Are your precision components wearing down too quickly? Facing corrosion issues that compromise part integrity? Chrome plating offers a proven solution that transforms ordinary machined parts into high-performance components.

Chrome plating provides exceptional wear resistance, corrosion protection, and surface hardness to CNC-machined parts. This electroplating process deposits a thin layer of chromium onto metal surfaces, extending component lifespan and enhancing performance while maintaining dimensional precision.

Chrome-plated precision components

As a CNC machining specialist, I've seen firsthand how chrome plating 1transforms ordinary parts into extraordinary components. The benefits extend far beyond aesthetic appeal, with significant improvements to functionality and longevity that directly impact your bottom line. Let's explore why this surface treatment continues to be a crucial consideration for high-performance applications.

What's the difference between hard chrome and decorative chrome plating?

Does your application need beauty or brawn? The distinction between these two chrome plating types determines whether you'll get the performance characteristics your project demands.

Hard chrome plating creates thick deposits (typically 0.0002-0.01 inches) focused on functional benefits like wear resistance and reduced friction. Decorative chrome is much thinner (0.00002-0.0002 inches) and is applied over nickel for aesthetic appeal in consumer goods and automotive trim.

Hard and decorative chrome plating comparison

Hard chrome plating, also known as industrial or engineering chrome, primarily serves functional purposes rather than aesthetics. In our machining facility, we regularly apply hard chrome to hydraulic rods, cylinder bores, and industrial equipment components that face extreme wear conditions. The process typically builds thicker deposits (0.0002" to 0.01") directly onto the substrate material.

The surface hardness achieved through hard chrome plating2 is impressive, typically ranging from 65-70 HRC. This exceptional hardness translates to superior wear resistance, making it ideal for components facing abrasive conditions. Additionally, hard chrome creates a low coefficient of friction that reduces galling and improves part performance in sliding applications.

Decorative chrome, by contrast, is all about appearance. The process creates much thinner chrome layers and is typically applied over nickel plating to achieve that brilliant, mirror-like finish we associate with automotive trim, bathroom fixtures, and consumer products. While it does provide some corrosion protection, its primary purpose is aesthetic enhancement rather than functional improvement.

| Feature | Hard Chrome | Decorative Chrome |

|---|---|---|

| Typical Thickness | 0.0002"-0.01" | 0.00002"-0.0002" |

| Primary Purpose | Functional | Aesthetic |

| Surface Hardness | 65-70 HRC | 40-45 HRC |

| Substrate Preparation | Minimal | Extensive (copper/nickel underlayers) |

| Cost Factor | Higher due to thickness | Lower for thin layers, higher for multi-layer systems |

How does chrome plating improve metal part durability?

Is your equipment constantly down for maintenance due to component failure? Chrome plating could be the solution that keeps your operations running and significantly reduces replacement costs.

Chrome plating creates an extraordinarily hard surface layer (65-70 HRC) that resists abrasion and wear while providing exceptional corrosion protection. The chromium oxide surface naturally inhibits oxidation, extending component life by 2-10 times compared to unplated parts.

Chrome plating durability demonstration

Chrome plating fundamentally transforms the surface properties of metal components, creating a protective barrier that shields the base material from numerous degradation factors. When we chrome plate critical components at our facility, we're essentially armoring them against the harsh realities of industrial use.

The durability improvements stem from multiple mechanisms working in tandem. First, the chromium layer itself possesses remarkable hardness, typically 65-70 HRC, which exceeds the hardness of most tool steels. This hardness translates directly to superior wear resistance. Components that would normally show significant wear patterns after a few months of service often remain dimensionally stable for years after chrome plating.

Corrosion protection represents another critical durability factor. Chrome naturally forms a passive chromium oxide layer that inhibits further oxidation. This self-healing characteristic provides exceptional protection against atmospheric corrosion, many chemicals, and harsh operating environments. In salt spray testing, properly applied chrome plating routinely delivers protection measured in thousands of hours, far exceeding unplated materials.

The low coefficient of friction inherent to chrome surfaces (typically 0.05-0.12 when lubricated) reduces mechanical wear in moving assemblies. Parts that slide against each other experience less galling, scoring, and adhesive wear. This property is particularly valuable in applications like hydraulic cylinders, where smooth operation and minimal friction directly impact system efficiency and component lifespan.

| Durability Factor | Improvement with Chrome Plating | Practical Benefit |

|---|---|---|

| Wear Resistance | 2-10× improvement | Extended maintenance intervals |

| Corrosion Protection | 500+ hours salt spray resistance | Operation in harsh environments |

| Surface Hardness | 65-70 HRC typical | Resistance to deformation and impact |

| Friction Reduction | Coefficient of 0.05-0.12 | Lower operating temperatures, less power consumption |

Which industries are best suited for chrome plating?

Are you wondering if chrome plating makes sense for your specific application? Certain industries gain exceptional value from this process, while others might benefit more from alternative treatments.

Chrome plating delivers outstanding ROI in aerospace, automotive, heavy equipment, and hydraulic systems where components face extreme wear and corrosion. The process is particularly valuable for cylinder rods, hydraulic components, mold tooling, and industrial equipment exposed to harsh operating conditions.

Chrome plating applications across industries

Chrome plating has established itself as an indispensable surface treatment across numerous industrial sectors, though its implementation varies significantly based on specific performance requirements and economic considerations. In our experience serving diverse clients, we've identified several industries where chrome plating consistently delivers exceptional value.

The aerospace industry represents one of the most demanding applications for chrome plating. Aircraft landing gear components, actuator rods, and engine parts operate under extreme stresses while requiring absolute reliability. Here, hard chrome plating provides the necessary wear resistance and corrosion protection3 that keeps critical systems functioning safely through thousands of operational cycles. The high cost of component failure in this sector easily justifies the investment in premium surface treatments.

Automotive manufacturing, particularly in performance and heavy-duty vehicle segments, heavily utilizes chrome plating. Engine components like piston rings, valve stems, and fuel injection systems benefit from chrome's hardness and low friction properties. Our automotive clients regularly report 30-50% extended service intervals after implementing chrome-plated components in high-wear applications.

The hydraulic systems industry represents perhaps the most widespread application for hard chrome. Piston rods, cylinder bores, and valve components operate under substantial mechanical stress and often in corrosive environments. Chrome plating these components dramatically improves seal life, reduces fluid contamination from wear particles, and maintains system efficiency over extended operational periods.

| Industry | Key Chrome Applications | Primary Benefits |

|---|---|---|

| Aerospace | Landing gear, actuators, structural components | Fatigue resistance, weight-to-strength ratio |

| Automotive | Engine components, suspension parts | Wear resistance, friction reduction |

| Hydraulics | Cylinder rods, bores, and valves | Extended seal life, corrosion protection |

| Plastic Molding | Injection molds, die components | Release properties, cycle time reduction |

| Heavy Equipment | Earthmoving components, structural elements | Abrasion resistance, reduced maintenance |

Chrome plating vs. anodizing: Which is right for your product?

Confused about whether to choose chrome plating or anodizing for your metal components? The right surface treatment depends on your specific material, performance needs, and budget constraints.

Chrome plating excels for steel and most alloys requiring maximum hardness and wear resistance. Anodizing is aluminum-specific, more environmentally friendly, and often less expensive, but doesn't match chrome's hardness or abrasion resistance. Each process serves different performance priorities.

anodizing comparison

Selecting the optimal surface treatment requires careful consideration of material compatibility, performance requirements, and economic factors. Having provided both chrome plating and anodizing services to our clients, I can attest that each process serves distinctly different applications despite both being electrochemical treatments.

Chrome plating and anodizing differ fundamentally in their interaction with the base material. Chrome plating deposits a distinct layer of chromium onto the substrate, effectively adding material to the component. This additive process works well with most metals, including steel, stainless steel, copper alloys, and nickel alloys. The resulting chrome layer maintains consistent properties regardless of the base material.

Anodizing, by contrast, is a conversion process that transforms the surface of aluminum into aluminum oxide. Rather than adding material, it converts the existing surface through an electrochemical process that creates a porous structure that can be sealed and often dyed. This process is primarily limited to aluminum and its alloys, making material compatibility the first decision point.

Performance characteristics differ significantly between these treatments. Chrome plating delivers exceptional hardness (65-70 HRC) that anodizing cannot match—even hard anodizing typically achieves only 45-60 HRC. For applications requiring maximum wear resistance or low friction, chrome plating generally provides superior results. However, anodizing creates excellent electrical insulation properties and superior paint adhesion that chrome cannot provide.

| Factor | Chrome Plating | Anodizing |

|---|---|---|

| Compatible Materials | Most metals | Primarily aluminum |

| Surface Hardness | 65-70 HRC | Type II: 30-40 HRC, Type III: 45-60 HRC |

| Thickness Range | 0.0002"-0.01" typical | 0.0001"-0.003" typical |

| Corrosion Resistance | Excellent for many environments | Excellent for atmospheric exposure |

| Environmental Impact | Higher (especially hexavalent) | Lower |

| Relative Cost | Higher | Lower |

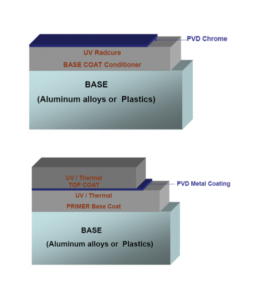

What are the latest developments in eco-friendly chrome plating?

Concerned about the environmental impact of traditional chrome plating? Recent innovations are addressing these challenges while maintaining the performance benefits you need.

The industry is rapidly transitioning from hexavalent chrome (Cr6+) to trivalent chrome (Cr3+) processes that reduce environmental and worker safety concerns. New technologies like physical vapor deposition (PVD) chrome and proprietary "hex-free" systems offer promising alternatives with 85-90% of traditional chrome performance.

Eco-friendly chrome plating technology

The chrome plating industry is undergoing significant transformation driven by regulatory pressure and growing environmental awareness. Traditional hexavalent chrome processes, while delivering exceptional performance, pose recognized health and environmental risks that have prompted increasingly strict regulations worldwide, including the EU's REACH regulations and similar measures in North America and Asia.

Trivalent chrome technology represents the most commercially mature alternative, offering significantly reduced toxicity while maintaining many performance characteristics of traditional chrome plating. In our facility, we've implemented trivalent systems that achieve approximately 85-90% of the hardness and wear resistance of hexavalent processes. While not identical in performance, these systems satisfy requirements for many applications while dramatically improving worker safety and reducing environmental impact.

More advanced alternatives continue emerging from research labs into commercial implementation. Physical Vapor Deposition (PVD) chrome4 processes create extremely hard chromium nitride surfaces without using traditional electroplating chemistry. These processes eliminate liquid waste streams entirely but require significant capital investment in vacuum chamber equipment. Similarly, emerging technologies like High Velocity Oxygen Fuel (HVOF) chrome carbide coatings provide exceptional wear resistance as an alternative to hard chrome in specialized applications.

Closed-loop recovery systems represent another important development for facilities maintaining traditional chrome processes. These systems capture and recycle chromium compounds, reducing waste generation by up to 95% while recovering valuable materials. Combined with improved ventilation systems and worker protection protocols, these technologies make even traditional chrome plating substantially safer than processes from previous decades.

| Technology | Environmental Advantage | Performance Level | Implementation Complexity |

|---|---|---|---|

| Trivalent Chrome | Low toxicity, reduced waste | 85-90% of hexavalent | Moderate equipment changes |

| PVD Chrome | No liquid waste, no chromium compounds | Comparable or superior hardness | High (vacuum systems required) |

| HVOF Coatings | No hexavalent chrome | Superior wear resistance | High (specialized equipment) |

| Closed-loop Recovery | 90-95% reduced waste discharge | Maintains traditional performance | Moderate to high |

Conclusion

Chrome plating offers exceptional value for CNC-machined parts facing demanding conditions. Whether you need maximum durability, wear resistance, or aesthetic appeal, modern chrome processes can deliver the performance your application demands while addressing environmental concerns.

- Explore the advantages of chrome plating, including wear resistance and corrosion protection, to enhance your CNC-machined parts' performance. ↩

- Learn about hard chrome plating's functional benefits, including wear resistance and surface hardness, crucial for high-performance applications. ↩

- Discover how chrome plating's corrosion protection can significantly extend the lifespan of your metal components in harsh environments. ↩

- Discover how PVD chrome processes eliminate liquid waste and provide superior hardness, revolutionizing chrome plating. ↩