Finding lightweight spreaders without compromising on strength is an uphill task. Custom CNC-machined spreaders are the answer. To solve issues like warping, distributed load balancing, and excess weight, spreaders are meticulously designed for spatial and material optimisation to enhance durability.

In this blog, we will explore what CNC-machined spreaders are, why the strength-to-weight ratio matters, their key design factors, manufacturing challenges, and more. So, keep reading!

1) What is a CNC-Machined Spreader?

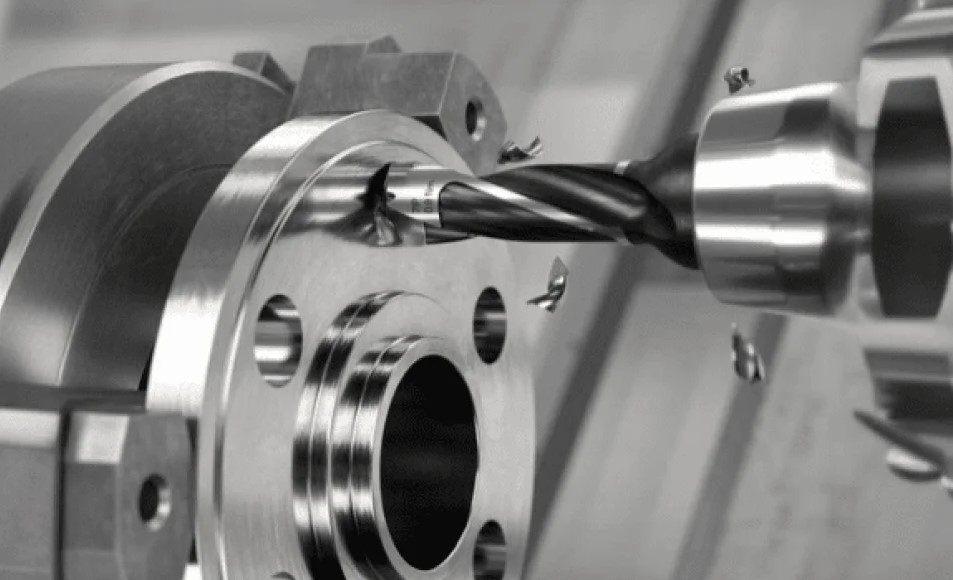

As the name suggests, a CNC-machined spreader is designed to actively assist in the distribution of force, weight, or material across a surface or structure. Using Computer Numerical Control (CNC) technology that meticulously slices and shapes metals, composites, and plastics, these spreaders are manufactured to output reliability in any condition.

Well, different industries deploy spreaders for a myriad of uses—be it construction for load bearing, aircraft for alignment purposes, or even farming for even seed dispersal.

Standard spreaders are mass-produced and have fixed dimensions and materials. While they can be useful for generic purposes, they are not tailored to the most specific requirements of projects. Custom CNC-machined spreaders, in contrast, can be manufactured to a very precise design, including material, size, weight, and tolerance, to become more efficient while still being stronger or lighter.

- There are different types of spreaders

Structural spreaders: In construction, ships, and cranes, structural spreaders are important for maintaining balance and stabilising loads.

Agricultural spreaders: In agriculture, spreaders are utilised to uniformly distribute seeds, fertilisers, and soil.

Aerospace spreaders: In aviation, aerospace spreaders are made from alloys or carbon fibre, which makes them strong and lightweight.

Industries that prioritise performance and safety value custom spreaders, which are meticulously crafted using CNC precision technology to achieve an optimal balance of strength and weight.

2) Why Strength-to-Weight Ratio Matters

The strength-to-weight ratio indicates how strong a material or component is in comparison to its weight. A higher value indicates a part can bear a greater load without unnecessarily increasing in weight. This is beneficial for the product to stay strong, reliable, and lightweight.

Having a good strength-to-weight ratio enhances performance by improving equipment efficiency, for instance, lowering fuel or energy use. In the long run, durability also increases because using strong and lightweight materials puts less stress on the equipment, thereby reducing wear and tear.

Finally, it impacts costs because the parts are cheaper to transport and require less expensive, more efficient support systems.

Generally speaking, this equilibrium is critical for multiple fields. In the aerospace sector, every kilo accounts for fuel savings. In automotive manufacturing, lighter vehicles provide quicker acceleration, improved fuel economy, and better handling. Reducing the weight of sports equipment, such as bicycles, tennis rackets, and helmets, improves performance and retains safety.

In the case of industrial machinery, lowered weight paired with high strength-to-weight ratios makes parts easier to install, operate, and maintain, even with the rigorous demands of the workload.

This balance improves cost efficiency, allowing for the development of multi-functional tools with the potential to serve different industries while maintaining strength and durability.

3) Material Selection for Custom CNC-Machined Spreaders

The selection of the correct material for the CNC spreader is really important. It is going to determine the strength, weight, durability, cost, and other environmental factors of the spreader. These determine the cost, performance, and reliability. Let’s review the basic selection criteria for different requirements.

Alloyed Aluminium (6061, 7075, and Other Types)

Aluminium alloys are a more common option because of their relatively better strength-to-weight ratio, anti-corrosion properties, and easier machining.

6061 aluminium, its strength is easily weldable and resistant to corrosion, which helps to aid its use as a general-purpose spreader in agricultural and structural spreaders.

7075 aluminium is considerably stronger and oftentimes is preferred in the aerospace industry or industries where weight is critical but strength is a priority.

Stainless Steel for Heavy-Duty Use

In cases where maximum strength combined with a harsh environment is present, stainless steel is the obvious choice. Obstacles such as rust, chemicals, and a large impact load make this option more durable, albeit much heavier than aluminium.

For this reason, stainless steel spreaders are commonplace in the marine, construction, and heavy industrial sectors, which emphasise the need for dependability.

Titanium for Lightweight Needs that are High Performance

For spreaders, titanium is well regarded as it offers a precise balance between strength and weight, even better than aluminium, along with titanium alloys with anti-corrosion properties.

Because of this, titanium is widely used in the aerospace and defence industries as well as high-end sports equipment. Even though it is more expensive, titanium spreaders are a better choice for the industry as they perform better.

Brass and Copper For Specialised Applications

While brass and copper may not be the most widely used metals, they are specifically valuable in applied mechanics. As for brass, it resists corrosion and is non-magnetic with a low coefficient of friction and wear, meaning it can be used in some mechanical or decorative part. Moreover, copper can be used in electric or thermal connectors due to its good conductivity.

Composite Materials and New Lightweight Metals

The best example of advanced composites is carbon-fibre composites; they provide an exceptional weight-to-strength ratio, do not corrode, and can be moulded into complicated shapes, which is ideal for aerospace, marine, and high-performance sports equipment.

Another example of new metals is the magnesium alloy, which is intended for spaces where extreme weight reduction is needed.

Meeting the industry's demands and needs, custom CNC spreaders are tailored to provide a specific application, in which performance, durability, and efficiency are balanced with the demands of each industry.

4) Key Design Factors for Balancing Strength and Weight

Combining strength and weight for custom CNC-machined spreaders requires equally balanced factors. Logic and smart design techniques that improve performance and strength are required. There are multiple strategies that focus on achieving this balance.

a) Optimising Wall Thickness and Geometry

Maintaining appropriate wall thickness allows the spreader to bear the load without being cumbersome. Geometry has its implications too; tapered and curved profiles are superior as they are less prone to being stressed compared to flat and blocky shapes.

b) Adding Ribs, Gussets, and Reinforcements Collaterally

To put it another way, ribs and gussets can be used to reinforce stressed areas to stiffen them without a significant increase in weight. Collateral reinforcement, as opposed to general or holistic reinforcement, allows targeted stiffening where it is minimally needed.

c) Implementing Hollow Sections or Honeycomb Structures

Specifically in the aerospace or high-performance equipment industries, replacing solid components with hollow or honeycomb elements is a proven means of weight reduction without compromising stiffening efficiency.

d) Removing Mass in Low-Stress Regions

To put it another way, a spreader may be designed with regions that are not subjected to load. Such areas can be trimmed or hollowed out without compromising function or safety. The precision trimming of outer surfaces enabled via CNC machines falls within this category.

e) Stress Testing and FEA as Pre-Manufacturing Steps

Simulations of stress and FEA are performed to find gaps and regions with excess material before manufacturing. This type of analysis allows designers to better control the effect of material placement to avoid underperformance and thus achieve the desired balance of weight and strength.

Applying these methods enables designers to make spreaders that are more lightweight and stronger, thus enhancing efficiency, durability, and cost savings in many areas.

5) Manufacturing Challenges and Solutions

Achieving an optimal balance between strength and weight incurs several difficulties. Resolving these difficulties in advance can help an organisation improve its quality and efficiency.

Avoiding Thin Part Distortion

Preserving the section's lightweight characteristics might warp due to the machining's heat and stress. To help prevent this, manufacturers can use proper fixturing, balanced cutting paths, controlled feed rates, and, in some instances, pre- and post-machining stress-relief heat treatments.

Selecting Tools for Diverse Materials

Different materials, such as aluminium, stainless steel, and titanium composites, need different cutting tools and coatings. With titanium, for example, carbide tools with special coatings help minimise wear and overheating. Some composites are better served with high-speed steel or diamond-coated tools. Selecting the proper tools improves the finish and reduces the need for additional work.

Maintaining Tight Tolerances Over Multiple Production Runs

For custom spreaders, the requirement could be as precise as a micron. Tolerance drift can be caused by tool wear, thermal expansion, and machine calibration over a period of time. Regular recalibration of the machine, inspection of the tools, as well as real-time measurement systems aid in ensuring every part is made to precise standards.

Managing Machining Time and Cost Without Compromising Quality

Machining complex geometries on the lighter segments is expensive and time-consuming. To manage the costs, manufacturers need to optimise the tool paths, combine operations, and apply high-efficiency milling strategies. To increase accuracy, some producers separate the roughing and finishing processes onto different machines.

6) Precision Tolerances in CNC-Machined Spreaders

Precision tolerances are critical within performance and assembly for CNC-machined spreaders. Tolerances too loose can mean functioning and fitting issues, which can lead to stress concentrations, uneven load distribution, and even premature wear. Well, reliability and safety are improved with tight tolerances, ensuring the alignment of components.

When it comes to spreaders made from aluminium, tolerances can vary from ±0.005" (±0.13 mm) for normal cases to ±0.001" (±0.025 mm) for exacting cases. Steel spreaders can achieve similar ranges, although tighter tolerances may require slower machining and more tool changes due to the hardness of the material.

In the aerospace and defence industries, titanium spreaders have tolerances of ±0.002" (±0.05 mm), which is considered demanding due to the focus on weight and accuracy.

7) Surface Finishes and Treatments for CNC Spreaders

The functions that surface treatments and finishes perform on CNC spreaders include increasing the performance, wear resistance, durability, and even the aesthetic of the parts. Let’s have a look;

Anodising Aluminium for Corrosion Resistance

Anodising for aluminium spreaders forms a protective, hard oxide layer that prevents corrosion and wear. Anodising can also be dyed for colour. This treatment is particularly beneficial in marine, aerospace, and outdoor industries.

Powder Coating for Protection and Appearance

Protection from scratching, moisture, and even chemicals can be gained from a thick layer of colour, which is applied through powder coating. Also, spreaders are made more appealing as they are able to blend in with equipment or even company branding. This is effective with both steel and aluminium, as well as other metals.

Heat Treatments for Improved Material Strength

Some heat treatments, like annealing or quenching, can improve a spreader’s strength, hardness, and fatigue resistance. These treatments are beneficial to titanium, steel, and some aluminium alloys, especially in high-stress environments.

Polishing and Deburring for Smooth Operation and Safety

Sharp edges from machining are eliminated by deburring and polishing, therefore improving the look of the spreader and smoothing friction in moving parts. These actions also make the spreader easier to handle and prevent injury to the user as well as damage to associated parts.

8) Cost Factors in Producing Custom CNC-Machined Spreaders

The custom CNC spreaders have a specific price due to a set of production factors that directly impact their strategy and pricing.

- How Material Choice Influences Cost: Material directly relates to price. Aluminium is cheap and simple to machine and serves as a good option. However, due to their complicated machining and higher raw material costs, stainless steel, titanium, and composites are more expensive.

- Processing Time and Complexity of Machining: Narrow tolerances, fine wall features, and complex shapes increase costs due to the need to slow down cutting speeds, add tools, and lengthen setup times.

- Batch Size and Economies of Scale: Increased production runs boost unit costs as the setup costs are spread over more pieces. With reduced quantities, the opposite happens, and per-piece cost greatly increases.

- Post-Processing and Finishing Expenses: Increased costs of heat treatments, polishing, and coatings are justified by adding value to the product by improving its appearance and durability. Costs rise even more when multiple treatments are needed, and overall costs of the product skyrocket.

By striking a balance among all factors, maintaining the set spreader performance and costs becomes attainable.

9) Common Applications of CNC-Machined Spreaders

The exact spreaders are applied to multiple industries that require lightweight, high-strength components, and a CNC-specific spreader for exact load distribution.

- Aerospace Structural Supports, Spreaders, and Brackets

In aerospace, spreaders made of aluminium, titanium, or composites help in applying and distributing forces within an aircraft's frame, wings, and engine mounts. Also, the alloy's strength-to-weight ratio is beneficial in improving safety and fuel consumption.

- Automotive Suspension and Chassis Components

In vehicles, spreaders are used to reinforce the suspension systems of the chassis frame and roll cages. Also, the vehicle's handling and safety features ensure CNC and Precision machining.

- Fertiliser Spreader and Conveyor Parts

In farming, CNC spreaders for fertiliser are used in seeders, fertiliser distributors, and conveyor systems to ensure even distribution of materials. Thus, improving crop yields and equipment efficiency.

- Marine spreaders for masts and rigging

Spreaders used in marine applications are some which need to boast high corrosion resistance. Therefore, the spreaders used to stabilise the masts and rigging and other load-bearing parts on ships or yachts have to survive harsh saltwater environments.

By offering Fully detailed designs, unrivalled strength and supreme precision, the CNC spreaders are able to function throughout the span of numerous industries.

10) How to Choose the Right CNC Machining Partner

To ensure the performance and budget requirements are met with high-quality spreaders, the right partner for CNC Machining requires careful selection.

- Evaluating Capabilities and Experience: Strive to build a partnership that can accommodate complex geometries, small tolerances, and multiple materials.

- Understand Their Quality Control Procedures: Your reliable partner should have well-defined, non-conformance reporting inspection processes for every batch with dimensions, tolerances, and counts.

- Importance of Material Sourcing and Certification: Make sure that they obtain materials from suppliers that issue certifications.

- Communication and Design Support: Maintaining open lines of communication is critical. A reliable partner stays with you during production and provides updates, while also offering design edits and recommending changes to improve the component's strength-to-weight ratio.

With all of these factors, you will be able to choose a CNC machining partner that gives you the precision and consistency you are looking for, with the right mixture of quality, cost, and efficiency.

11) Conclusion

The versatility of custom spreaders manufactured through CNC machining is unrivalled. A wise selection of materials, paired with strategic engineering design, enables the achievement of an optimal strength-to-weight ratio.

So, for designers and manufacturers, investing in spreaders ensures dependable performance, efficiency, and durability that they provide across industries for heavy-duty applications.