Your precision components are at constant risk of unexpected failure. Environmental factors and mechanical stress can create invisible cracks that compromise integrity, potentially causing catastrophic breakdowns when you least expect them.

Stress crack testing evaluates how materials respond to mechanical and environmental stressors before failure occurs. By simulating real-world conditions, these tests identify potential weaknesses in CNC-machined parts, helping manufacturers choose appropriate materials and optimize designs for specific applications

I've seen firsthand how proper stress testing can make the difference between parts that fail prematurely and those that perform reliably for years. Let me share what I've learned about this critical quality assurance process and why it matters so much for your precision components.

What is stress crack testing and why is it critical for precision parts?

You're investing thousands in precision components that could fail unexpectedly without proper testing. Hidden stresses from machining processes might be creating microscopic flaws that will grow under load.

Stress crack testing is a quality assurance process that evaluates a material's resistance to cracking under various stressors. For precision parts, these tests simulate real-world conditions to identify potential failure points before components enter service. Critical applications in aerospace, medical devices, and automotive systems depend on this testing to prevent catastrophic failures.

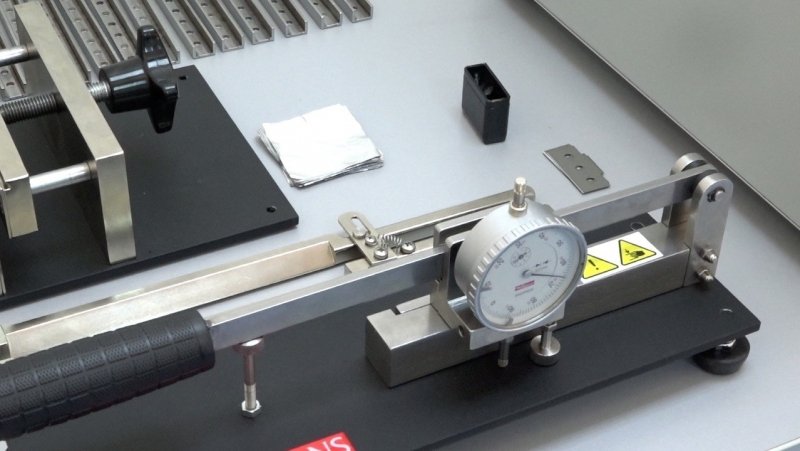

Advanced stress crack testing equipment

In our Kunshan facility, we implement several stress testing protocols depending on the material and application requirements. The most common methods include Environmental Stress Crack Resistance (ESCR) testing, constant load testing, and strain point testing. Each provides unique insights into material performance under different conditions.

ESCR testing is particularly valuable for plastic components, as it exposes materials to chemical agents while under mechanical stress. This combination accelerates the development of cracks that might otherwise take months or years to appear in service. We typically subject test specimens to bending stress while immersed in a chemical solution, then observe for crack formation.

For metal components, we often employ constant load testing, where parts are subjected to a fixed load for extended periods while exposed to potential corrosive environments. This helps identify susceptibility to stress corrosion cracking, a particularly insidious failure mode that can affect even high-quality stainless steels and aluminum alloys.

The latest advancements incorporate digital imaging and AI-powered analytics to detect microscopic crack formations before they compromise structural integrity. These technologies allow us to catch potential issues that would be invisible to the human eye.

Which materials are most susceptible to stress cracking in manufacturing?

You've selected what you thought was the perfect material for your project, but without proper testing, you might be overlooking inherent vulnerabilities. Certain polymers and alloys have hidden weaknesses that only reveal themselves under specific conditions.

Materials vary greatly in their susceptibility to stress cracking. Polymers like polycarbonate, acrylic, and ABS are highly vulnerable to environmental stress cracking when exposed to certain chemicals. Among metals, high-strength aluminum alloys and austenitic stainless steels can experience stress corrosion cracking in specific environments despite their otherwise excellent properties.

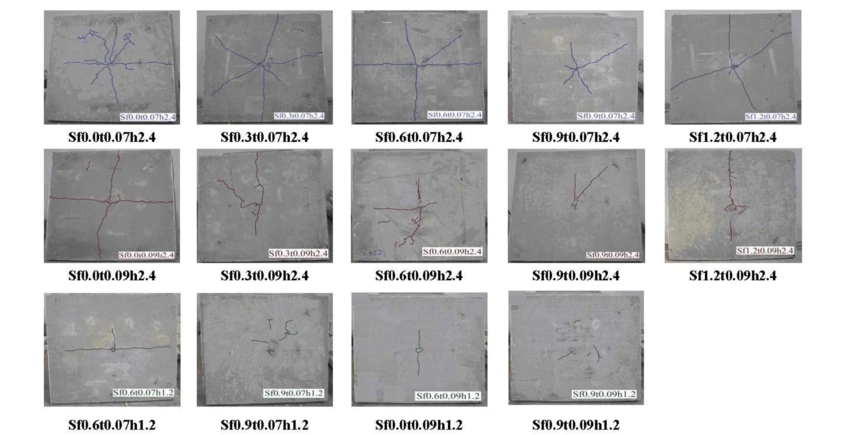

Comparison of stress crack patterns in different materials

When selecting materials for critical applications, understanding stress cracking behavior becomes essential for long-term reliability. I've seen numerous cases where seemingly minor environmental factors led to premature failure in otherwise well-designed components.

In polymers, amorphous thermoplastics tend to be more susceptible to stress cracking than semi-crystalline varieties. For example, polycarbonate—valued for its optical clarity and impact resistance—can develop cracks when exposed to common substances like cleaning solutions while under stress. Even more concerning, these cracks often develop without any visible warning signs until catastrophic failure occurs.

For metal components, the manufacturing process itself can introduce residual stresses that make parts more vulnerable to stress corrosion cracking. This is particularly true for machined parts where aggressive cutting parameters generate localized heat and mechanical stress. Without proper stress relief treatments, these internal stresses can combine with environmental factors to initiate crack formation.

The microstructure of alloys also plays a crucial role in stress crack resistance. For instance, in aluminum alloys, the size and distribution of precipitates can dramatically affect susceptibility to stress corrosion cracking. Similarly, in stainless steels, the presence of sigma phase or sensitization due to improper heat treatment can create weak points where cracks initiate.

In our experience, thorough material testing before production begins is the most cost-effective approach. We maintain a comprehensive database of material performance under various stress conditions, allowing us to make informed recommendations based on your specific application requirements.

How do different testing methods compare for CNC-machined components?

You're faced with choosing between multiple testing approaches, each with different costs and timeframes. Without the right method, you could miss critical flaws or waste resources on unnecessary tests.

Different testing methods provide varying insights into stress crack behavior. Accelerated testing exposes parts to extreme conditions to predict long-term performance in weeks rather than years. Constant strain testing maintains fixed deformation to identify threshold stress levels, while cyclic loading simulates real-world conditions where stresses fluctuate over time.

Various stress testing methods for machined components

The selection of an appropriate testing method depends on several factors, including the material properties, application requirements, and time constraints. In our facility, we tailor testing protocols to each component's specific needs.

For high-volume production components, we often implement a multi-stage testing approach. Initial screening uses accelerated tests to quickly identify potential issues, followed by more specialized testing for components that show vulnerability. This tiered approach optimizes both time and resources while maintaining rigorous quality standards.

One particularly effective method for CNC-machined components is the use of notched specimen testing. By introducing a controlled stress concentrator, we can evaluate how effectively a material resists crack propagation from existing flaws. This is especially relevant for machined parts where tool marks or sharp transitions can create natural stress concentrators.

For components subject to cyclic loading, fatigue crack growth testing provides essential data on how quickly cracks propagate under repeated stress. We use servo-hydraulic testing machines that can apply millions of load cycles while monitoring crack growth with microscopic precision. The resulting data allows us to establish safe inspection intervals and predict component lifespan with high confidence.

Digital image correlation techniques have revolutionized stress testing by allowing full-field strain measurement during tests. By applying a speckle pattern to component surfaces, we can track microscopic deformations across the entire part rather than just at discrete sensor locations. This comprehensive approach reveals strain concentrations that might otherwise go undetected.

When corrosive environments are a concern, we combine mechanical loading with controlled exposure to specific chemicals or atmospheric conditions. These tests are particularly important for components used in marine applications, chemical processing, or outdoor environments where multiple stress factors interact simultaneously.

How can proper stress testing extend component lifespan?

Your components are failing earlier than expected, causing costly downtime and replacement expenses. Without understanding the root causes, you're trapped in a cycle of reactive maintenance and emergency repairs.

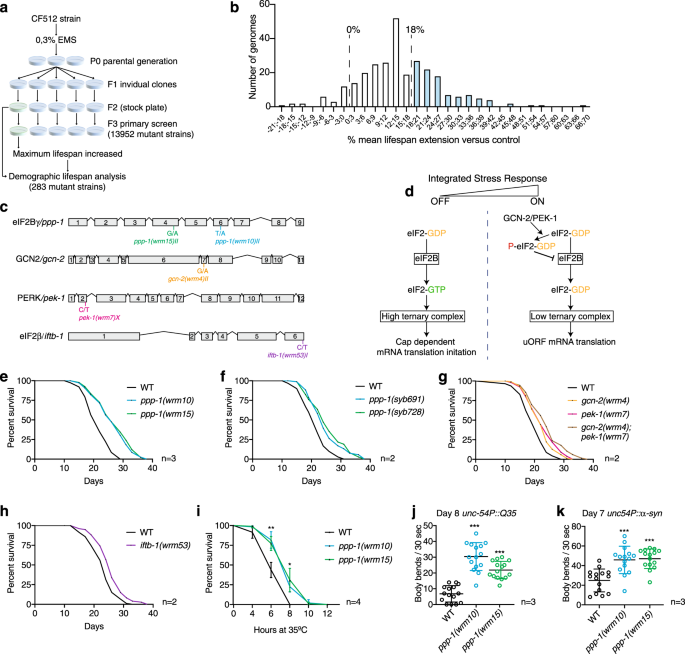

Proper stress testing identifies potential failure modes before components enter service, allowing engineers to optimize designs and material choices. By understanding crack initiation and propagation behavior, manufacturers can implement targeted improvements that significantly extend service life while preventing unexpected failures in critical applications.

Extended component lifespan through proper stress testing

In my 15 years of manufacturing experience, I've repeatedly seen how comprehensive stress testing translates directly to improved product longevity. The data gathered from these tests drives informed decisions that enhance both design and manufacturing processes.

One of the most valuable outcomes of stress testing is the ability to establish realistic safety factors for components. Without empirical data on crack initiation thresholds, engineers must rely on conservative estimates that often lead to overdesigned, heavier, and more expensive parts. With proper test data, designs can be optimized to meet performance requirements without unnecessary material usage.

For components subject to cyclic loading, stress testing helps establish the fatigue limit—the stress level below which the material can endure virtually infinite cycles without failure. By designing components to operate below this threshold, we can dramatically extend service life. In cases where operating below the fatigue limit isn't practical, stress test data helps establish appropriate inspection and replacement intervals.

Surface treatments and finishing operations can significantly impact stress crack resistance. Through comparative testing, we can quantify the benefits of processes like shot peening, which introduces compressive surface stresses that inhibit crack formation. Similarly, testing helps optimize post-machining heat treatments that relieve internal stresses introduced during manufacturing.

Material selection becomes much more precise with proper stress test data. Rather than relying solely on published specifications, which often represent idealized conditions, we can evaluate actual performance under application-specific conditions. In many cases, this reveals that a less expensive material performs adequately, reducing costs without compromising reliability.

For critical components, we can implement accelerated life testing combined with statistical analysis to generate Weibull distributions that predict failure rates over time. This data is invaluable for maintenance planning and warranty programs, allowing for preventive replacement before components reach their likely failure point.

Conclusion

Implementing comprehensive stress crack testing is not just quality control—it's an investment in your component's reliability and longevity. By understanding how materials respond to real-world stresses, we can deliver precision parts that perform exceptionally even in demanding applications.