In the high-stakes world of ocean racing, every component of a sailboat plays a role in determining speed, handling, and overall performance. While hull design, sail materials, and rigging often get the spotlight, one of the most critical and frequently overlooked elements is the fastener. These small but essential parts are responsible for holding together the most load-bearing structures on a racing yacht, from keel bolts to mast fittings. When a fastener fails under stress, it can compromise not only performance but also safety.

Material choice, therefore, becomes more than just a matter of cost or convenience; it becomes a matter of strategy. In environments where saltwater, vibration, and high loads are the norm, selecting the right fastener can mean the difference between a smooth crossing and a catastrophic failure. While stainless steel has long been the industry standard, many competitive sailors are now turning to a superior alternative: titanium fasteners, precisely CNC-machined for maximum performance.

Titanium CNC fasteners combine the unmatched strength-to-weight ratio of titanium with the precision and consistency of computer-controlled manufacturing. The result is a fastening solution built for the brutal demands of ocean racing, lightweight, corrosion-resistant, and exceptionally durable. In this article, we'll explore why titanium CNC fasteners have become the premium choice for serious sailors who want to push their vessels to the limit, without compromising on safety or reliability.

Why Titanium? Key Material Advantages

When you're building a racing sailboat that’s expected to perform under pressure, the materials you choose aren’t just a matter of preference; they directly impact speed, durability, and long-term cost. Among the wide range of materials available for marine fasteners, titanium has emerged as a top-tier option, especially for competitive sailors. Its performance characteristics are far beyond what traditional stainless steel can offer.

Let’s explore the specific reasons why titanium fasteners are not just better, but smarter.

Strength-to-Weight Ratio: Lighter Without Compromise

One of titanium’s standout advantages is its superior strength-to-weight ratio. Pound for pound, it’s significantly stronger than stainless steel, yet weighs about 45% less. This isn’t just impressive on paper; it translates to real-world benefits on the water.

- High tensile strength: Grade 5 titanium (Ti-6Al-4V), commonly used in fasteners, offers tensile strength upwards of 950 MPa.

- Weight advantage: Replacing stainless steel fasteners with titanium reduces mass without sacrificing holding power.

- Improved acceleration and responsiveness: Lowering the boat’s total weight allows for faster starts and tighter maneuverability during races.

This weight reduction becomes even more crucial in racing classes where every kilogram matters and where the distribution of mass influences handling and trim.

Corrosion Resistance: Built for Salt and Spray

Saltwater is relentless. It creeps into every crevice, corrodes the unprotected, and weakens materials over time. Titanium, however, naturally forms a passive oxide layer that makes it highly resistant to corrosion, even in constantly wet or briny conditions.

- No rust or pitting: Unlike stainless steel, titanium won’t corrode from crevice exposure or electrochemical reactions in mixed-metal environments.

- Minimal maintenance: There's no need for anti-corrosion sprays, sacrificial anodes, or constant monitoring.

- Perfect for dissimilar metal assemblies: Titanium's inertness makes it ideal for use with carbon fiber, aluminum, and composite hulls, reducing galvanic corrosion risk.

For sailors tired of dealing with seized bolts or unexpected corrosion damage mid-race, titanium is a quiet game-changer.

Durability Under Stress: Made for the Ocean’s Worst

Ocean racing isn’t gentle. The constant vibration, slamming forces from waves, and varying stress loads test every bolt and bracket. Titanium stands out here too, with excellent fatigue resistance and high mechanical stability under fluctuating loads.

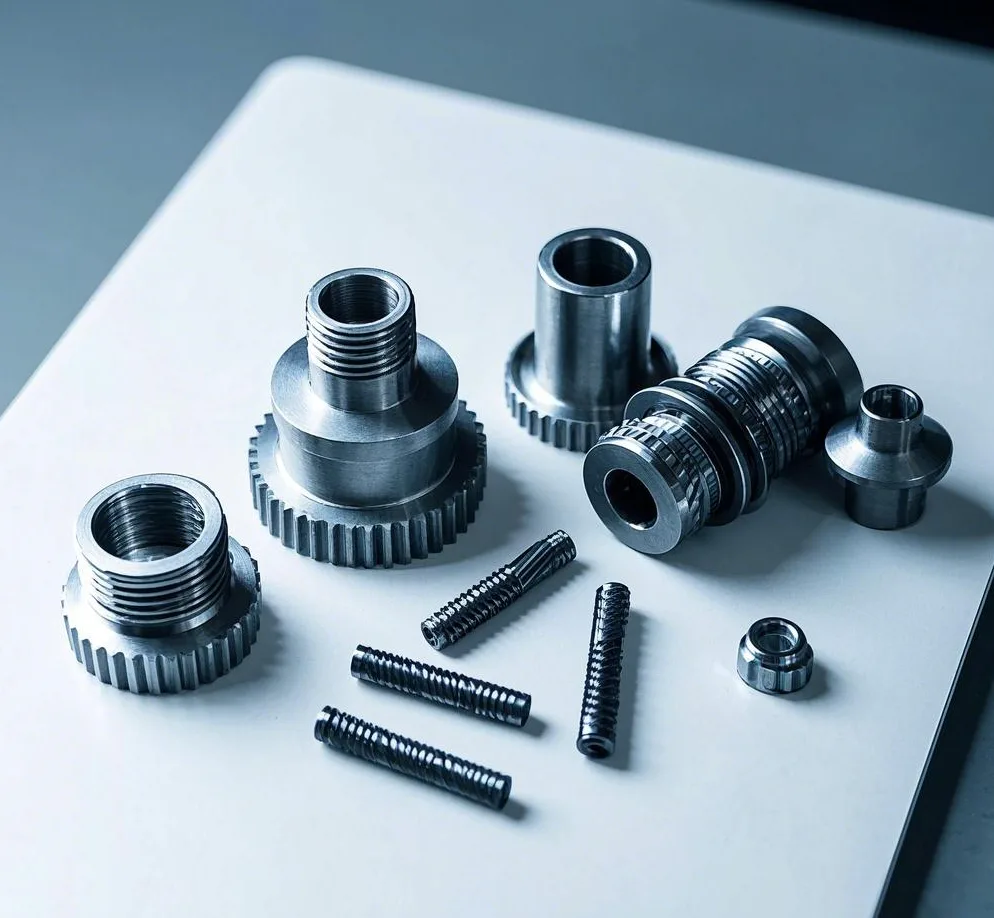

CNC-machined titanium parts

- Exceptional fatigue life: Titanium retains strength after thousands of stress cycles, making it ideal for hardware like chainplates and spreader bases.

- No work-hardening: Stainless steel can become brittle over time. Titanium resists this degradation.

- Minimal deformation: Even after extreme tension or impact, titanium is less likely to stretch or deform.

This means titanium fasteners continue performing reliably, even when exposed to heavy wind loads or sudden shocks during a broach or tack.

Long-Term Maintenance Benefits: Fewer Replacements, Less Hassle

Every sailor knows the frustration of dealing with stuck, rusted, or worn-out fasteners. Over time, those issues add up in both labor and money. Titanium dramatically reduces these headaches by lasting longer and holding up better to repeated use.

- Low galling risk (with proper prep or coating): Easier disassembly, even after seasons of exposure.

- Better thread retention: Threads maintain integrity longer, especially when paired with precise CNC machining.

- Cost-effective over time: Although the upfront cost is higher, the need for fewer replacements makes titanium a worthwhile long-term investment.

For racers who push their boats hard and want to spend more time sailing than fixing, titanium is a smart way to future-proof the vessel.

CNC Machining and Thread Integrity

Titanium is only as good as the precision with which it’s shaped. When fasteners are exposed to dynamic marine loads, especially in high-stakes ocean racing, consistency isn’t optional; it’s essential. This is where CNC machining becomes the silent enabler of performance. By using computer-controlled tools, each fastener is manufactured to exacting standards that hand machining simply can’t match.

Let’s break down how CNC machining directly contributes to superior thread integrity and structural safety on modern sailboats.

Precision Manufacturing: The Backbone of Reliable Threads

Thread engagement is where forces transfer. If threads are loose, too tight, or unevenly cut, the connection is compromised, no matter how strong the material. CNC machining eliminates that uncertainty by cutting threads with sub-millimeter accuracy.

- Exact pitch and depth: Threads are milled to tight tolerances, ensuring maximum surface contact with mating components.

- Zero warping: CNC machines apply uniform pressure and tool paths, minimizing distortion even in harder materials like titanium.

- Perfect repeatability: Whether it’s the first fastener or the hundredth, every part meets the same dimensional standard.

This precision directly translates into stronger assemblies and more confident installations.

Batch Consistency: Say Goodbye to Tolerance Errors

In racing, it’s not just about one bolt; it’s about the entire system. Whether you're securing a mast collar or assembling chainplates, having uniform fasteners is critical to maintaining balance and structural symmetry.

CNC machining offers that consistency by removing the variability of manual labor. Every part in a batch follows the exact same toolpath, using the same calibrated program.

- Interchangeability: Identical fasteners mean less confusion during rigging and faster replacements if needed.

- Fewer surprises: No mismatched threads or misaligned washers during final assembly.

- Simplified inventory: One drawing, one spec, one outcome — reducing the margin for error in rigging upgrades.

For boatbuilders and riggers alike, that level of trust in a fastener’s uniformity simplifies both design and workflow.

High-Load Applications: Where Precision Really Matters

While every bolt on a sailboat plays a role, certain areas are under constant or extreme strain, especially in offshore or high-speed racing. These points demand more than strength; they require flawless thread geometry to hold fast without loosening or shearing.

Key examples include:

- Keel bolts: Absorb dynamic loads from hull flex and wave impact. Thread failure here can compromise structural integrity.

- Mast step fasteners: Central to mast stability, especially in fractional rigs where compression loads are high.

- Backstay and chainplate bolts: Transmit rig tension under constant adjustment and wind pressure.

Using CNC-machined titanium fasteners in these locations ensures that threads won’t strip, creep, or deform over time, even with repeated rig tuning or high-load sailing.

Safety and Reliability: No Room for Compromise

Sailors trust their lives to the integrity of their hardware. Loose or misaligned threads can cause catastrophic failure, particularly in offshore conditions where forces are amplified and help is far away.

The benefits of CNC machining go beyond numbers and tolerances; they’re about peace of mind:

- Reduced vibration-related loosening: Cleaner threads result in a tighter, more secure fit.

- Improved torque tolerance: Fasteners can be tightened to precise specs without damage.

- Predictable load behavior: CNC accuracy makes it easier to model stress and strain in simulation tools or FEA analysis.

Ultimately, precision threads are about confidence, knowing that when you tighten down a titanium bolt before a transoceanic race, it’s going to hold through squalls, pitch, and every gybe in between.

Weight Savings Compared to Stainless Steel

In ocean racing, where every gram counts, reducing unnecessary weight is one of the most effective ways to gain a competitive edge. Sailors invest heavily in carbon fiber sails, lightweight hulls, and minimal interiors, but often overlook the weight penalty hidden in stainless steel fasteners. Replacing them with titanium isn’t just a luxury upgrade; it’s a deliberate strategy for performance optimization.

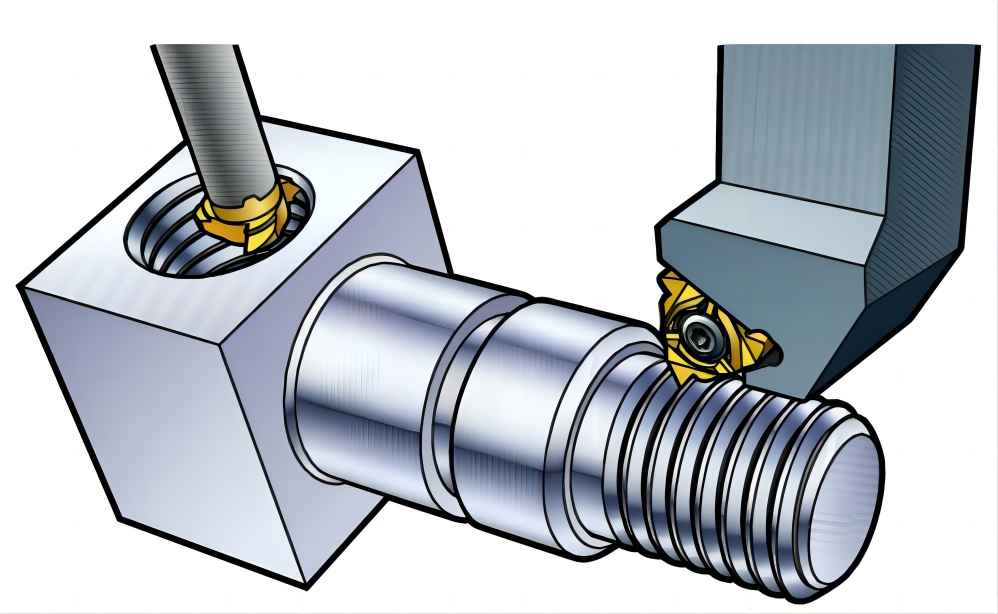

CNC Machining: Titanium vs. Steel

Let’s break down how titanium CNC fasteners contribute to meaningful weight reduction and what that means for real-world sailing dynamics.

Quantitative Advantage: The Weight Difference That Adds Up

On a per-unit basis, titanium is about 45% lighter than 316 stainless steel. This difference, while small in a single bolt, becomes significant when multiplied across an entire yacht.

- Example: A typical stainless M12 bolt weighs ~100g, while its titanium equivalent weighs ~55g.

- On a 40-footer: Swapping 200 stainless fasteners with titanium could reduce total weight by over 9 kg, just in bolts.

This may seem marginal in isolation, but in race design, it’s rarely about one component. It’s about cumulative optimization across the vessel.

Cumulative Effect: How It Impacts Total Boat Weight

Ocean racing yachts are engineered for efficiency. A few kilograms saved in fasteners can free up room elsewhere, whether it’s for essential provisions, performance gear, or simply better weight distribution.

- Improved ballast-to-displacement ratio: Lighter topside components allow for more strategic ballast placement low in the hull.

- Enhanced agility: Less mass above the waterline means quicker tacks, faster acceleration, and a more responsive helm feel.

- Fuel savings (on support vessels or hybrid racers): Reduced weight translates to lower power demands, especially on long offshore passages.

When weight reduction happens without compromising strength or integrity, the performance trade-off is always worth it.

Performance Gains: Not Just Lighter - Faster and Smarter

Swapping to titanium fasteners isn’t just about shaving numbers off the scale. It’s about enhancing the boat’s entire handling profile. Reduced weight results in tangible gains across multiple performance dimensions.

- Higher speed potential: Less weight equals less drag through the water, especially in light wind conditions.

- Better planning: Boats reach planing speeds more easily, especially downwind or on reaching legs.

- More forgiving motion: Reduced mass can minimize pitching and slamming, improving crew comfort and sail trim stability.

In racing, every tenth of a knot matters. Over a 600-mile leg, those fractional gains translate into hours.

Strategic Placement: Where Weight Savings Matter Most

Not every bolt needs to be titanium. To maximize cost-efficiency and performance, smart builders and teams focus on high-leverage areas where weight has the most impact.

Critical zones include:

- Mast fittings and rigging terminals: High above deck, any weight reduction here improves the boat’s righting moment.

- Deck hardware and traveler systems: Frequent load transfer points benefit from both lighter and stronger fasteners.

- Interior bulkhead connections: Helps offset heavier equipment without compromising hull stiffness.

By targeting specific components, teams can balance investment with impact, achieving meaningful savings without overspending on full replacement.

Galling Resistance and Surface Coatings

Titanium fasteners bring many advantages to ocean racing, but they come with a particular challenge: galling. This form of cold welding or surface adhesion happens when similar metals slide against each other under pressure, especially in threaded connections. If not addressed correctly, galling can damage fasteners during installation or removal, increasing the risk of failure and adding time-consuming complications.

Fortunately, this issue can be managed effectively with surface treatments and smart assembly practices. Let’s explore how.

Understanding Galling: A Titanium-Specific Concern

Titanium’s natural oxide layer protects it from corrosion, but under pressure and friction, its surface becomes prone to adhesion. When threaded titanium fasteners are tightened, especially dry and at high torque, the microscopic surface peaks can fuse, locking the bolt in place.

This is not a manufacturing defect. It’s a material property that shows up most in:

- Threaded titanium-to-titanium joints

- High-speed or power-driven installations

- Unlubricated threads under high pressure

The result can be seized fasteners, stripped threads, or even sheared bolts during removal, all costly and avoidable if proper measures are taken.

Surface Treatments: DLC and TiN as Protective Shields

To prevent galling without sacrificing titanium’s core benefits, many high-performance fasteners receive surface coatings. These act as lubricious barriers between mating threads, reducing metal-on-metal contact.

Two popular options stand out:

- DLC (Diamond-Like Carbon):

- Ultra-hard carbon-based layer

- Excellent wear and friction resistance

- Maintains corrosion protection

- TiN (Titanium Nitride):

- Ceramic-style golden coating

- High hardness and low friction

- Frequently used in aerospace and motorsport fasteners

Both coatings not only reduce galling but also increase the lifespan of the fastener threads by minimizing surface wear over repeated uses.

Key Benefits of Coatings: Friction Reduction and Thread Life

The difference between a coated and uncoated titanium bolt becomes clear during assembly. Coated fasteners install smoothly, maintain torque accuracy, and allow for future disassembly without drama.

Benefits include:

- Lower torque resistance: Easier tightening without increased preload.

- More consistent clamp force: Better thread engagement and load distribution.

- Extended service life: Threads retain shape and functionality over more cycles.

- Reduced installation risk: Less likelihood of thread seizing or bolt snapping.

Especially in environments where rigging adjustments happen frequently, coated titanium fasteners significantly reduce maintenance risks.

Practical Tips: Preventing Galling During Installation

While coatings are a powerful solution, best practices also play a major role in galling prevention. Even uncoated titanium fasteners can perform reliably if installed correctly.

Here are key tips:

- Use appropriate anti-seize lubricants: Marine-grade thread paste or MoS₂ (molybdenum disulfide) based lubricants are ideal.

- Avoid dry torqueing: Always apply lubrication or install coated fasteners to prevent dry metal contact.

- Hand-tighten first: Reduce friction by engaging threads slowly and evenly.

- Use torque-limiting tools: Avoid over-tightening or sudden torque spikes with power tools.

By treating titanium fasteners with care, and not just strength, you unlock their full potential without fighting their natural properties.

Applications in Sailboat Hardware

Titanium CNC fasteners aren't just impressive in theory; their value is most evident when applied to real-world sailing components. Ocean racing boats are exposed to punishing conditions: constant vibration, high tensile loads, salt spray, and frequent adjustments. In this context, every hardware system secured by fasteners needs to be strong, corrosion-resistant, and as light as possible.

Let’s examine how titanium fasteners are used in critical hardware zones onboard racing sailboats, and why their properties make a measurable difference.

Keel Bolts: Foundation of Structural Security

Few fasteners take more abuse than keel bolts. These are the primary connectors between the hull and the ballast keel, absorbing massive lateral and vertical loads in rough seas and tight maneuvers. A failure here can be catastrophic, both in terms of safety and boat integrity.

Titanium is especially suited to this application for several reasons:

- High tensile and shear strength: Withstands continuous pounding from hull flex and wave impacts.

- Corrosion immunity: Resists saltwater intrusion where bolts penetrate the hull.

- Long-term reliability: Prevents crevice corrosion and fatigue cracking, often seen with stainless bolts over time.

In performance sailboats or carbon hulls, titanium keel bolts reduce the risk of galvanic corrosion while lightening the structural load below the waterline.

Mast Fittings: Lightweight Precision Above Deck

The mast is a critical source of weight aloft, which makes every gram saved above deck worth several below. Titanium fasteners used here improve stability, righting moment, and overall responsiveness, without compromising strength.

Common titanium applications in this zone include:

- Gooseneck fittings

- Mast step bolts

- Sheave box mounts

- Spreader roots

Because mast components often endure fluctuating compression and tension, titanium’s fatigue resistance ensures these fittings remain secure, even under violent heel angles or sail changes.

Rigging Hardware: Handling Constant Tension and Vibration

Standing rigging components, such as shrouds, forestays, and backstays, are held in place by fasteners that must endure both static load and dynamic vibration. Titanium’s thread integrity and resistance to seizing are essential for riggers making frequent adjustments or inspections.

Key rigging areas where titanium fasteners shine:

- Chainplates and turnbuckles

- Stemhead fittings and forestay terminals

- Backstay split plates and adjusters

These are not only high-stress locations but also areas where saltwater collects. The added corrosion protection of titanium prevents long-term degradation in these hard-to-reach zones.

Custom CNC Solutions: Tailored to Fit Competitive Builds

One of the major advantages of CNC machining is the ability to design custom fasteners, and titanium lends itself well to small-batch, high-precision production. This opens the door for purpose-built components tailored to the exact tolerances and loads of a racing yacht.

Examples include:

- Flush-deck fasteners for aerodynamic hardware mounting

- Non-standard head profiles for low-clearance rigging

- Threaded inserts for composite hull connections

- Integrated eyelets or tabs for multi-use fasteners

Rather than forcing a standard bolt into a critical system, teams can spec titanium hardware that’s shaped around performance, not compromise.

Case Studies and Real-World Examples

While technical specifications and lab-tested data make a strong case for titanium CNC fasteners, their true value is best demonstrated in action. Across competitive sailing fleets, titanium has earned its reputation not through theory, but through performance, race after race, season after season.

Let’s take a closer look at real-world evidence that supports titanium’s adoption in high-stakes racing environments.

Ocean Racing Yachts: Field-Proven Performance

Top-tier offshore racing teams have long known the benefits of reducing failure points and optimizing weight. Titanium fasteners have been embraced not just in grand prix yachts, but increasingly in performance cruiser-racers and one-design classes.

Some observations from teams and yard reports include:

- Volvo Ocean Race boats: Multiple teams transitioned to titanium fasteners in their 2nd generation builds, citing improved reliability in spreader fittings and chainplates after noticing micro-cracking in stainless hardware during initial campaigns.

- IMOCA 60 class: Lightweight, precision-machined titanium bolts are frequently used in canting keel systems and rudder stocks, components under extreme loads in transatlantic crossings.

- Mini Transat 6.50 yachts: Builders favor titanium for rigging points and deck-mounted hardware, where grams saved on the bow or masthead impact balance and acceleration.

These teams invest in titanium not for marketing, but because it holds up under punishing conditions, delivering measurable gains without sacrificing safety.

Maintenance Logs: Corrosion Resistance in Practice

One of the clearest long-term advantages of titanium fasteners is the absence of corrosion-related failures. Unlike stainless bolts, which can develop crevice corrosion or freeze in place, titanium hardware remains clean and serviceable even after multiple seasons at sea.

From surveyor reports and maintenance records:

- After 2–3 years of offshore use, titanium bolts removed from keel shoes and mast bases typically showed zero corrosion or thread wear, even in areas with trapped moisture or limited airflow.

- No need for forced removal or cutting: Unlike stainless bolts that seize, titanium fasteners were unthreaded manually with minimal effort when properly lubricated or coated.

- Reduced inspection burden: Owners and service yards noted fewer problems with thread deformation or bolt head corrosion, especially in locations with mixed materials (e.g., aluminum mast collars).

These real-world patterns confirm what the material data suggests: titanium performs reliably where other metals degrade.

Fleet Comparisons: Titanium vs Stainless Setups

Several racing teams and boatyards have done side-by-side comparisons of similar vessels, one fitted with stainless steel fasteners, the other upgraded to titanium. The insights have been consistent.

Some of the most commonly reported differences:

- Fewer structural issues during refits: Titanium-equipped boats show less wear on structural joins (e.g., mast step, bulkhead tie-ins) due to more consistent torque and less corrosion creep.

- Noticeable weight improvement: Crews report better helm feel and acceleration in lighter titanium-equipped boats, especially in light-air regattas.

- Easier part sourcing: With CNC-machined custom titanium fasteners, teams get exact replacements instead of adjusting components to fit standard bolts.

While upfront costs are higher, the operational data increasingly support titanium’s return on investment, particularly for teams aiming to win or owners looking for minimal upkeep.

Installation, Maintenance, and Cost Considerations

While titanium CNC fasteners deliver exceptional performance benefits, their full potential depends on correct installation, smart maintenance, and a clear understanding of cost-value balance. These fasteners are not “fit and forget” in the conventional sense, but when handled properly, they demand far less long-term attention than stainless steel.

Below, we’ll explore the practical side of working with titanium fasteners, including torque, inspection, and the investment equation.

Installation Best Practices: Get It Right from the Start

Unlike common stainless hardware, titanium fasteners require specific attention during installation to avoid issues like galling or torque misalignment. The use of CNC precision does not eliminate the need for proper prep; in fact, it makes precise torque application even more important.

To ensure safe and consistent installation:

- Always use anti-seize compound: A marine-grade molybdenum disulfide (MoS₂) or nickel-based lubricant is essential, even on coated threads.

- Torque slowly and evenly: Use a calibrated torque wrench and increase load gradually to avoid sudden binding.

- Avoid power tools: Impact drivers can induce heat and increase galling risk. Manual or low-speed drivers are preferable.

- Match fasteners to material interfaces: For instance, when bolting into aluminum or carbon fiber substrates, use insulators or isolating washers to avoid galvanic corrosion at the joint interface.

Installers unfamiliar with titanium should not assume it's interchangeable with stainless; it's a higher-performance material that rewards precision.

Inspection and Preventive Maintenance: Lower Effort, Longer Life

One of titanium’s major advantages is its minimal maintenance demand. Once installed properly, it resists corrosion, deformation, and loosening better than most alternatives. Still, regular inspections remain critical, especially in high-load areas.

Typical inspection and maintenance observations:

- Visual checks for oxidation or surface wear: Titanium usually maintains a dull silver finish; any darkening or pitting is unusual and worth investigating.

- Annual thread lubrication check: In exposed locations, especially above deck, reapply anti-seize during rig checks or winterization.

- Monitor clamping force areas: Over time, repeated flexing (such as at chainplates) can lead to interface compression; check torque values annually.

- Thread integrity tests during haul-outs: Titanium threads are durable, but fatigue from misalignment or improper torque can still develop if ignored.

Compared to stainless steel, titanium often reduces maintenance time by half or more, especially in salt-heavy or tropical environments.

Cost vs. Performance: The Investment Case for Titanium

There’s no avoiding it, titanium CNC fasteners cost significantly more upfront than stainless steel or bronze equivalents. But for many performance sailors, the equation shifts when you consider total lifecycle value.

Breakdown of the cost-performance argument:

- Initial cost: Titanium bolts can cost 3–5x more than stainless, but often eliminate the need for backup hardware, corrosion inhibitors, or frequent replacements.

- Installation labor: While initial care is required, coated or lubricated fasteners are easier to install correctly and remove without damage.

- Long-term savings:

- Fewer replacements over the life of the boat

- Reduced service time during refits or rig upgrades

- Avoidance of secondary damage from seized or corroded bolts

In high-end applications, especially ocean racing, bluewater cruisers, or expedition yachts, the cost is typically justified by:

- Reduced weight → better performance

- No corrosion → fewer surprises offshore

- Repeatable performance → improved safety and reliability

It’s not about replacing every bolt; it’s about investing in the right places. By strategically using titanium fasteners where performance and reliability matter most, sailors can maximize value without overextending the budget.

Conclusion

Titanium CNC fasteners are more than just an upgrade; they’re a strategic choice for sailors serious about performance, reliability, and longevity. In the world of ocean racing, where every decision affects speed, safety, and service life, the shift from traditional stainless steel to titanium is not just about staying ahead; it's about staying intact.

By combining an exceptional strength-to-weight ratio with unmatched corrosion resistance and fatigue durability, titanium offers a clear material advantage. When shaped through CNC machining, these fasteners deliver the kind of consistency and thread integrity that high-load applications demand, especially in areas like keel bolts, mast fittings, and rigging terminals. Add the long-term benefits of reduced maintenance and the ability to customize components for unique racing geometries, and the case becomes even stronger.

Of course, titanium isn't for every bolt or every boat. But for teams aiming to extract every ounce of speed, minimize downtime, and invest in reliability over the long haul, titanium CNC fasteners are a deliberate and forward-thinking solution. They don't just hold parts together; they hold together the integrity of a race-ready vessel.