Are you worried about the reliability of your vacuum chamber? A hidden welding defect could be the culprit. It's time to shed light on "lack of fusion."

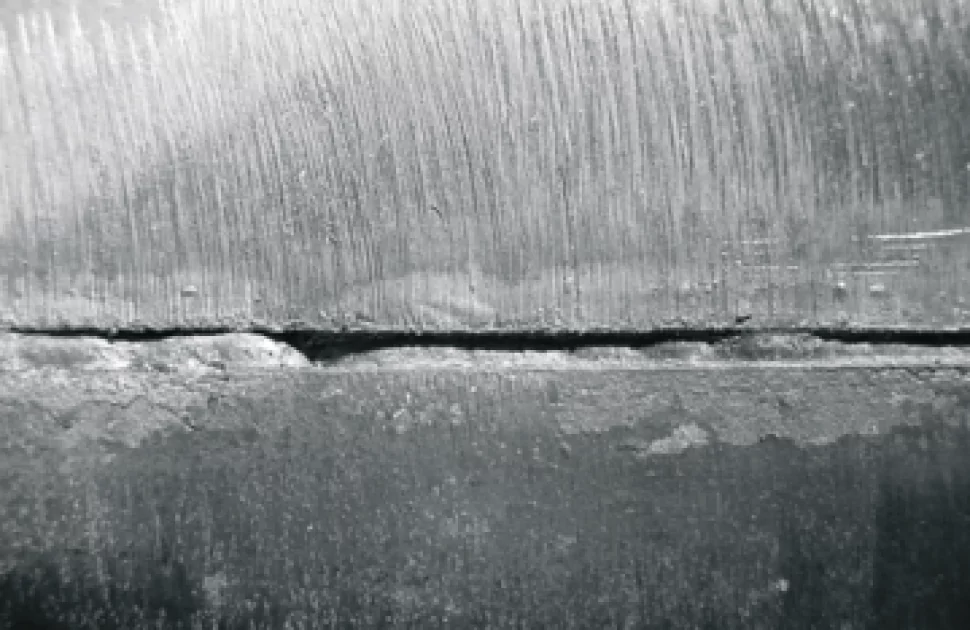

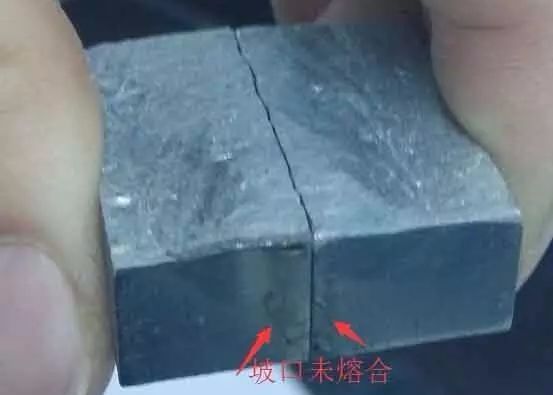

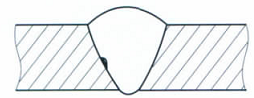

Lack of fusion happens when the weld metal doesn't properly bond to the base metal. This can create weak spots in your vacuum chamber, leading to leaks and performance issues.

Let's dive deeper and find out what causes it and how to prevent it.

What is Lack of Fusion?

Worried about the quality of your welds? Lack of fusion could be a silent threat. Let's get to the bottom of it.

Lack of fusion means the weld metal and base metal didn't melt together properly. This creates a gap or weak connection, compromising the strength and seal of your vacuum chamber.

How Does it Relate to Vacuum Chamber Performance?

Lack of fusion is a big deal for vacuum chambers. I know this from years of experience in CNC machining. A vacuum chamber needs to be perfectly sealed. Any small leak can mess up the whole process. Think about it: these chambers are used in industries like semiconductors and aerospace. Even a tiny defect can lead to big problems.

If there is lack of fusion, the weld isn't strong. It also isn't airtight. This means the vacuum chamber can't hold the required vacuum level. This can cause inaccurate experimental results. It can also lead to production delays.

I've seen firsthand how critical welding is. My company makes custom vacuum chambers. We need to make sure every weld is perfect. We use precision machines and have strict quality control. This ensures our chambers meet the high standards of our clients. Remember, a small welding defect can have a huge impact on performance. So, don't overlook the importance of proper welding techniques.

Analyzing the Causes of Lack of Fusion: Is it a Process or Material Issue?

Is your welding process giving you headaches? Maybe lack of fusion is to blame. Let's break down the reasons why this happens.

Lack of fusion can stem from incorrect welding settings, contaminated materials, or poor technique. It's crucial to pinpoint the exact cause to prevent future issues.

Welding Process

Analyzing the Causes of Lack of Fusion: Is it a Process or Material Issue?

Lack of fusion can come from different places. It could be how you are welding (the process). Or, it could be the stuff you are welding (the material). Let's look at each one.

| Cause | Explanation |

|---|---|

| Process | |

| Wrong Settings | If the welding machine isn't set right, the metal won't melt enough. This includes current, voltage, and speed. |

| Bad Technique | If the welder isn't skilled, they might not move the welding torch correctly. This can cause uneven heating. |

| Contamination | If the metal is dirty, the weld won't stick well. This includes rust, oil, and other stuff. |

| Material | |

| Wrong Material | Using the wrong type of welding rod can cause problems. Make sure it matches the metal you are welding. |

| Material Quality | If the metal itself is bad, it can affect the weld. This includes impurities or inconsistencies. |

I've seen this in my own work. We once had a batch of parts that kept showing a lack of fusion. After a lot of checking, we found out the welding current was too low. Just a small change fixed the problem.

Sometimes, it's the material. If the metal has too much oil on it, the weld won't stick. Always clean the metal before welding. This will help you avoid a lack of fusion. Keep a close eye on both your process and your materials.

How Serious is Lack of Fusion?

Are you underestimating the impact of a lack of fusion? Think again! It can have severe consequences.

Lack of fusion weakens the weld joint, reducing its strength and making it prone to failure. This can lead to leaks, structural damage, and even catastrophic accidents.

How Serious is Lack of Fusion?

Lack of fusion is more than just a small problem. It can cause big issues, especially in things like vacuum chambers. I know this because we make parts that need to be perfect.

Think about a car part. If a weld fails, it could cause an accident. Or, think about a part in an automated machine. If the weld is bad, the machine might break down. This costs time and money. In vacuum chambers, lack of fusion can cause leaks. This ruins experiments and delays production.

I remember one time we were making a vacuum chamber for a client. We did a thorough inspection and found a small area with a lack of fusion. We had to reweld it. If we hadn't caught it, the chamber wouldn't have worked right.

Lack of fusion also affects how long the part lasts. A weak weld will break down faster. This means you'll have to replace the part sooner. So, it's always better to prevent a lack of fusion in the first place. Use the right welding techniques, check your work carefully, and don't cut corners.

How to Detect Lack of Fusion?

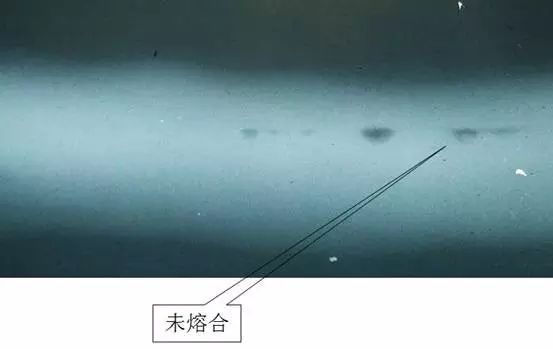

Think you can spot a lack of fusion with the naked eye? You might be wrong. Accurate detection requires specific methods.

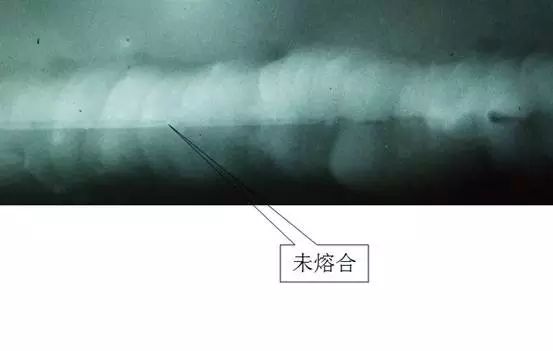

Visual inspection, while helpful, often isn't enough. Non-destructive testing methods like ultrasonic testing and radiography are essential to identify hidden lack of fusion defects.

How to Detect Lack of Fusion?

Finding a lack of fusion isn't always easy. Sometimes, it's hidden beneath the surface. I've learned that you need to use the right tools and methods to catch it.

| Method | How it Works | Advantages | Disadvantages |

|---|---|---|---|

| Visual Inspection | Looking at the weld with your eyes. | Simple, quick, and cheap. | Only finds surface defects. Misses hidden problems. |

| Dye Penetrant Testing | Applying a special dye to the weld. The dye seeps into cracks and makes them visible. | Good for finding surface cracks. | Only finds surface defects. |

| Ultrasonic Testing | Sending sound waves through the weld. The waves bounce back differently if there are defects. | Finds defects inside the weld. | Requires skilled operators. It can be expensive. |

| Radiography (X-ray) | Taking an X-ray of the weld. The X-ray shows any defects inside. | Very good for finding internal defects. | It can be expensive. Requires safety precautions. |

I remember when we started using ultrasonic testing. Before that, we relied mostly on visual checks. But we kept having issues with some parts failing. Once we started using ultrasonic testing, we found a lot of hidden lack of fusion. It made a big difference in the quality of our work.

So, don't just rely on your eyes. Use a combination of methods to find lack of fusion. This will help you make sure your welds are strong and reliable.

How to Avoid a Lack of Fusion?

Tired of dealing with a lack of fusion? It's time to take proactive steps. Prevention is key.

Proper welding techniques, correct machine settings, and clean materials are crucial. Regular training and quality control checks also play a vital role in preventing a lack of fusion.

How to Avoid a Lack of Fusion?

Avoiding a lack of fusion is key to making good welds. I've learned that paying attention to details can make a big difference. Here are some tips to help you prevent it:

- Use the Right Settings: Make sure your welding machine is set up correctly. This includes the right current, voltage, and speed. If the settings are off, the metal won't melt properly.

- Clean Your Materials: Always clean the metal before welding. Remove any rust, oil, or dirt. These things can prevent the weld from sticking.

- Use the Right Technique: Use the right welding technique for the job. This means moving the welding torch correctly and keeping a steady hand.

- Choose the Right Materials: Use the right type of welding rod for the metal you are welding. Make sure the materials are compatible.

- Get Training: Make sure your welders are properly trained. They should know how to use the equipment and techniques correctly.

- Check Your Work: Regularly check your work for defects. Use visual inspection and other testing methods to catch problems early.

I remember when we first started our CNC machining factory in Kunshan. We had some problems with a lack of fusion. But we learned from our mistakes. We improved our training, bought better equipment, and started paying more attention to quality control. Now, we rarely have problems with a lack of fusion. By following these tips, you can avoid a lack of fusion and make strong, reliable welds.

Conclusion

Lack of fusion poses a significant threat to vacuum chamber integrity. By understanding its causes, detection, and prevention, you can ensure the reliability and performance of your equipment.