Are hidden defects threatening your machined parts' integrity? Undetected flaws can lead to catastrophic failures, costly recalls, and damaged reputation when components fail in critical applications.

Ultrasonic flaw detection improves CNC machined part quality by identifying internal defects invisible to the naked eye. This non-destructive testing method uses high-frequency sound waves to detect cracks, voids, and inclusions before parts enter service, ensuring safety and reliability without damaging components.

In our machine shop, we've seen firsthand how implementing advanced quality control methods1 makes the difference between parts that merely meet specifications and those that truly excel in performance. Let me share how ultrasonic flaw detection has transformed our approach to quality assurance and why it might be crucial for your components too.

What are the core principles behind ultrasonic flaw detection technology?

Do you worry about what might be hiding inside your critical machine components? Internal defects can lurk beneath perfect-looking surfaces, waiting to cause failures precisely when reliability matters most.

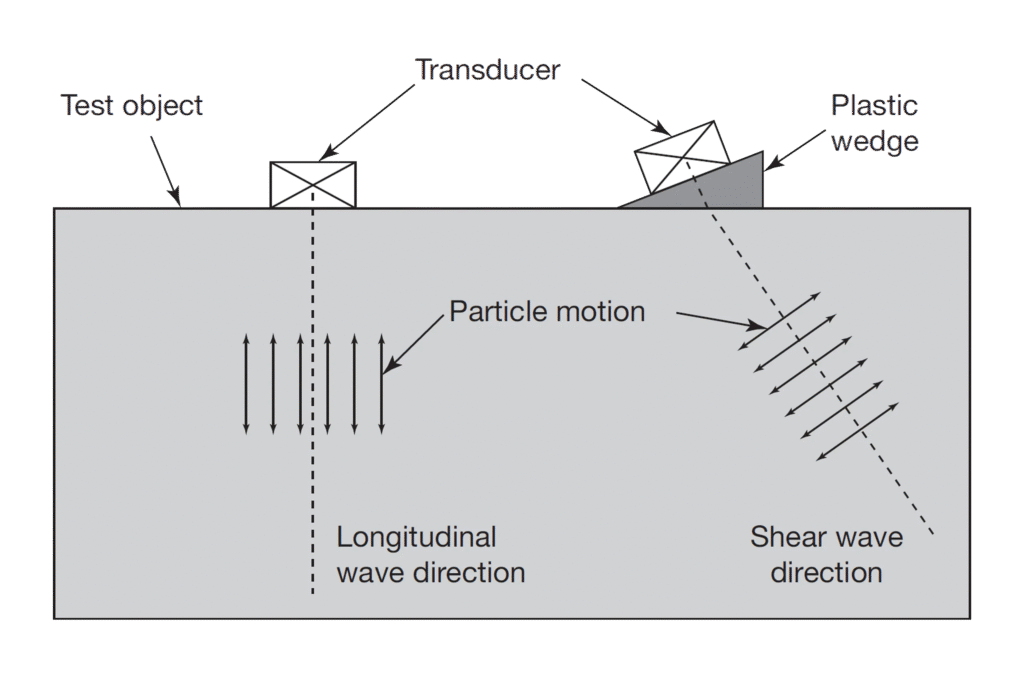

Ultrasonic flaw detection works by transmitting high-frequency sound waves (typically 1-10 MHz) through materials and analyzing the reflected signals. When sound encounters a boundary—like a crack or void—it reflects back to the transducer, creating distinctive patterns that reveal the size, shape, and location of defects.

The science behind ultrasonic testing is both fascinating and practical for ensuring machined part quality. At its core, this technology relies on the same principles that dolphins and bats use for echolocation. When we inspect a component, we're essentially "seeing" with sound.

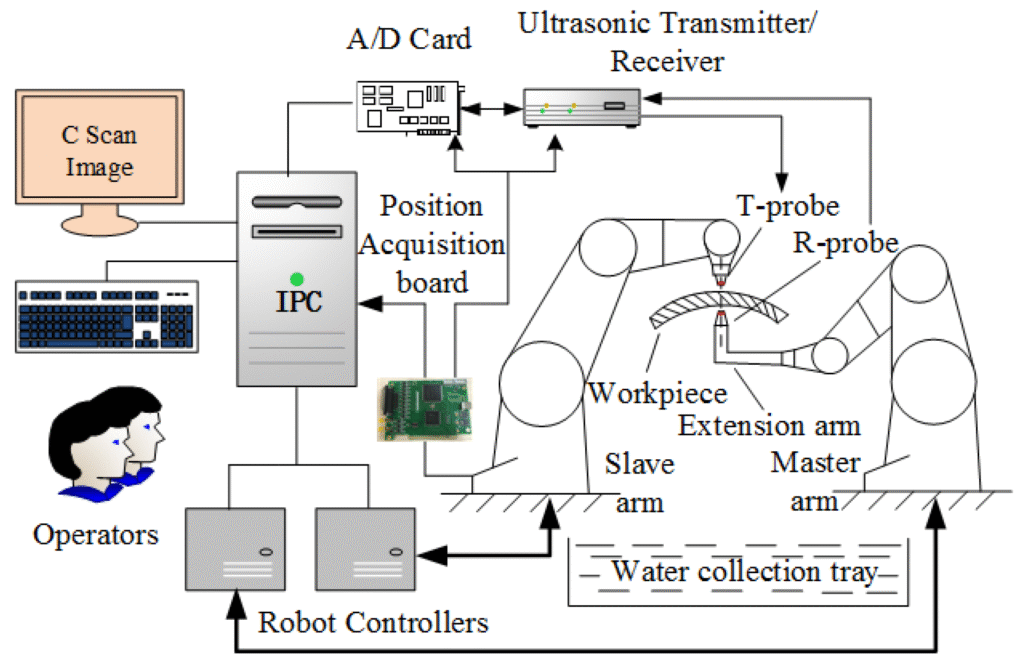

The process starts with a transducer2 that converts electrical signals into mechanical vibrations. These vibrations travel through the material as ultrasonic waves. In defect-free material, the waves travel at a predictable speed and pattern. However, when they encounter discontinuities like cracks, porosity, or inclusions, part of the wave energy reflects back to the transducer.

Modern ultrasonic equipment measures three critical factors:

- Time of flight - How long it takes for the echo to return

- Amplitude - The strength of the returning signal

- Signal shape - The characteristic pattern of the reflection

| Wave Behavior | What It Indicates | Detection Capability |

|---|---|---|

| Strong reflection | Large defect or complete boundary | Cracks as small as 0.5mm |

| Partial reflection | Smaller defect or gradual change in density | Porosity clusters and inclusions |

| Signal attenuation | Material density changes or scattering | Grain structure issues and material consistency |

| Time delay | Distance to defect | Precise depth measurement (±0.1mm) |

In our facility, we've used this technology to catch welding defects in vacuum chamber joints and microscopic cracks in critical automotive components that would have otherwise gone undetected until catastrophic failure. The ability to "see" inside metal without destroying it has revolutionized how we approach quality verification.

How can manufacturers integrate ultrasonic testing into quality control workflows?

Are your current inspection methods missing critical hidden defects? The smooth surface and perfect dimensions of a machined part might hide internal flaws that could lead to premature failure and safety concerns.

Integrating ultrasonic testing into quality control requires strategic implementation at critical production stages. Manufacturers should establish testing protocols based on part criticality, create detailed inspection maps for complex geometries, train dedicated technicians, and implement digital documentation systems to track findings and maintain traceability.

Implementing ultrasonic testing into existing quality control workflows requires thoughtful planning but delivers exceptional returns on investment through enhanced quality assurance. From our experience working with precision components, successful integration follows a structured approach.

First, we conduct a risk assessment3 of all parts to determine which components would benefit most from ultrasonic inspection. Not every part requires this level of scrutiny—we prioritize safety-critical components, parts subject to fatigue loading4, and items where failure would be catastrophic. For example, in our sailboat component production, we focus ultrasonic testing on load-bearing structural elements rather than cosmetic features.

Next comes the development of part-specific inspection protocols. This involves creating:

| Implementation Element | Description | Key Considerations |

|---|---|---|

| Inspection maps | Diagrams showing critical inspection zones | Focus on stress concentration areas, welds, and thickness transitions |

| Reference standards | Calibration blocks with artificial defects | Must match the material and geometry of production parts |

| Acceptance criteria | Clear pass/fail thresholds | Based on industry standards (ASTM, ISO) and customer requirements |

| Documentation templates | Records of inspection findings | Digital systems with searchable databases are preferred |

Technician training represents another crucial element. We've found that effective ultrasonic testing requires both theoretical knowledge and practical experience. Our approach includes shadowing experienced inspectors, practicing on reference standards with known defects, and gradually increasing responsibility under supervision.

Finally, the workflow must incorporate decision paths based on inspection results. When we detect a defect, our system triggers specific actions—ranging from additional inspection to reworking or scrapping the part—depending on the defect's nature and location. This systematic approach ensures consistent quality decisions regardless of who performs the inspection.

When should ultrasonic testing be preferred over other NDT methods for metal components?

Is your current testing method actually revealing the defects that matter most? Many traditional inspection techniques only scratch the surface, missing critical internal flaws that could lead to catastrophic failures.

Ultrasonic testing should be preferred when inspecting thick metal sections, detecting subsurface defects, assessing weld integrity, examining complex geometries, or evaluating material uniformity. Unlike X-ray testing, it poses no radiation hazards and excels at finding planar defects like cracks that might be invisible to radiographic methods.

Selecting the optimal non-destructive testing5 method depends heavily on the specific inspection requirements and component characteristics. Through our years of manufacturing precision parts, we've learned that ultrasonic testing offers distinct advantages in several key scenarios.

Thick-walled components present a particular challenge for many inspection methods. While X-ray techniques struggle with penetration limitations as thickness increases, ultrasonic waves can travel deep into materials—sometimes up to several meters in steel—while maintaining detection sensitivity. This makes ultrasonic testing ideal for our larger vacuum chamber components and heavy industrial machinery parts.

Material composition also influences testing method selection. In our experience with various metal alloys, ultrasonic testing performs exceptionally well with:

| Material | Ultrasonic Advantage | Typical Applications |

|---|---|---|

| Stainless steel | Excellent penetration and flaw resolution | Vacuum chambers, medical components |

| Aluminum alloys | High sensitivity to common defects like porosity | Aerospace parts, lightweight structural components |

| Titanium | Detection of critical alpha-case and hydrogen embrittlement | Medical implants, high-performance components |

| Welded joints | Identification of lack-of-fusion defects | Pressure vessels, structural assemblies |

Defect orientation plays another critical role in method selection. Ultrasonic testing excels at finding planar defects like cracks, especially those oriented perpendicular to the sound wave path. We've found it particularly valuable for detecting fatigue cracks in automotive components and stress corrosion cracking in marine applications—defects that might be missed by radiographic methods if improperly aligned.

Cost and safety considerations also favor ultrasonic testing in many scenarios. Unlike radiographic testing, ultrasonic methods require no radiation sources, eliminating the need for special facilities, evacuation procedures, and radiation badges. This makes on-site and in-process testing much more practical, allowing us to integrate inspection directly into our production workflow rather than moving parts to specialized testing facilities.

What defects can ultrasonic testing identify that other methods might miss?

Are you confident your parts are truly defect-free beneath the surface? Visual and dimensional inspections can't reveal the hidden flaws that often lead to the most devastating failures.

Ultrasonic testing excels at detecting tight cracks, incomplete fusion in welds, laminations in rolled materials, porosity clusters, and inclusions deep within metal components. Its ability to locate planar defects perpendicular to the sound wave path makes it uniquely suited for finding fatigue cracks and stress corrosion cracking that other methods might overlook.

The detection capabilities of ultrasonic testing truly set it apart from other inspection methods. In our manufacturing facility, we've repeatedly encountered situations where ultrasonic testing revealed critical defects that would have remained hidden using conventional inspection techniques.

Subsurface crack detection represents perhaps the most valuable capability of ultrasonic testing. These cracks often develop beneath an unblemished surface, making them invisible to visual inspection, dye penetrant testing, and magnetic particle inspection. We encountered this when inspecting high-stress sailboat fittings—components that looked flawless under magnification but contained subsurface fatigue cracks detectable only with ultrasonic methods.

The unique detection capabilities of ultrasonic testing extend to numerous defect types:

| Defect Type | Why Other Methods Miss It | Ultrasonic Detection Advantage |

|---|---|---|

| Lack of fusion in welds | Often occurs below the surface, with no visual indication | Sound waves reflect strongly at unbonded interfaces |

| Laminations | Parallel to the surface, invisible from the exterior | Easily detected with angle beam techniques |

| Hydrogen-induced cracking | Develops subsurface in high-strength steels | Detectable before propagating to the surface |

| Shrinkage voids | Internal casting defects with no surface expression | Create distinctive reflection patterns |

| Material property variations | No dimensional or visual differences | Changes in acoustic impedance reveal inconsistencies |

The precision of defect characterization also distinguishes ultrasonic testing. Beyond simply detecting a flaw, modern equipment can provide detailed information about defect size, orientation, and depth. This proved critical when we were machining components for semiconductor vacuum chambers, where the exact location and orientation of a defect determined whether the part could be salvaged or required replacement.

Time-of-flight diffraction (TOFD) and phased array ultrasonic testing6 (PAUT) represent advanced ultrasonic techniques that further enhance detection capabilities. These methods create detailed images of internal structures, allowing us to "see" inside complex geometries and precisely locate defects that would be missed or mischaracterized by conventional testing. For instance, when examining complex automotive transmission components, phased array technology enabled us to detect and accurately size small inclusions near critical stress points that conventional single-element probes would have missed entirely.

Conclusion

Ultrasonic flaw detection has transformed our approach to quality control, helping us deliver defect-free precision components. By revealing hidden flaws that other methods miss, this technology ensures safety, reliability, and customer confidence in every part we manufacture.

- Explore advanced quality control methods that can significantly improve manufacturing outcomes. ↩

- Learn about the critical function of transducers in ultrasonic testing and defect detection. ↩

- This resource outlines effective risk assessment strategies for identifying critical components. ↩

- Explore the effects of fatigue loading on components and the importance of inspection. ↩

- Learn about non-destructive testing methods and their advantages in ensuring component integrity. ↩

- Discover the benefits of phased array ultrasonic testing for complex component inspection. ↩