Modern CNC machining is steadily moving away from the old routine of completing a part first and checking quality afterward. Today, more manufacturers want inspection to happen while the part is being made. This shift is driven by shorter lead-time expectations, tighter tolerances, and the need for real-time visibility into what is happening inside the machine. Instead of relying on post-process checks, shops are integrating inspection directly into milling and turning centers to catch issues before they become scrap.

What is Automated Quality Inspection?

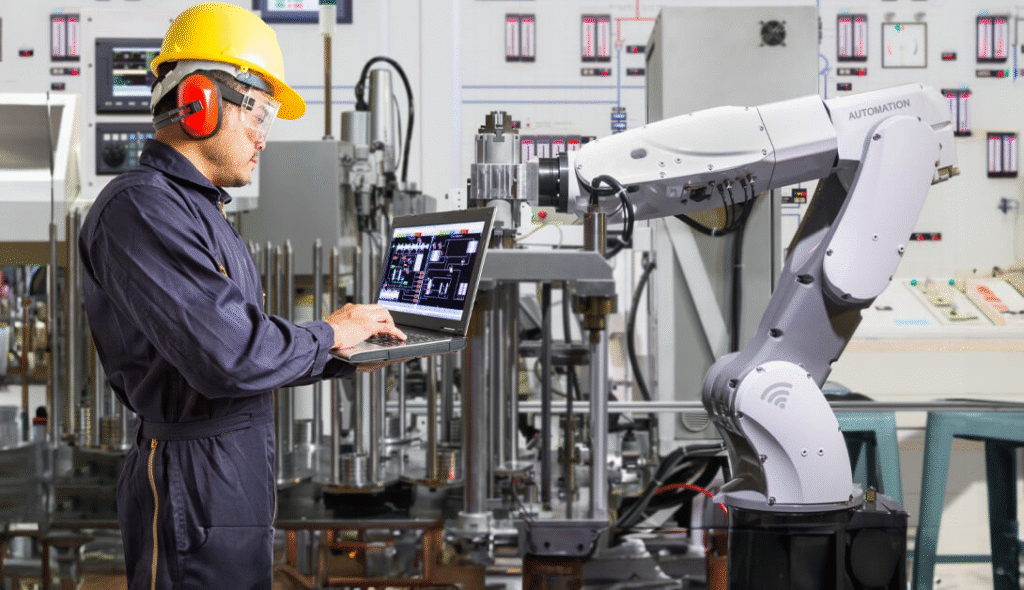

As production becomes more automated, on-machine quality verification is no longer seen as an optional upgrade. It is becoming a standard practice in advanced manufacturing environments where speed, consistency, and data-driven decision-making matter. Embedded inspection enables CNC machines to detect tool wear, measure critical features, and adjust the process instantly. This approach reduces delays, improves accuracy, and gives manufacturers a clearer picture of part quality at every stage of machining.

Evolution of Quality Inspection in CNC Manufacturing

Quality inspection in machining has changed significantly over the last few decades. Manufacturers once relied entirely on manual measurements taken after the part left the machine. As production volumes increased and tolerances became tighter, this approach started to show clear weaknesses. Modern CNC environments now focus on detecting errors as early as possible, ideally during machining itself. This shift happened gradually as shops adopted automated probing routines, optical inspection tools, and integrated sensors that can operate inside the cutting environment.

Early manufacturing workflows treated machining and inspection as two separate stages. Today, both stages are becoming interconnected, allowing machining centers to measure features, compare data against specifications, and correct the process without waiting for an operator. This evolution reflects a broader industry trend toward digital manufacturing and intelligent production systems.

Below are the key steps in this transition.

Traditional post-machining inspection workflow

Before automation, quality checks were performed after machining was complete. Typical steps included:

- Moving the part to a gauge station or CMM room

- Measuring features manually with micrometers, calipers, height gauges, or surface plates

- Waiting in line for CMM availability, especially in busy shops

- Returning the part to the machine if adjustments were required

This process created delays, especially when several machines shared one inspection area. Any dimensional error discovered late meant additional setups and extra machining time.

Limitations: delays, operator dependency, higher scrap risk

Traditional inspection introduced several challenges that became more severe as tolerances tightened. Key limitations included:

- High dependency on operator skill and consistency

- Increased risk of scrap due to late detection of tool wear or thermal drift

- Longer lead times caused by transportation between machining and inspection stations

- Reduced throughput when CMM queues built up during peak hours

These issues made post-process inspection unsuitable for high accuracy, high volume, or complex parts. Once an error was found, it was often too late to salvage the component.

Transition to in-process and automated systems

Manufacturers gradually moved toward systems that collect inspection data while the part is still clamped. This shift was enabled by CNC integrated probes, optical sensors, and machine software that can interpret measurements in real time.

Examples of early improvements include:

- In-cycle probing routines that measured work offsets at the start of each operation

- Tool wear detection using contact or non-contact sensors

- Automated correction of tool length or diameter based on probe feedback

Over time, these features evolved into full-on on-machine inspection systems that continuously monitor production. Instead of discovering problems at the end, shops can now identify deviations during roughing, semi-finishing, or finishing, leading to more stable, predictable machining outcomes.

Core Technologies Behind Embedded Quality Inspection

Modern CNC machines now integrate several inspection technologies that work directly inside the machining environment. These tools allow real-time measurements, automated feedback, and continuous monitoring without removing the part from the fixture. Before breaking down each technology, it is important to understand that these systems are designed to survive harsh shop conditions, such as coolant, vibration, and chip movement. Their reliability makes in-process inspection practical and accurate, even during demanding operations.

Quality Control and Inspection for CNC Machining

These technologies also support different types of measurement tasks. Some are ideal for precise dimensional checks, while others excel at capturing surface details, contours, or tool wear. The combination of contact probes, cameras, and non-contact laser sensors gives manufacturers a flexible approach to monitoring quality throughout the machining cycle.

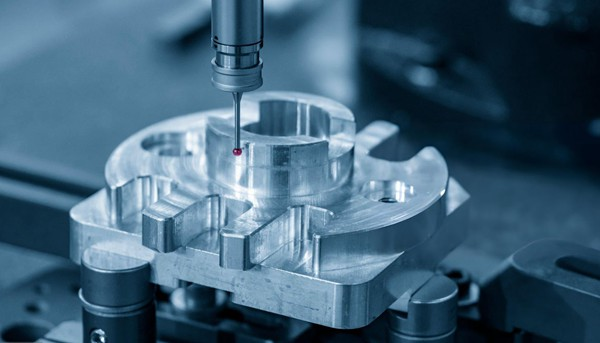

On-Machine Touch Probes

On-machine probing is one of the most widely adopted inspection tools because it fits easily into most CNC setups. Probes use a contact stylus to measure structural features, verify geometry, and check tool positions. Once a probing cycle is triggered, the probe touches specific surfaces and records their positions through the machine control system.

After a few probing contacts, the machine can determine whether the part is aligned correctly, whether the tool has shifted, or if a feature has drifted from its expected location. This allows immediate correction without stopping production.

Key functions include:

- Measuring work offsets and part orientation before machining starts

- Verifying tool length and diameter after tool changes

- Checking the dimensional accuracy of machined pockets, bores, and surfaces

Touch probes also help detect slow changes like tool wear and thermal expansion, which are common in long machining cycles. In both milling and turning applications, they support tasks such as in-cycle measurement, broken tool detection, and verification of critical dimensions during finishing.

Vision Systems

Vision-based inspection uses high-resolution cameras mounted inside the CNC enclosure. These systems capture images of the part or tool and analyze them through built-in software. Before diving into the specific uses, it is helpful to understand that vision systems work best when the machine has good lighting and chip control, which allow the camera to capture clean images.

Vision inspection supports tasks such as:

- Detecting edges, corners, and surface boundaries

- Identifying patterns or verifying shapes for repeatable part geometry

- Recognizing part orientation or confirming the correct component is loaded

These systems are valuable for complex geometries, especially where contact probes cannot reach or where surface visual characteristics matter. They are often used in medical machining, mold making, and parts that require cosmetic or surface quality verification.

Laser Scanners and Optical Sensors

Laser-based inspection tools use non-contact measurement to capture precise shapes and contours at high speed. Before listing their specific advantages, it is important to note that laser scanners are ideal for dynamic or delicate surfaces because they do not physically touch the part. They can read micro profiles, detect contour variations, and generate accurate three-dimensional data.

Key capabilities include:

- Scanning full profiles and verifying that features match CAD models

- Capturing small surface deviations that contact probes might miss

- Inspecting delicate, hardened, or heat-sensitive materials

Materials such as titanium, Inconel, composite structures, and hardened tool steels benefit significantly from non-contact inspection. Laser sensors maintain accuracy even when dealing with reflective surfaces or sharp edges, making them suitable for aerospace components, turbine blades, complex molds, and high-precision parts where surface form matters as much as dimensional accuracy.

How Embedded Inspection Works During Production

Embedded inspection is most effective when it becomes part of the machining cycle rather than a separate task. Modern CNC controls allow measurement routines to run at specific points in the program, giving continuous visibility into how the process is progressing. This approach ensures that deviations are identified as soon as they appear, whether they are caused by tool wear, thermal expansion, or small variations in material hardness. By placing measurement steps inside the cycle, manufacturers reduce uncertainty and maintain tighter control over final dimensions.

CNC machining quality inspection process

In-process inspection combines sensor feedback, machine logic, and automated adjustments. The CNC interprets measurement data and applies compensation without delaying production. This creates a closed feedback loop where machining and inspection work together rather than independently. Below are the main stages of how this workflow functions.

Measurement during setup, roughing, semi-finish, and finishing

Measurement is used throughout the machining cycle to verify alignment, tool condition, and dimensional accuracy. Each stage serves a different purpose:

- Setup: Probing routines confirm work offsets, confirm part orientation, and ensure fixtures are seated correctly. Any misalignment detected here prevents early scrap.

- Roughing: Sensors check whether material removal is proceeding as expected. Probes may measure reference features to verify stock allowance.

- Semi-finishing: Additional checks ensure that the remaining material is consistent before finishing tools engage. This reduces the chance of cutter overload.

- Finishing: Critical dimensions are measured immediately after cutting. If a feature is slightly off, the CNC can adjust tool offsets and re-pass the area if needed.

By distributing measurement across the cycle, shops avoid surprises at the end when final inspection takes place.

Automated tool compensation based on probe, vision, or laser data

Once measurement data is collected, the CNC control evaluates it against programmed specifications. If the deviation is within a correctable range, the machine updates tool wear offsets automatically. This avoids manual edits to tool length, diameter, and cutter compensation values.

Typical automatic adjustments include:

- Increasing or decreasing tool wear values

- Updating cutter radius compensation

- Adjusting finish pass depths

- Modifying toolpath for minor contour corrections

This automated response keeps machining consistent, especially during long cycles where thermal drift or gradual wear would otherwise degrade accuracy.

Real-time alerts and deviation dashboards

Modern CNC machines present inspection data through dashboards on the control panel. Operators can see trend lines, tolerance ranges, and deviation warnings while machining is running. This helps detect patterns such as:

- Sudden tool chipping

- Gradual drift caused by heat buildup

- Inconsistent material hardness

- Clamping or fixturing issues affecting geometry

Real-time alerts prevent small variations from turning into scrap-generating defects.

Integration with digital twins and NC program updates

Advanced shops integrate measurement data with digital twins or virtual machining models. The digital twin compares real machining results with the simulated ideal, allowing engineers to refine toolpaths and optimize machining parameters.

This integration supports:

- Automatic updates to NC programs when recurring deviations are identified

- Verification of process stability based on live data

- Continuous improvement of machining strategies for repeat jobs

As machines and software become more interconnected, cycle inspection becomes a central part of predictive quality control rather than a simple measurement step.

Key Benefits of Automated On-Machine Inspection

Integrating inspection directly into CNC machining provides measurable improvements across productivity, consistency, and overall quality control. Instead of relying on manual checks at the end of a cycle, manufacturers gain continuous visibility into part accuracy while machining is still underway. This shift reduces uncertainty and helps maintain predictable results even during complex operations or long machining hours. The benefits become more significant when dealing with tight tolerances, high-value components, or difficult materials.

Automatic Visual Inspection for Precision Machining Parts

Below are the main advantages of adopting embedded inspection.

Reduced Lead-Time

Automated on-machine inspection shortens lead time by removing many delays associated with offline checks. When measurements happen inside the machine, parts do not wait in queues or depend on limited resources.

Key improvements include:

- Avoiding long CMM queues that slow down production

- Reducing the number of manual measurements needed between operations

- Detecting errors early so machining does not stop for rework

- Streamlining changeovers because offsets and alignments are measured automatically

By eliminating multiple handoffs and reducing downtime, the entire machining workflow becomes faster and more efficient.

Lower Scrap and Rework Rates

One of the strongest advantages of embedded inspection is the ability to catch problems when they first appear. Real-time measurement prevents small deviations from turning into major defects.

The main contributors to lower scrap include:

- Early detection of tool wear that would otherwise cause undersized or tapered features

- Identification of thermal drift during long cycles, especially on large workpieces

- Verification of clamping and setup accuracy before roughing begins

- Automatic tool compensation to maintain accuracy through the entire operation

These capabilities are especially valuable when working with Inconel, titanium, or hardened steels, where even minor dimensional errors can lead to complete part loss. By stabilizing dimensional accuracy at every stage, manufacturers maintain consistent quality with far fewer rejects.

Improved Traceability and Documentation

Embedded inspection automatically records measurement data for every part produced. Instead of handwritten notes or scattered files, all records are stored digitally within the machine or connected software.

Benefits include:

- Secure and time-stamped inspection logs for audit requirements

- Traceable measurement history for each serialized or coded component

- Better process control when shops analyze trends in tool wear or feature variation

- Full documentation for industries that demand strict compliance, such as aerospace and medical

When combined with barcode or QR identification, each part carries its own measurement record, which strengthens quality assurance and simplifies customer reporting.

Applications Across Industries

Embedded quality inspection is now used across many sectors where accuracy, repeatability, and documentation matter. As CNC machines take on more complex work, industries with strict performance and safety requirements rely heavily on in-process measurement to maintain consistency. These systems help manufacturers control deviation before it affects performance, especially for components that must withstand pressure, load, or medical contact. Each industry uses embedded inspection in slightly different ways based on part geometry, tolerances, and regulatory needs.

Below are the main sectors where on-machine inspection has become a critical part of production.

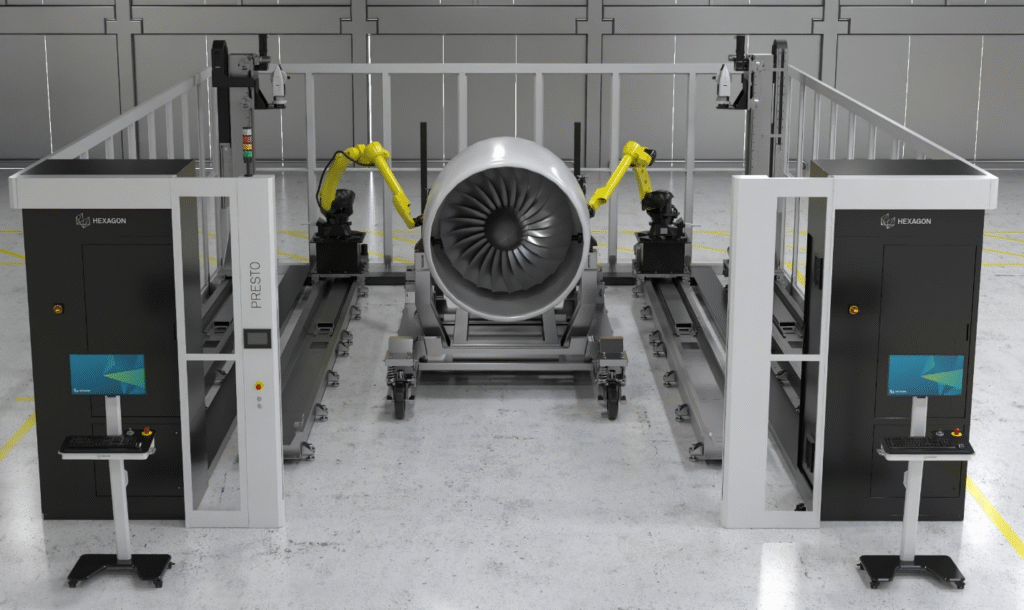

Aerospace turbine blades, blisks, structural components

Aerospace manufacturers were early adopters of automated inspection because their components operate under extreme stress. Turbine blades and blisks require precise profiles to maintain airflow efficiency and engine balance. Even small dimensional errors can result in performance loss or early fatigue.

Automated Quality Inspection System Ramps Up Aerospace Production

On-machine inspection supports aerospace production by:

- Measuring contours and airfoil profiles directly inside the machining center

- Detecting tool wear that affects the leading and trailing edges

- Verifying pocket depths, cooling channels, and surface transitions

- Ensuring consistent geometry across large batches of high-value parts

For aerospace structural components, embedded inspection reduces the risk of machining defects that would otherwise be caught only during final CMM checks.

Medical implants and surgical instruments

Medical manufacturing demands highly consistent geometry, smooth surface finishes, and precise fit with biological interfaces. Any deviation can affect safety or compliance with regulatory standards. On-machine inspection is particularly useful for implants and instruments because it verifies shape and surface features while they are still clamped.

Common applications include:

- Inspecting orthopedic implants such as knee and hip components

- Checking small surgical tools where traditional gauges struggle

- Confirming edge quality and surface transitions required for patient safety

- Recording traceable digital measurement logs for audit requirements

The ability to verify every part during production supports high mix, low volume medical environments where flexibility and accuracy are equally important.

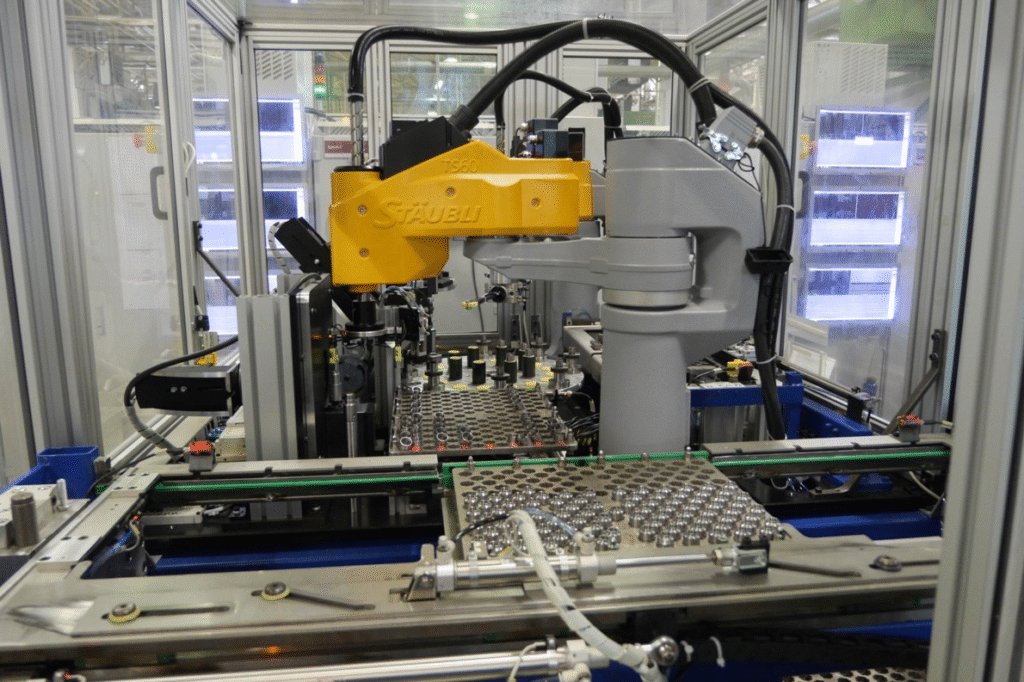

Automotive precision parts and electric vehicle components

Automotive machining has shifted toward more automated inspection as vehicles adopt tighter tolerances and advanced materials. EV components, such as motor housings and battery casings, require consistent fit and thermal performance, which depends heavily on dimensional accuracy.

On-machine inspection improves automotive manufacturing by:

- Checking bore concentricity, housing dimensions, and sealing surfaces

- Monitoring tool wear during high-volume production

- Reducing scrap during machining of lightweight alloys and hardened steels

- Stabilizing accuracy for multi-shift operations

Automotive suppliers use embedded inspection to maintain throughput while keeping quality predictable.

High mix, low volume manufacturing environments

Shops that handle frequent changeovers and diverse parts benefit from automated inspection because manual checks slow down production. In these environments, consistency depends on quick verification rather than lengthy measurement cycles.

Embedded inspection supports these shops by:

- Automatically aligning parts regardless of minor fixture variations

- Updating offsets and monitoring tool condition for each unique job

- Reducing operator dependency when dealing with unfamiliar geometries

- Providing fast feedback that keeps short-run jobs on schedule

For high mix, low volume work, the main advantage is flexibility combined with dependable quality control.

Conclusion

Automated quality inspection inside CNC machines has moved from being an optional upgrade to becoming a core part of modern machining. By measuring parts during production instead of waiting for offline checks, manufacturers gain faster feedback, better accuracy, and a more stable machining process overall. Problems related to tool wear, thermal drift, or setup variation are identified early, which reduces scrap and avoids time-consuming rework. This shift improves lead-time, supports consistent part quality, and strengthens traceability across every production batch.

As industries demand tighter tolerances and more reliable documentation, embedded inspection continues to play a larger role in how shops operate. Technologies such as touch probes, camera-based vision systems, and high-speed laser scanners are becoming more capable and more accessible to manufacturers of all sizes. Combined with automated tool compensation, digital connectivity, and predictive analytics, these systems are shaping a future where machining and inspection work seamlessly together. Embedded quality control will remain an essential part of advanced CNC environments as efficiency, data-driven decisions, and process intelligence become the new standard.