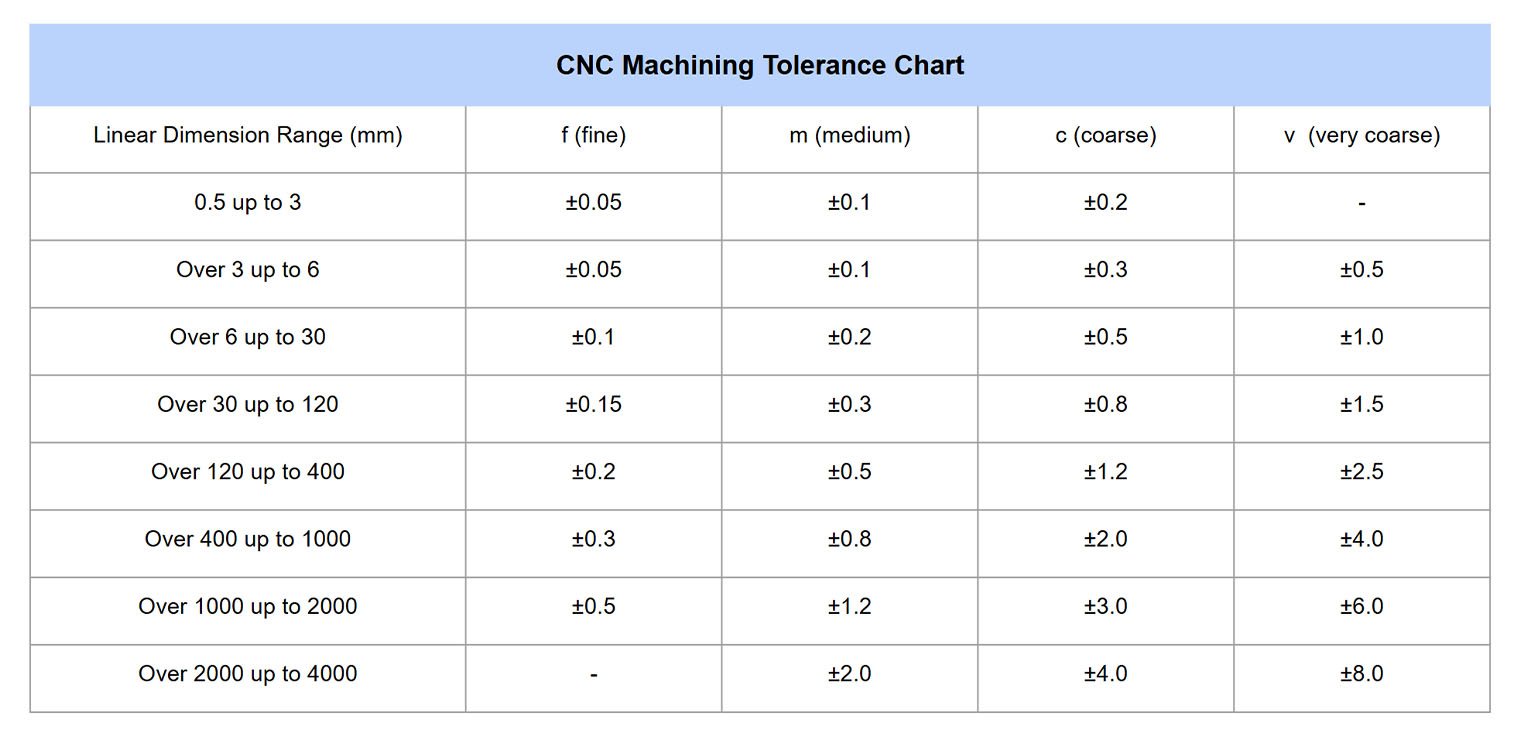

Machining tolerance is crucial in CNC manufacturing—it dictates precision and quality. Understanding it ensures parts fit together correctly, affecting performance and cost.

Machining tolerance determines accuracy and consistency in CNC manufacturing. It defines dimensional limits, impacting how parts interact. Proper tolerance selection optimizes material use and ensures functionality across applications.

CNC machining relies heavily on tolerance for precision. Defining exact dimensional boundaries helps meet design specifications and reduces waste, crucial for automotive, aerospace, and medical device industries.

What Factors Determine the Optimal Machining Allowance for Different Materials?

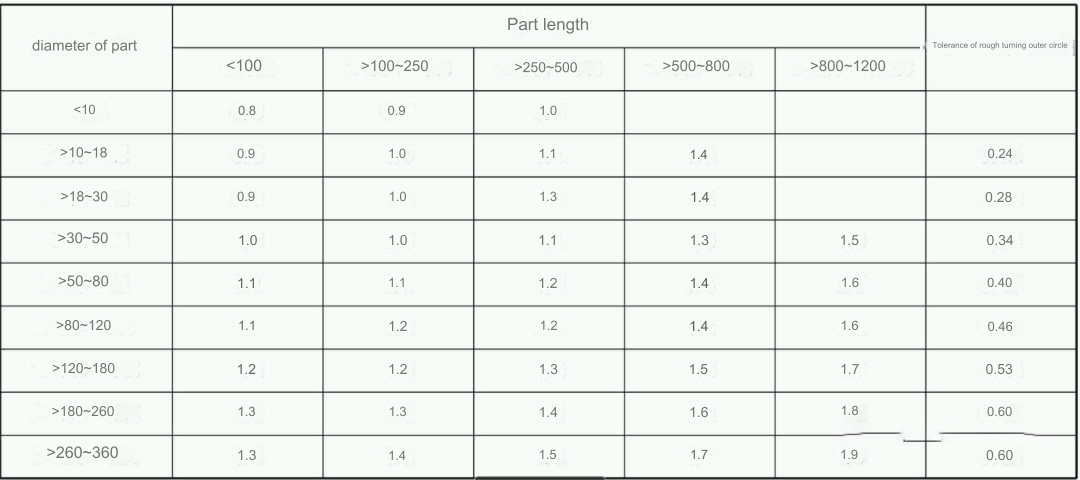

Selecting the optimal machining allowance involves material properties, complexity, and application. Misjudging these factors might lead to costly mistakes and inefficient processes.

Material properties impact machining allowance selection. Density, hardness, and stability influence how much extra material is needed. Considering these factors ensures efficient production and minimal waste.

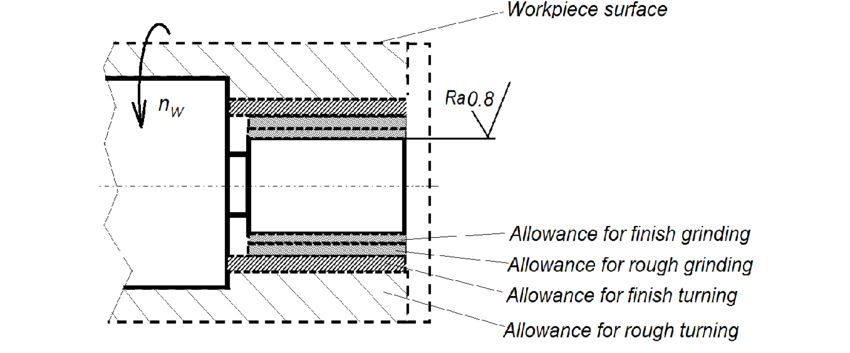

Machining allowances depend on material and process specifics. Softer materials may need more allowance to compensate for deformation. Tougher materials might need precision adjustments to ensure compatibility with other components. Here’s a simple table for clarification:

| Material Type | Typical Allowances | Factors Affecting Allowance |

|---|---|---|

| Metal | 0.1-0.5mm | Hardness, Tool Wear |

| Plastics | 0.2-1mm | Flexibility, Thermal Expansion |

| Composites | 0.1-0.3mm | Layer Structure, Rigidity |

Knowing these standards helps guide proper allowance choices for different materials.

How Does Material Type Influence Machining Allowance Selection?

Material characteristics are pivotal in allowance decision-making. Different materials require distinct treatments, influencing the machining process's efficacy and efficiency.

Material type dictates machining allowances since each has unique properties. Metals need precise control, while plastics allow flexibility. Composites vary greatly, demanding tailored approaches for dependable interaction.

Understanding how material impacts allowance selection is critical. Metals, prone to thermal expansion, demand minimal tolerance for precision. Plastics, subject to deformation, necessitate larger allowances. Composites require careful evaluation of their structural layers. Considerations like ductility and stiffness guide effective machining strategies.

What Are the Cost Implications of Improper Machining Allowances?

Improper machining allowances can burden budgets and compromise product quality. Navigating these pitfalls requires informed decisions about material and process compatibility.

Incorrect machining allowances lead to increased material waste and rework. Overestimating allowance causes inefficiencies, while underestimating risks causes inaccuracies. Balancing allowance ensures cost-effective production without sacrificing quality.

Cost repercussions from improper allowances are significant. Excessive allowances mean increased expenses from material wastage and prolonged machining times. Insufficient allowances risk defective outcomes, needing additional corrective measures. Effective allowance decisions mitigate these scenarios, aligning with quality standards and budget constraints.

When Should Different Types of Machining Allowances Be Applied?

Determining when various allowances should be applied hinges on purpose, material, and operation specifics. This ensures alignment with design and economic goals.

Choosing the right allowance type means considering material behavior and intended application. Hard materials need precision, while softer ones might permit more flexibility. Proper timing for allowance application safeguards process efficiency and product quality.

Machining Types Application

Timing the application of machining allowances depends on manufacturing conditions. For instance, precision-driven projects involving metal alloys demand strict tolerances. Contrarily, mass-production plastics may embrace wider margins. Judging these parameters wisely secures operational success and customer satisfaction.

Conclusion

Understanding machining tolerance and allowance impacts manufacturing success, directly influencing cost, efficiency, and product quality. Accurate selection is paramount in meeting industrial demands.