Tool Condition Monitoring (TCM) Overview

Tool Condition Monitoring (TCM) monitors how a cutting tool performs while being used for machining (especially in CNC milling) by systematically checking a cutting tool's performance to detect when the tool has reached the end of its useful life due to wear, breakage, or chipping. The integration of a variety of sensors, including cutting force sensors, vibration sensors, acoustic emission sensors, or even optical image sensors into TCM, enables real-time decision making on the timing of the replacement of a cutting tool or adjusting it to improve part quality and reduce the time that a machine is out of operation to optimize tool costs.

TCM differs from Machine Condition Monitoring, which monitors the health of the machine tool (i.e., the bearings, spindles, drive motors, and structure of the machine tool) by monitoring parameters such as spindle vibration, motor current, or temperature to prevent machine-related failures and maintain the overall health of the system. Tool monitoring, however, concentrates solely on the state of the cutting tool and its impact on the machining process; whereas machine monitoring aims to keep the "machine" healthy, TCM keeps the "tool" healthy. Both TCM and machine monitoring are important components of smart manufacturing; however, each is designed to monitor and diagnose different types of failures using different types of sensors and diagnostic methodologies.

Fundamentals of Tool Wear

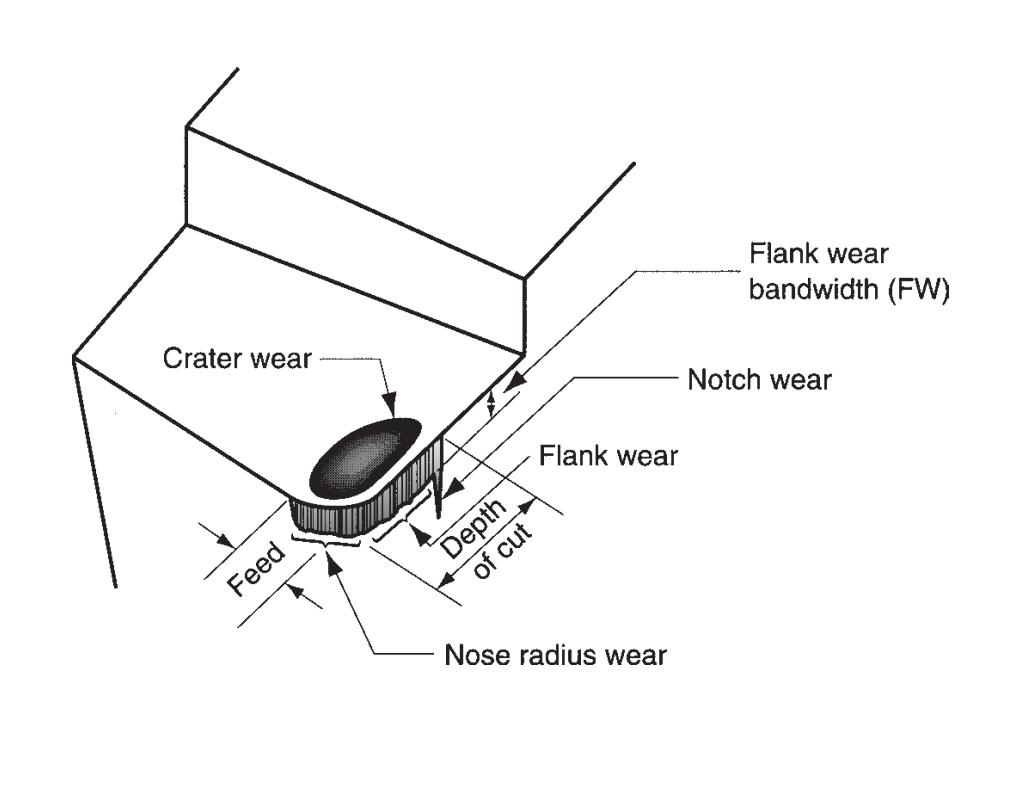

Flank wear is the most prevalent type of wear that occurs at the interface of the tool's flank face and the machined surface, creating erosion over time. Crater wear occurs at the interface between the chip and the rake face of the tool, creating a depression due to high temperatures and interactions between the chip and the tool. In addition to these two types of wear, there are several other types of wear, such as chipping (small chips breaking off the cutting edge from either thermal shock or mechanical shock); adhesion (workpiece material welding onto the tool and breaking away from it, taking some of the tool material with it); diffusion (atoms from the workpiece migrating into the tool at very high temperatures); and plastic deformation (the permanent deformation of the tool edge due to excessive heat or pressure).

Wear can be described in terms of four different stages. The first stage is known as the "running-in" stage, and this is the initial stage of wear for the cutting edge, in which minor wear develops as the cutting edge begins to settle. Once the running-in stage has occurred, the second stage, which is referred to as the "steady-state," will begin. This is the stage in which the wear progression of the cutting edge is relatively stable. However, if the cutting conditions become worse (e.g., an increase in temperature, a decrease in cooling, etc.), the cutting edge will enter into a third stage, which is the "rapid-wear" stage. This stage is characterized by a continued and accelerated deterioration of the cutting edge, and eventually will enter into a fourth stage, which is the "severe-wear" stage. During the severe-wear stage, the cutting edge will experience catastrophic failure (edge failure) and/or severe chipping, resulting in the loss of the tool.

The rate at which wear develops is dependent upon both the cutting parameters as well as the material properties of the tool. Increased cutting speeds tend to raise the temperature of the tool, which causes an acceleration in diffusion and adhesive wear. High feed rates and/or depths of cut tend to increase the mechanical loads on the tool, which accelerates abrasion and chipping. Wear is also greatly affected by the hardness and abrasiveness of the workpiece material, as both characteristics tend to increase frictional contact, thermal loads, and mechanical stress.

Methods of Tool Wear Monitoring

Direct Methods

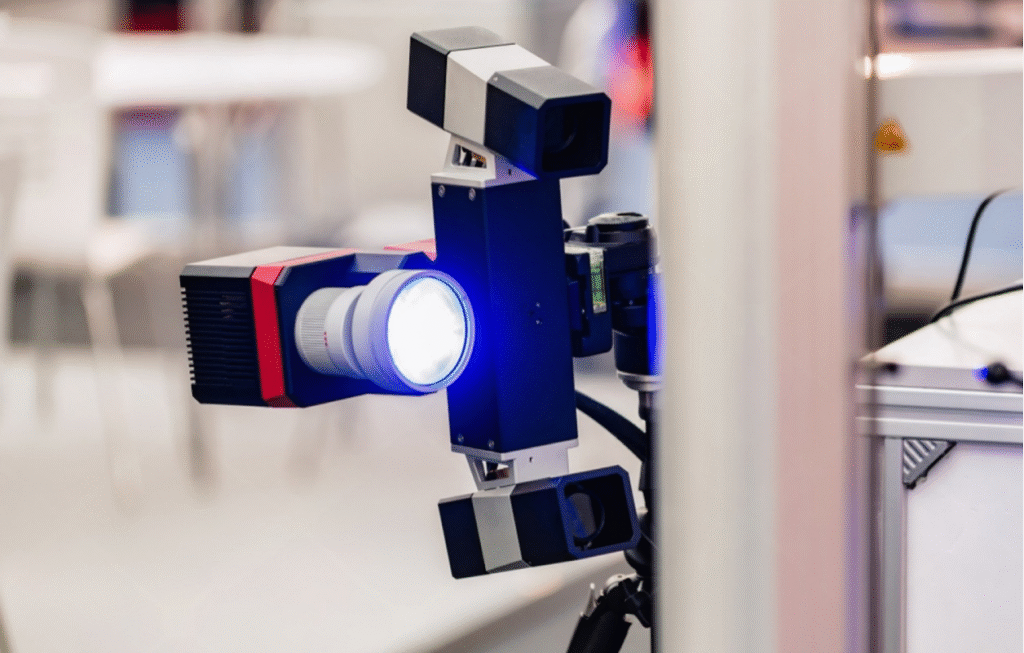

Rather than using contact sensors to measure tool-wear conditions, both of the two direct tool-wear measuring technologies listed below use machine vision, or an optical measurement technology, to visually determine tool-wear conditions by viewing an image of the cutting tool's edge or tool-tip and determining if the cutting tool has become worn by analyzing the image.

- Optical/Vision-Based Techniques

High-resolution images of the cutting tool are captured by machine vision systems at the edge, tip, or flank of the cutting tool, either before or immediately after milling, and are analyzed to determine wear features of the cutting tool, including flank wear width, chipping, or edge rounding. Since this type of measurement system does not make contact with the cutting tool, it will not affect the machining process and can be mounted inside the CNC spindle or added to a camera mounted directly to the machine for in-process monitoring. Many of these systems utilize simple, basic image processing techniques, such as edge detection or threshold-based image segmentation, to identify areas of wear on the cutting tool. As a result of advancements in cameras and lighting systems, these types of systems are generally less expensive than other sensor systems and can be retrofitted into existing smart manufacturing, or Industry 4.0, configurations.

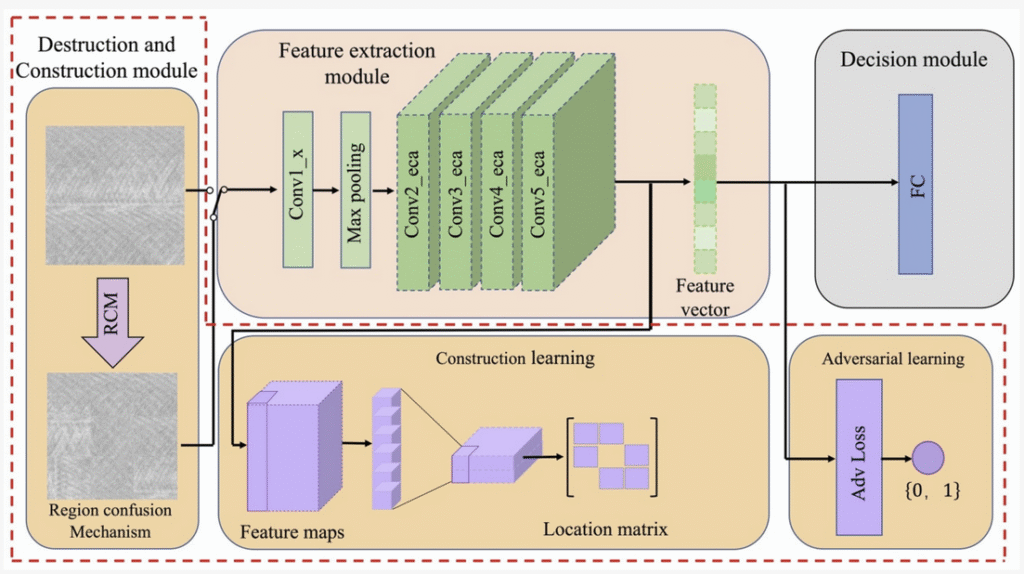

- Surface Texture Analysis and Fine-Grained Image Classification (ECADCL)

Another direct method of tool wear measurement is to analyze the machined surface produced by the cutting tool. As the cutting tool becomes dull, the surface texture of the machined surface changes. This is done by taking images of the surface produced by the cutting tool and then applying advanced image classification techniques to the images to infer the condition of the cutting tool. A recent example of this technique is ECADCL (Efficient Channel Attention Destruction and Construction Learning), a learning technique that identifies fine-grained differences in surface texture to classify wear conditions.

Advantages

- The fact that they are non-contact means that vision-based methods of tool wear measurement do not interfere with the mechanical operation of the machining process or reduce the lifespan of the sensors.

- Vision-based tool wear measurement methods are typically lower in cost when compared to traditional heavy sensor instrumentation; many require only standard off-the-shelf cameras, lighting, and computer software.

- Vision-based tool wear measurement methods are also flexible with regard to being able to be easily integrated into existing CNC equipment; for instance, a camera can be added to the tool-changer area of the machine or installed inside the enclosure to inspect the cutting tool in situ between passes.

Indirect Methods

When compared with direct visual inspection, Indirect TCM uses sensor data to determine the condition of a cutting tool and will not stop the machining operation. The method analyzes sensor data, which has changed as the tool deteriorated, in order to make a continuous and real-time determination of the amount of wear.

- Sensor-Based Monitoring

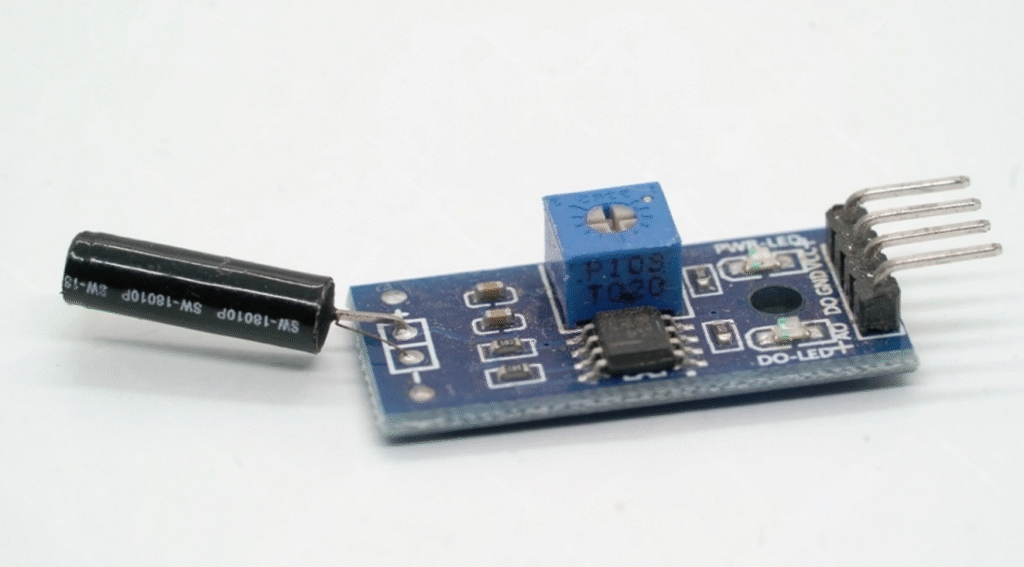

There are many types of physical sensor data that can be used for this purpose. For example, vibration sensors measure how the dynamic behavior of the tool spindle system changes over time. Force and motor current signals can also measure the increase in the energy that is required when a tool is worn and the machine is experiencing increased resistance due to the wear. In addition, acoustic emission (AE) sensors measure the high-frequency stress waves produced during the cutting process and microfractures, which have a high sensitivity to the early stages of tool wear. Finally, sound and temperature signals can provide additional data regarding the cutting conditions. While each of the sensor types has its advantages, using only one type of sensor may be unreliable due to noise and the complex nature of machining.

vibration sensor

- Multi-Sensor Fusion for Enhanced Reliability

In order to minimize the limitations of single-sensor systems, multi-sensor data fusion uses data from multiple sources, such as AE, vibration, and sound, to develop a more reliable and accurate monitoring system. This enables the different sources of data to cross-validate information in order to reduce false alarm rates that result from noise or other transient events that could affect only one type of sensor. Ultimately, multi-sensor data fusion systems offer a much more complete picture of the machining process and therefore greatly improve diagnostic reliability.

- Data Fusion Approaches

Fusion of data can take place at three primary levels:

- Signal Level Fusion: The raw data from each of the sensors is combined prior to extracting features from the data. A novel example of signal level fusion is angular matrix imaging, a technique that transforms multi-sensor time series data (for example, data from AE and vibration sensors) into two-dimensional, grayscale images. The angular matrix imaging preserves the temporal relationships between the data and provides a powerful means for training image-based deep learning models to classify the fused data.

- Feature Level Fusion: Individual features (for example, statistical properties or frequency components) are extracted from the raw data from each of the sensors. The feature vectors are then combined into a single vector that is input to a classification algorithm.

- Decision Level Fusion: Each sensor data stream is processed independently by a separate model to generate a separate wear prediction. A final decision is generated by fusing the individual predictions together. Fusing the individual predictions together can be done using various techniques, including a voting scheme or a meta-classifier.

Data-Driven Approaches

AI is revolutionizing CNC milling by using machine learning and deep learning to create predictive intelligence that replaces the traditional reactive nature of maintenance. The use of AI in CNC milling is creating an automation of the feature extraction from machine data and allowing companies to predict tool failures with unprecedented accuracy.

Using powerful models such as Convolutional Neural Networks (CNNs) and Long Short-Term Memory (LSTM) networks, today's systems are able to extract meaningful features from large amounts of sensor data. Using Deep Residual Networks with Attention Mechanisms (which work like a "smart zoom" function) allows for automatic identification of key trends or patterns in vibration, acoustic emissions, and current signals while simultaneously identifying and eliminating irrelevant background noise. Thus, these systems allow for highly accurate, real-time tool condition assessments.

These AI-based approaches combine multiple sources of sensor data, which is one of their major advantages. This allows for all relevant data to be combined into a single, overall assessment of the health of the cutting tool. Additionally, this allows for continuous improvement through learning (adaptive learning). In other words, the system will continue to improve its prediction capabilities based on new data collected during actual operations. This technique provides a reliable method for assessing the performance of cutting tools when operating under varying conditions (different materials and machining parameters).

Whether it is a turning, drilling, grinding, or milling operation, the results are clear: Companies can expect to make very accurate (over 90%) predictions about when a tool will fail, minimize the amount of unplanned downtime, and save money by preventing wasted parts and costly tool failures. Therefore, implementing a predictive maintenance strategy is no longer a luxury but a necessary component to maximize both productivity and tool life in today’s manufacturing environment.

Deep Learning and Intelligent Monitoring Systems

Deep learning has brought about profound improvements to tool wear monitoring in CNC milling through an entirely new generation of intelligent systems that are significantly better than all previous generations of tool wear monitoring. The most widely used method utilizes Deep Residual Networks enhanced with Attention Modules; one example is the Convolutional Block Attention Module (CBAM), which combines the power of the two methods, allowing the intelligent system to automatically select the most important features of the sensor data and disregard irrelevant (noise) information while enhancing diagnostic precision significantly.

Another major improvement was converting time-series sensor data (vibration, acoustic emission, and current sensors) into a 2-D matrix representing the signal as a "visual image." As these matrixed signals are processed by Convolutional Neural Networks (CNNs), the CNN processes the signals as "patterns," and this allows for a tremendous amount of automatic feature extraction that could never be accomplished using manual methods.

The automated process allows for accurate classification of the tool wear states (initial, normal, rapid, and severe wear) through highly accurate classification and achieves exceptional robustness and accuracy by processing multi-sensor data directly, achieving recognition rates of over 90%. This gives you a reliable, data-driven foundation for predictive maintenance that will minimize unplanned downtime and protect your machinery from severe damage.

Industrial Implementation and Benefits

- Predictive Maintenance with Real-time Data: AI-powered multi-sensor detection identifies tool performance in real-time and, by identifying signs of wear or impending failure (before they occur), allows for immediate action.

- Reducing Waste & Optimizing Use of Tools: Predicting when a tool will fail maximizes its potential for use, minimizing the number of times a tool needs to be replaced and therefore reducing waste generated by failed or otherwise non-functioning tools.

- Increasing Consistency of Production: Maintaining consistent conditions on tools used for production processes maintains consistency in products produced and increases total product quality, and minimizes variation.

- Foundational Technology for Smart Manufacturing Systems: The above technologies are key components of Industry 4.0 (Smart Manufacturing Systems), providing the ability to perform data-driven predictive maintenance and enable automated scheduling of planned maintenance.

Challenges and Limitations

- Data Quality and Data Volume: The quality of the data used is very important to effective monitoring. However, sensor "noise" (random variations in the output) can degrade the data quality. Additionally, the fact that the amount of data available at early or extreme wear stages is significantly less than the volume of data present during the normal wear stages of a tool can make it difficult for the model to identify all tool conditions.

- Computational Requirements High: While models like deep residual networks provide high levels of accuracy in identifying tool conditions, they have large requirements for processing power. In order to obtain acceptable performance with these models, companies will typically need to invest in advanced graphics processing units (GPUs) and may not be able to do so on existing hardware.

- Generalizability Limited: Models that are trained for a specific application are generally not capable of being generalized for use with different applications. Therefore, using the same model that was used to monitor tool wear on an end mill to monitor tool wear on a drill, or to monitor tool wear on a new type of material, or even on a new type of CNC machine, may result in reduced accuracy of the results unless the model is retrained at a cost and effort.

- Installation/Integration of Systems: Integrating retrofit systems for modern monitoring systems into diverse types of CNC equipment can be challenging due to the complexity, invasiveness, and expense of installing sensors and data acquisition hardware on diverse CNC machines. As a result, widespread adoption of the technology is difficult in many industries.

Conclusion

Tool wear detection has become a primary component of intelligent manufacturing by providing a smarter and data-driven approach to CNC machining (CNC milling). The use of cutting-edge sensor technology (acoustic emissions, vibrations, stray flux, current) combined with Artificial Intelligence (AI) and Deep Learning capabilities of today's monitoring tools allows for predictive machining and adaptability. Modern tool wear monitoring systems can now detect when a tool is in a state of wear and predict when it will fail, therefore enabling proactive preventive measures. Intelligent manufacturing achieves its ultimate goal through these predictive and adaptive machining capabilities. It allows for increased precision, greatly reduced unplanned downtime and tooling costs, and increased overall productivity. These advancements provide an intelligent evolution of the CNC operation and mark a new level of efficiency and reliability for CNC operations.