Ever had a project fail unexpectedly with no visible cause? Static electricity might be the hidden culprit damaging your precision components before they even leave our facility.

Electrostatic Discharge (ESD) is an instantaneous flow of electricity between two electrically charged objects. In CNC machining, even a minor 100-volt discharge can damage sensitive electronic components, while humans only feel ESD above 3,000 volts. Proper ESD controls are essential for component reliability.

Electrostatic discharge occurring during CNC machining

After 20 years in precision manufacturing, I've seen ESD silently destroy countless components. Let me walk you through what causes these invisible threats and how we prevent them in our Kunshan facility, where we handle sensitive parts for automotive, medical, and semiconductor industries daily.

How does ESD occur during precision manufacturing?

The friction of cutting tools against materials creates static buildup. Parts moving across surfaces generate charges that can instantly damage sensitive components without warning.

ESD occurs when two differently charged objects make contact, causing a rapid transfer of electrical energy. In CNC environments, this commonly happens during material handling, tool changes, or when parts contact ungrounded surfaces, potentially generating charges exceeding 20,000 volts despite being completely invisible.

Measuring static charge on machining equipment

In our Kunshan facility, we've invested heavily in understanding ESD mechanics during machining operations. The primary culprit is tribocharging—the generation of electrical charge through friction. When the cutting tool contacts the workpiece, electrons transfer between the surfaces. Similarly, when materials slide against each other during processing or handling, charge separation occurs.

Material properties greatly influence ESD risk. Insulative materials like plastics and ceramics readily hold static charges, while conductive materials like metals discharge quickly when grounded. This creates a particular challenge when machining composite parts that combine both types.

Relative humidity plays a crucial role, too. We've documented significantly higher static buildup during winter months when our shop's humidity drops below 30%. At these levels, static charges dissipate more slowly, increasing ESD risk substantially. This is why we maintain controlled humidity levels between 40-60% in areas where we machine sensitive electronic components.

Temperature fluctuations compound the problem. When cold materials enter warm machining areas, condensation can form momentarily, changing surface conductivity and creating unpredictable static conditions.

What damage can ESD cause to machined components?

The silent killer in manufacturing—ESD can create microscopic burns and melting points completely invisible to the naked eye. Your parts might look perfect, but fail prematurely.

ESD damage ranges from immediate catastrophic failures to latent defects that emerge only after components are in service. For semiconductor parts, even discharges as low as 10 volts can create junction breakdown, while sensitive circuits may experience gate oxide damage at 100 volts—far below human perception threshold.

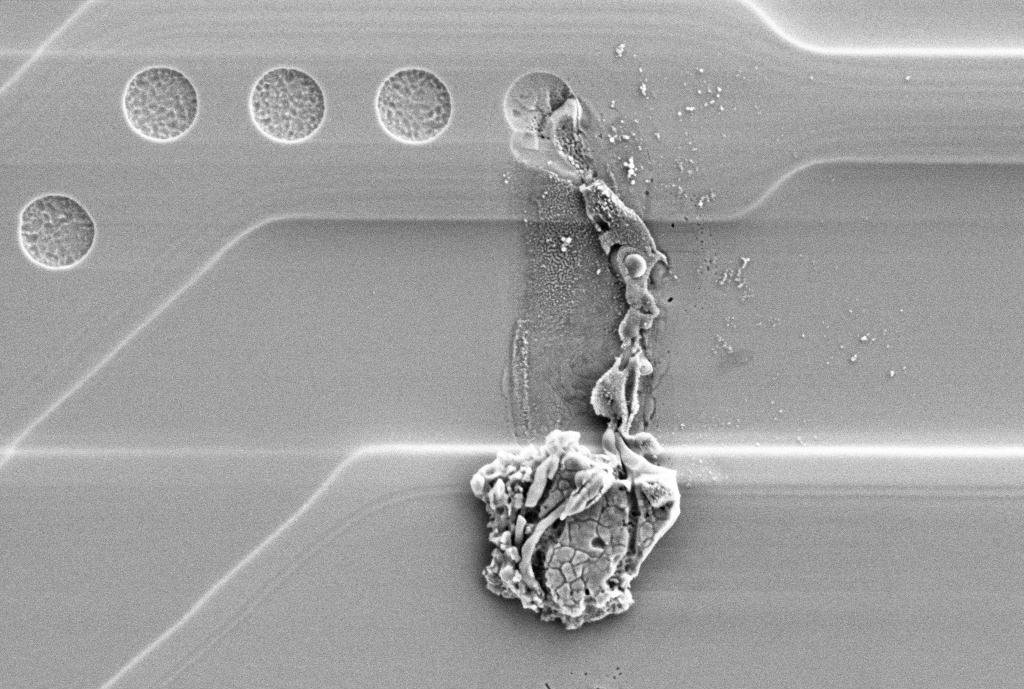

Microscopic view of ESD damage

The most insidious aspect of ESD damage is its often invisible nature. When a discharge occurs during the machining process, it can create localized heating that exceeds 1,800°F (1,000°C) at the point of contact. This momentary thermal spike causes microscopic damage that standard quality control inspections might miss.

In our experience machining vacuum chamber components for semiconductor applications, we've observed several distinct categories of ESD damage:

- Catastrophic Failures: Complete electrical pathway destruction, rendering components immediately non-functional

- Parametric Damage: Performance degradation without complete failure

- Latent Defects: Damage that weakens components but doesn't cause immediate failure, leading to field failures months later

The financial impact of ESD damage extends far beyond scrapped parts. For our automotive customers, ESD-damaged components that pass initial testing but fail in vehicles can lead to warranty claims exceeding $100,000. For medical equipment manufacturers, similar failures could compromise patient safety.

I remember one particularly costly incident where a batch of precision-machined sensor housings passed all dimensional inspections but failed electrical testing at the customer's facility. After exhaustive investigation, we traced the problem to an ungrounded fixture that had created micro-arc burns on critical surfaces. This taught us that ESD prevention isn't just good practice—it's essential for our business survival.

Which factors increase ESD risk in machining environments?

Low humidity is the biggest ESD risk factor in our facility. Winter months require extra precautions as heating systems dry the air, making static buildup more likely and more powerful.

Several environmental and operational factors significantly increase ESD risk, including relative humidity below 30%, insulative materials like plastics or ceramics, rapid material movement, synthetic clothing, and ungrounded equipment. Recognizing these risk multipliers is essential for effective ESD control.

Using an ionizing air gun to neutralize static charge

Our team has mapped numerous factors that elevate ESD risk during machining operations. After analyzing hundreds of static events in our facility, we've identified these key risk amplifiers:

Environmental Factors

| Factor | Risk Level | Mitigation Strategy |

|---|---|---|

| Humidity below 30% | Very High | Humidification systems, ionized air |

| Temperature below 65°F (18°C) | Moderate | Climate control, material acclimation |

| Air filtration systems | Moderate | Grounded filtration components |

| Poor grounding infrastructure | Very High | Comprehensive grounding audit |

Material Factors

| Material Type | ESD Risk | Handling Requirements |

|---|---|---|

| PTFE/Teflon | Extreme | Ionization during machining |

| Acrylic/Polycarbonate | High | Conductive fixtures, ionized air |

| Aluminum | Low | Standard grounding procedures |

| Stainless Steel | Very Low | Basic ESD awareness |

The combination of environmental and material factors creates compound risk scenarios. For example, machining acrylic components during low-humidity winter months without ionization presents approximately 15 times higher ESD risk than working with aluminum under normal conditions.

Tool speed also impacts static generation. Our testing shows that high-speed operations (above 15,000 RPM) generate significantly more static charge than lower speeds. This is particularly problematic for precision micromachining, where high speeds are often necessary for quality results.

What are the most effective ESD prevention techniques?

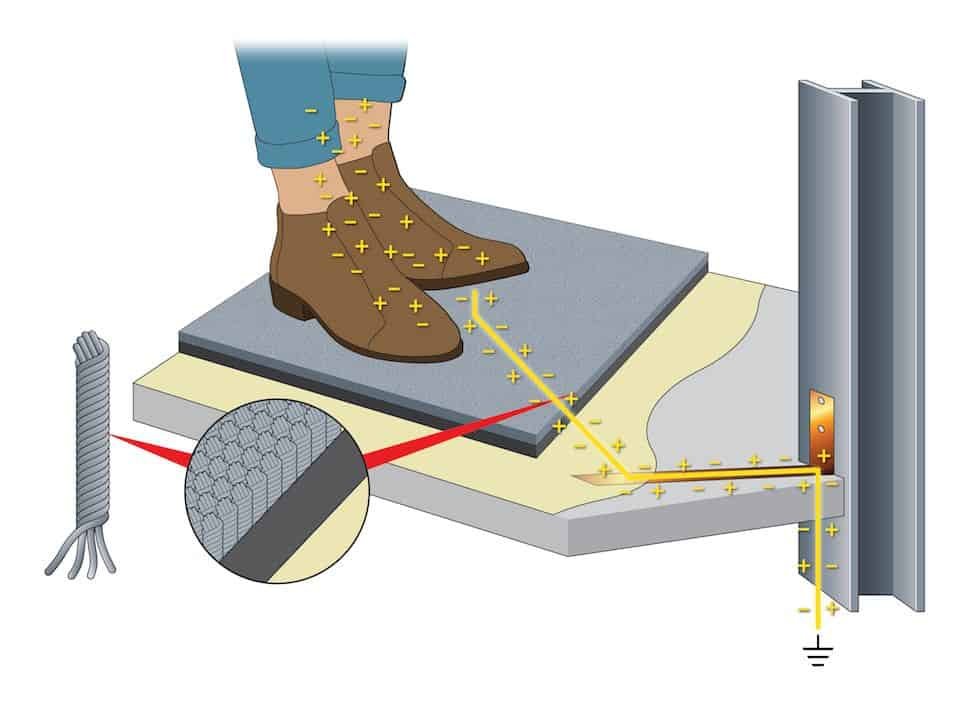

We've implemented a multi-layered ESD defense system that starts with our facility design. Conductive flooring, humidity control, and personal grounding equipment protect your sensitive components.

Effective ESD prevention requires a comprehensive approach, including personnel grounding with wrist straps and footwear, conductive work surfaces, humidity control between 40-60%, air ionization, proper grounding of all equipment, and regular training programs for all staff members.

Complete ESD-protected workstation

In our Kunshan facility, we've developed a multi-tiered approach to ESD protection based on decades of manufacturing experience. Our strategy addresses not just obvious sources of static but also subtle contributors that many facilities overlook.

The foundation of our system is a comprehensive grounding. Every piece of machining equipment maintains a resistance to ground of less than 1 ohm, verified weekly. All workbenches incorporate ESD-dissipative surfaces connected to a common ground point, creating an equipotential environment that prevents charge buildup between surfaces.

For personnel protection, we implement what we call our "3-Point Contact Rule":

- ESD footwear with verified resistance checks at entry points

- ESD smocks made of carbon-infused fabric that shield parts from charges on personal clothing

- Wrist straps are used when handling the most sensitive components

Environmental controls represent another critical layer. We've installed:

- Humidity monitoring stations throughout the facility

- Automatic humidification systems that activate when levels fall below 40%

- Temperature stabilization to prevent condensation issues

- Ionizing air blowers at critical workstations that neutralize static charges by emitting both positive and negative ions

Perhaps most importantly, we've cultivated an ESD-aware culture. Every team member receives quarterly training on static recognition and prevention. We conduct random audits where supervisors use field meters to check for unexpected charge buildup, creating accountability for ESD compliance.

One innovation we've implemented is "ESD process mapping," where we analyze each step of our machining workflow to identify potential static generation points and implement targeted countermeasures.

What testing methods ensure ESD protection is working?

Trust but verify—our daily testing regimen ensures ESD protection remains effective. Every morning, we test wrist straps, footwear, and surface resistivity before machining begins.

Worker testing ESD-safe footwear

Comprehensive ESD testing includes daily verification of personnel grounding equipment (wrist straps and footwear) using test stations, weekly surface resistivity measurements, monthly ionizer performance checks, and quarterly comprehensive audits of the entire ESD control system, including grounding continuity.

Our testing protocols have evolved significantly over two decades of precision manufacturing. We've found that successful ESD management requires both routine verification and investigative testing to identify emerging problems before they affect product quality.

The cornerstone of our verification system is our "Start-of-Shift" protocol, where every operator performs and logs these checks:

- Wrist Strap Testing: Using calibrated testers, operators verify their wrist straps maintain resistance between 800kΩ and 10MΩ

- Footwear Testing: Each person steps on a resistance meter that confirms proper grounding through ESD shoes

- Workstation Verification: Surface resistivity measurements ensure work surfaces remain within the 1MΩ to 1GΩ range

Beyond daily checks, our maintenance team conducts weekly environmental assessments:

| Test Type | Frequency | Acceptable Range | Action if Failed |

|---|---|---|---|

| Surface Resistivity | Weekly | 1×10⁶ to 1×10⁹ Ω | Clean or replace the surface |

| Point-to-Ground Resistance | Weekly | <1 Ω | Repair the grounding connection |

| Ionizer Balance | Monthly | ±30V | Calibrate or service the unit |

| Humidity Levels | Continuous | 40-60% RH | Adjust HVAC systems |

| Field Strength Survey | Quarterly | <100V/inch | Identify and eliminate charge sources |

We also employ more sophisticated testing for high-value projects. Using charged plate monitors, we can measure the effectiveness of our ionizers in neutralizing static charges. Event monitors placed near critical machines record any ESD events, allowing us to correlate them with specific processes or environmental changes.

Perhaps most valuable is our "ESD Failure Analysis" protocol, where we use specialized microscopy to examine components that experience electrical failures. This has helped us identify subtle ESD damage patterns and refine our preventive measures accordingly.

Conclusion

ESD protection isn't just technical compliance—it's our commitment to your component quality. Through proper grounding, environmental controls, and rigorous testing, we ensure your precision parts perform flawlessly from our machines to the final application.