Ever received components that failed under pressure? Leaking connections, burst pipes, and ruptured vessels not only cause costly downtime but can endanger lives. Without proper testing, these failures are inevitable.

Hydrostatic pressure testing is a non-destructive examination method that verifies component integrity by filling them with water and pressurizing beyond normal operating conditions to identify leaks or structural weaknesses before installation. This critical safety procedure ensures reliability in high-pressure applications.

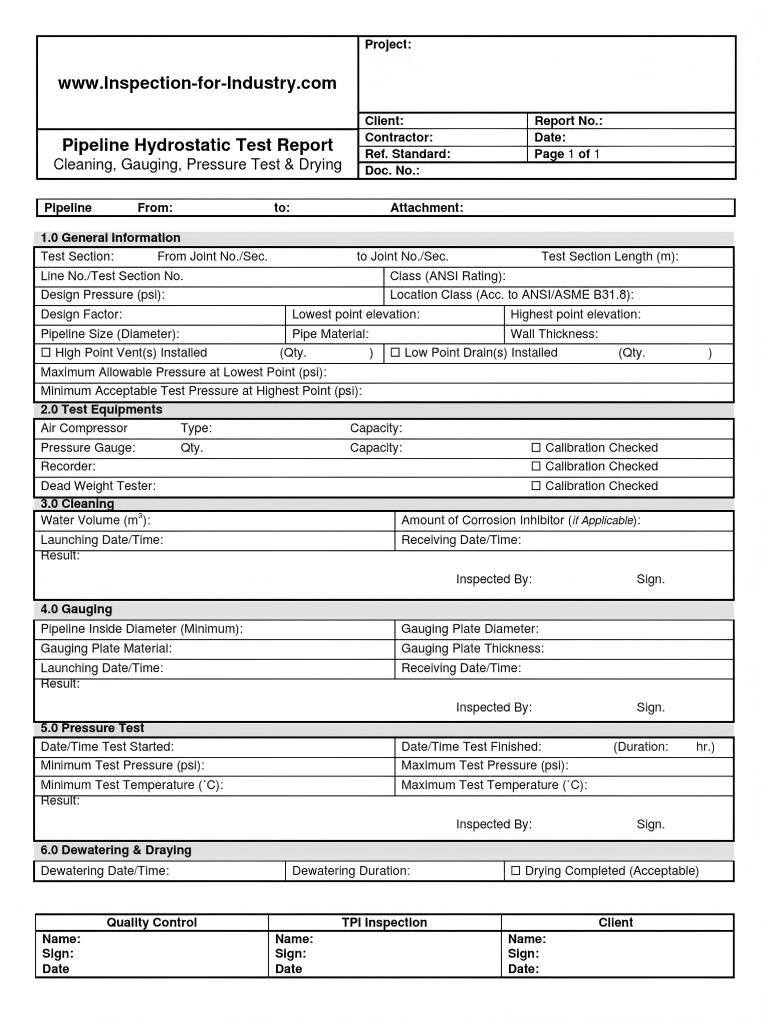

Industrial hydrostatic pressure testing setup

In my years of machining critical components, I've seen firsthand how proper pressure testing prevents catastrophic failures. Let me walk you through everything you need to know about this essential quality control process that separates reliable manufacturers from the rest.

How does hydrostatic testing ensure the integrity of machined components?

Worried about component failure in your critical systems? Without proper validation, even microscopic flaws in machined parts can lead to catastrophic leaks, equipment damage, or worse—putting both operations and personnel at risk.

Hydrostatic testing ensures component integrity by applying water pressure at 1.5 to 2 times the design operating pressure, revealing leaks, weak points, and manufacturing defects that might otherwise go undetected. This non-destructive method validates both structural strength and pressure containment without compromising the part.

Leak detection during hydrostatic testing

Hydrostatic testing works on principles established in physics and materials science. When we subject a component to elevated internal pressure, any structural weaknesses become immediately apparent. The process begins with sealing all openings in the component, then gradually filling it with water to eliminate air pockets. Using water rather than air is crucial for safety—water is incompressible and stores minimal energy, meaning even if a failure occurs during testing, the result is a leak rather than an explosion.

In our facility, we've developed a systematic approach to hydrostatic testing that goes beyond simple pass/fail evaluation. We monitor pressure over specified holding periods, typically 10-30 minutes, observing for any pressure drops that might indicate micro-leaks. For precision components with complex internal geometries, we use specialized fixtures and adapters to ensure complete testing of all internal chambers and passages.

The benefits extend beyond simple leak detection. Hydrostatic testing also:

| Benefit | Description |

|---|---|

| Material verification | Confirms that material strength meets specifications |

| Weld integrity | Validates the quality of welded or bonded joints |

| Dimensional stability | Ensures components maintain critical dimensions under pressure |

| Documentation | Provides verifiable test results for certification purposes |

| Quality assurance | Builds confidence in component reliability |

I remember a particular automotive cooling system component that passed all visual and dimensional inspections but failed hydrostatic testing due to a microscopic porosity issue in the casting. This detection prevented what would have been a costly recall and potential engine damage for our customer.

What pressure levels are required for different industry applications?

Frustrated by conflicting information about required test pressures? Using incorrect pressure levels can either miss critical defects or unnecessarily stress components, leading to premature failures or invalid test results.

Different industries require specific hydrostatic test pressure levels based on their operating environments and safety factors. Automotive components typically test at 1.5x operating pressure (70-200 psi), aerospace parts at 1.5-2.5x (up to 10,000+ psi), and industrial hydraulics at 1.5x working pressure (commonly 3,000-5,000 psi).

High-pressure hydrostatic testing gauge

The determination of proper test pressure is a critical element that varies significantly across different sectors. In my experience working with diverse client specifications, I've found that understanding the relationship between normal operating conditions and appropriate test pressures is essential for meaningful validation results.

For precision automotive components, we typically apply moderate pressures that reflect the operational stresses these parts will encounter. Cooling system components might test at 25-30 psi, while fuel system components require higher pressures around 100-150 psi. The marine industry presents unique challenges, with components needing to withstand both pressure and corrosive environments. Sailboat hydraulic systems typically test at 1.5 times their working pressure, often around 3,000 psi for steering systems.

The most demanding applications come from the aerospace and semiconductor industries. Vacuum chambers for semiconductor manufacturing require extremely precise testing to ensure they can maintain the required vacuum levels. For these components, we often perform both pressure and vacuum testing, with pressure tests sometimes exceeding 2,000 psi depending on the specific application.

Here's a breakdown of common industry pressure requirements:

| Industry | Common Operating Pressure | Typical Test Pressure | Key Considerations |

|---|---|---|---|

| Automotive | 50-150 psi | 75-225 psi | Temperature variations, vibration resistance |

| Marine | 1,000-2,000 psi | 1,500-3,000 psi | Corrosion resistance, long-term durability |

| Aerospace | 3,000-5,000 psi | 4,500-12,500 psi | Weight optimization, extreme reliability |

| Semiconductor | Vacuum to 1,000 psi | Vacuum to 2,000 psi | Ultra-clean requirements, precision sealing |

| Industrial Hydraulics | 2,000-5,000 psi | 3,000-7,500 psi | Cycle durability, contamination resistance |

| Medical Equipment | 50-300 psi | 75-600 psi | Sterilization compatibility, biocompatibility |

We recently completed a project for a high-performance racing team where their fuel delivery components required testing at 2.5x normal operating pressure due to the extreme conditions these parts would face on the track. This extra margin of safety proved valuable when the vehicle experienced unexpected pressure spikes during competition.

Which international standards govern hydrostatic testing procedures?

Confused by the maze of testing standards and certifications? Failing to comply with the right standards not only risks product rejection but can create serious liability issues if components fail in service.

Hydrostatic testing procedures are governed by several key international standards, including ASME B31.3 for process piping, ASTM F1476 for pressure vessel components, ISO 1167 for plastic piping, and API 570 for metallic piping systems. Compliance with these standards ensures testing methodology is consistent, repeatable, and recognized globally.

Hydrostatic testing standards documentation

The landscape of regulatory standards for pressure testing is complex and evolving constantly. Through our work with multinational clients, I've gained extensive experience navigating these requirements across different regions and applications. Achieving compliance requires more than simply meeting a pressure value—it demands proper documentation, calibrated equipment, and qualified personnel.

The ASME Boiler and Pressure Vessel Code (BPVC) stands as perhaps the most comprehensive standard globally, particularly Section VIII, which details requirements for pressure vessels. For components we machine that will be incorporated into pressure vessels, we must adhere to these exacting standards. The testing procedures specify not just pressure levels but also test duration, temperature considerations, and acceptable examination methods.

For our automotive clients, SAE standards often apply, particularly SAE J1290 for automotive hydraulic brake hoses and assemblies. The aerospace sector relies heavily on AS4059 for fluid cleanliness and multiple NASA and military specifications, depending on the specific application.

The European market introduces additional considerations through the Pressure Equipment Directive (PED) 2014/68/EU, which establishes essential safety requirements for pressure equipment within the European Union. When we ship components to European clients, ensuring compliance with these standards is essential.

Here's a comparative overview of major hydrostatic testing standards:

| Standard | Application Area | Key Requirements | Documentation Needed |

|---|---|---|---|

| ASME B31.3 | Process piping | 1.5× design pressure minimum | Test reports, material certifications |

| ASTM F1476 | Gasketed joints | Performance-based requirements | Test data, joint qualification |

| ISO 1167 | Thermoplastic pipes | Time-to-failure methodology | Test conditions, failure analysis |

| API 570 | In-service inspection | Risk-based inspection intervals | Inspection reports, repair documentation |

| PED 2014/68/EU | European pressure equipment | Conformity assessment procedures | Technical file, CE marking |

| ASME BPVC Sec. VIII | Pressure vessels | Detailed fabrication and test requirements | U-stamp certification documentation |

One particularly challenging project involved machining vacuum chamber components for a semiconductor client that needed to meet both ASME BPVC standards and SEMI standards specific to the semiconductor industry. The intersection of these requirements created a complex testing protocol that we developed specifically for this application.

How can manufacturers integrate hydrostatic testing into quality control processes?

Struggling to maintain consistent quality while meeting tight production schedules? Ad-hoc testing approaches lead to bottlenecks, inconsistent results, and missed defects that can damage your reputation and customer relationships.

Manufacturers can integrate hydrostatic testing into quality control by establishing clear test specifications, investing in appropriate testing equipment, training dedicated personnel, implementing detailed documentation systems, and creating feedback loops to address recurring issues. This systematic approach transforms pressure testing from a final inspection to an integral quality assurance tool.

Factory quality control station with hydrostatic testing equipment

Over my years in precision machining, I've learned that effective integration of hydrostatic testing requires a holistic approach that considers workflow, personnel, and production requirements. In our facility, we've evolved from treating pressure testing as a separate operation to incorporating it seamlessly into our production process.

The key to successful integration begins with proper planning at the design and quotation stage. When we receive new projects requiring pressure integrity, we immediately identify testing requirements and incorporate them into the production routing. This ensures appropriate resources are allocated and testing is considered from the beginning rather than treated as an afterthought.

Our implementation follows a stage-gate approach where components must pass pressure testing before proceeding to subsequent operations or shipping. For high-volume production, we've invested in semi-automated testing systems that maintain consistency while improving throughput. These systems include automatic data logging that generates test certificates without manual intervention, reducing both human error and documentation time.

Training has proven essential for testing effectiveness. We've developed specialized training programs for operators performing hydrostatic testing, focusing not just on the mechanics of the test but also on understanding failure modes and interpretation of results. This knowledge enables them to identify subtle issues that might otherwise go unnoticed.

An effective quality control integration includes these elements:

| Element | Implementation Approach | Benefits |

|---|---|---|

| Test Planning | Define test parameters in work instructions | Consistent methodology, clear acceptance criteria |

| Equipment Calibration | Regular verification against certified standards | Accurate, traceable results |

| Process Validation | Periodic testing of known good/bad samples | Verification of test efficacy |

| Failure Analysis | Root cause investigation of test failures | Process improvement opportunities |

| Data Management | Digital recording of test results | Traceability, trend analysis capability |

| Customer Specifications | Translation of requirements to test protocols | Alignment with end-user expectations |

I recall implementing this approach for a series of critical hydraulic manifolds we machined for an agricultural equipment manufacturer. By integrating pressure testing at multiple stages of production, we were able to identify issues with a specific cutting tool that was creating micro-burrs in internal passages. This early detection prevented dozens of potentially defective parts from progressing through production.

What specialized equipment is needed for accurate hydrostatic testing?

Wondering if your current equipment is providing reliable results? Inadequate or poorly calibrated testing equipment leads to inconsistent readings, false failures, and missed defects—ultimately undermining confidence in your quality control system.

Accurate hydrostatic testing requires specialized equipment, including calibrated pressure gauges (accuracy of ±0.5% or better), high-pressure pumps capable of reaching 1.5-3× design pressure, proper test fixtures and sealing mechanisms, pressure recorders for documentation, and safety barriers to protect operators during high-pressure testing.

Modern hydrostatic testing equipment setup

The evolution of hydrostatic testing equipment has been remarkable over my career in precision machining. What once involved basic mechanical gauges and manual pumps has transformed into sophisticated systems with digital monitoring, data logging, and automated test sequences. This technological progression has improved both accuracy and efficiency.

The foundation of any reliable hydrostatic test system is the pressure generation equipment. For our testing applications, we utilize both pneumatic-hydraulic intensifiers for higher pressures and direct-drive hydraulic pumps for lower-pressure applications. Each system includes precise pressure regulation capabilities to ensure controlled pressure application and accurate hold periods.

Pressure measurement is equally critical. We employ digital pressure transducers with accuracies of ±0.25% full scale, calibrated annually against NIST-traceable standards. These connect to data acquisition systems that record pressure over time, allowing us to detect even minimal pressure drops that might indicate micro-leaks. For certain aerospace applications, we use differential pressure sensors that can detect extremely small leakage rates.

Fixturing represents one of the most challenging aspects of hydrostatic testing. Each component geometry requires specialized holding fixtures and sealing methods. We've developed a modular fixturing system that accommodates various part geometries while ensuring reliable sealing under high pressure. For complex internal passages, we use custom-designed plugs and adapters that isolate specific sections for targeted testing.

Here's an overview of essential equipment for comprehensive hydrostatic testing:

| Equipment | Purpose | Key Specifications |

|---|---|---|

| Pressure Source | Generate test pressure | Capacity 1.5-3× maximum test pressure, stable output |

| Measurement Devices | Monitor and record pressure | Digital accuracy ±0.25% or better, calibration current |

| Fixturing | Hold and seal test components | Material compatibility, pressure rating above test levels |

| Fluid Management | Fill, circulate, and drain test fluid | Filtration capability, air removal systems |

| Safety Equipment | Protect operators | Shields, remote operation capability, pressure relief devices |

| Documentation System | Record test results | Digital data capture, certificate generation, traceability |

Recently, we invested in a fully automated testing system for a series of high-volume hydraulic components. This system not only performs the pressure test but also conducts dimensional verification, assigns unique identification, and generates comprehensive test documentation. The integration of these functions has reduced our testing time by 65% while improving detection sensitivity.

Conclusion

Hydrostatic pressure testing is essential for ensuring component integrity and safety. By implementing proper testing protocols, equipment, and standards, we deliver precision-machined parts that perform reliably under pressure, preventing costly failures and protecting lives.