Metal parts fail when they matter most. Aircraft components crack mid-flight, automotive parts break under stress, and industrial equipment fails under load—all potentially causing catastrophic consequences.

Forged materials outperform cast or machined alternatives because the forging process aligns the metal's grain structure, eliminating porosity while enhancing strength, toughness, and fatigue resistance. This creates components that maintain integrity under extreme stress, temperature fluctuations, and continuous operation.

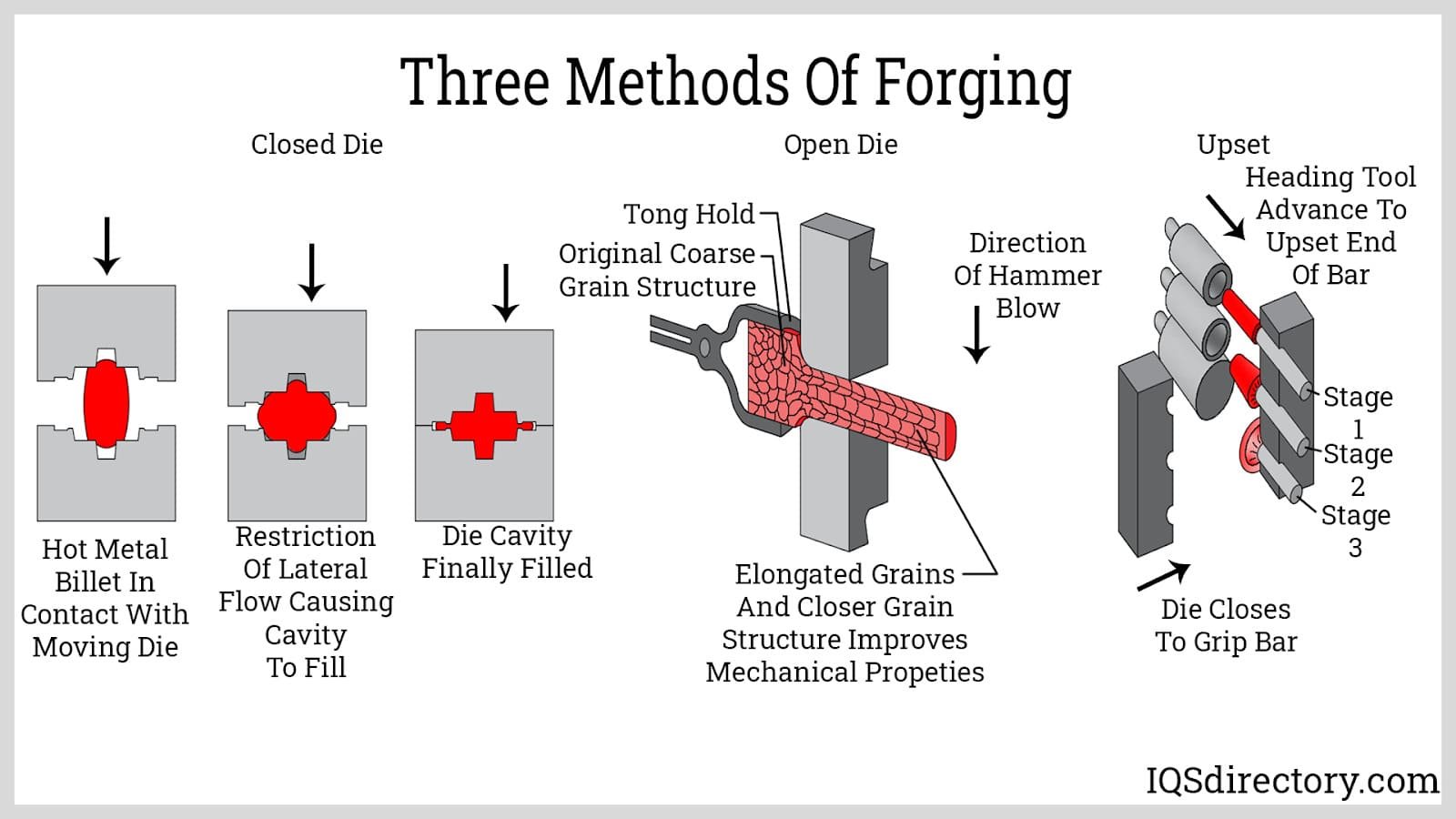

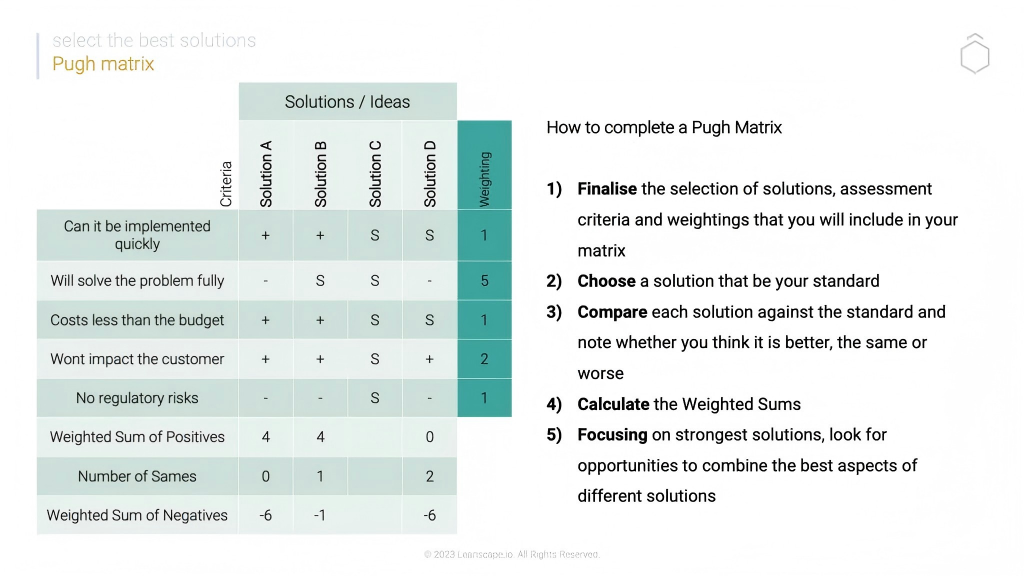

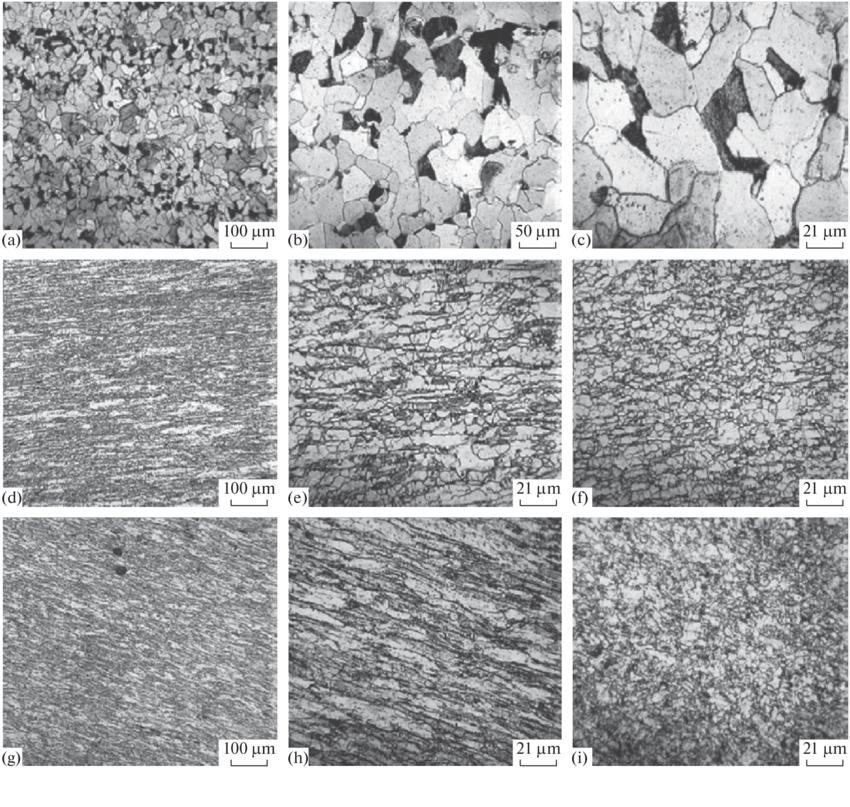

Comparison of forged vs cast material structure

As a CNC machining specialist, I've seen countless designs fail due to poor material selection. When components need to withstand extreme conditions, forged materials consistently outperform alternatives. Let me share why forging creates superior parts and how this knowledge can improve your next critical project.

How Does the Forging Process Enhance Material Properties?

Your components are only as reliable as their microstructure. When metal parts fail unexpectedly, the cause often traces back to internal flaws that could have been eliminated through proper manufacturing methods.

The forging process dramatically improves material properties by applying controlled pressure to reshape metal while maintaining its solid state. This compression eliminates internal voids, refines grain structure, and creates directional strength aligned with anticipated stress patterns—resulting in components with 25-30% greater strength and significantly improved impact resistance compared to cast alternatives.

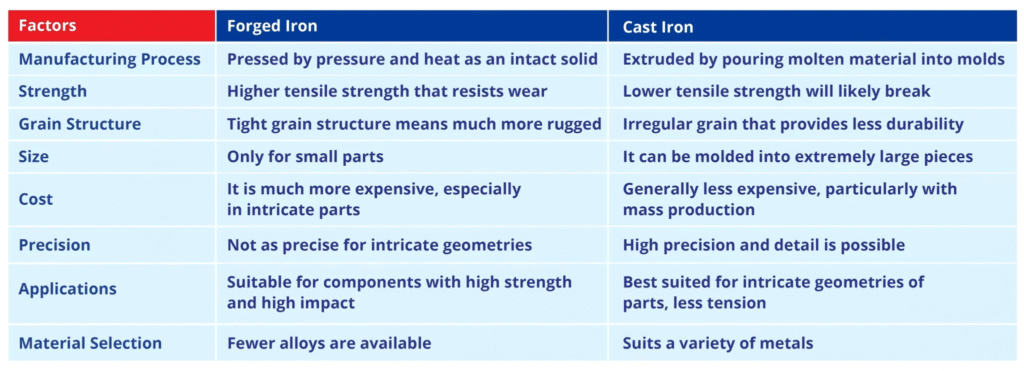

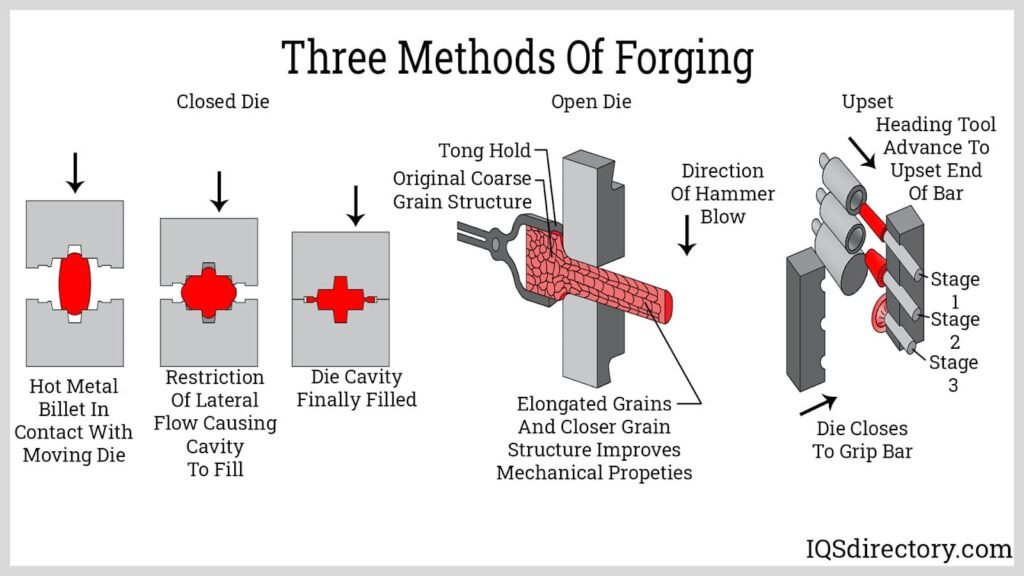

Forging process showing metal deformation

Forging transforms metal at both macro and microscopic levels, creating a foundation for exceptional component performance. The process begins with heating metal to its plastic deformation temperature—not melting point—then applying precise pressure through dies. This pressure forces the material to flow while remaining solid, fundamentally altering its internal structure.

I recall working with an automotive customer struggling with premature crankshaft failures in high-performance engines. Their cast components couldn't withstand the stress, leading to catastrophic failures. After switching to forged blanks, which we then precision-machined, failures virtually disappeared. The forged material's directional strength matched the rotational forces perfectly.

The most significant advantages come from grain flow alignment. Unlike casting, where metal crystals form randomly as liquid solidifies, forging manipulates these grain structures directionally. This creates a "grain flow" that follows the component's shape, providing maximum strength precisely where needed. Additionally, forged parts exhibit:

| Property | Improvement vs. Cast | Benefit in Application |

|---|---|---|

| Tensile Strength | 25-30% higher | Resists breaking under tension |

| Yield Strength | 35-40% higher | Maintains shape under stress |

| Fatigue Resistance | 50-100% greater | Extends service life under cyclic loading |

| Impact Resistance | Significantly higher | Better absorbs sudden forces |

| Internal Integrity | No porosity or voids | Eliminates failure initiation points |

These improvements make forged components the clear choice for applications where failure isn't an option.

Which Industries Benefit Most from Forged Components?

Aircraft crashed, car engines seized, and industrial equipment failed—catastrophic failures that could have been prevented with stronger components. When lives and expensive machinery hang in the balance, material selection becomes critical.

Industries with extreme operating conditions benefit most from forged components, particularly aerospace, automotive, oil and gas, power generation, and heavy equipment manufacturing. These sectors require parts that maintain integrity under tremendous stress, temperature variations, and continuous high-speed operation—conditions where forged materials consistently outperform alternatives.

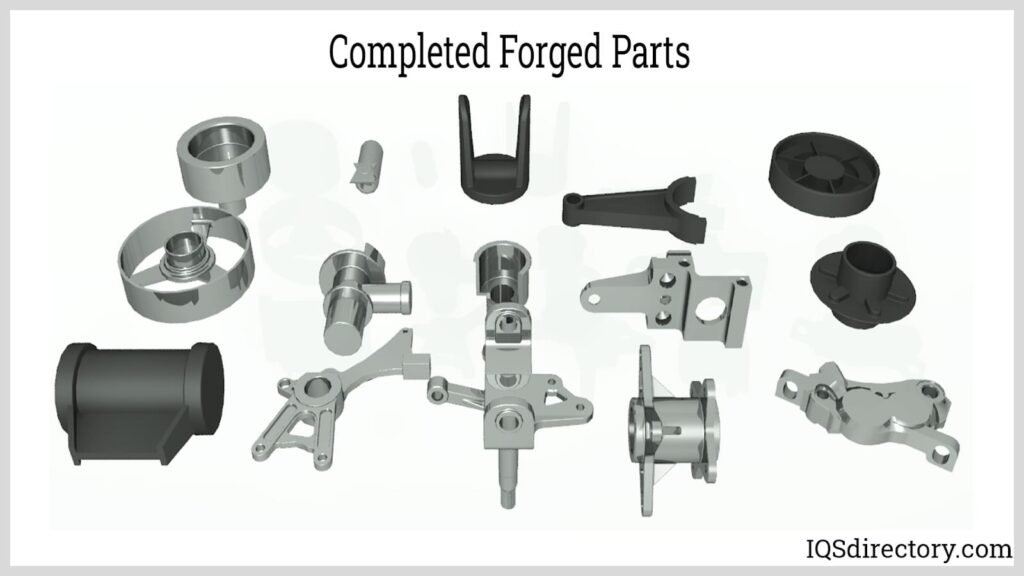

Forged components in various industry applications

Across multiple industries, forged components provide essential reliability for mission-critical applications. In my decades of manufacturing experience, I've supplied precision-machined forged components to customers in virtually every demanding sector.

The aerospace industry represents perhaps the most compelling case for forged materials. When aircraft components fail at 30,000 feet, second chances don't exist. Critical components like landing gear, turbine discs, and structural elements almost exclusively start as forgings. We regularly machine these forged blanks to final specifications, maintaining the exceptional internal properties while achieving precise dimensions.

In the automotive world, performance vehicles depend on forged crankshafts, connecting rods, and drivetrain components. A Formula 1 engine operating at 18,000 RPM generates forces that would destroy cast components within seconds. Even in consumer vehicles, forged components provide safety margins that protect lives.

The oil and gas industry presents another compelling case:

| Component | Operating Condition | Why Forging is Critical |

|---|---|---|

| Valve Bodies | High pressure (20,000+ PSI) | Prevents catastrophic rupture |

| Wellhead Components | Extreme temperatures | Maintains properties in harsh environments |

| Drill Bits | Extreme abrasion and impact | Resists deformation and wear |

| Pressure Vessels | Corrosive environments | Eliminates internal flaws that accelerate corrosion |

| Subsea Equipment | Reliability requirements | Must function without maintenance for decades |

Heavy equipment manufacturers similarly rely on forged components for earthmoving equipment, mining machinery, and construction equipment, where component failure causes expensive downtime and potential safety hazards.

In each case, the superior mechanical properties, directional strength, and structural integrity of forged materials provide critical performance advantages that justify their selection.

When Should You Choose Forging Over Other Manufacturing Methods?

Your project deadlines tighten, budgets shrink, and performance expectations keep rising. With multiple manufacturing options available, choosing the wrong process can lead to component failure, project delays, or budget overruns.

Choose forging when component performance is critical, when failure would cause catastrophic consequences, or when long-term reliability justifies higher initial costs. Forging is particularly advantageous for components subjected to dynamic loading, impact forces, or extreme operating conditions where material integrity directly impacts performance and safety.

Decision matrix for manufacturing method selection

The decision between forging and alternative manufacturing methods requires balancing multiple factors. Having advised countless clients on optimal manufacturing approaches, I've developed a framework for making this decision.

The primary consideration must be the component's performance requirements. When parts must withstand extreme stress, cyclical loading, or impact forces, forging typically provides the optimal solution despite potentially higher initial costs. A perfect example from our experience involved a marine equipment manufacturer who initially chose cast components for cost savings, only to face repeated failures in the field. Switching to forged blanks, which we then precision-machine, has eliminated the failures entirely, actually reducing total costs when accounting for warranty claims and reputation damage.

Production volume also significantly influences the decision. The tooling costs for forging dies can be substantial, making other processes more economical for very low volumes. However, for medium to high volumes, these initial costs amortize rapidly.

Consider these key decision factors:

| Factor | Favor Forging When | Consider Alternatives When |

|---|---|---|

| Stress Requirements | High dynamic or impact loads | Static loads only |

| Safety Criticality | Failure causes injury or death | Failure consequences are minimal |

| Service Environment | Extreme temperatures or corrosion | Controlled, moderate conditions |

| Weight Sensitivity | Strength-to-weight ratio critical | Weight not a primary concern |

| Production Volume | Medium to high volumes | Very low quantities needed |

| Geometric Complexity | Simple to moderately complex | Extremely intricate features |

| Near-Net Shape Needs | Moderate machining acceptable | Minimal finishing required |

Modern hybrid approaches often provide optimal solutions. We frequently CNC machine forged blanks that already have the approximate shape and enhanced material properties, combining the structural benefits of forging with the precision and complexity possible through machining.

This integrated approach leverages the strengths of both processes: forging for internal material properties and rough shaping, followed by precision machining for final dimensions, surface finish, and complex features.

Why Does Grain Structure Matter in Forged Metal Components?

Your components failed unexpectedly, despite meeting all specified material requirements and dimensional tolerances. The mystery of such failures often lies invisible to the naked eye—in the microscopic grain structure that determines how materials behave under stress.

Grain structure in metals acts like wood grain in lumber, determining directional strength and failure points. Forging creates a refined, directional grain flow that follows component contours, enhancing strength precisely where needed. This optimized microstructure dramatically improves fatigue resistance, impact strength, and overall component reliability compared to random grain patterns in cast or machined-from-billet alternatives.

Microscopic view of metal grain structure

The invisible world of metal microstructure fundamentally determines performance limits in high-stress applications. Throughout my manufacturing career, I've seen countless examples where identical chemical compositions perform dramatically differently depending on their processing history.

Metal grains are crystal structures that form as metal solidifies or is worked. In cast components, these grains form randomly as the molten metal cools, creating a non-directional structure with potential weakness planes. Machining from solid bar stock retains the grain structure of the original material—typically aligned in one direction only, regardless of the final component shape.

Forging, by contrast, manipulates these grain structures through controlled deformation. The pressure applied during forging breaks down large grains into finer structures while aligning them to follow the component's shape. This creates what engineers call "grain flow"—directional strength precisely aligned with anticipated stress patterns.

I witnessed this principle dramatically demonstrated when a customer brought in two seemingly identical connecting rods—one cast, one forged. Both had identical dimensions and material specifications. Under metallurgical examination, however, the differences became clear:

| Characteristic | Cast Component | Forged Component | Performance Impact |

|---|---|---|---|

| Grain Size | Large, uneven | Fine, uniform | Finer grains create more grain boundaries, blocking crack propagation |

| Grain Direction | Random | Following component contours | Strength aligned with stress directions |

| Density | Potential porosity | Fully dense | Eliminates stress concentration points |

| Inclusion Distribution | Concentrated | Dispersed and reduced | Fewer potential failure initiation sites |

| Deformation Response | Brittle failure | Progressive deformation | Provides warning before catastrophic failure |

These microstructural advantages translate directly to real-world performance. Components that appear identical by every standard measurement can perform dramatically differently under stress based solely on their internal grain structure.

For critical applications requiring both complex geometries and optimized grain structures, our hybrid approach provides the best solution: starting with forged near-net-shape blanks to establish ideal internal properties, then precisely machining to final dimensions while preserving those beneficial grain patterns.

Conclusion

Forged materials deliver superior performance through enhanced grain structure, eliminated porosity, and directional strength—making them ideal for critical applications where failure isn't an option. By combining forging's material advantages with precision CNC machining, we create components that meet the most demanding performance requirements.