Marine environments expose every component on a vessel to challenging conditions that include saltwater corrosion, bio-fouling, and crushing hydrostatic pressure (every component). A tiny dimensional error, or a surface that was simply not protected, can result in huge downtimes and can lead to disastrous failures. CNC machining today can deliver tolerances at the micron level with repeatable accuracy across propeller shafts, steering components, brackets, etc., so that every single key component can handle the extreme conditions of operating the vessel over the sea.

Material Selection for Marine CNC Machining

In this section, we will review the material science of marine CNC machining, from well-established alloys to cutting-edge composites.

Marine Grade Alloys

Aluminum 5083 is a non-heat-treatable Al-Mg alloy that has good weldability, a high strength-to-weight ratio, and forms a passivation layer capable of resisting seawater corrosion, making it ideal for rudder stocks, deck fittings, lightweight brackets, and so forth. This alloy has a tensile strength of up to 317 MPa and survives salt-spray testing with zero pitting for up to 500 hours.

Stainless Steel 316L and Super Duplex 2507: 316L stainless steel has low carbon content and resistance to pitting and crevice corrosion near coastal or splash zones, and equipment in this type of environment is often specified as 316L, such as fuel injector bodies and hydraulic pump housings. For extreme chloride environments, for example, for deep water pump impellers or high-pressure manifolds, we might specify Super Duplex 2507 (UNS S32750), which typically has a PREN > 40 and great resistance to stress corrosion cracking (SCC) failure modes at yield strengths > 600 MPa.

Composite Materials

Fiberglass polymer (FRP): While FRP has low weight and high chemical resistance, it can also be CNC machined in corrosion-proof access hatches, panels, and non-structural bulkheads. That durability in saline environments means limited maintenance cycles from the owner, as well as added downtime for the vessel.

Carbon Fiber Reinforced Polymer (CFRP): CFRP has an incredibly high stiffness and specific strength and has been used in racing yacht masts, high-performance propeller boss fins, and lightweight structural supports. Being quite expensive, its weight savings can be viewed as added speed and fuel savings.

Material Properties – Trade-offs

Marine engineers face material property selection, plastic/composite versus "counterpart," as a consideration of factors like corrosion resistance versus material cost. For example, Aluminum 5083 is low cost and has good corrosion resistance and good finish machining, also, whereas we all know super duplex steels cost more but will last longer. Equally important is manufacturability—i.e., 5083 machines well, whilst duplex steels and composites can require better tooling and therefore heavily reduced speeds, with not only increased cost of service within the CNC shop but also slow planning to manufacture. Balancing all of these considerations will ensure CNC-machined components will deliver long-life performance with minimal maintenance and ultimately a return on investment.

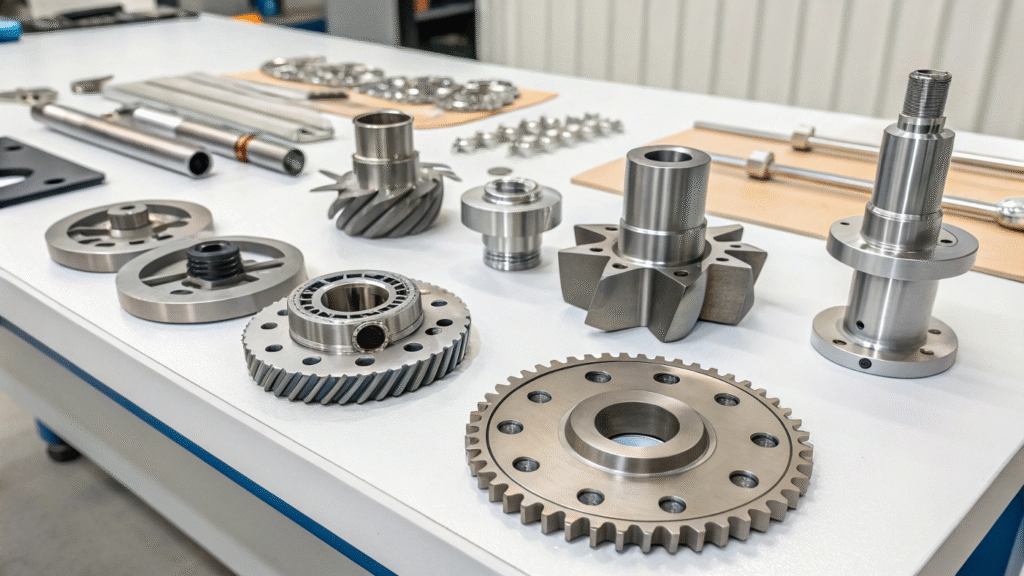

Precision Machining Processes for Marine Parts

Multi-Axis Milling

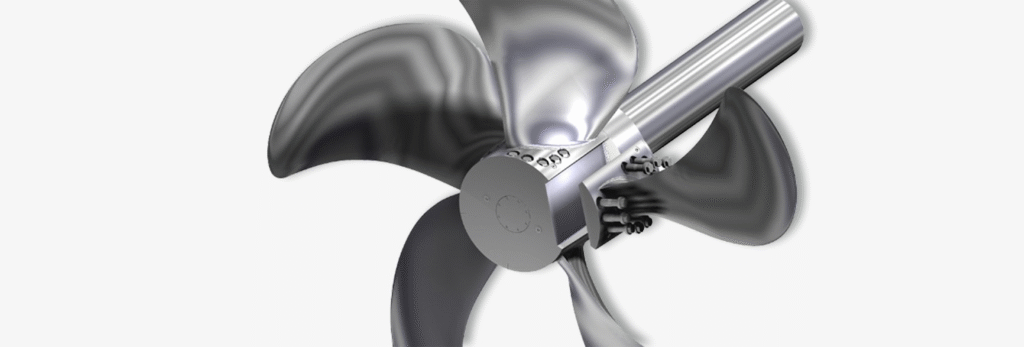

Today’s 5-axis CNC mills can make a contour of complex geometries with one setup, which is critical for marine propeller blades and intricate hull accessories. 5-axis machines have the capability of dynamic tilting of both the tool and the workpiece to obtain micron-level surface finishes and tight tolerances (as tight as 0.01 mm), which eliminates or minimizes post-machining refinements and maximizes hydrodynamic performance of components such as propellers and boss rings. Depending on how the tool path is generated and optimized using CAM (computer aided manufacturing) software, the cutter engagement, balance of material removal rates, and management of heat build-up are all affected while machining heat sensitive materials like aluminum 5083 or super duplex 2507 alloys which allows the operator to avoid work hardening or distortion of the machined part.

Precision Turning (Lathes)

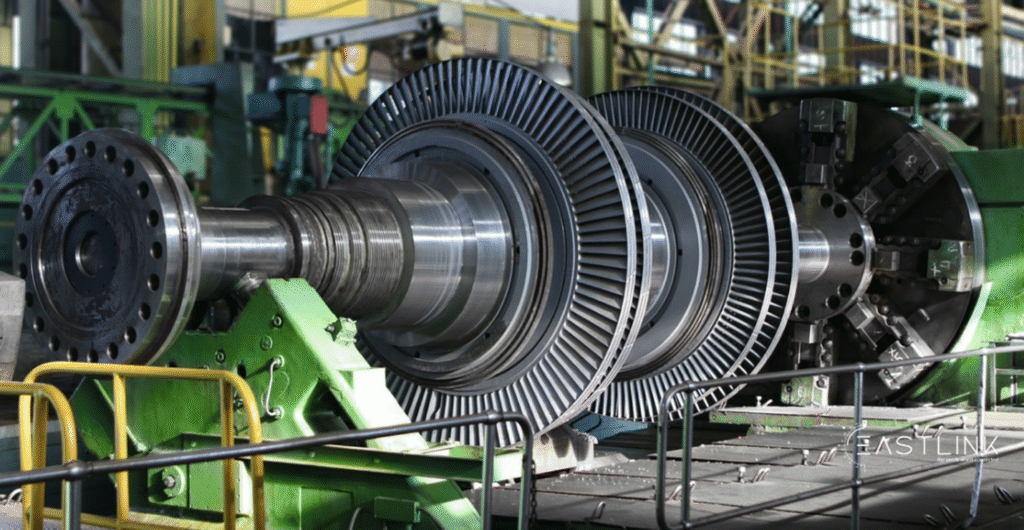

CNC turning centers with live tooling or sub spindle configurations can create high precision shafts, such as rudder stocks and propeller shafts, in a single chucking.

rotor: a long shaft machined with several disc stagesReference

Live tooling for multi-tasking operations allows for the ability to drill, mill, or tap rotary features with only a reposition between operations, and improves concentricity of features and reduces cycle times. Surface finishes of Ra < 0.8 µm are routine, and run-out tolerances can be held below 0.01 mm; this is critical for maintaining balanced rotation in high-speed thrust bearings and steering components.

Drilling and Tapping

Accurate hole making and fastener engagement are essential for reliable mounting of rudder stocks or attachment of fuel injector assemblies. Cobalt or carbide drill bits with split points are recommended with tough alloys such as 316L stainless steel, which minimize drilling walking. The pre-drilled holes are made following material-specific tap drill charts, often specified as 85 % of the major diameter for coarse threads. The ratio between major diameter (inside the thread) and the root diameter (bottom of the thread) improves average thread strength, and pre-drilled holes are usually provided for traces of torque specifications. CNC tapping cycles are either conventional or rigid tapping, and utilize synchronized peck tap methods to allow for chip evacuation and to minimize thread galling on the straying threads, delivering repeatability and good thread form and thread alignment for marine grade fasteners.

Surface Finishes

Electropolishing

An electrochemical method that takes away microscopic peaks and trapped contaminants from stainless steels and high-strength alloys, electropolishing increases corrosion resistance by re-establishing the metal's natural passive oxide film. It will also reduce surface drag; this is very important when the part is part of an underwater housing and as a lined propeller hub, all while it is held within tight limits (< 0.0001 - 0.0002" removal).

Laser Cladding

Laser cladding is an innovative process that deposits an overlay coating (wear- and/or corrosion-resistant coatings, including Ni-based alloys and stainless steel powders) to serve as a remedy for a worn surface or add value to an acceptable new part. In the marine repair shops, laser cladding is a process that can repair valve seats, bearing journals, and propeller shafts (all in one setup that produces very little scrap and lost time). The clad layers of the coating bond metallurgically to the surface of the substrate and will resist wear in a saline environment at very high stresses, as intended.

HVOF/PTFE Coatings

High-velocity oxy-fuel (HVOF) is a means of spraying dense ceramic or metallic coatings (WC-Co, TiC) to negate abrasive wear and cavitation. A subsequent layer of PTFE adds a layer that offers low-friction and non-stick properties, which reduce marine fouling of hull fittings and nozzle assemblies. Further, operating with laser texturing before PTFE application adds to the adhesion and erosion resistance of fuel-injector bodies as well as seals.

Critical metrics

Surface roughness (Ra) is the approximate average of the deviations for a machined surface's peaks and valleys (the metric measurement in microns). In the marine CNC parts, surface targets for an Ra ≤ 0.8 microns on shafts and sealing faces will produce a smooth surface with minimal turbulence and biofilm adhesion and potential mechanical wear. The combined finish target and expected outcomes balance the performance vs. cost, depending on target finishes of 0.4 microns for dynamic seals to a 3.2 micron finish for structural fittings.

Sacrificial Anode

Sacrificial anodes (generally made of zinc, aluminum, or magnesium) are attached to the hull fittings or shafts to protect the metal surfaces from corrosion through galvanic action. The anodes are electrically bonded to the component, corroding instead of the structural pieces, which remain intact. Corrosion rates are recorded so that the anodes are replaced when corrosion losses reach about 40% of the nominal weight to provide cathodic protection. It is common to include the provision for installing the anodes (such as tapped mounting holes) during CNC finishing operations, as this encourages installation without any modification or thinking. This simple and effective surface treatment can help increase service intervals and lower service costs for sailboats and other marine craft.

Benefits of CNC Machining in the Marine Industry

CNC machining offers a variety of advantages to make it an indispensable process in marine manufacturing today. First is precision and consistency; having tolerances of ±0.005 mm allows CNC to ensure that critical items like propeller shafts, rudder stocks, and injector housings will function as intended even under high stress situations. Second, CNC offers custom solutions; low volume and high complexity are key elements to CNC, allowing one-off or prototype marine parts to be fabricated easily without having to pay the cost of setting up to forge or cast parts. Decreased lead times are another advantage; CNC reduces the number of steps performed and allows for the reduction of human error; this is significant when making just-in-time repairs and outfitting vessels quickly. Lastly, CNC machining is scalable and can shift from prototyping to production without sacrificing quality, making it useful to shipbuilders, OEMs, and offshore equipment manufacturers.

Conclusion

The introduction of CNC machining has transformed the marine sector by offering micron-level precision, repeatable tolerances, and durable edge finishes able to withstand saltwater corrosion, biofouling, and extreme pressure. Propeller shafts and thrust bearings, bespoke hull fittings, and housing assemblies (to name only a few) are precision CNC processes that improve performance, reduce maintenance downtimes, and extend the service lives of components.

Incorporate advanced CNC solutions on your next marine project and improve lead times, design customizations, and scalable production. And, if you have a few minutes to spare, connect with seasoned CNC practitioners today to plan for sustainable vessel reliability, improved operational capacity, and stay ahead of the increasing competitive pressures in the maritime market.