When precision parts fail due to welding issues, production halts. Frustrated engineers face rework costs, delayed shipments, and potential customer dissatisfaction while management demands immediate solutions.

Effective welding defect repair involves systematically identifying the flaw type, evaluating its severity, and selecting appropriate correction methods based on material properties and component function. Proper documentation and preventive measures ensure long-term quality improvement while maintaining structural integrity.

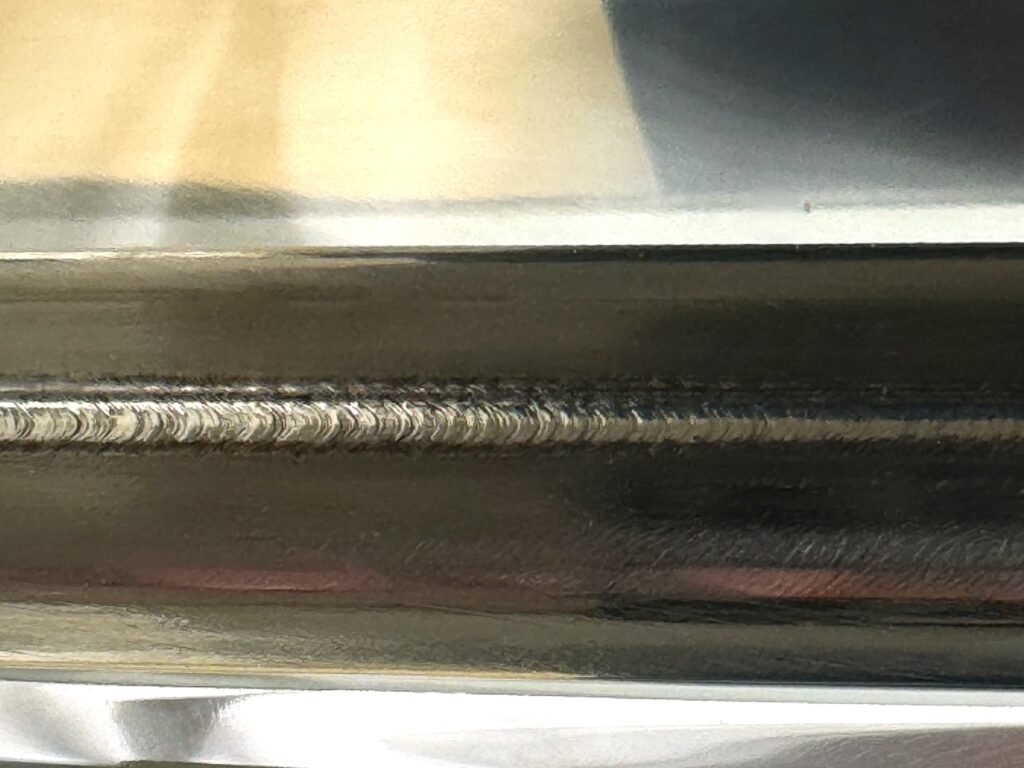

Welding defect repair on a CNC-machined component

In my years running a CNC machining facility, I've seen countless welding issues threaten project timelines and budgets. The difference between success and failure often comes down to having a structured approach to defect repair. Let me share what I've learned about effectively handling these challenging situations.

What Are the Most Common Welding Defects in Precision Manufacturing?

Production deadlines loom while quality control flags yet another batch with welding defects. Your team scrambles to identify issues as customers demand updates on their critical components.

The most common welding defects include porosity (gas bubbles trapped in the weld), cracks (both visible and microscopic), incomplete fusion, undercutting, and distortion. These typically result from improper technique, contamination, incorrect parameters, or material incompatibility during the welding process.

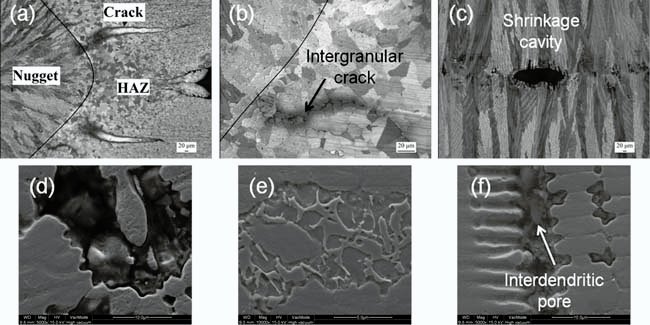

Microscopic view of welding defects

Welding defects in precision manufacturing vary significantly in severity and repair complexity. Porosity, perhaps the most frequent issue we encounter, presents as small holes or cavities within the weld metal. In aluminum alloy components, our standard acceptance criteria allow single pores under 1mm in diameter (maximum two pores per 100mm section) on non-critical surfaces. However, sealing surfaces, functional areas, and visible exterior welds must remain pore-free.

Cracks represent the most dangerous defect category, requiring immediate attention regardless of location. These fractures can propagate over time, potentially causing catastrophic failure. Incomplete fusion occurs when the weld metal fails to properly melt and flow into the base material, creating weak points. Undercutting, where a groove melts into the base material alongside the weld, reduces wall thickness and weakens the structure.

Distortion presents unique challenges in precision components, as thermal expansion during welding can pull parts out of tolerance. We've developed specialized fixturing techniques to minimize this effect, particularly for vacuum chambers where dimensional accuracy directly impacts functionality.

Our quality control system categorizes defects by severity:

| Defect Type | Acceptable Criteria | Required Action |

| Porosity | <1mm, max 2 per 100mm (non-critical) | Wind chisel removal and rewelding |

| Cracks | Zero tolerance | Complete removal and rewelding |

| Incomplete Fusion | Zero tolerance on critical surfaces | Excavation and rewelding |

| Undercutting | <0.5mm on non-load-bearing areas | Filler addition or mechanical repair |

What Decision Factors Should Guide Your Welding Repair Method Selection?

The defective components sit on your workbench as you weigh repair options. The wrong decision could compromise quality, waste materials, or miss delivery deadlines while pressure mounts.

Choose repair methods by considering defect type, location, component function, material properties, available equipment, operator skill level, and cost-effectiveness. Safety-critical parts require more conservative approaches, while cosmetic repairs permit broader technique selection.

Manufacturing engineer examining a welding defect

Selecting the optimal repair method requires balancing multiple factors. Material properties fundamentally dictate available options - what works for steel often fails with aluminum or exotic alloys. For instance, our approach to porosity in aluminum differs significantly from how we address the same defect in stainless steel components.

Component function serves as another critical decision factor. Parts subject to fatigue loading, like automotive suspension components, demand complete defect elimination and stress-relieving post-repair. In contrast, cosmetic or non-load-bearing elements might allow for less invasive repairs.

Access to the defect location often constrains repair choices. We recently faced a challenge with internal weld defects in a complex vacuum chamber. The limited access required specialized tooling and ultimately led us to develop a custom repair procedure combining mechanical removal and a modified welding technique.

Cost-benefit analysis must include:

| Factor | Considerations |

|---|---|

| Equipment requirements | Specialized tools vs. standard equipment |

| Downtime impact | Repair time vs. replacement time |

| Skill requirements | Standard operator vs. specialist technician |

| Quality assurance | Testing required to verify repair integrity |

| Long-term reliability | Expected service life after repair |

Our decision matrix prioritizes safety and function while recognizing business realities. For example, when repairing aluminum sailboat components, we might choose a more expensive repair method that preserves saltwater corrosion resistance over a cheaper alternative that would ultimately fail in marine environments.

When Should Rework Welding Be Applied vs. Mechanical Machining Solutions?

You discover defects in a critical batch with tight tolerances. Your team debates whether to break out the welding equipment or solve the problem through machining alone as the delivery clock ticks.

Apply rework welding when structural integrity and material properties must be fully restored. Choose mechanical solutions for cosmetic defects when heat-affected zones must be avoided or when precision fit is paramount. Consider hybrid approaches when neither method alone achieves the required outcomes.

Mechanical repair technique on a welded component

The choice between welding rework and mechanical solutions represents one of the most nuanced decisions in manufacturing repair. Welding inherently introduces heat that can alter material properties, create residual stresses, and potentially cause distortion. Meanwhile, mechanical solutions remove material, potentially weakening components or changing critical dimensions.

In our facility, we've established clear guidelines based on extensive experience. For crack repair in structural components, complete removal followed by proper welding remains the gold standard. The process typically involves grinding or machining a V-groove along the crack to ensure complete penetration during rewelding. For aluminum vacuum chambers, we've found that proper pre-heating and slow cooling dramatically reduce the risk of new defects during repair.

Mechanical solutions excel when dealing with minor surface imperfections or when the component cannot tolerate additional heat input. For precision-machined components with tight tolerances, welding repairs often necessitate subsequent machining to restore dimensions, essentially creating a hybrid repair process.

We recently developed a specialized approach for automotive components:

| Defect Type | Primary Method | Secondary Process | Verification |

|---|---|---|---|

| Surface porosity | Mechanical filling | Surface finishing | Visual/dye penetrant |

| Structural cracks | Complete rewelding | Stress relief | X-ray/ultrasonic |

| Incomplete fusion | Excavation and rewelding | Heat treatment | Load testing |

| Cosmetic flaws | Surface machining | Polishing | Visual inspection |

The key factor often comes down to the specific quality requirements. When full material continuity is essential, welding typically proves necessary. When dimensional accuracy takes precedence, mechanical methods often provide superior results.

How Can Advanced Repair Technologies Improve Quality Outcomes for Welded Components?

Traditional repair methods have failed on a high-value component with complex geometry. Your team needs innovative solutions as the customer threatens to take their business elsewhere if quality issues persist.

Advanced technologies like laser welding, friction stir repair, cold spray deposition, and ultrasonic impact treatment can significantly improve repair quality. These methods offer precise heat control, reduced distortion, and enhanced material properties compared to conventional techniques.

Laser welding repair technology

The landscape of welding repair technologies has evolved dramatically in recent years. In our facility, we've invested in several advanced systems that have transformed our repair capabilities. Laser welding represents perhaps the most significant advancement, allowing precise, localized repairs with minimal heat-affected zones. This technology has proven particularly valuable for thin-walled components and materials sensitive to thermal distortion.

Friction stir repair, while less common, offers remarkable advantages for certain aluminum components. By mechanically mixing materials without melting, this process avoids many traditional welding defects. We've successfully implemented this technique for repairing porosity in 6000-series aluminum sailboat parts, achieving superior strength compared to traditional TIG repair methods.

Cold spray technology provides a unique solution for building up material without significant heat input. For components where dimensional restoration is more important than full structural continuity, this approach offers considerable advantages. We recently used cold spray to repair a vacuum chamber flange with minor surface imperfections, avoiding the need for a complete replacement.

Complementary technologies enhance these advanced processes:

| Technology | Primary Benefit | Best Application |

|---|---|---|

| Laser welding | Minimal heat distortion | Precision components |

| Friction stir repair | Enhanced mechanical properties | Aluminum structural parts |

| Cold spray | No heat-affected zone | Dimensional restoration |

| Ultrasonic impact treatment | Stress relief | Fatigue-loaded components |

| Advanced NDT | Better defect characterization | Complex geometries |

Implementation of these technologies requires significant investment in both equipment and operator training. However, for high-value components or critical applications, the improved quality outcomes and reduced rejection rates typically justify the higher repair costs.

How Do Repair Methods Impact the Structural Integrity of High-Precision Components?

The repaired parts look perfect, but questions remain about their performance under load. Engineers worry about hidden weaknesses while management pushes to ship the components and maintain customer relationships.

*Repair methods can significantly affect a component's structural integrity through changes in microstructure, residual stress patterns, and mechanical properties. Proper procedure selection, qualified technicians, and comprehensive testing ensure repairs meet or exceed original specifications without compromising performance.8

Testing the structural integrity of the repaired welded part

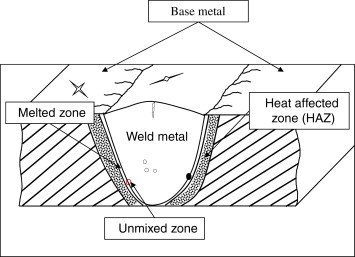

Understanding the metallurgical impact of repair processes is fundamental to ensuring long-term component performance. Every repair method introduces changes to the base material. Welding creates distinct zones with varying properties: the fusion zone, the heat-affected zone (HAZ), and the unaffected base material. Each zone behaves differently under load, potentially creating stress concentrators at its boundaries.

In our experience with high-precision vacuum chambers, improper repair procedures can compromise vacuum integrity even when welds appear visually perfect. We've developed specialized repair sequences that include pre-heating, controlled interpass temperatures, and post-weld heat treatment to minimize residual stresses and prevent microscopic leak paths.

For automotive components subject to cyclic loading, fatigue performance after repair demands special attention. Conventional wisdom suggests that repaired welds never fully match the properties of original, defect-free welds. However, we've found that carefully controlled repairs with proper post-processing can sometimes exceed original properties by relieving residual stresses from the initial fabrication.

Our quality assurance protocol for critical repairs includes:

| Test Method | Property Verified | Application |

|---|---|---|

| Radiographic testing | Internal defects | Structural welds |

| Ultrasonic testing | Crack detection | Thick sections |

| Dye penetrant | Surface flaws | All repairs |

| Hardness testing | Material properties | HAZ evaluation |

| Pressure testing | Seal integrity | Vacuum chambers |

| Tensile testing | Strength properties | Sample coupons |

The most successful repair approaches consider the entire component lifecycle. For instance, when repairing sailboat components exposed to marine environments, we must ensure that repair procedures don't create galvanic couples that could accelerate corrosion. Similarly, vacuum chamber repairs must maintain material properties that ensure consistent thermal expansion during operational temperature cycles.

Conclusion

Effective welding defect repair requires systematic assessment, appropriate method selection, and rigorous quality verification. By understanding defect characteristics and repair impacts, manufacturing engineers can restore component integrity while minimizing costs and production delays.