Leaks in machined components can lead to system failures, costly repairs, and even dangerous situations. Many manufacturers discover these issues too late, after parts are already installed in critical applications.

Tracer gas testing is a non-destructive inspection method that uses specialized gases like helium or hydrogen to identify even microscopic leaks in machined parts. Detection equipment measures the escape of these trace gases through defects, providing quantifiable verification of component integrity beyond what traditional methods can achieve.

Industrial tracer gas testing system inspecting CNC-machined parts

As a precision CNC machining facility, I've seen firsthand how tracer gas testing has become essential for quality assurance. Our customers increasingly demand verified leak-proof components, particularly for critical applications where failure isn't an option. Let me walk you through why this testing method matters and how it works.

How Does Tracer Gas Testing Detect Leaks in Complex CNC Components?

Traditional pressure testing often misses microscopic defects that can cause big problems later. With high-value machined components, these hidden flaws represent significant liability and safety risks.

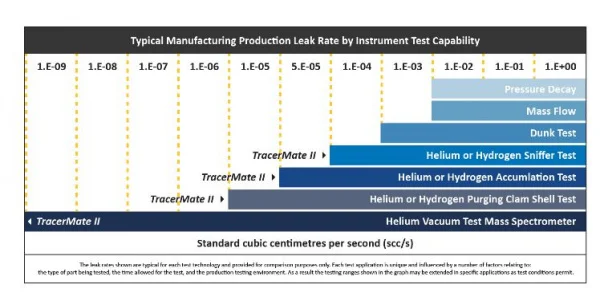

Tracer gas testing works by introducing gases with small molecular sizes (typically helium, hydrogen, or SF6) that can penetrate even the tiniest defects. Specialized detectors then identify the presence and quantity of escaped gas, providing precise measurements of leak rates down to incredibly small volumes.

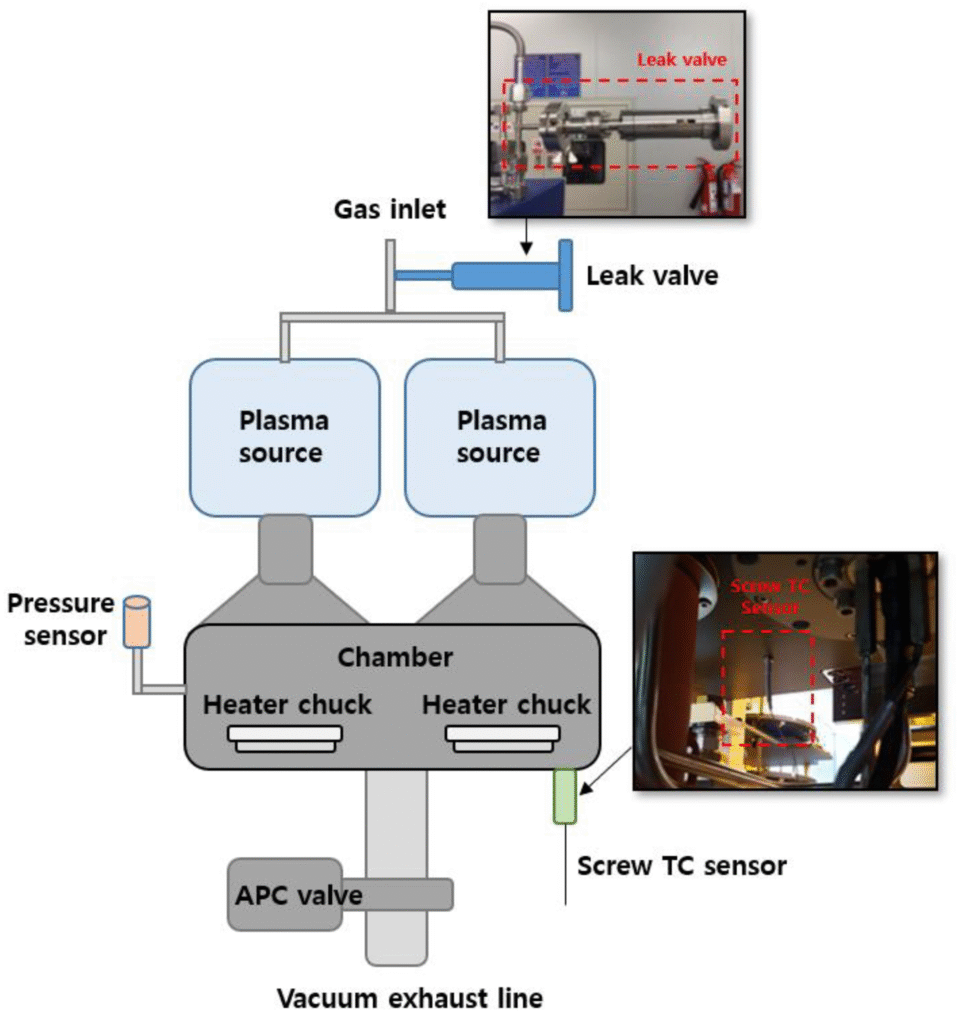

Close-up of tracer gas detection on a vacuum chamber component

The detection process involves several key steps that make this method remarkably effective for complex CNC components. First, the part is either filled with tracer gas or placed in a sealed chamber containing the gas. Then, high-sensitivity detectors—often using mass spectrometry technology—measure any gas that escapes through defects.

What makes this method particularly valuable for precision-machined parts is its sensitivity and accuracy. While pressure testing might detect larger leaks, tracer gas can identify defects as small as 10^-12 mbar·l/s—essentially molecular-level imperfections. For context, that's equivalent to detecting the escape of less than one cubic centimeter of gas over a thousand years!

In our machining operations, we've implemented tracer gas testing for critical components like vacuum chambers and automotive fluid systems. The process allows us to verify the integrity of complex internal channels and sealed joints that would be impossible to inspect visually. By quantifying the leak rate rather than simply providing pass/fail results, we can also track manufacturing consistency over time and identify when processes begin to drift before defects occur.

The equipment setup varies depending on component requirements:

| Testing Approach | Best For | Detection Limit | Testing Time |

|---|---|---|---|

| Vacuum Method | Hermetically sealed parts | 10^-12 mbar·l/s | 5-15 minutes |

| Pressure Method | Components with internal channels | 10^-8 mbar·l/s | 2-10 minutes |

| Accumulation Method | Large assemblies | 10^-6 mbar·l/s | 10-30 minutes |

When Should You Choose Tracer Gas Testing Over Alternative Inspection Methods?

Your project deadline is approaching, but you're worried about component integrity. Conventional testing methods seem inadequate for the critical parts you're machining, yet you're hesitant about the cost of additional testing.

Tracer gas testing becomes essential when components must maintain absolute leak integrity in challenging environments or when handling sensitive materials. While it typically costs more than simpler methods, it provides verification that's impossible to achieve with visual inspection, dye penetrant testing, or basic pressure testing.

Visual comparison of tracer gas versus traditional inspection methods

Choosing the right inspection method depends largely on your component's end-use criticality and required leak-tightness specifications. In our manufacturing experience, we've found clear guidelines for when tracer gas testing delivers the most value.

First, consider safety-critical applications where component failure could lead to catastrophic consequences. For aerospace components, medical devices, or automotive safety systems, the higher cost of tracer gas testing is easily justified against the potential liability and safety risks. I recall a project for a medical device manufacturer where tracer gas testing identified microscopic casting pores in an aluminum housing that had passed all conventional inspections but would have eventually leaked sterilization chemicals.

Second, evaluate the performance requirements. Components operating under vacuum conditions or containing pressurized gases/fluids typically demand verification beyond what basic methods provide. For vacuum chambers we produce, helium leak testing has become standard because even minuscule leaks render the equipment useless for semiconductor manufacturing processes.

Another critical factor is regulatory compliance. Many industries have established standards that specifically require quantifiable leak testing results that only tracer gas methods can provide. For example:

| Industry | Typical Requirement | Required Detection Sensitivity |

|---|---|---|

| Aerospace | AS9100D / NADCAP | 10^-9 mbar·l/s |

| Medical Devices | ISO 11607 | 10^-7 mbar·l/s |

| Automotive | IATF 16949 | 10^-5 to 10^-8 mbar·l/s |

| Semiconductor | SEMI E19-0618 | 10^-10 mbar·l/s |

The cost-benefit analysis ultimately depends on risk assessment. While tracer gas testing adds 5-15% to inspection costs, it substantially reduces the risk of field failures. We've found this investment particularly worthwhile for production runs where rework or recalls would be exponentially more expensive.

What Tracer Gas Types Are Most Effective for Metal Component Testing?

Selecting the wrong tracer gas can lead to false negatives, wasted time, and even damaged components. Many manufacturers struggle with inconsistent results because they haven't optimized their gas selection.

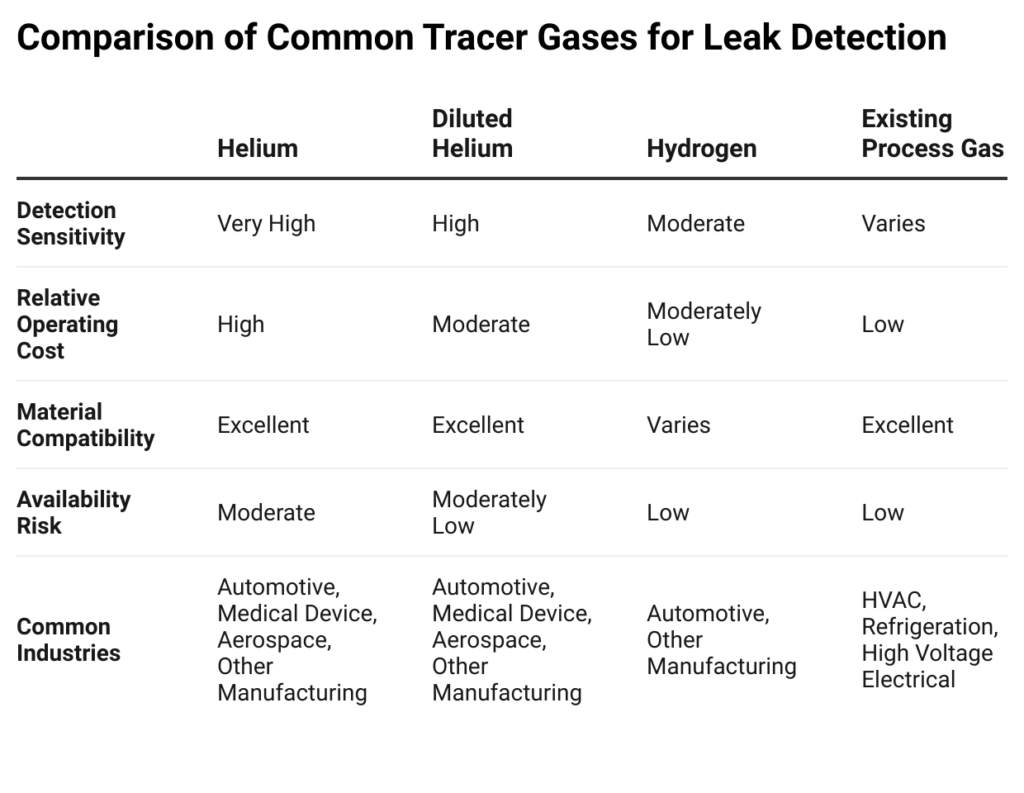

The most effective tracer gases for metal component testing are helium, hydrogen (typically in a 5% mixture with nitrogen for safety), and sulfur hexafluoride (SF6). Each gas offers specific advantages based on molecular size, detection sensitivity, cost, and environmental considerations.

Comparison of helium, hydrogen, and SF6 tracer gas systems

The selection of the optimal tracer gas for testing metal components depends on several factors that directly impact detection efficacy and operational costs. After years of testing various machined components, I've discovered that each gas has distinct advantages that make it suitable for specific applications.

Helium remains the gold standard for high-precision components due to its small molecular size (0.26nm) and inert nature. It can penetrate extremely small defects without reacting with the metal substrate, making it ideal for testing components with stringent leak requirements like vacuum chambers and aerospace parts. However, its rising cost (increasing by approximately 300% in the last decade) and limited global supply have forced manufacturers to consider alternatives.

Hydrogen (typically used in a 5% concentration with nitrogen as a carrier gas for safety) offers comparable sensitivity at a significantly lower cost—often 70-80% less expensive than helium testing. Its molecule is even smaller than helium (0.24nm), potentially detecting even finer defects. The main drawbacks include its flammability risk if used in higher concentrations and potential for material interaction with certain alloys, causing embrittlement in some scenarios.

Sulfur hexafluoride (SF6) presents another alternative, particularly suitable for larger components where extreme sensitivity isn't required. While its larger molecular size (0.49nm) means it won't detect the smallest defects, its high molecular weight makes it easier to contain during testing, reducing background contamination issues. However, SF6's significant environmental impact as a greenhouse gas (23,000 times more potent than CO2) has led to restrictions in many regions.

The effectiveness of these gases also varies by detection method:

| Tracer Gas | Best Detection Method | Relative Cost | Environmental Impact | Detection Limit |

|---|---|---|---|---|

| Helium | Mass Spectrometry | High | Low | 10^-12 mbar·l/s |

| Hydrogen (5%) | Thermal Conductivity | Low | Very Low | 10^-7 mbar·l/s |

| SF6 | Infrared Spectroscopy | Medium | Very High | 10^-8 mbar·l/s |

In our facility, we've transitioned many standard applications to hydrogen testing to manage costs while reserving helium for the most critical high-vacuum components. For customers concerned about sustainable manufacturing practices, this approach also reduces the environmental footprint of testing procedures while maintaining detection reliability.

How Can Tracer Gas Testing Improve Your Quality Control Process?

Quality control issues continue plaguing your production, with leaking components discovered only after assembly or, worse, in the field. These failures damage customer relationships and create expensive warranty claims.

Tracer gas testing enhances quality control by providing objective, quantifiable leak measurements that become powerful process control data. Beyond simple pass/fail results, these measurements establish statistical process control baselines, identify trends before failures occur, and validate design improvements with precise before/after comparisons.

Engineers reviewing leak rate data trends from tracer gas testing

Implementing tracer gas testing as part of a comprehensive quality control strategy creates multiple advantages that extend well beyond simple defect detection. From my experience integrating these systems into our CNC machining operations, I've seen transformative improvements in several key areas.

First, the quantitative nature of tracer gas testing allows for statistical process control implementation that's impossible with subjective inspection methods. By tracking leak rates over time—even when all components pass—we can identify subtle trends that indicate tool wear, material variations, or process drift. For example, when machining a series of hydraulic valve bodies, we noticed gradually increasing leak rates that, while still within specification, pointed to progressive tool wear affecting surface finish in critical sealing areas.

Second, tracer gas testing enables precise validation of design improvements. When a customer approached us about reducing the weight of an aerospace component, we could quantitatively compare prototype designs by measuring exact leak rates before and after material reductions. This data-driven approach allowed us to confidently remove 18% of the material weight while maintaining the required leak specifications.

The implementation of tracer gas testing also substantially improves supplier qualification and incoming inspection processes. By establishing quantifiable acceptance criteria, companies can:

| Benefit | Implementation Approach | Typical Result |

|---|---|---|

| Reduce Supplier Variability | Require tracer gas test reports with shipments | 40-60% reduction in component variation |

| Eliminate Subjective Assessments | Replace visual/bubble tests with quantified rates | 90% reduction in inspector disagreements |

| Enable Predictive Maintenance | Track leak rate trends on production equipment | 30% reduction in unexpected downtime |

| Validate Process Changes | A/B testing before full implementation | Faster qualification of improvements |

Additionally, tracer gas testing significantly reduces the cost of quality by shifting detection earlier in the production process. When we implemented helium testing for vacuum chamber components, we identified leaks before final assembly, reducing rework costs by approximately 65% compared to our previous approach of testing only completed assemblies.

The digital data generated through tracer gas testing also creates valuable documentation for regulatory compliance, customer assurance, and internal continuous improvement efforts. Modern systems can automatically record test results with component serial numbers, creating traceable records that support root cause analysis and prove compliance with industry standards.

What Industry Standards Apply to Tracer Gas Testing for Aerospace Components?

Aerospace customers are demanding leak testing certification, but you're unsure which standards apply. Missing or incorrect certifications could disqualify your parts or create liability issues.

Aerospace tracer gas testing must comply with several industry standards, primarily SAE AS4059 for cleanliness, MIL-STD-883K for hermeticity testing, and AWS D17.1 for fusion-welded aerospace components. These standards establish specific leak rate thresholds, testing methodologies, and documentation requirements.

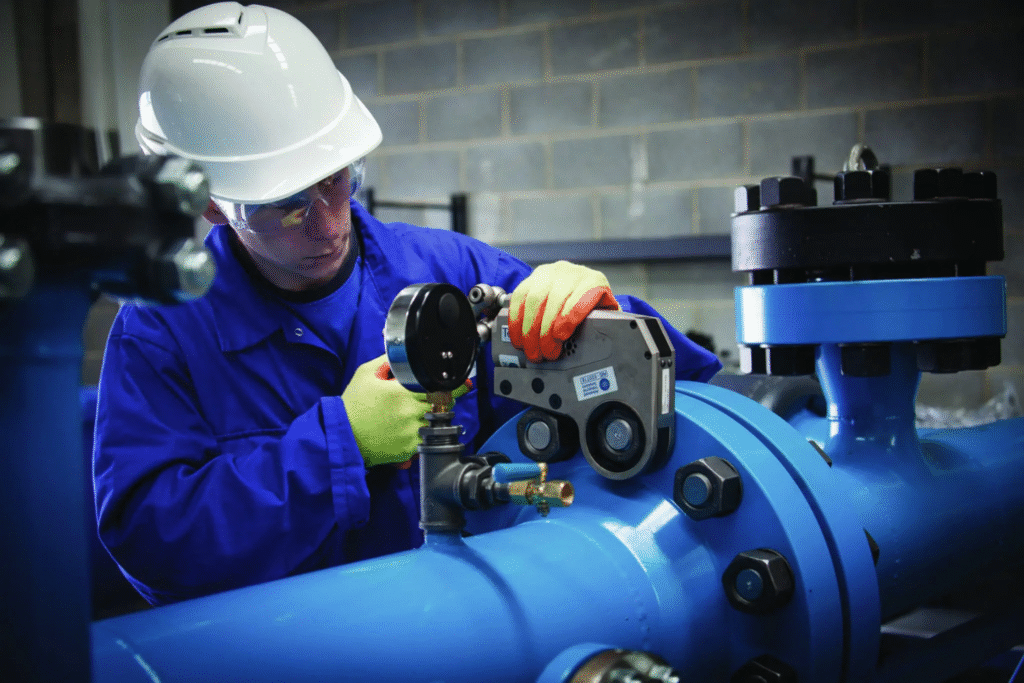

Technician performing standardized aerospace leak testing

The aerospace industry maintains some of the most stringent requirements for component integrity, with several overlapping standards governing tracer gas testing procedures. Having produced components for aerospace applications for over a decade, I've navigated this complex regulatory landscape and can highlight the most critical standards that apply.

SAE AMS 2750F serves as the foundation for thermal processing requirements, including the validation of hermetic seals in critical aerospace components. This standard dictates not just the acceptable leak rates but also the calibration requirements for testing equipment and the environmental conditions under which tests must be performed. For components we produce that enter the aerospace supply chain, we must maintain calibration records showing traceability to NIST or equivalent international standards with calibration intervals not exceeding 12 months.

ASTM E498/E498M-11(2017) specifically addresses standard test methods for leaks using the mass spectrometer leak detector in the tracer probe mode. This standard is particularly relevant for larger welded assemblies where locating the specific leak source is as important as quantifying the leak rate. The standard mandates specific probe distances, scan rates, and environmental controls to ensure repeatable results.

The European aerospace market follows EN 13185, which provides a detailed methodology for tracer gas detection techniques. When supplying components to European aerospace manufacturers, we must demonstrate compliance with this standard's specific requirements for test sensitivity and reporting formats.

For space applications, NASA's MSFC-SPEC-3636 outlines even more stringent requirements:

| Component Type | Maximum Allowable Leak Rate | Required Test Method | Documentation Requirements |

|---|---|---|---|

| Propulsion Components | 1×10^-9 mbar·l/s | Vacuum Chamber Helium | Full data recording and certification |

| Environmental Control | 1×10^-8 mbar·l/s | Accumulation Method | Statistical sampling allowed |

| Structural Components | 1×10^-7 mbar·l/s | Pressure Decay/Tracer Gas | Batch certification permitted |

| Electronic Housings | 1×10^-11 mbar·l/s | Mass Spectrometer Method | Individual certification required |

Additionally, aerospace prime contractors often maintain their own specifications that exceed these industry standards. For example, when producing components for a major aircraft engine manufacturer, we follow their proprietary standard that requires helium leak testing with a maximum allowable leak rate of 5×10^-10 mbar·l/s—approximately five times stricter than the general aerospace standard.

Certification documentation must include specific elements to be considered valid for aerospace applications: test equipment identification and calibration status, ambient conditions during testing, actual measured leak rates (not just pass/fail), operator qualification verification, and traceability to the specific component batch or serial number. We maintain these records for a minimum of seven years as required by AS9100D quality management systems.

Conclusion

Tracer gas testing provides unmatched precision for verifying leak-free machined components. By implementing this testing method with the appropriate standards, gases, and procedures, manufacturers can significantly improve quality assurance while meeting strict industry requirements.