Setting the wrong tolerances can wreck your project. Too tight? Costs skyrocket. Too loose? Parts fail. The frustration of rejected components costs both time and money.

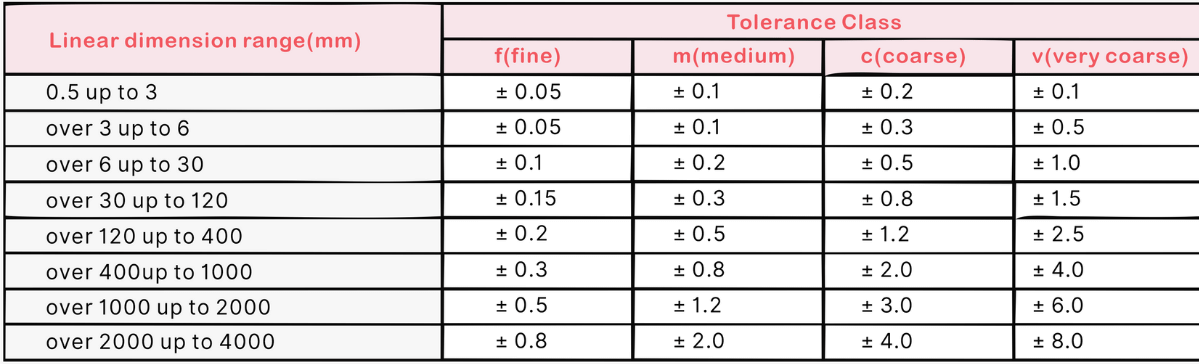

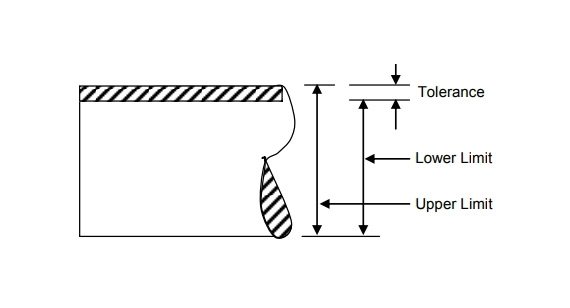

CNC machining tolerance1 is the acceptable deviation range from specified dimensions that a machined part can have while still functioning properly. Standard CNC tolerances typically range from ±0.005” for normal machining to ±0.0005” for precision work, with tighter tolerances increasing production costs2 significantly.

CNC machining tolerance inspection

Understanding machining tolerances isn't just technical talk—it directly impacts your bottom line. Let's explore how tolerances affect everything from material selection to production costs, so you can make informed decisions that balance precision with profitability.

How Do Tolerances Impact Production Costs?

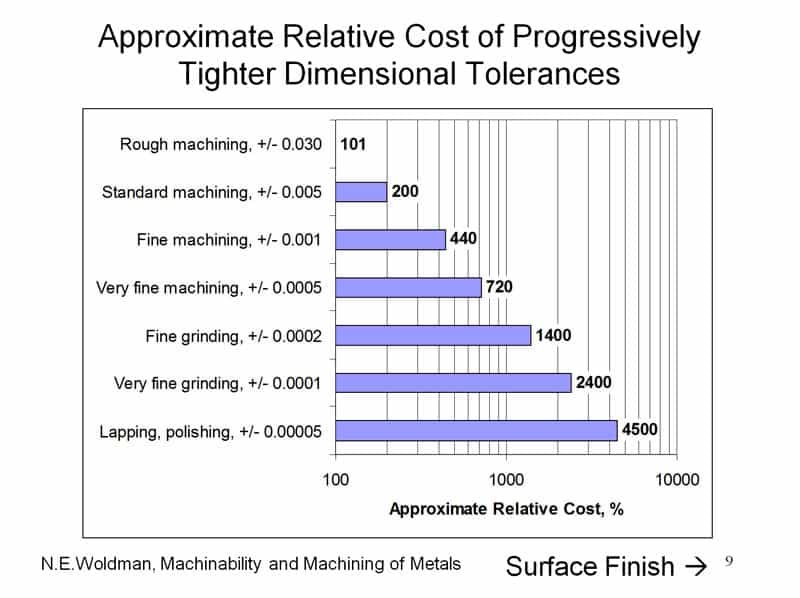

Tighter tolerances mean higher costs and longer lead times. Every extra decimal place of precision can double your production expenses and create bottlenecks in manufacturing.

Production costs increase exponentially with tighter tolerances because they require more precise machinery, additional setup time, slower cutting speeds, more frequent tool changes, and more rigorous inspection processes. A part with ±0.001" tolerance typically costs 30-50% more than the same part with ±0.005" tolerance.

Tolerance vs. cost relationship chart

When we talk about tolerance and cost relationships, we need to understand the real-world implications across different stages of production. Tighter tolerances impact nearly every aspect of the manufacturing process, creating a cascading effect on expenses.

Consider our recent project manufacturing precision automotive components: when a client requested tolerances of ±0.0005" instead of the standard ±0.002", we had to completely change our approach. This required using our highest-precision CNC machines, which have higher hourly rates. The setup time increased by 40% as our technicians needed to perform more calibration steps. Cutting speeds had to be reduced by 35% to maintain accuracy, and we needed to perform interim measurements approximately three times more frequently.

The finishing operations also became more complex, requiring additional passes and specialized tools. For inspection, we had to use our climate-controlled measurement room with more expensive CMM equipment rather than standard shop-floor measuring tools.

This combination of factors resulted in a manufacturing cost increase of nearly 70% compared to the standard tolerance version of the same part. While the client needed this precision for their specific application, many customers could have achieved their functional requirements with standard tolerances at significantly lower costs.

| Tolerance Level | Machine Requirements | Production Speed | Tool Wear | Inspection Requirements | Relative Cost |

|---|---|---|---|---|---|

| ±0.010" (0.25mm) | Standard machinery | 100% speed | Normal | Basic inspection | 1× (baseline) |

| ±0.005" (0.13mm) | Good precision | 80% speed | Increased | Regular inspection | 1.5× cost |

| ±0.002" (0.05mm) | High precision | 60% speed | High | Detailed inspection | 2-3× cost |

| ±0.0005" (0.013mm) | Ultra-precision | 40% speed | Very high | Climate-controlled inspection | 4-6× cost |

Which Materials Provide Tighter Tolerances?

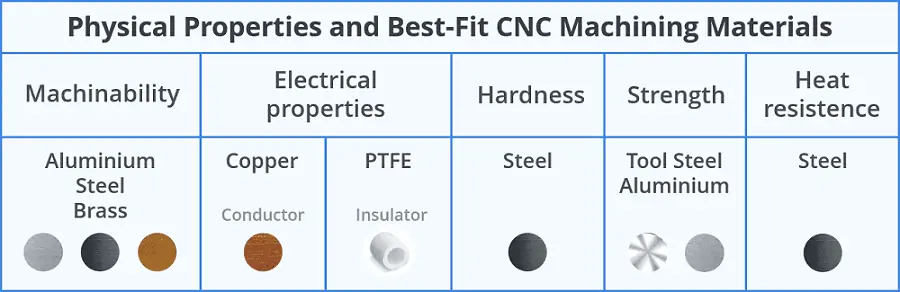

Some materials fight you every step of the way. Soft metals deform, composites splinter, and plastics expand with heat. Choosing the right material can make the difference between precision success and costly failure.

The best materials for tight tolerances are those with high dimensional stability, consistent internal structure, and good machinability. Aluminum 6061-T6 and tool steels like A2 and D2 maintain excellent tolerances. Stainless steel 304 provides good stability but requires more careful machining. Plastics generally offer poorer tolerance capabilities due to thermal expansion.

CNC machining materials comparison

Material selection isn't just about what's possible to machine—it's about finding the sweet spot between functionality, cost, and manufacturability. In our daily operations, we regularly see how different materials respond to precision machining processes, and the differences can be dramatic.

Take aluminum alloys, for instance. In our workshop, we can consistently achieve tolerances of ±0.0005" on 6061-T6 aluminum components without extraordinary measures. The material's excellent machinability, good thermal conductivity, and dimensional stability make it ideal for precision work. When we machine the same geometry in 304 stainless steel, maintaining those same tolerances requires significantly slower cutting speeds, more frequent tool changes, and additional stress-relieving processes between operations.

For ultra-high precision work, we often recommend beryllium copper alloys or pre-hardened tool steels, which can maintain tolerances in the ±0.0002" range even after thermal cycling. These materials maintain their stability exceptionally well but come with much higher material costs and require specialized machining knowledge.

Conversely, when working with engineering plastics like Delrin or PEEK, we have to compensate for their higher thermal expansion coefficients. We typically need to design machining sequences that minimize heat generation and allow for cooling periods. Even with these precautions, we generally recommend designing for tolerances no tighter than ±0.002" for most plastic components.

| Material | Achievable Tolerance | Stability | Machinability | Cost | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | ±0.0005" | Excellent | Excellent | $ | Precision instruments, fixtures |

| Stainless Steel 304 | ±0.001" | Very good | Good | $$ | Food processing, medical devices |

| Tool Steel A2 | ±0.0003" | Outstanding | Moderate | $$$ | Tooling, high-wear components |

| Titanium 6Al-4V | ±0.0008" | Excellent | Challenging | $$$$ | Aerospace, medical implants |

| Delrin (POM) | ±0.002" | Moderate | Very good | $ | Low-friction components |

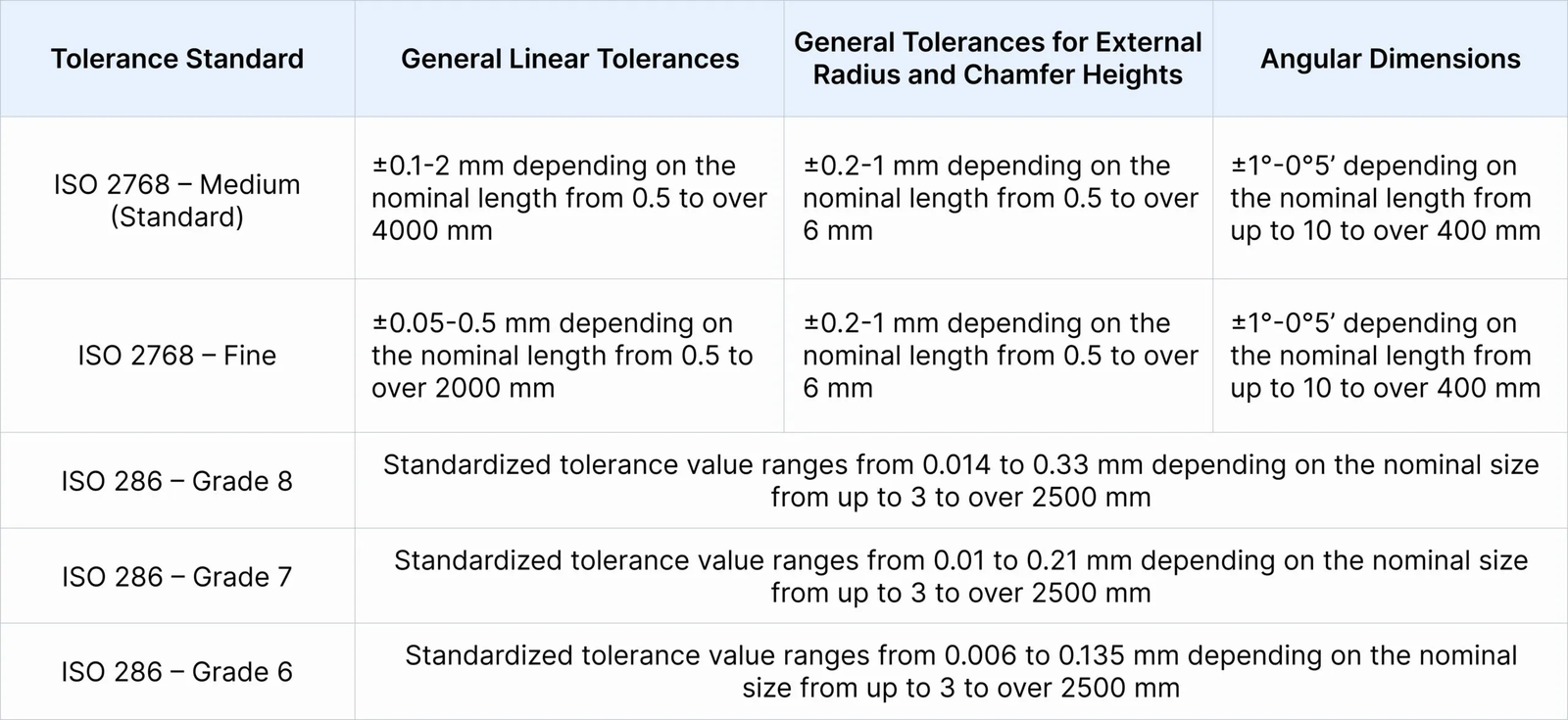

What Are Industry-Standard Tolerances?

Different industries have widely varying tolerance expectations. What's acceptable for construction equipment might be catastrophically loose for aerospace components. Understanding these standards saves you from overspecifying or underspecifying.

Industry-standard CNC machining tolerances typically range from ±0.005" to ±0.001" (0.127mm to 0.0254mm). Aerospace typically requires ±0.001" to ±0.0005", medical devices need ±0.002" to ±0.0005", automotive components use ±0.003" to ±0.001", and general industrial equipment functions well with ±0.005" to ±0.003" tolerances.

Industry tolerance standards document

Working with clients across different sectors has given us a valuable perspective on how tolerance requirements vary dramatically between industries. These differences aren't arbitrary—they reflect the functional needs, safety requirements, and economic realities of each sector.

In the aerospace industry, where we've produced components for flight control systems, tolerances of ±0.0005" are common and sometimes even tighter for critical components. This precision is essential due to the catastrophic consequences of failure and the need for perfect interchangeability of parts across global supply chains. Similarly, medical device manufacturing demands tolerances in the ±0.0005" to ±0.001" range for implantable devices, where precision directly impacts patient safety.

Automotive manufacturing presents an interesting middle ground. For standard vehicle components, tolerances of ±0.003" are often sufficient, balancing performance requirements with mass-production economics. However, for high-performance racing applications or engine components, tolerances tighten to ±0.001" or better.

General industrial machinery typically operates well with tolerances of ±0.005", which significantly reduces manufacturing costs while maintaining functional performance. For consumer products, even more relaxed tolerances are often acceptable, sometimes as wide as ±0.010" for non-critical features.

| Industry | Typical Tolerance Range | Critical Components Tolerance | Cost Sensitivity | Inspection Requirements |

|---|---|---|---|---|

| Aerospace | ±0.001" to ±0.0005" | ±0.0002" | Low | 100% inspection, documentation |

| Medical | ±0.002" to ±0.0005" | ±0.0003" | Medium | Full traceability, validated processes |

| Automotive | ±0.003" to ±0.001" | ±0.0005" | High | Statistical process control |

| Industrial | ±0.005" to ±0.003" | ±0.001" | Very high | Periodic inspection |

| Consumer | ±0.010" to ±0.005" | ±0.002" | Extremely high | Batch sampling |

When Should You Specify Custom Tolerances?

Applying blanket tolerance specifications wastes money and creates manufacturing headaches. Strategic tolerance allocation—tighter where it matters, looser where it doesn't—optimizes both performance and cost.

Custom tolerances should be specified when standard tolerances would compromise functionality or when they'd unnecessarily increase costs. Critical mating surfaces, bearing fits, and sealing interfaces often need tight tolerances, while non-functional features can have relaxed specifications. Always consider the assembly's functional requirements rather than arbitrarily applying tight tolerances.

Custom tolerance specification discussion

The art of tolerance specification is something we've refined through thousands of client projects. The most successful approach is always function-based tolerance allocation—applying precision exactly where it's needed and nowhere else.

I recall working with a client who initially specified ±0.001" tolerance across their entire pneumatic valve housing. After discussing their actual requirements, we determined that only two critical sealing surfaces and one bearing interface truly needed this precision. The remaining features could be machined to ±0.005" without any impact on performance. By applying this targeted approach, we reduced their manufacturing cost by 42% while maintaining perfect functionality.

For another aerospace customer, we took the opposite approach. Their initial specification had fairly loose tolerances, but our analysis showed that certain critical dimensions needed to be held much tighter to ensure proper assembly and operation in varying temperature conditions. By selectively tightening tolerances on just three critical dimensions, we eliminated an intermittent failure issue that had been plaguing their assemblies.

Custom tolerance specification requires thinking about the entire product lifecycle. Will the components need to be serviced in the field? Will replacement parts need to be perfectly interchangeable? Are there thermal cycling or vibration conditions that could affect fits over time? These considerations should drive tolerance decisions beyond just the initial assembly requirements.

| Feature Type | Tolerance Consideration | Example | Cost Impact |

|---|---|---|---|

| Mating surfaces | Fit type (clearance, transition, interference) | Shaft/bearing interface | High for tight fits |

| Sealing surfaces | Surface finish and flatness | O-ring grooves | Medium-high |

| Alignment features | Positional tolerance | Dowel pin holes | High |

| Threaded features | Thread class | Fastener holes | Low-medium |

| Non-functional surfaces | Visual only | Exterior surfaces | Low |

Conclusion

Understanding machining tolerances helps you balance precision with cost-effectiveness. Apply tight tolerances only where functionally necessary, choose appropriate materials, and follow industry standards to optimize both performance and production efficiency.