Surface roughness is an important technical indicator that reflects the micro-geometric error of the machining part's surface and is the primary basis for inspecting the surface quality of machining parts; whether it is reasonable or not, it is directly related to the machining parts' quality, service life, and production cost. Surface roughness refers to the finely spaced micro-irregularities on the surface texture, which is made up of three elements: roughness, waviness, and form.

Computer numerical control (CNC) machining service can maintain control over the parts' tolerances. The higher the manufacturing industry's accuracy standards, the smaller the tolerance value. The bigger the tolerance, on the other hand, the wider and lower the needed accuracy. When particular surface roughness values are required, post-processing methods are rarely used. This is because these processes are difficult to manage and can influence part dimensional tolerance.

But, How do surface roughness and tolerance level correlate with each other in CNC machining? In order to know, keep on reading to explore this relationship. Before we move ahead it's important to know the methods for surface roughness measurement.

Methods of Determining Roughness

There is a wide variety of equipment available for roughness measurement. But, here are two broad techniques to determine roughness.

- Contact type

- Non-contact type

Let’s move to a deep analysis of these techniques. A contact form of analysis in which a component of the measurement device actually contacts the surface to be measured during the experiment. But, in contact-type measurement, a sharp stylus tip may damage the surface, especially soft surfaces. The normal loads must be low enough for these measurements such that the contact stresses do not surpass the hardness of the surface to be tested. The contact-type stylus instruments with electronic amplification are most popular today. The International Organization of Standardization (ISO) recommends that the stylus technique is commonly used for reference purposes.

A non-contact optical profiler based on the principle of two-beam optical interferometry invented in 1983 and is now commonly used to measure smooth surfaces in the electronics and optical sectors. An atomic force microscope, which is essentially a nano-profiler that operates at ultra-low loads, was created in 1985. Surface roughness can be measured with lateral resolution varying from microscopic to atomic scales.

This equipment is often used in research to quantify extremely high lateral resolution roughness, especially nanoscale roughness. There are a number of other procedures demonstrated in the lab but never commercially deployed, or that have been used in specialized applications. Based on the physical principle involved, we'll classify the various techniques into six categories:

Mechanical stylus, optical, scanning probe microscopy (SPM), fluid, electrical, and electron microscopy approaches.

So, how exactly do all these processes work for surface roughness measurement? Let’s discuss this in detail.

Mechanical stylus method

This technique records and amplifies the vertical motion of the stylus on the surface to be measured at a constant speed. A stylus measurement head with a stylus tip and a scanning mechanism make up the instrument. Acquiring two-dimensional scans in the X direction while stepping in the Y direction by 5 m with the Y lead screw. It is used for precise sample positioning and yields a three-dimensional image.

Optical method

According to the study, various optical methods are used for Surface roughness.

Overall assessment may be performed with an optical microscope, which only gives qualitative data. Geometrical and physical approaches are two types of optical methods. Taper sectioning and light sectioning are two geometrical approaches. Specular and diffuse reflections, speckle patterns, and optical interference are examples of physical approaches.

Scanning Probe Microscopy (SPM) Methods

Scanning probe microscopies (SPM) are a group of equipment based on scanning tunnelling microscopy (STM) and atomic force microscopy (AFM). The first technique used to get a 3-dimensional image of a solid surface with atomic resolution is scanning probe Microscopy.

Scanning Tunneling Microscopy (STM)

STM operates on a simple basis. A sharp metal point (one electrode of the tunnel junction) is brought close enough to the surface to be probed (second electrode) that the tunnelling current varies from 0.2 to 10 nA, which is quantifiable at a convenient working voltage (10 mV to 2 V). At a distance of 0.3 to 1 nm, the tip is scanned across a surface while the tunnel current between the tip and the surface is measured.

Atomic Force Microscopy (AFM)

The AFM combines the STM with the stylus profiler's principles. To perceive the proximity of the tip to the sample in the AFM, the force between the sample and the tip is sensed rather than the tunnelling current. Moving the sample using piezoelectric scanners brings a sharp tip at the end of a cantilever into contact with a sample surface. This mode of functioning is known as "repulsive mode" or "contact mode". Atomic force microscopy is a nano-profiler that can work with very small samples. This approach determines the surface roughness with lateral resolution ranging from microscopic to atomic scales. This method is most commonly used to scale roughness with a very high lateral resolution, such as nanoscale roughness.

Fluid Methods

These techniques are mostly employed in service for constant assessment (quality control) operations. Since they work without touching the surface and are extremely rapid. This gives numerical data that may empirically correlate to roughness. The hydraulic and pneumatic gauging methods are the two most widely employed techniques.

Electrical Method

This technique utilises the capacitance approach based on the parallel capacitor idea. The capacitance between two conducting elements is related to their area and the medium's dielectric constant, but is inversely proportional to their separation. It's rather simple to calculate the effective capacitance between a rough surface and a smooth surface disc for various deterministic models. It's thought of as the sum of a number of small elemental areas at varying heights. Surface roughness affects the capacitance between a smooth disc surface and the surface to be measured. Based on this premise, a commercial instrument is available. Continuous inspection processes also employ the capacitance method.

Electron microscopy

Both reflection and replica electron microscopy may reveal macroscopic and microscopic surface characteristics. However, they have two main drawbacks: first, quantifiable data is difficult to obtain; and second, because of their intrinsically limited field of vision, they only display a few asperities, whereas the important point about surface contact is that it involves vast populations of interacting asperities.

The measurement method that is ultimately chosen is highly dependent on the user’s application. Measurement methods based on specular reflection, diffuse reflection, or speckle pattern are utilised for in-process inspection operations. Fluid or electrical technologies could be employed for continuous inspection (quality control) activities that need minimum information.

National Standard for CNC Machining Tolerance

Photo by Mastars on Unsplash

Variations may happen due to a variety of causes, ranging from the part's material to the machining process utilised. This is why parts are given machining tolerances throughout the design phase – an amount of permissible variation in a part's dimension.

So, what are machining tolerances, and why are they significant? Continue reading to find out how to choose tolerance that principle relates to CNC machining.

Every feature on a component has a size and a geometrical shape. The function of the part involves constraints for size and geometrical attributes (shape, orientation, and placement) variations, which when surpassed, damage this function. Most inspectors use the minimum zone solution to calculate form tolerances, which minimizes the maximum error between data points and a reference feature.

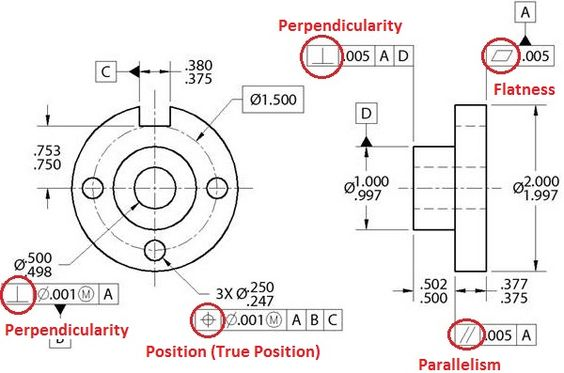

The American national standard institute (ANSI Y14.5M-1982), established a standardized approach for the National Standard on Dimensioning and Tolerancing known as the Geometric dimension and tolerancing (GD&T Y14.5 Standard). A standardized approach for showing tolerance standards on engineering drawings are established to increase the use of tolerance specifications as a communication tool.

To ensure that the aspects of size and geometry of all features are regulated, the tolerancing on the drawing should be complete, i.e. nothing should be assumed or left to judgment in the workshop or inspection department. The use of general size and geometry tolerances makes it easier to ensure that this requirement is met.

Form tolerance standards are used to regulate the derived items because points from the derived feature cannot be sampled directly. These points must be computed using sampled points from the outside. But, how can you choose tolerance for CNC machining?

Well, the Geometric dimension and tolerance (GD&T Y14.5 Standard) is helpful for designers and manufacturers to communicate tolerance information. Unfortunately, there is currently no standard for verifying tolerance specifications.

As previously stated, different materials and machining processes necessitate various tolerances. This means that machining tolerances aren't exactly 'standard.' However, some manufacturers have established rules for specific applications.

Some machine shops require tolerances from customers, and if these are not provided, they will either refuse to work on the component or use a standard tolerance of, say, ±0.005’’ (0.127 mm). The tolerance may be larger or smaller than 0.005.

ISO 2768 Permissible Geometric Tolerance

Tolerance Precautions

Consequently, what are Tolerance precautions that should be considered for CNC Machining? There are numerous significant aspects to consider while calculating tolerances. These are discussed below;

- Material: There are no two materials similar, and some are easier to work with than others. To define tolerances, it's crucial to examine the material's heat stability, hardness, stiffness, and abrasiveness.

- Machining technique: Because certain procedures are more precise than others, the type of machining employed can have a significant impact on the final output.

- Finishing and plating: Small amounts of material are added to the surface of a part during plating and finishing, which can change the dimensions of the part just enough to necessitate a different tolerance.

- Cost: The technique is more expensive if you restrict tolerance strictly. It's critical to maintain a precise tolerance in order to stay cost-effective. It's critical to ensure that your tolerance is precise, but not excessively so.

Photo by Daniel Smyth on Unsplash

Types of Tolerance

Do you know ASME categories different types of tolerance for machining purposes?

The Geometric Dimensioning and Tolerancing (GD&T) specifies five types of tolerances in general:

- Tolerances for form: A fundamental geometric tolerance that dictates the part's shape.

- Tolerances for profiles: Sets a boundary around a surface within which the surface's constituents must be contained.

- Tolerances for orientation: Determines the form's orientation with regard to a reference.

- Location tolerances: Indicates the feature's position in relation to a reference.

- Run-out: When a part is rotated on an axis, the run-out fluctuation of a target's feature is specified.

Surface Roughness for CNC Machining

There are various elements to consider when choosing the appropriate surface roughness for your project. Depending on the product's application, the desired durability, whether the item will be polished or painted, the importance of accurate dimensions, and the project's budget, the roughness average (Ra) may need to be higher or lower.

Under the same dimensional tolerances, the requirements for surface roughness of their CNC machining parts vary depending on the machine. This is the issue of cooperation's stability. The criteria for the stability and interchangeability of machined parts vary in the design and fabrication of mechanical parts for various types of machines.

But what are the different types of machining and how can you get started? Let's look into this expanding field. The following three types are represented in the existing mechanical parts design manual:

Surface roughness in CNC machining has an impact on how the created object interacts with its surroundings. A typical 'as machined' CNC machining finish is smooth to the touch with an average roughness (Ra3.2), but visible machining lines from the cutting tool are visible. Most parts can be made with this amount of roughness, although in some cases a smoother surface is necessary. When developing sliding parts, a smoother surface might be advantageous since it reduces friction between parts and improves wear performance.

The first is mostly employed in precision machinery that requires a high level of fit stability. During service or after continuous assembly, the wear limit of machined parts must not exceed 10% of the dimensional tolerance of the parts. This is mostly utilised on the friction surfaces of extremely essential machined parts, like the inner surface of the cylinder, the spindle neck of precision machine tools, the spindle neck of coordinate boring machines, and more precise bits that suit highly particular requirements.

The other is used in typical precision equipment that requires high fit stability, a mechanical component wear limit of no more than 25% of the machined part's dimensional accuracy, and a very close contact surface. Machines, tools, surfaces that work with rolling bearings, taper pinholes, and contact surfaces that move at quite fast speeds are all examples of its application.

The third type is primarily used in general machinery where the wear limit of mechanical parts must not exceed 50% of the dimensional tolerance value and there are no contact surfaces for relative moving parts, likewise tight surfaces, keys, and keyways' working surface; contact surface with low relative movement speed as well as a bracket hole, bushing, working surface with a hole for the wheel shaft, reducer, and so on.

Photo by Mastars on Unsplash

Relationship b/w Roughness and Tolerance

Now, how do roughness and tolerance relate to each other in Computer numerical control (CNC) machining?

The surface roughness that is compatible with the tolerance level is the most usually used.

If the smaller the dimensional accuracy requirements for mechanical components, then lower the surface roughness value of the mechanical parts. However, there is no established functional link between them under normal circumstances. Some machinery and instruments have very smooth surface requirements for example; handles, handwheels, sanitary equipment, food machinery, and mechanical parts with a changed surface.

It means that the surface roughness requirements are high but the dimensional tolerance requirements are low. Under typical circumstances, the tolerance level and the surface roughness value of CNC machining items with dimensional tolerance requirements have a reasonable relationship.

According to some mechanical components design manuals and monographs, there are a lot of calculation formulas available. It represents the relationship between the surface roughness and the dimensional tolerances of mechanical parts. You can read the formula list to choose from.

When you actually read it. You will notice that the same empirical formula is used with different values. It may cause confusion for the people who have very limited knowledge in this area. Simultaneously, it makes selecting surface roughness in the work of mechanical parts more complex.

Selection of Tolerance Principle for CNC Machine

Computer Numerical Control (CNC) machining demands extreme accuracy. In this profession, even millimeters can lead to major mistakes. Unfortunately, no machine can guarantee 100 percent accuracy all the time.

Therefore, What basic tolerance principle should be adopted for CNC Machining? Let’s explore this thing together.

As we know, tolerance is the control of the correctness of CNC machined parts. There are standard tolerances for CNC machined items such as threads, cuts, and pipes. Standard tolerances are required for numerically controlled machined parts for a variety of applications. When the customer does not select the tolerance level, most CNC milling services provide ±0.1 mm, which is also the typical CNC machining component tolerance standard specified by the mechanical engineer. The most frequent worldwide standard organizations that set CNC machining tolerances are (ISO) International Organization for Standardization, (ASME) American Society of Mechanical Engineers, and others. Now discuss them in-depth.

Basically, the International Organization for standardization (ISO 2768) standard is broken into two parts, each of which aims to simplify drawings by establishing precision levels as general rules:

- General tolerance: Its levels are described as f-fine, m-medium, c-coarse, and v-very coarse for linear and angular dimensions.

- Geometrical tolerance; Tolerance classes H, K, and L establish geometrical tolerances for features with different precision levels.

As an illustration, a drawing could be designated as International Organization for standardization ISO 2768-mK, which means it must adhere to the tolerance limits for Part 1's "medium" and Part 2's "K" tolerance classes. You can simplify your drawing by including the ISO 2768 specification and avoid specifying tolerances for each dimension and feature.

The standard is formed of general guidelines because there are situations when a dimension of a part requires a tighter tolerance than those defined by ISO 2768. Such occurrences are common, therefore review the drawing title block for general tolerance requirements and make a note of any special part specifications or project requirements.

Whereas, the American Society of Mechanical Engineers(ASME Y14. 5) standard specifies geometric dimensioning and tolerancing symbols, definitions, and regulations. The standard's purpose is to ensure that detailed information is provided clearly all across the design and manufacturing process for mechanical components.

It basically tells the manufacturing personnel and equipment how accurate and precise each regulated feature of the part needs to be. On engineering drawings and computer-generated three-dimensional solid models, the Geometric and Dimensions Tolerance (GD&T) use a symbolic language that expresses nominal geometry and its permissible variance.

Tolerances are chosen according to the production process. Typically, the higher the tolerance, the lower the cost. Excessive tolerance selection carries the risk of prospective and actual performance breakdowns, service deterioration, functional undesirableness, and poor looks. Limit tolerancing is the most practical and widely used. It allows for the arbitrary selection of tolerances for a chain of measurements and ensures a good fit, but it does not take production costs into account.

The standard methods for determining tolerances do not directly maximize costs and tolerances. Their main focus is defining tolerances so that the design may work first and, preferably, be the cheapest.

The Bottom line

Consequently, what exactly is the relationship between surface roughness and tolerance level in CNC machining?

The average texture of a part's surface is measured by surface roughness. The surface roughness that is compatible with the tolerance level is the most usually used. The smaller the dimensional accuracy requirements for mechanical components, the lower the surface roughness value of the mechanical parts, however, there is no permanent function link between them under normal circumstances.

The International Organization for Standardization (ISO) and the American Society of Mechanical Engineers (ASME) are the two most common international standard organizations that determine CNC machining tolerances. A common 'as machined' CNC machining finish is smooth to the touch with an average roughness (Ra3.2). If these are not available, a standard tolerance is used as ± 0.005" (0.127 mm).