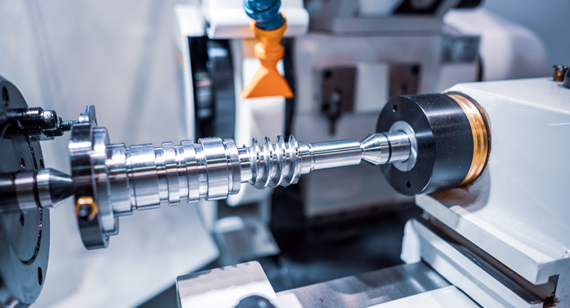

CNC production has transformed modern manufacturing, making it possible to deliver complex, high-precision parts at scale. Whether it’s aerospace components, automotive parts, or medical devices, CNC machining enables consistent replication of designs across large batches. But with this efficiency comes risk; if even a small error slips through at the start, it can multiply across hundreds or thousands of parts, leading to costly rework or scrap.

This is where First Article Inspection (FAI) steps in. FAI is a structured verification process carried out on the very first part, or a small sample, before mass production begins. By comparing the machined part against engineering drawings, material specs, and finish requirements, manufacturers can confirm that the setup is correct and the process is capable of delivering compliant parts. In simple terms, FAI acts as an early checkpoint, catching problems before they snowball.

Catching errors early doesn’t just prevent financial losses; it builds confidence with customers, ensures compliance with industry standards, and strengthens a manufacturer’s reputation for quality. In this article, I’ll walk you through the fundamentals of FAI in CNC production, highlighting its cost-saving potential, the types of inspections involved, the role of GD&T in ensuring accuracy, and the best practices that make FAI an essential tool for modern batch manufacturing.

What is First Article Inspection (FAI)?

In manufacturing, especially in CNC production, every new part starts with a critical question: Does the very first piece meet the requirements exactly as intended? This is where First Article Inspection, or FAI, comes into play. At its core, FAI is a formal process of verifying that the first part produced in a batch matches all the engineering drawings, material specifications, and finish requirements before the rest of the production continues. It acts as a safeguard, ensuring that errors are identified early and corrected quickly, rather than being repeated across an entire lot.

Purpose of FAI in Manufacturing

The primary goal of FAI is to confirm that the production process is set up correctly and that machines, tools, and operators are aligned to deliver accurate results. In CNC production, even the smallest variation in tooling, material setup, or machine calibration can lead to deviations. By conducting a thorough inspection on the very first piece, manufacturers can validate:

- Dimensional accuracy: Does the part fall within the tolerances specified on the drawing?

- Material compliance: Is the correct grade of steel, aluminum, titanium, or plastic being used?

- Surface finish and treatment: Does the coating, anodizing, or polishing meet functional and cosmetic standards?

This early validation is not only about catching mistakes but also about proving that the production system is capable of delivering quality consistently.

FAI vs Regular Quality Checks

It’s important to distinguish FAI from the regular quality checks performed during production. Standard inspections are often sampling-based and conducted throughout the process to ensure ongoing consistency. FAI, however, is more comprehensive and typically occurs before full-scale production starts. While a quality check might involve measuring a handful of features, FAI usually requires a complete verification against the engineering drawing, covering critical dimensions, material properties, finishes, and sometimes even functional tests.

Think of FAI as a one-time deep dive, while regular checks are ongoing, spot assessments. Both are necessary, but FAI provides the foundation that ensures later checks are based on a process that has already been proven reliable.

When FAI is Performed in Production

FAI is most commonly performed in three scenarios:

- At the start of a new production run, whenever a new part is being manufactured, the first article is inspected before mass production begins.

- After engineering changes – If there’s been a revision in design or tolerance, FAI confirms that the updated requirements are correctly implemented.

- When processes or suppliers change – A new CNC machine, a different batch of raw material, or a change in tooling can introduce variability. FAI ensures that these changes haven’t compromised quality.

In industries such as aerospace, defense, and medical device manufacturing, these scenarios are not optional; they are mandated by standards like AS9102 or ISO guidelines.

Beyond Cost Savings: Broader Benefits of FAI

While one of the clearest advantages of FAI is preventing costly rework and scrap, the benefits stretch far wider:

- Quality Assurance: By verifying compliance early, FAI raises confidence that subsequent parts will meet customer expectations.

- Customer Trust: Clients are reassured when they know the first article has been rigorously checked and approved, making them more likely to return with repeat orders.

- Compliance with Standards: For industries bound by strict quality frameworks, FAI is not just best practice; it’s a requirement that ensures traceability and accountability.

- Internal Process Improvement: FAI often uncovers weaknesses in setup, programming, or operator training. Correcting these improves overall efficiency and reduces long-term errors.

In this way, FAI serves as both a quality gate and a process improvement tool. It gives manufacturers the chance to validate, adjust, and refine before defects multiply.

Cost-Saving Benefits of FAI in Batch Manufacturing

In CNC batch production, profitability depends not only on precision but also on efficiency. Every wasted hour on a machine, every scrapped part, and every rework order chips away at margins. This is why First Article Inspection (FAI) plays such a crucial role; it prevents minor setup errors from escalating into large-scale losses. By dedicating time to a single thorough inspection at the beginning of production, manufacturers protect themselves from costly mistakes later on.

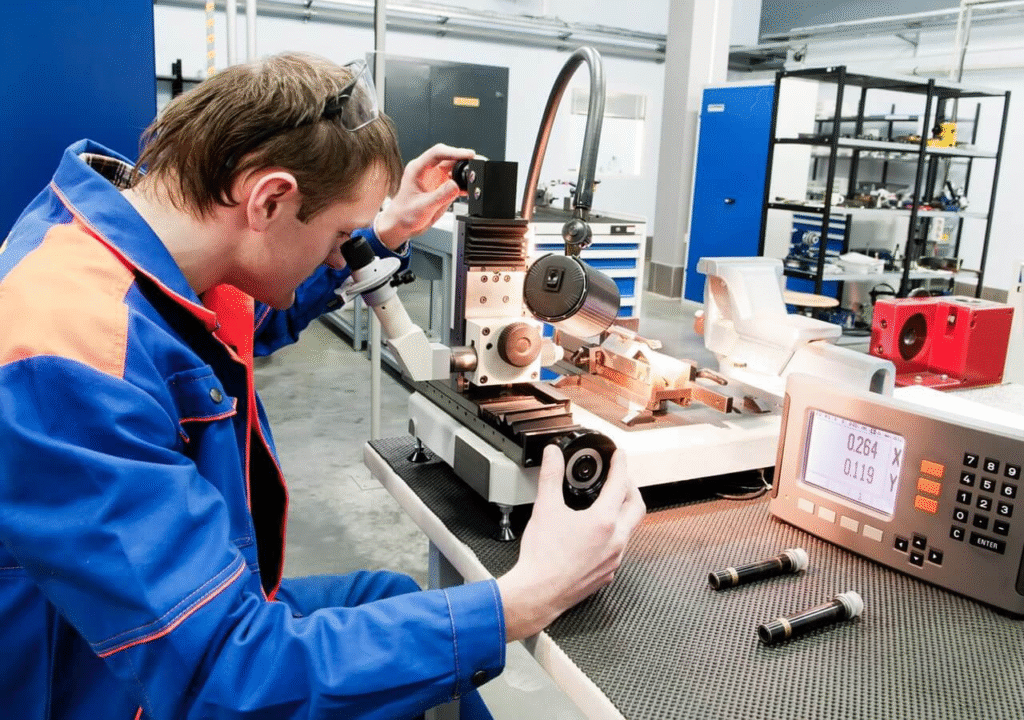

First Article Inspection (FAI) in Manufacturing

Detecting Errors Before They Multiply

One of the biggest cost-saving advantages of FAI lies in early error detection. When a new program is loaded into the CNC machine, or when tools and fixtures are changed, there is always a chance of error. A single incorrect offset, tool wear issue, or misinterpreted tolerance can lead to dozens, or even hundreds, of defective parts if left unchecked.

- In aerospace manufacturing, for example, a miscalculated hole position might render an entire batch of precision brackets unusable.

- In automotive production, an out-of-spec bore diameter can affect assembly fit, forcing mass recalls or expensive rework.

By inspecting the first article thoroughly, manufacturers ensure that mistakes are identified when they only affect a single piece, rather than an entire run. This upfront step transforms potentially large-scale waste into a single controlled correction.

Preventing Large-Scale Defects Across Batches

Batch production thrives on repeatability. Once the machines are set, they can produce hundreds of identical parts with little variation. But this efficiency also means that errors repeat consistently if they aren’t caught early. FAI acts as a gatekeeper; no mass production proceeds until the first part is verified.

Imagine producing 1,000 machined housings with a misplaced thread or a misaligned pocket. Without FAI, the issue would only surface during final assembly, forcing an entire lot into quarantine. The time and cost of re-machining or scrapping such volumes far outweigh the minimal time investment in conducting a first article check.

Reducing Material Waste and Labor Costs

Materials used in CNC production, such as titanium, stainless steel, or engineering-grade polymers, are rarely cheap. Scraping multiple defective parts results in wasted raw stock, machining time, and operator effort. FAI helps minimize this waste by verifying compliance at the very beginning.

- Material cost savings: Scrap is reduced because nonconforming parts are detected immediately.

- Labor efficiency: Operators spend less time troubleshooting defects later, focusing instead on productive machining.

- Machine availability: Machines remain free for profitable production rather than being tied up correcting errors.

This translates into leaner operations where both time and resources are used effectively.

Lowering the Risk of Customer Penalties and Contract Losses

In industries like aerospace, defense, or medical devices, contracts often include strict quality clauses. Delivering nonconforming parts not only damages reputation but can also trigger financial penalties, warranty claims, or even loss of the contract. By catching deviations in the first article, manufacturers avoid shipping defective products and protect themselves from downstream liabilities.

- Penalty avoidance: Prevents fines tied to late deliveries or nonconforming shipments.

- Reputation safeguard: Builds a track record of reliability, encouraging long-term contracts.

- Customer retention: Demonstrates commitment to quality, which is critical in high-value, repeat business sectors.

The financial cost of losing a customer relationship often dwarfs the expense of performing FAI, making it a strategic investment in customer trust.

Streamlining Continuous Improvement and Process Efficiency

FAI doesn’t just protect against immediate losses; it also provides valuable data for continuous improvement. Every first article inspection generates a detailed record of measurements, deviations, and corrective actions. Over time, these records help identify recurring issues in tooling, programming, or setup, allowing teams to refine processes and reduce costs permanently.

- Root cause analysis: FAI data reveals systemic weaknesses in machining or inspection practices.

- Process refinement: Adjustments made early prevent chronic waste in future runs.

- Long-term savings: Eliminating recurring defects improves throughput and reduces hidden costs like downtime and machine wear.

Instead of being a one-time cost, FAI becomes a continuous improvement tool—feeding insights back into production for ongoing efficiency gains.

Real-World Examples of Cost Avoidance

Practical scenarios highlight how FAI saves money in measurable terms:

- Case 1: Aerospace Brackets – A supplier avoided scrapping a $50,000 titanium batch when FAI caught an incorrect chamfer dimension on the very first part. A simple program correction prevented a massive loss.

- Case 2: Medical Device Components – In orthopedic implant production, surface roughness outside tolerance was detected early. Instead of scrapping hundreds of parts, the finishing process was adjusted immediately.

- Case 3: Automotive Shafts – A dimensional error in spline depth was identified during FAI. Without the inspection, over 5,000 shafts would have been defective, leading to warranty claims and customer dissatisfaction.

These examples underline the practical impact: FAI is not a theoretical quality step but a tangible cost-saving mechanism.

Return on Investment (ROI) Perspective

Some manufacturers hesitate to allocate resources to FAI, viewing it as an added step. But when examined through an ROI lens, the benefits far outweigh the costs. The expense of a single inspection, often less than an hour of machine time and inspector effort, is negligible compared to the potential losses from scrapping or reworking an entire batch.

- Small investment: A detailed FAI might require one inspector and one machine for an hour.

- Massive savings: Preventing defects in even a 100-part batch can save thousands in material, machining, and labor costs.

- Customer retention: Delivering defect-free parts the first time strengthens supplier relationships, reducing the hidden cost of losing repeat business.

In essence, FAI is a financial safeguard. It transforms quality assurance into a measurable business advantage, protecting both margins and reputations.

Key FAI Checks: Dimensional, Material, and Finish

A First Article Inspection is only as strong as the checks it covers. In CNC production, a part is rarely judged by a single measurement; it must meet dimensional, material, and surface finish requirements all at once. Skipping or rushing through these checks defeats the purpose of FAI, as a defect in any one area can compromise the functionality, compliance, or aesthetics of the final product. Each of these three areas, dimensions, materials, and finishes, plays a distinct role in ensuring that the manufactured part is truly production-ready.

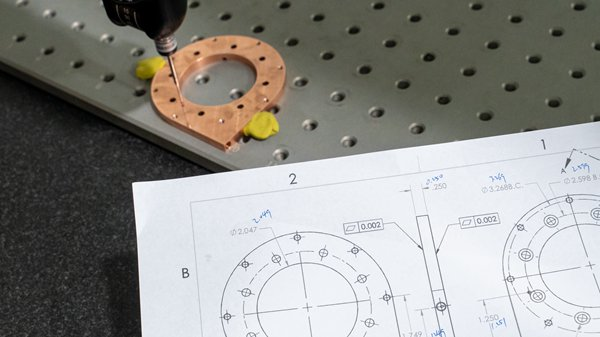

Dimensional Checks: Verifying the Geometry

The foundation of FAI lies in dimensional verification. Even if the correct material and finish are used, a part with dimensions outside of tolerance is effectively useless. In CNC machining, dimensional accuracy ensures proper assembly, fit, and performance under load.

To achieve this, inspectors rely on a combination of basic and advanced tools:

- Handheld instruments such as calipers, micrometers, and height gauges for quick, precise measurements of straightforward features.

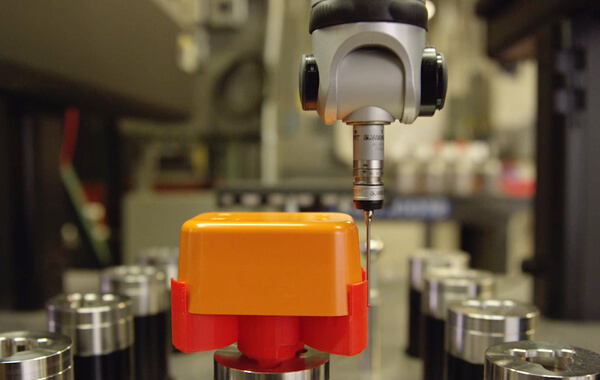

- Coordinate Measuring Machines (CMMs) for high-accuracy probing of complex geometries and GD&T features like concentricity, true position, and flatness.

- Optical and laser-based systems are used for non-contact measurement of delicate thin-walled parts.

Dimensional checks confirm whether the machined part matches the engineering drawing exactly.

Common Dimensional Errors and Their Consequences

Dimensional errors may arise from tool wear, incorrect offsets, or programming mistakes. For example:

- A slightly oversized bore may cause bearing misalignment.

- A shallow pocket depth may prevent proper assembly of mating components.

- Misplaced holes can throw off an entire assembly, leading to rework of multiple parts.

In industries like aerospace, even a 0.05 mm deviation can result in part rejection. By catching these discrepancies during FAI, manufacturers save themselves from high-stakes batch rejections later.

Material Verification: Confirming the Core Properties

Beyond dimensions, the material itself must be correct. A part machined perfectly to size is still nonconforming if the wrong grade of metal or polymer is used. Material verification during FAI ensures that the raw stock matches the specified engineering requirements.

This process often includes:

- Certificate of compliance review – Checking supplier-provided mill certificates to validate alloy composition.

- Hardness and tensile testing – Confirming mechanical strength aligns with design intent.

- Traceability checks – Ensuring that every part can be linked back to its raw material batch.

Importance of Material Verification

The stakes of using incorrect material are high. Consider the consequences:

- Mechanical failure – A component designed for high stress may crack or deform prematurely.

- Non-compliance – Aerospace or medical industries demand strict adherence to standards. Using the wrong material can result in regulatory violations.

- Financial loss – Even if the part fits dimensionally, nonconforming materials mean the entire batch is scrapped, wasting both machining and raw material costs.

Verifying material properties at the very first stage ensures that the production line never processes stock that is doomed to fail.

Surface Finish and Treatment Checks: Ensuring Function and Aesthetics

Once dimensions and materials are confirmed, attention turns to surface finish and treatments. Surface characteristics may seem secondary, but in many industries, they are just as critical as size or strength.

Surface checks typically involve:

- Roughness measurements (Ra, Rz) using profilometers to confirm that finishes meet functional requirements such as bearing surfaces or sealing faces.

- Visual inspections for coatings, anodizing, or plating uniformity.

- Adhesion and thickness checks for treatments like paint, powder coat, or electroplating.

How Finish Errors Affect Performance and Cost

A poor surface finish can cause both functional and cosmetic issues:

- Functional issues: Excessive roughness on sealing surfaces may lead to leaks. Incorrect plating thickness may cause premature corrosion.

- Assembly problems: High-friction surfaces may increase wear during assembly or operation.

- Aesthetic concerns: In consumer-facing products, scratches, discoloration, or uneven coatings damage brand reputation.

Each of these failures results in returns, warranty claims, or costly reprocessing. FAI ensures that finish standards are verified at the outset, avoiding downstream surprises.

FAI for Injection Molded Parts

The Combined Importance of All Three Checks

Dimensional accuracy, material verification, and surface finish are not independent silos; they work together to define part quality. A defect in any one of them can render a part unacceptable. For this reason, FAI includes all three checks in a structured way:

- Start with dimensions – Confirm geometry matches the drawing.

- Verify material – Ensure the right substrate supports the design.

- Inspect finish – Validate the last layer of function and presentation.

By approaching inspections in this sequence, manufacturers create a complete picture of part conformity. This comprehensive strategy is what makes FAI so effective in preventing costly errors before batch production begins.

GD&T and Inspection Consistency

In CNC production, accuracy is not just about measuring the right numbers; it’s about interpreting design intent correctly. Traditional dimensional drawings can sometimes be ambiguous, leaving room for misinterpretation between designers, machinists, and inspectors. This is where Geometric Dimensioning and Tolerancing (GD&T) provides clarity. By defining allowable variations in form, orientation, and location, GD&T ensures that everyone, engineers, machinists, and quality teams, shares the same understanding of what “within tolerance” really means.

Why GD&T Matters in Modern CNC Production

The complexity of today’s parts makes simple linear tolerances insufficient. A hole might be the correct size, but if it’s off-position by even a fraction of a millimeter, the entire assembly could fail. GD&T addresses these issues by specifying requirements in a way that reduces subjectivity.

- Designers use GD&T to communicate functional intent instead of just numeric dimensions.

- Machinists program and set up machines with precise guidelines for alignment, concentricity, and flatness.

- Inspectors gain a standardized framework for verifying whether a part truly meets functional needs.

Without GD&T, inspection results often vary depending on who measures and how they interpret the drawing. With GD&T, inspection becomes consistent, repeatable, and less prone to disputes.

Basics of GD&T: The Building Blocks

To understand GD&T’s role in inspections, it’s useful to look at its main categories of control. These symbols and callouts form the “language” of precision engineering:

- Form controls – Define shape accuracy (flatness, straightness, roundness, cylindricity).

- Orientation controls – Govern how features are angled or aligned (parallelism, perpendicularity, angularity).

- Location controls – Specify exact positioning (true position, concentricity, symmetry).

- Profile controls – Manage the contour of surfaces (profile of a line, profile of a surface).

Each symbol provides an unambiguous expectation for how the part must perform in the real world, not just how it should measure with a caliper.

CNC Machining: The Fundamentals of GD&T and Geometric Dimensions

How GD&T Reduces Interpretation Errors

One of the hidden costs in manufacturing is inconsistent interpretation. For example, a drawing that says “±0.1 mm” for hole position might be read differently by two inspectors depending on where they measure from. GD&T solves this problem by:

- Defining datums, reference points, or surfaces that serve as the foundation for all measurements.

- Establishing tolerance zones, clear geometric boundaries where a feature can exist and still be acceptable.

- Providing functional context, ensuring that parts fit together and work as intended, even if individual dimensions vary slightly.

This clarity prevents back-and-forth arguments between suppliers and customers, saving both time and money.

Examples of GD&T in Action

Several GD&T controls are especially valuable during FAI because they directly affect assembly performance:

- Positional tolerances: Ensure holes and slots are located precisely, critical for fasteners and alignment pins.

- Concentricity: Keeps rotating components like shafts and bearings balanced, preventing vibration and premature wear.

- Perpendicularity: Guarantees that mating surfaces align correctly, avoiding assembly stress or leaks in sealed joints.

- Flatness and parallelism: Essential for mounting surfaces, ensuring even load distribution and stability.

These examples highlight how GD&T links inspection directly to part functionality rather than abstract numbers.

Standardizing Inspections Across Operators and Shifts

In batch manufacturing, multiple inspectors or operators may check parts over different shifts. Without GD&T, each person might measure slightly differently, introducing inconsistency. GD&T eliminates this variability by providing a single interpretation standard.

- Operators: Know exactly where and how to measure.

- Inspectors: Apply consistent tolerance zones across all checks.

- Auditors and customers: Gain confidence in the repeatability of inspection results.

This standardization builds trust in the process and ensures that every part is judged fairly, regardless of who inspects it.

The Business Benefits of GD&T in FAI

Adopting GD&T in First Article Inspections goes beyond technical accuracy—it delivers measurable business benefits:

- Fewer disputes: Clear acceptance criteria reduce disagreements between customers and suppliers.

- Improved efficiency: Inspectors spend less time debating results and more time validating parts.

- Traceability: Documentation linked to GD&T symbols provides transparent evidence of compliance.

- Reduced scrap and rework: By aligning inspections with functional intent, GD&T minimizes unnecessary rejections.

Ultimately, GD&T transforms FAI from a subjective check into an objective validation process, aligning engineering, production, and quality control under a common standard.

FAI Reporting and Documentation

Performing a First Article Inspection is only half the job. The other half lies in documenting the results clearly, accurately, and in a way that creates traceability for future audits or customer reviews. A well-prepared FAI report serves as both proof of compliance and a reference point for continuous improvement. Without proper documentation, even the most thorough inspection loses much of its value, because there is no evidence to confirm that the part met all requirements at the start of production.

First Article Inspection Reports

The Structure of an FAI Report

An FAI report is not just a collection of measurement notes. It follows a structured format that ensures all critical information is captured. At a minimum, a report typically includes:

- Part identification – Part number, revision level, and drawing references.

- Supplier details – Manufacturer’s name, lot number, and date of inspection.

- Measured values – Actual dimensions compared against nominal values and tolerances.

- Material and certification data – Material grade, heat lot, and compliance certificates.

- Finish and treatment confirmation – Verification of surface roughness, plating, coating, or anodizing.

- Inspector approvals – Signatures and dates from the responsible quality personnel.

This structure ensures that the report provides a complete picture, covering every critical aspect of the inspected part.

What Information is Typically Included

Beyond the basic structure, reports often include detailed breakdowns that add depth and traceability:

- Ballooned drawings: Each dimension or feature on the drawing is numbered, linking directly to a measurement entry in the report.

- Deviation records: Any dimension outside tolerance is flagged, with corrective actions or justifications noted.

- Special requirements: If the part is subject to regulatory or customer-specific standards (e.g., AS9102, ISO 9001), those requirements are cross-referenced.

- Functional notes: Some reports also include context on how deviations may or may not impact function.

These elements make the report not only a compliance document but also a communication tool between supplier and customer.

The Importance of Documentation for Traceability

Traceability is one of the most critical functions of FAI documentation. In industries such as aerospace and medical devices, the ability to trace a part back to its material lot, machine settings, and inspection results is non-negotiable. Good documentation:

- Supports audits: External auditors can quickly confirm compliance.

- Protects liability: If a failure occurs, documented proof of initial conformity limits supplier exposure.

- Strengthens relationships: Customers are more likely to trust a supplier who provides detailed, professional reports.

Without documentation, disputes over responsibility can arise, often costing more than the inspection itself.

Digital vs Paper-Based FAI Reports

Traditionally, FAI reports were paper-based, with hand-written entries and physical storage. While still used in smaller shops, this method is prone to errors and difficult to manage over time. Modern manufacturers increasingly adopt digital reporting systems for greater accuracy and efficiency.

- Paper-based reports: Simple to create but harder to store, retrieve, and audit. Prone to transcription errors.

- Digital reports: Allow automated data entry directly from CMMs or measurement devices, reducing human error. Easily searchable and shareable across departments and with customers.

Advantages of Digital FAI Reports

The shift to digital brings multiple benefits:

- Speed: Automated data import shortens reporting time significantly.

- Accuracy: Reduces manual entry errors.

- Integration: Digital reports can connect with ERP or quality management systems.

- Accessibility: Reports are easier to share with global customers or regulatory bodies.

For companies managing high volumes of parts or working in highly regulated industries, digital reporting is quickly becoming the standard.

FAI Reports as Living Documents

A final point often overlooked is that FAI reports are not static. They can serve as reference documents for future production runs, helping manufacturers identify recurring issues or evaluate process improvements. By reviewing past reports, quality teams can spot trends, such as repeated deviations on certain features, and address root causes.

This transforms FAI documentation from a compliance requirement into a tool for continuous improvement, helping not only to catch errors early but also to prevent them from recurring in future batches.

Best Practices for Effective FAI

Carrying out a First Article Inspection is not just about running through a checklist; it’s about building a system that consistently prevents errors before mass production begins. While many manufacturers perform FAIs, the difference between a box-ticking exercise and an effective process lies in preparation, execution, and follow-up. Applying best practices ensures that inspections deliver their intended value: fewer errors, lower costs, and higher customer confidence.

Planning Inspections Before Full Production

One of the most common mistakes is leaving FAI as a last-minute task. An effective inspection should be planned alongside production setup rather than treated as an afterthought. This planning phase involves:

- Reviewing engineering drawings in advance to identify critical dimensions, materials, and finishes.

- Preparing ballooned drawings and inspection checklists before machining the first part.

- Ensuring that the required measuring equipment (CMM, micrometers, profilometers) is available and calibrated.

By organizing these details beforehand, manufacturers avoid delays, reduce the risk of missing key checks, and ensure the first article is inspected without disrupting production flow.

First Article Inspection Procedure

Training Operators and Inspectors

Even with the best tools, FAI is only as reliable as the people carrying it out. Proper training of both operators and inspectors ensures accuracy and consistency.

- Operators must understand how machining setups influence dimensional accuracy, so they can make adjustments before defects spread.

- Inspectors must be familiar with GD&T, tolerance interpretation, and the correct use of measuring equipment.

- Cross-training can also improve communication, ensuring that production teams and quality teams work with a shared understanding of requirements.

Without training, there is a higher risk of human error, either through misreading drawings or misusing equipment. Investing in people minimizes these risks.

Using Calibrated Tools and Automated Measurement Systems

Inspection tools are only as trustworthy as their calibration status. Relying on uncalibrated instruments introduces hidden errors that can invalidate the entire inspection. Best practice dictates:

- Establishing a calibration schedule for all measuring devices.

- Using calibration stickers or records for traceability.

- Applying automated measurement systems like CMMs or vision-based tools, where possible, to reduce human variation.

Automation doesn’t replace human expertise but enhances consistency. For example, automated CMMs can generate complete inspection reports in minutes, saving time and improving repeatability across shifts.

Reviewing FAI Results Promptly

Performing the inspection is not enough; a timely review of results is critical. Delays in reviewing FAI reports can allow defective parts to slip into production. To prevent this, manufacturers should:

- Assign responsibility for the immediate review and approval of FAI results.

- Establish a clear escalation process if deviations are detected.

- Involve design engineers when nonconformities suggest deeper design or tolerance issues.

Quick response ensures that any corrections, such as tool offsets or program adjustments, are made before production ramps up.

Continuous Improvement Using FAI Data

Beyond confirming compliance, FAI generates valuable data that can guide process improvements. Treating inspections as a learning tool adds long-term value:

- Trend analysis: Comparing results across multiple FAIs highlights recurring issues, such as tool wear or misinterpretation of GD&T.

- Supplier evaluation: Reviewing reports from outsourced components can identify which suppliers consistently meet or miss expectations.

- Feedback loop: Sharing FAI findings with design teams ensures that tolerances, materials, and finishes are practical for manufacturing.

By closing the loop between inspection data and production processes, companies can continuously refine both quality and efficiency.

Why Best Practices Matter

FAI is often viewed as a compliance requirement, but when done correctly, it becomes a strategic advantage. Proper planning, trained personnel, calibrated equipment, timely reviews, and data-driven improvements elevate FAI from a cost center to a profit protector. Manufacturers who embrace these best practices not only avoid errors but also strengthen their competitive position by delivering consistent, high-quality parts every time.

Conclusion

First Article Inspection is far more than a routine quality control step; it is the foundation of reliable CNC batch production. By carefully inspecting the very first part against drawings, material requirements, and finish standards, manufacturers stop problems before they multiply across hundreds of components. What may seem like an extra step in the beginning often becomes the single most important safeguard against costly scrap, rework, and delivery delays.

The true strength of FAI lies in its ability to bring together all elements of manufacturing quality. Dimensional checks confirm that machining setups and programs are correct. Material verification ensures that the part’s core strength and compliance are never in doubt. Surface finish inspection guarantees both function and aesthetics. Combined with the clarity of GD&T, these checks eliminate ambiguity, reduce disputes, and provide inspectors and operators with a shared language of precision. Documentation then ties the process together, offering proof of compliance, traceability for audits, and a foundation for continuous improvement.

By integrating best practices, planning inspections early, training personnel, relying on calibrated tools, and reviewing results promptly, manufacturers transform FAI into a strategic advantage. It becomes not just a way to meet standards but a way to earn customer trust, protect margins, and build a reputation for consistent quality. In today’s competitive landscape, where precision and reliability are non-negotiable, First Article Inspection is no longer optional. It is a discipline every CNC production facility should embrace, ensuring that every batch begins not with uncertainty, but with confidence.