Welding can change the shape and size of metal parts. This is because of the heat involved. Are these changes predictable?

Yes, welding deformation can be predicted. Understanding how the metal shrinks and bends can help you plan for it. You can even use computer simulations to see what will happen.

If you want to know how much your part will change shape after welding, keep reading.

How Can I Predict Welding Deformation?

Welding deformation is a common problem, but understanding why it happens is the first step in predicting it. Can we figure out what will happen before we even start welding?

Yes, there are several ways to predict welding deformation. These include simple observations, calculations, and advanced computer simulations. Each method offers a different level of accuracy.

Simple Observations and Rules of Thumb

I've found that starting with simple observations can be very helpful. For example, metal usually shrinks more across the weld than along it. Also, welding on one side of a plate tends to bend it. Knowing these basic rules can help you make educated guesses about how your part will deform.

Calculations

For more precise predictions, you can use calculations. These calculations consider factors like the type of metal, the amount of heat used, and the shape of the part. By calculating the stresses caused by welding, you can estimate the amount of deformation. You can also draw stress curves to visualize the stress distribution.

Computer Simulations

The most advanced way to predict welding deformation is with computer simulations. These simulations use a method called Finite Element Analysis (FEA). FEA divides the part into many small elements and calculates the effects of heat and stress on each one. This allows you to see a detailed picture of how the part will deform.

There are two main types of FEA simulations:

Thermal Elastic-Plastic FEA (TEP-FEM): This method simulates the entire welding process, including heating and cooling. It's very accurate but can take a long time to compute.

Inherent Strain Method (ISM): This method is faster because it focuses on the residual strains in the weld. It's less accurate than TEP-FEM but good for quick predictions.

I've used FEA simulations to optimize welding procedures and minimize deformation. They can be a powerful tool in ensuring the final product meets the required specifications.

How Can I Reduce Welding Deformation?

Even if we can predict welding deformation, is there anything we can do to minimize it? What steps can we take to keep our parts from changing shape too much?

Yes, there are many ways to reduce welding deformation. Some common methods include pre-bending, using fixtures, and choosing the right welding sequence. The goal is to control how the metal expands and contracts during welding.

Design Considerations

The design of the weldment itself plays a crucial role in minimizing distortion. I always try to follow these design principles:

Minimize Weld Metal: The more weld metal you use, the greater the shrinkage forces. Use only the necessary amount to meet strength requirements.

Intermittent Welding: Use intermittent welds instead of continuous welds whenever possible. This reduces heat input and distortion.

Balanced Welds: Place welds symmetrically around the neutral axis of the structure. This balances shrinkage forces and minimizes bending.

Welding Techniques

The way you weld can also significantly affect deformation. Here are some techniques I've found effective:

Backstep Welding: Weld in short segments, moving in the opposite direction of the overall weld path. This helps distribute heat more evenly.

Low Heat Input: Use the lowest possible heat input that still achieves good weld quality. This minimizes the size of the heat-affected zone.

Proper Welding Sequence: Plan the welding sequence to balance heat input and minimize stress buildup. For example, weld from the center outward.

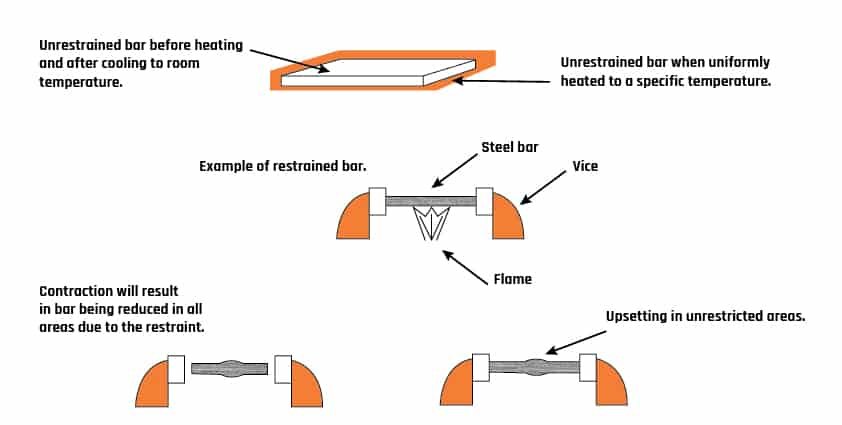

Using Restraints

Restraints like clamps, jigs, and fixtures can prevent the metal from moving during welding. This can be very effective in controlling distortion. However, it's important to be careful not to over-restrain the part, as this can lead to increased residual stresses.

I've used these techniques in my shop to produce high-precision parts with minimal welding deformation. It takes careful planning and attention to detail, but the results are worth it.

Conclusion

Welding deformation is predictable and manageable. By understanding the principles behind it and using the right techniques, you can minimize its effects. Whether you're using simple observations or advanced computer simulations, the key is to plan ahead and take control of the welding process.