What is Quality Inspection in CNC Machining?

CNC machining quality inspection is the organized effort to confirm that machined parts meet all design, safety, and functional specifications. It uses tools from hand calipers to sophisticated automatic equipment such as CMMs (Coordinate Measuring Machines) and laser scanners to measure dimensions, tolerances, and surface finish with precision.

Quality inspection is different from quality assurance (QA) (putting procedures in place to stop defects or reduce the likelihood of defects from happening during process design) and quality control (QC), which may use broader operational methods. Quality inspection is a category of QC. It is the process of evaluating a product against criteria in order to either accept or reject it.

Quality inspection serves a primary purpose: confirming that machined parts can be identified as conforming, safe, and reliable, in order to stop defective parts from being sent to customers, and therefore support industry standards

Key Stages of CNC Quality Inspection

Quality inspection is the basis of manufacturing quality, assuring that every part is built to predetermined expectations of performance, safety, and reliability. When manufacturers build in ongoing systematic inspection processes at every phase of the manufacturing process, they can eliminate defects, reduce waste, and produce higher-quality products. Below, we detail the key stages of CNC quality inspection:

- Raw Material Verification.

The first step to producing any high-quality machined part is to verify the raw materials. Before any machining starts, the material being used must be verified against grade, hardness, and/or composition. This verification can and should include reviewing material certificates (3.1 Material Certificate, etc.) and performing tests for composition and properties using X-ray detectors. A large failure could be expensive, so verification is paramount.

- First Article Inspection (FAI).

When the first part is completed, the opportunity to conduct First Article Inspection (FAI) will provide feedback about whether the part meets design specifications. This full inspection will completely check dimensional tolerances and firm checks for CAD models and engineering drawings. FAI is especially useful if the manufacturer is producing parts for the first time or any first articles with changes to designs. The baseline for all first article inspection reference processes is documented.

- In-Process Checks.

Quality assurance is not just about the quality of the end product, but also an evaluation of the process for each manufacturing process. In-process inspections involve checking each stage of the process in real time. Included during in-process inspection are checks for dimensions, tolerances, and surface finish, for example. Some manufacturers use Statistical Process Control (SPC) tools to measure and identify variations and trends, with the potential to enable immediate adjustments by operators in their processes. Continuous checks drive down defect rates at each stage of the process and contribute to quality overall.

- Dimensional and Surface-Finish Assessment.

Dimensional measurement will confirm geometric tolerances and surface condition. The dimensional measurement can be performed with coordinate measuring machines (CMM), optical comparators, and handheld precision tools (micrometers, calipers, and gage blocks) that will measure against reference values shown in CAD or 2D drawings. Surface finish can be measured with profilometers and is reported as Ra, Rz, or other standard parameters. Correct surface topography affects sealing, wear, friction, and aesthetics, so surface finish checks are often specification-driven.

- Non-Destructive Testing (NDT).

For hidden defects that cannot be seen visually, NDT methods, including ultrasonic testing, dye-penetrant, magnetic particle, and radiography, can find flaws underneath, such as cracks, voids, or inclusions, without destroying the part. The type of NDT will depend on the material, shape, and safety-critical nature of the part.

- Final Inspection & Functional Testing.

Final inspection of an assembly is a complete verification that each critical characteristic meets specifications prior to release. Functional tests are representative of service conditions, such as fit-checks, torque testing, pressure/leak testing, or cycle tests, which means you are validating the part not just dimensionally, but for intended performance. This step is the last gate before shipment.

- Assembly and Fit Verification.

For the components to be built to be a part of an assembly, fit and alignment are critical. This includes how the machined part sits with other machined components, and the process should not require forced alignment but instead be convenient and properly fit. Go/no-go gauges, fixtures, and/or CMMs will be used to check various aspects of fit-up, all to assure the product functions consistently as intended, even extending to the product life cycle overall reliability.

Tools and Techniques Used in Inspection

This section discusses the main instruments and methodologies that define the present quality inspection practice in CNC machining.

Precision Measurement Tools:

At the worktable, dimensional accuracy will often start with the first few familiar instruments any machinist picks up.

- Calipers (digital, dial, or vernier) - they are quick and adaptable to measuring outside, inside, and depths. Digital calipers work and are able to provide quick checks; they are now the most significant for the shop floor over a dial or vernier caliper, which will provide assistance for especially critical inspections where battery dependence does not work.

- Micrometers - This tool will provide more resolution than a caliper and will be more favorable for critical diameter and thickness measures when hundredths or thousandths of a millimeter are necessary.

- Gauges (go/no-go, plug gauges, thread gauges) - perfect for high volume verification and user-selected pass/fail coverage after inspection. Thread gauges will also assist in fitting threaded features as designed. Go/no-go gauges will be the quickest inspections for repeated runs.

- Gauge blocks & surface plates will be strictly used for calibration and organization of measures, and we decided to have a calibrated, flat surface to measure on.

Advanced Equipment: CMMs, profilometers, and hardness testers

When parts exhibit complex geometry, tight geometric tolerance, or surface issues that impact function (seals, bearings, optics), you progress to advanced measurement technology.

Coordinate measuring machine (CMM)

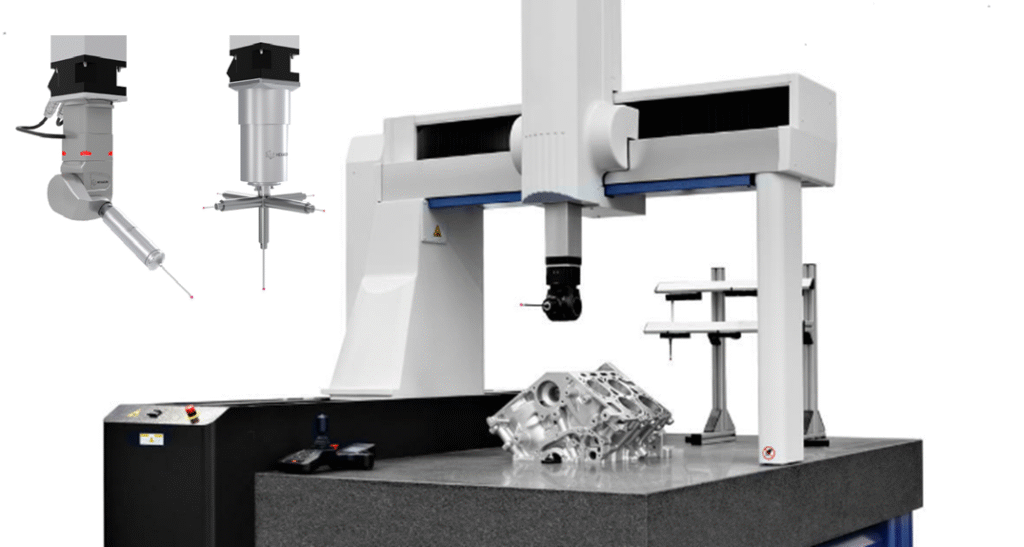

- Coordinate Measuring Machines (CMMs) measure 3-D geometry with high repeatability by probing a part and capturing precise coordinates. CMMs are essential for first article inspections, complex GD&T tolerance checks, and when you want the entire dimensional map instead of only a few spots. CMMs reduce operator variation since the software drives measurement routines and reports.

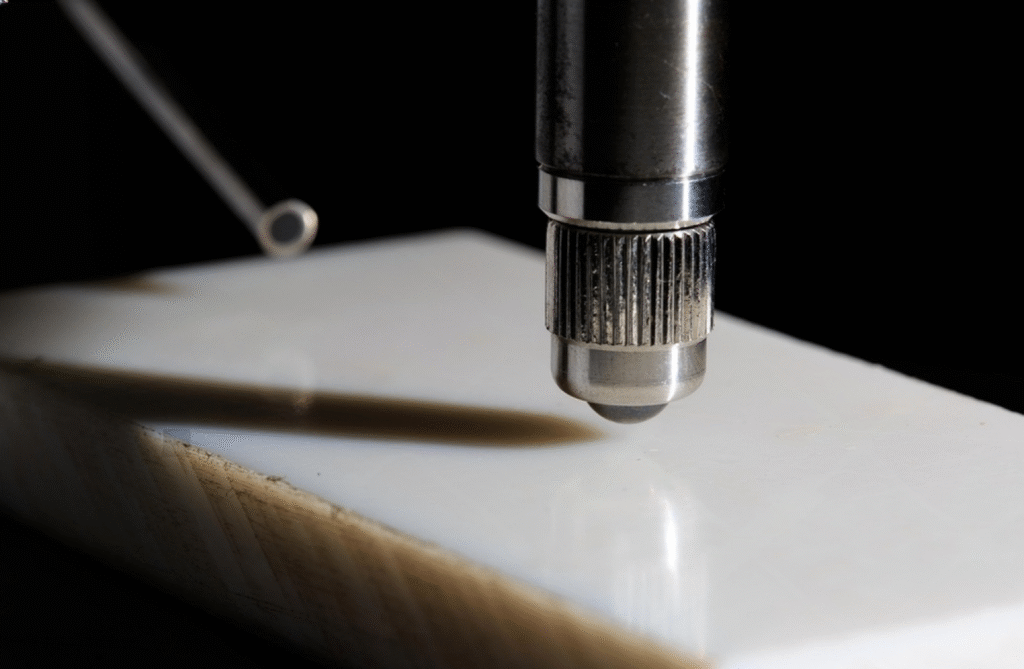

- Profilometers and surface-roughness testers check surface texture — a functional quality of performance that impacts friction, sealing, fatigue life, and painting/adhesive performance. Contact (stylus) and optical profilometers measure roughness parameters like Ra and Rz; modern profilometers also contain filters and specifications compliance known to match ISO/DIN processes. Effective surface-roughness control is often as important as dimension control in high-performance parts.

- Hardness testers (Rockwell, Brinell, and Vickers) check and confirm heat treatment and material properties for their specifications. Hardness measurements can correlate to strength and wear resistance, and they are utilized both on incoming material and post-process inspections to identify bad heat processes, incompatible batches, or drift of processing.

Non-Destructive Testing (NDT):

NDT methods allow you to examine the internal condition or hidden defect of a part without destroying it — this is very important for safety critical application (aerospace, automotive, oil & gas).

- Ultrasonic testing (UT) sends high-frequency sound into a part and evaluates the sound signal to detect cracking, voids, and inclusions internally. UT is sensitive and works well on thick sections and welds.

- Radiographic testing (X-ray / gamma ray) provides an image of the internal structure to show porosity, inclusions, and assembly issues not visible from the outside. Radiography is useful when you need a permanent record of the internal condition.

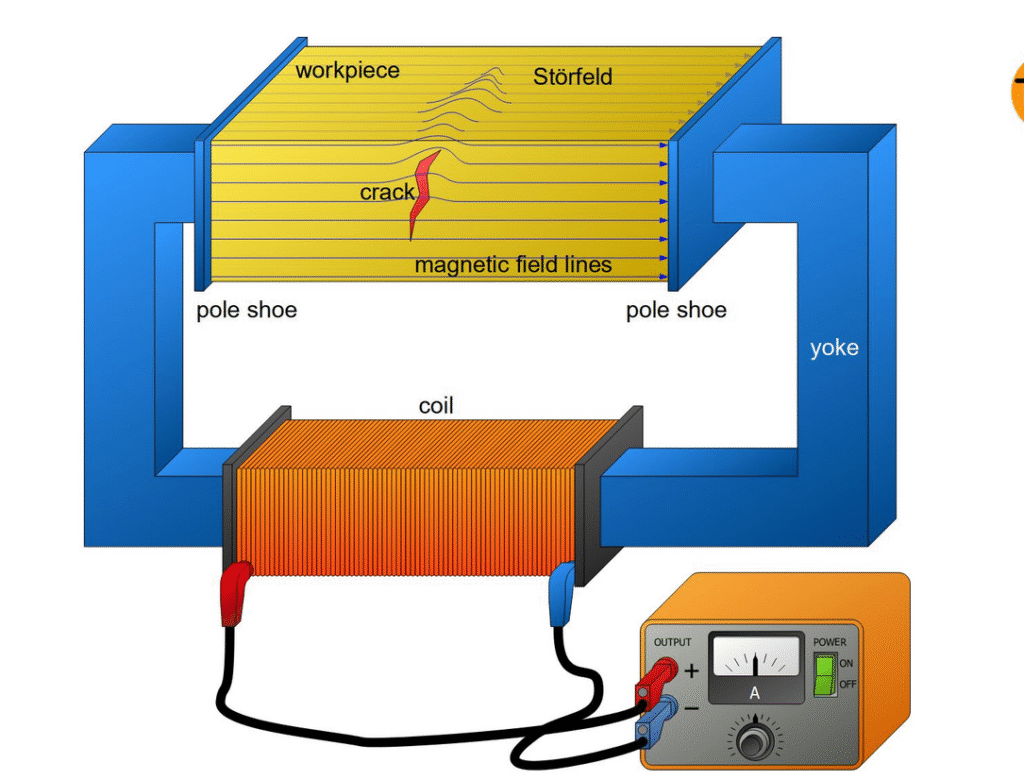

- Magnetic particle inspection (MPI) reveals surface and near-surface cracking of ferromagnetic materials by magnetizing the part, then applying ferrous particles that collect at the discontinuity.

Magnetic particle inspection (MPI)

- Eddy current testing and dye penetrant are also methods of NDT that assess conductivity-related features or very fine surface cracks.

The specific NDT method used will depend on the material, geometry, defect type, and the type of required sensitivity. NDT methods provide more than dimensional inspection when checking structural integrity — the NDT methods are required for high-risk or high-cost components.

Visual and manual inspections

Many common problems can be detected quickly by visual and manual checks, both before and often in parallel with advanced inspection:

- Magnifiers and microscopes allow you to verify surface finish, burrs, micro-cracks, and machining marks at drastically elevated magnifications.

- Borescopes and videoscopes allow inspection of internal bores, threaded holes, and blind cavities without disassembly; modern borescopes allow for high-resolution images and video for documentation.

- Dial indicators and comparator gauges detect run-out, concentricity problems, and flatness deviations quickly when setting up and running the first parts.

Visual checks are low-cost and an effective mechanism for catching obvious defects early—protecting against unnecessary rework or entering bad parts into expensive processes like assembly or coating. Good lighting, check-lists, and a consistent level of training will make visual checks far more assuring.

Digital tools: SPC, real-time monitoring, and traceability.

Data is essential to quality in modern machining. Digital tools help to close the loop between measurement and actions:

- Statistical Process Control (SPC) software compiles the data collection automatically, builds control charts, and alarms when a process drifts off-control, turning your measurements into patterns you can act upon, instead of waiting for scrap to accumulate the material to notice trends like tool wear, machine drift, or build issues. Some have even advanced SPC to real-time software that can trigger alarms and correction workflows automatically.

- Tool monitoring and machine monitoring systems sometimes integrate with CNC controllers that capture proxies for vibration, spindle load, and cutting force. These datasets can then detect tool breakage, pattern signals experienced during the process that may correlate with measured part variations, and give a prediction of the tool life remaining, enabling adaptive interventions to planning based on calendar events.

- Traceability and quality management software are methods by which inspection work could record inspection results tied to batches, serial numbers, and operators. Traceability can support audits and investigations of failures and is a principle of continuous improvement, because you can see evidence of both the columns of measurements, or quantitative metrics, and trends in the corrective actions performed that span weeks, months, or years. Some shops feed inspection data into ERP or Quality Management System, to create documentation for compliance that has logs of corrective actions taken.

Factors Affecting Inspection Outcomes

- Calibration and Tool Wear

Cutting tools and measuring instruments alike wear with use. Worn cutting tools may change chip formation and dimensional forces; they have an impact on chip formation and dimensional forces on the machine that can create tolerances that are consistent but off-spec. Similarly, without scheduled/guided calibration and maintenance (e.g. gauges, micrometers, CMM probes) when wear would accumulate, dimensions would cease to be accurate. Therefore, a disciplined calibration program (traceable standards, documented schedule and intervals, and allowable procedures) is necessary to manage measurement uncertainty to acceptable levels and still allow for defensible inspection records.

- Environmental Conditions (humidity, temperature)

Thermal expansion and corrosion from humidity, as well as airborne contaminants, all impact dimensions and surface condition. Even minor changes in temperature of the shop environment can yield microns of spindle growth and growth of the part itself even if the environment during machining didn't change. Additionally, humidity and airborne contaminants bring different mechanical phenomena such as rust or dimensional drift of hygroscopic materials. Tiny tolerances too may necessitate climate control, stable machine warm-up routines, and sensors that monitor in a localized scope to effectively convert the application of raw measurement into useful data.

- Operator training and expertise.

The inspection process is a human-machine duet: trained inspectors read the measurements, select the inspection tools, and identify the anomalies that an automated inspection device may miss. Formalized training serves to reduce measurement variation by having a standardized method of measuring: fixturing to hold the measured parts, probing sequences, and referencing datum surfaces. Training also ensures consistent application of GD&T. Ongoing upskilling, competencies, and documentation of processes convert the tacit knowledge of the inspectors to a repeatable activity and reduce false-fail rates due to human error.

- Adherence to industry standards (ISO 9001, AS9100, etc.).

Compliance with an industry-recognized quality-management standard immediately embeds controls associated with inspection within the organization’s business processes. ISO 9001 denotes documented processes, calibration traceability, and corrective-action loops; AS9100 enhances those same elements to mitigate and control risk in an aerospace-specific context, including actions related to the retention of records, oversight of suppliers, and the aforementioned processes. Certification based on any quality management standard requires inspection processes to have disciplined recordkeeping processes, highlights systemic weaknesses, and increase confidence from buyers within regulated supply chains.

Best Practices for Effective Quality Inspection

- Scheduled Maintenance and Calibration of Machinery

Well-maintained machinery will do a better job of delivering parts within nominal tolerance and require less rework. This includes cleaning and lubricating the moving parts, removing and replacing worn parts, and checking the geometry of the machines. The calibration of tool-holders and spindles should also be carried out at regular intervals. If drifts occur without detection for a long period of time, even small drifts can add up and be detrimental to accuracy and surface finish. Establish scheduled maintenance so that the maximum tool life and output accuracy are achieved.

- Use of SPC and Data-Driven Monitoring

Statistical Process Control (SPC) has emerged as a more common method for managing and tracking machining processes through real-time data streams and has illustrated not only the detection of defects but also the isolation of emerging trends and variation that may produce defective parts. Control charts, process capability studies, and the monitoring of incoming data separate normal variation from indications that require corrective action. SPC suggests that defects are not inspected or detected, but rather, a more forward-thinking predictive and preventative approach to distinguishing, monitoring, and controlling defective processes.

- Investing in Quality Control Software for Traceability.

Traceability is critical, as is the situation where there are regulatory requirements (e.g., aerospace, medical). Quality control software has been improved, with nearly everything that components, raw material lots, and machine settings can now be associated with inspection data. Aside from audit-ready reporting, the software will track revision history, link electronic certificates of conformity, and facilitate root cause investigation. Near real-time alerts are sent for deviations; all the data is now in one place, with all outcomes having value and reducing analysis time.

- Ongoing Training of Inspection Personnel.

Automated tools exist; however, human skill is critical. Inspectors must be trained consistently in reading drawing specifications and understanding the operational use of various measurement tools (i.e. micrometers, CMMs, and surface profilometers), reading SPC charts, and measuring accurately. Training must all aim to avoid mistakes with misreading tolerances, incorrect tool handling, and determining when it is appropriate to utilize soft skills when training (e.g. when the problem is present vs. a minor defect with broad implications).

- Creating a Culture of Quality and Accountability.

The technical tools and processes alone are of no value for greatness. A working culture where quality is front and center on the shop floor, and every operator, supervisor, and manager has quality as part of their accountability to uphold parts integrity, is equally important. Leadership at all levels needs to set the tone for accountability by demonstrating expectations, adhering to standard operating procedures, and demonstrating high standards. Ultimately, the training must instill the importance of quality in employees' culture and values and lead to decreased complacency and speed in improvements.