extensive work, weight reduction and material integrity are paramount concerns. CNC turning produces critical components like hydraulic fittings, valve bodies, shafts, and bushings that must maintain performance under extreme conditions. The demanding nature of aerospace applications requires specialized material handling, with full traceability and certification being non-negotiable requirements.

The automotive industry represents another major beneficiary of precision turning. Modern vehicles contain numerous precision-turned components in engines, transmissions, braking systems, and fuel delivery systems. High-volume production with consistent quality is essential in this sector. Our facility regularly produces components like fuel system components, transmission parts, and sensor housings that require tight tolerances but must remain cost-competitive.

Medical device manufacturing presents perhaps the most stringent requirements for turned components. Implantable devices, surgical instruments, and diagnostic equipment components demand extraordinary precision, biocompatibility, and surface finish quality. Materials like titanium and specialized stainless steels must be processed under controlled conditions with validated processes. The orthopedic implant sector particularly benefits from advanced turning capabilities for components like bone screws, where thread profile accuracy directly impacts clinical outcomes.

Other industries with specialized turning requirements include:

| Industry | Critical Requirements | Common Applications |

|---|---|---|

| Oil & Gas | Corrosion resistance, pressure rating | Valve components, downhole tools, and flow control devices |

| Defense | Material certification, security protocols | Guidance components, munitions, and communication hardware |

| Semiconductor | Ultra-high precision, cleanliness | Vacuum chamber components, test equipment parts |

| Marine | Corrosion resistance, reliability | Propulsion components, hardware, and fluid systems |

The exceptional versatility of modern CNC turning has made it indispensable across these diverse industries, each benefiting from specific capabilities that address their unique challenges.

What are the key differences between CNC turning and CNC milling?

Confusing turning and milling capabilities lead to suboptimal manufacturing decisions. Many engineers don't fully grasp the fundamental differences, resulting in inappropriate process selection and preventable manufacturing issues.

CNC turning and milling differ fundamentally in how they create parts: turning rotates the workpiece while cutting tools remain relatively stationary, while milling rotates the cutting tool against a fixed workpiece. Turning excels at cylindrical parts with rotational symmetry, while milling handles complex geometries with flat surfaces, pockets, and non-round features.

Side-by-side comparison of CNC turning and milling operations

Understanding the fundamental differences between these processes has helped me guide countless customers to the optimal manufacturing approach for their specific requirements. Motion mechanics represent the most basic difference—in turning, the workpiece rotates while the cutting tool moves linearly, while milling involves a stationary workpiece and rotating cutting tools that move along multiple axes. This fundamental distinction drives many of their respective strengths and limitations.

Turning and milling excel at different geometries. Turning naturally produces cylindrical, conical, and curved profiles with rotational symmetry. Creating a perfectly round shaft is straightforward with turning but challenging with milling. Conversely, milling excels at producing flat surfaces, pockets, slots, and complex 3D contours that would be difficult or impossible on a turning center without live tooling capabilities.

Modern multitasking machines have begun blurring these distinctions. Turn-mill centers combine both capabilities, allowing complex parts to be completed in a single setup. These hybrid machines can perform turning operations and then use live tools to create features like keyways, holes, and slots without removing the workpiece, dramatically improving accuracy and reducing handling time. I've seen cases where parts that once required four separate operations can now be completed in a single setup on these advanced machines.

The economic comparison between turning and milling depends heavily on part characteristics:

| Feature | CNC Turning | CNC Milling |

|---|---|---|

| Optimal Part Geometry | Cylindrical, rotational symmetry | Prismatic, complex 3D features |

| Material Removal Rate | Generally higher for compatible geometries | Moderate, depends on cutter size and material |

| Surface Finish | Excellent on cylindrical surfaces | Good, but may require secondary operations |

| Setup Complexity | Generally simpler for appropriate parts | Can require complex fixturing |

| Tool Costs | Generally lower tool costs | Higher tool investment for complex features |

Understanding these differences allows us to recommend the optimal process—sometimes a combination of both—for each customer's specific requirements.

How can design optimization reduce costs in CNC turned parts?

Poor design choices often lead to unnecessarily expensive turned parts. Many engineers miss simple opportunities to reduce costs without compromising part functionality or quality.

Design optimization can substantially reduce CNC turning costs by simplifying geometries, standardizing features, and minimizing unnecessary tolerances. Strategic changes like using standard sizes, eliminating deep features, and designing appropriate transitions can reduce machining time, tool wear, and setup complexity while maintaining part functionality.

Before and after examples of cost-optimized part designs for CNC turning

From my experience working with thousands of different turned part designs, I've identified specific optimization strategies that consistently deliver cost savings while maintaining or improving part functionality. Feature standardization represents one of the most impactful approaches—using standard drill sizes, thread specifications, and groove widths eliminates the need for special tooling and reduces setup time. For instance, specifying a 12mm hole instead of 12.2mm can reduce costs without affecting part function in many applications.

Material selection optimization provides another significant opportunity for cost reduction. While engineers often specify materials based on their experience or historical precedent, analyzing the actual mechanical requirements can often identify more economical alternatives. For example, I recently worked with a customer who had specified 17-4 PH stainless steel for a component experiencing minimal stress and corrosion exposure. By shifting to 303 stainless, we reduced material costs by 40% and improved machinability significantly.

Tolerance rationalization consistently yields substantial savings. After reviewing thousands of part prints, I've found that approximately 30% of specified tolerances are unnecessarily tight for the application. Applying appropriate tolerances only where functionally required can

- Explore this link to understand how CNC turning can enhance precision and efficiency in your manufacturing projects. ↩ ↩

- Discover the importance of dimensional accuracy in manufacturing and how it affects product quality and performance. ↩

- Exploring this topic can provide insights into improving tool life and surface finish in CNC turning operations. ↩

- Learning about machining characteristics helps in selecting the right materials for efficient and effective turning operations. ↩

- Understanding this ratio is crucial for preventing machining issues and ensuring high-quality outcomes in manufacturing. ↩

- Explore how Precision CNC turning enhances production efficiency and quality across multiple sectors, ensuring optimal performance and compliance. ↩