Struggling with shaping workpiece again and again, still not finding satisfactory results? It’s a common problem for many machinists. Yes, they daily struggle with uneven edges, large waste productions, and uneven edges. But you don’t have to worry, because in this blog, there’s a solution for your problem. Forming knife? Yes!

These knives in lathe tooling offer the perfect fix. They can shape even the complex profile in just one step. In this blog, we will cover what these knives are, how they work, types, materials, challenges, applications, and more. So, just stay connected!

1) What is a Forming knife

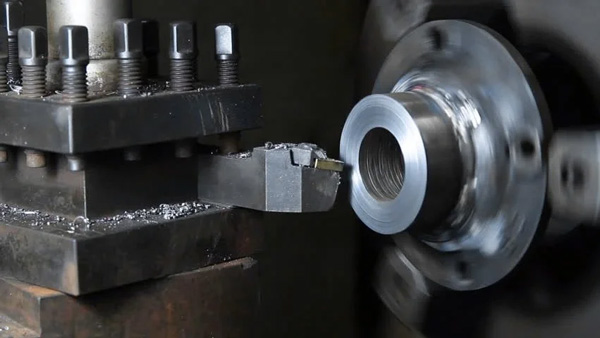

In lathe processing, a forming knife is a cutting tool that is used to shape the workpiece into the desired profile or contour. You know, other tools just reduce the diameter or length of the material. On the other hand, a forming knife can shape the complex parts like grooves, radii, or even decorative patterns in just one motion.

Actually, the shape of the metal lathe tool exactly matches the desired shape of the workpiece. So, when the lathe spins, it forms the knife contour in the exact shape.

Well, the main purpose of these knives is to save your time and give you uniform results. You don't have to perform the operation by passing your workpiece to multiple tools. Yes, a single knife can perform the whole task in one cut. Therefore, it is perfect for mass production where precision nd uniformity are the priority. For example, automotive, furniture, or metal component manufacturing.

Think of it as a cookie-cutter; when you press it into dough, it forms exactly the desired shape. Likewise, a forming knife just presses and cuts the rotating workpiece into the required design. Therefore, if you want to make repeated profiles (like threads, tapers, or ornamental edges), then a forming knife is the best tool.

2) Working Principle & Geometry

The working principle of a form-fitting knife is not very complex; it is simple but precise. What happens is that the workpiece rotates on the lathe, and the forming knife slowly comes toward it. The forming knife has exactly the same pattern as is required for the workpiece.

After the knife contacts the materials, it starts cutting and removing the material. And, the knife does it until the surface of the workpiece becomes exactly the same as the tool.

It is worth discussing that the contact of the knife with the workpiece depends upon the geometry of the tool. Geometry will decide how smooth and accurate the contact wi be, and it will cut. There are some geometries to consider.

- Profile shape or contour: Well, it is the actual design that you want on the workpiece. This design is exactly built into the knife. This design will determine what your finished part will look like.

- Nose radius: The tip of the knife is usually round, which helps create smooth transitions between surfaces. Moreover, it will prevent sharp corners that are not good for the part. Yes, sharp corners can weaken the part.

- Lead angle, approach angle, and exit angle: Proper angles for cutting can't be ignored. Yes, these angles have the charge to control how the tool enters and leaves the cut. If there were a proper angle, it would reduce cutting forces, vibration, and tool wear.

- Clearance angles (side and trailing): These tool angles for cutting are also very important. They make sure that only the cutting edges of the knife touch the workpiece. It prevents friction and rubbing that can otherwise affect the surface of the workpiece.

With the rotation of the lathe, the tool traces the shape on the rotating surface of the workpiece. So, to get the precision and smoothness in the final part, the geometry of the tool should exactly match the design. It will ensure better results and repeatable shaping every time.

3) Types and Configurations of Forming Tools

To meet different machining needs, forming knives are available in different types and configurations in the market. Selection can vary depending on the complexity of the design, the production volume, and the material of the workpiece. In this section, we will discuss some main types of forming knives.

a) Integral or solid forming tools

These forming joints are usually made from a single piece of material. They are usually made from high-speed steel or carbide. As these tools are solid, they offer good strength and stability. Generally speaking, they are usually used for creating simple shapes or for low-production volumes. For example, if you want to create some identical grooves or a metal rod, solid forming is the solution.

b) Insert or tipped forming tools

These tools have detachable cutting heads (inserts)that are fixed to a holder. These inserts are usually made of carbide or ceramic for high wear resistance. When u feel the cutting edge is becoming dull, you can simply replace it with a new one, and you don’t have to replace the whole tool. So, it reduces the cost of the cutting operation.

c) Multi-edge form tools

These tools are very easy to use. It has several identical cutting edges arranged in sequence. When one tool becomes raw, you can simply rotate the tool and use the new one. It saves your time, and it is really helpful in industries where thousands of identical parts are produced daily.

d) Combination form tools

These tools have multiple shapes in one tool. For example, a single tool can contour and chamfer at the same time. So, it will save your time, and you can get your desired part in a single pass.

e) Special designs

Some knives are specific to specific tasks. For example, internal profiles, radius forming, or convex and concave shapes. The internal profile tool and radius forming tool will create smooth, curved edges.

Well, each type of forming tool is just designed to boost precision, efficiency, and the durability of the workpiece.

4) Materials and Coatings for Forming Knives

The material and the coating on the forming knife directly affect its performance. Therefore, it is really important to get a know-how of the right combination of material and coating so that you may get cleaner cuts, longer tool life, and higher efficiency.

Tool substrate materials

High-Speed Steel (HSS): High-speed steel is the most common material being used for forming knives. It offers good strength and has the ability to handle an average cutting speed. The best thing is that it can be sharpened easily and is best for shaping general items, especially when the workpiece is made of softer metals like aluminium or brass.

Carbide or cemented carbide: Well, these are harder than high-speed steel. They have the ability to cut the workpiece at high speed while maintaining sharpness. If the target material is of stainless steel or cast iron, carbide-forming knives are the best. Yes, because they can maintain their cutting edges even at high temperatures.

Ceramic, CBN, and PCD: Okay, these types of forming knives are used for special types of applications. For example,

- Ceramic tools are best for hard metal workpieces and high-speed operations.

- CBN (Cubic Boron Nitride) is excellent for hardened steels.

- PCD (Polycrystalline Diamond) is suitable for non-ferrous metals and composites.

No doubt these materials are expensive, but they offer superior precision and tool life.

Coatings and surface treatments

Coatings like TiN (Titanium Nitride), TiAlN (Titanium Aluminium Nitride), and DLC (Diamond-Like Carbon) are applied on the forming knives to enhance performance. The coating is really necessary as it helps reduce friction, improve heat resistance, and prevent wear.

For example, if you coat the forming knife with TiAlN, it will help keep it cool, while DLC coating is popular for a smooth surface that minimises material sticking.

5) Setup and Mounting in Lathe

Setting up and mounting a forming knife is a really important step. If you don’t do it efficiently, it can affect the performance of your work. Even a small mistake can lead to wrong dimensions and poor surface finish. So, you have to be careful while setting up and mounting a forming knife. Have a look at the steps below;

- Clean the workspace: Before starting the operation, just clean the lathe bed, tool post, and holder to remove any dirt, oil, or chips. To ensure the proper alignment, cleanliness is really necessary.

- Secure the tool holder: The holder should be fixed tightly. If it is not stable, it can move during cutting and cause instability in operation.

- Mount the forming knife correctly: The forming knife should be properly aligned on the holder. It should be at the centre of the workpiece. You know, if the height is incorrect, it can cause chatter, tool breakage and uneven cutting.

- Check alignment: Keep in mind that the front face of the tool should be perpendicular to the axis of the workpiece. To check it, you can use a ruler or a dial indicator.

- Perform a trial run: At first, just run the lathe at a slow speed. Observe the contact between the tool and the workpiece. There should be no vibration or any type of noise; the work should be smooth.

- Adjust feed rate and speed: Try to use a moderate cutting speed. Too high a speed can cause profile distortion or even damage to the tool.

- Use lubrication or coolant: It is really important to apply any coolant to the forming knife and workpiece. It will help reduce heat, stickiness and will give the surface a fine look.

6) Challenges, Errors & Corrections

i) Tool chatter

When the forming knife vibrates during cutting, it can create uneven surfaces. It is due to weak rigidity, poor clamping, or high feed rate

Correction: Just tighten the tool and align the forming knife properly. Moreover, try slowing down the cutting speed and ensuring the setup is stable.

ii) Profile distortion

It also happens that the final shape does not match the desired profile. It may happen due to tool misalignment, incorrect geometry, or uneven tool pressure.

Correction: To fix it, check the tool height and again align it carefully. Moreover, check if the cutting tool has the exact shape as required.

iii) Excessive tool wear

You know, when you use the forming knife on a hard tool, it can lose its sharpness. And, it can reduce the surface quality and accuracy of the final product.

Correction: To avoid this issue, just use coolant and try to use cated tools, such as TiN or TiAlN, and lower the feed rate.

iv) Poor surface finish

If the cutting edge of the forming knife were dull or the speed of the cutting were too high, it would cause a rough or uneven finish. Apart from this, this issue can also appear due to vibrations.

Correction: To handle this issue, sharpen the tool immediately, just slow down the speed of cutting, and keep an eye on other cutting conditions.

v) Heat buildup

Due to continuous operation, the temperature can rise and damage the tool edge and cause the material to stick.

Correction: What you have to do is to maintain the flow of coolant, cutting speed, and feed to keep the temperature under control.

7) Applications of Forming Knives

Industries that require accurate shapes, smooth surfaces, and consistent profiles use forming knives widely. With the help of a forming knife, they can produce very intricate designs in just one run. It saves both their time and effort.

- Automotive Industry: To shape the parts like shafts, gears, and bushings, forming knives are used. You know these components require an accurate profile and finishes to perform well in engines and mechanical systems. Therefore, forming knives are really vital in the automotive industry.

- Woodworking Industry: In furniture and decoration work, you can add detailed mouldings, grooves, and patterns with the help of forming knives. For example, you can create decorative edges on table legs or door frames using specially shaped forming knives.

- Aerospace Industry: The applications of forming knives in the aerospace industry can’t be denied. As these knives can cut hard materials like titanium and aluminium alloys, they are of quite importance. They help reduce the weight of the part while providing tight tolerances, which are the priority for aircraft safety and reliability.

- Electronics and Precision Engineering: Forming knives have also made their place in electronics. For metal forming small and complex components, like connectors and metal housings, forming knives are used. For the perfect fitting of tiny electrical parts, efficiency is paramount.

- Tool and Die Making: To create precise grooves, cotours, and radii, forming knives are the best tool ever. With them, you can form high-quality parts of every design and size.

- Plastics and Composites Machining: Forming knives are not suitable just for metals. Yes, they can also be used to shape plastic and composite materials without cracking or damaging them.

8) Advances & Trends in Forming Knives

With the modern manufacturing needs, the field of forming knives is evolving greatly. These knives have become more precise, efficient, and reliable than ever before because of new materials, digital tools, and advanced coatings. Let’s discuss;

- Advanced Materials

These days, forming knives are being prepared from high-quality and high-performance materials, like carbide, CBN, and PCD. You know these materials have high heat stability, heat resistance, and stability towards high cutting speeds.

- Innovative Coatings

Nowadays, coatings of TiAlN, AlCrN, and DLC have become standard. These coatings help in controlling the heat, reducing friction, and improving surface finish. With these coatings, forming knives can work efficiently even at higher cutting speeds.

- CNC and CAD/CAM Integration

The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) allows precise modelling of tool geometry before production. This ensures that the forming knife perfectly matches the desired profile and reduces setup time.

- 3D Simulation and Digital Inspection

You know everything is becoming smarter day by day. Likewise, in forming knife operations, advanced simulation tools can predict the quality of permanence and potential errors. Therefore, it offers the exact required specification.

9) Conclusion

To achieve precision and efficiency in lathe processing, firning knives are of utmost importance. If you set up the system correctly, choose materials wisely and focus on coatings, you can create even complex designs in a single step. Moreover, modern advancements like CNC integration and advanced coatings have made forming knives more durable and accurate.

So, whether you are doing metalworking, woodworking, or aerospace, forming knives can help you shape any material with speed, consistency, and outstanding performance.