An inspection is an activity such as measuring, examining, testing or gauging one or more characteristics of a product and comparing the results with specified requirements in order to establish whether conformity is achieved for each characteristic. (This definition comes from the ISO 2859 standard, which is derived from MIL-STD 105 E.)

The term inspection refers to the activity of checking products, whereas audit applies to analyzing manufacturing processes and/or systems. The quality inspector usually follows a pre-established checklist that is based on the product specifications. Inspected products can be the components used for production, semi-finished goods, or (most often) finished goods before shipment to a customer.

By carrying out quality control inspections before, during, and after production – it is the key to consistency in product quality.

A factory usually cannot turn defective inputs (components, or raw materials) into good products. And the problems are much harder to detect once the materials are embedded in the final product.

Some special metal materials are very expensive, we will check if they are real through spectral analysis. The raw material suppliers who work with us are able to provide you with material certificate as required.

Typically, in an in-line inspection, the first products that got out of the line are inspected for conformity. If issues are raised at this stage, the factory can immediately take some corrective actions and avoid delays. In any case, in-process products are rarely checked, even though it can be very valuable. It takes a trained technician to reliably detect errors on unfinished products. The technicians in Baichuan can ensure that they have been in the machining industry for more than 25 years. So many problems can be corrected by technicians in time during processing.

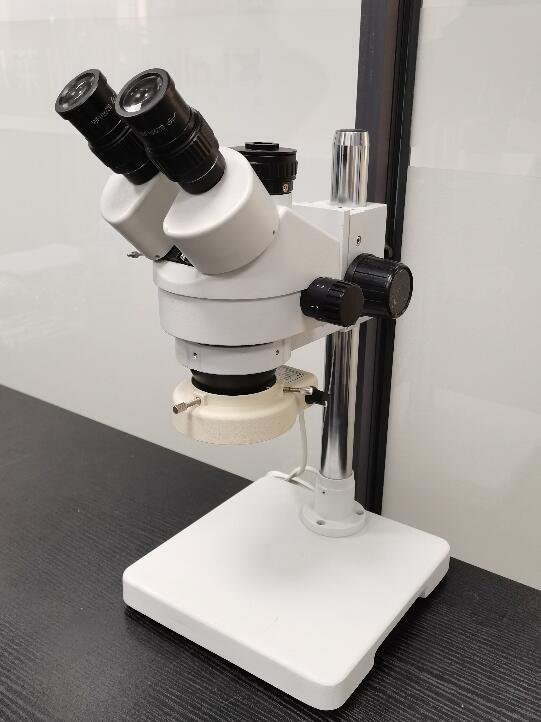

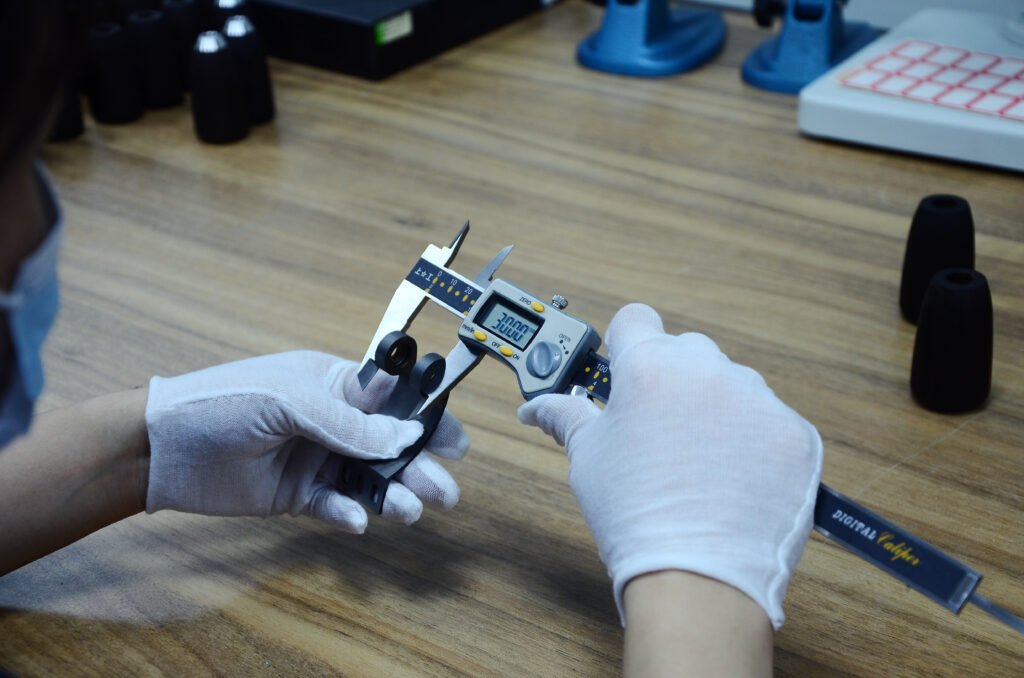

The final quality inspection is also the most important part of product quality control. We will prove all with the data to make our clients assured. Our machine shop is fully equipped with testing equipment such as 0.0025mm accuracy CMM, Projector, Microscope, Hardness Guage, etc as bellow:

A classic, bridge-style coordinate Measuring Machine (CMM) accurately measures the geometry of an object along X, Y and Z axes using a touch-trigger, scanning or vision probe to take a series of precise points on the surface of an object.

CMMs can be made from a wide variety of materials, however a combination of granite and aluminium has been widely adopted by the industry due to its stiffness to weight ratio and allowing the constructed materials to be thermally dynamic. Changes in ambient temperatures and thus expansion or contractions of the machine’s materials are monitored and compensated for in the user software.

The probes position can be manually controlled or, automatically (CNC) through the use of a computer. The position is defined using a reference sphere in the X-Y-Z coordinate system. CMMs also allow the probe angle to be controlled to enable the measurement of complex surfaces that may otherwise be unreachable.

The most common use of a CMM is to test the accuracy of a manufactured part against its original design to ensure stringent quality requirements are met and adhered to.

The Laser Projection System allows a size-for-size transfer of complete component drawings from a CAD system to the floor, assembly table, CNC-machining table or any other area needing part or material alignment.

The patterns are projected with a brilliant red or green laser line onto almost any surface. The size, form, position, and height of the projection can be easily changed.

Windows based software allows users to see a graphical preview of projection details and control all elements of image placement. This software allows direct input of standard DXF format files for maximum compatibility with a wide range of CAD systems. Optional CNC code converters allow direct projection of G-code files as well.

As the source factory of Baichuan, we have the supporting quality inspection equipment. The quality inspection adds a safety factor to the quality of the products, maintains the company’s brand image, and helps reduce trade risks. Quality inspection can be carried out at all stages of the production process to ensure that delays are avoided and that many defects on the product are discovered as far as possible before the product enters the market. Thorough quality inspection can minimize the risk of our products being returned and claimed. risk.

We are happy to provide you with a free test report!

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.