Sailboat fittings aren't just accessories; they're essential to both safety and performance on the water. From winches and cleats to blocks and shackles, every component plays a role in ensuring smooth operation, especially in the unforgiving conditions of open seas.

In recent years, anodized aluminum has become increasingly popular in the marine hardware world, and for good reason. It strikes a perfect balance between strength, weight, and corrosion resistance, making it especially suited to the harsh, salty environments boats endure. Whether you're refitting an old vessel or building a new one, understanding the value of anodized aluminum fittings can help you make smarter, longer-lasting choices for your sailboat.

Why Anodizing is Ideal for Salty Environments

Corrosion Resistance

Saltwater is among the most aggressive environments for metal hardware. Aluminum, while naturally corrosion-resistant due to its oxide layer, is still vulnerable in prolonged marine exposure. Anodizing enhances this resistance significantly. The process thickens the natural oxide layer through controlled electrochemical treatment, forming a dense, uniform barrier that protects the underlying metal.

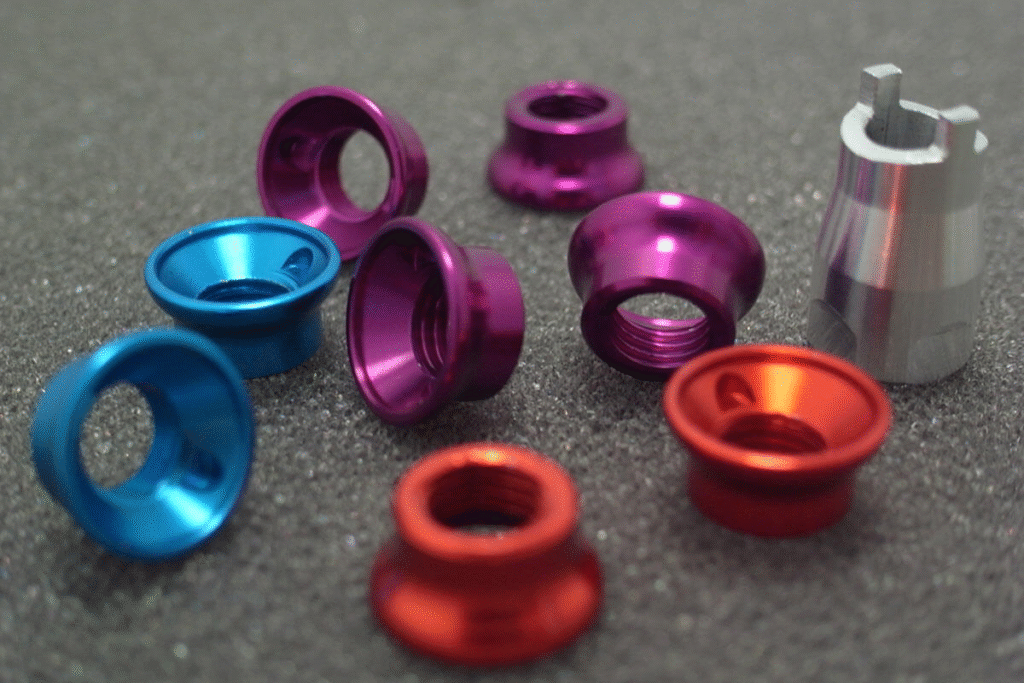

Anodized Aluminum Sailboat Fittings

This anodized layer is not a coating that can peel or flake; it's integrated into the surface. As a result, fittings like cleats, shackles, and sail tracks are better equipped to withstand salt-laden air and direct seawater contact. Compared to untreated aluminum or even some grades of stainless steel, anodized aluminum fittings offer superior long-term corrosion resistance, reducing the risk of pitting, discoloration, or structural weakening.

Durability and Longevity

Durability is non-negotiable in marine applications. Anodized aluminum excels in this area by offering a surface that is harder than bare metal. It resists mechanical wear from friction, impact, and vibration, all of which are routine on a sailboat. The added hardness translates to fewer replacements and longer operational life for fittings under constant use.

Because the anodized surface maintains its integrity over time, sailboat owners benefit from extended service intervals and reduced maintenance costs. Over several seasons, this reliability adds up, especially in high-use areas such as winch bases or traveler systems, where component failure is not an option.

Surface Hardening

Anodizing doesn't just preserve, it reinforces. The hardened layer on anodized aluminum significantly boosts scratch and abrasion resistance. This is particularly important for components exposed to frequent mechanical contact, such as blocks, fairleads, or pulleys that guide lines under tension.

Aluminum Folding Mast Step Anodized in a Sailboat

Unlike painted or powder-coated surfaces, anodized aluminum won't chip or bubble under wear. Even when abraded, the damage remains superficial, without compromising structural strength. This resilience ensures fittings maintain both performance and appearance throughout extended use.

UV Protection

Constant exposure to sunlight can degrade most materials over time. UV rays can discolor, weaken, or embrittle untreated surfaces. Anodized aluminum, however, stands up well to solar exposure. The anodic layer resists UV degradation, helping maintain the material's mechanical properties and aesthetic finish, even in equatorial sailing conditions.

Many anodized fittings retain their color and finish for years without fading or chalking, especially when sealed during the anodizing process. This is a key reason why high-end sailboats often feature colored anodized hardware: it looks sharp and lasts.

Non-Reactive to Marine Chemicals

Marine environments expose fittings to more than just saltwater. Cleaning agents, lubricants, fuels, and spilled hydraulic fluid are common onboard. Fortunately, anodized aluminum is chemically stable and non-reactive to most marine-grade chemicals. The anodic layer resists chemical etching and staining, helping fittings retain their integrity even in engine compartments or below-deck installations.

This resistance extends to acidic and alkaline substances, meaning anodized fittings are less likely to degrade from routine maintenance or accidental spills. That chemical resilience makes them ideal for sailboats, where reliability and longevity are essential.

CNC Customization for Winch Bases, Blocks, and Shackles

Precision and Accuracy

In the marine environment, precision isn't a luxury; it's a necessity. Sailboat hardware must fit perfectly and function reliably under stress. CNC (Computer Numerical Control) machining enables this level of accuracy. By using computer-controlled tools to cut and shape metal, CNC processes eliminate the variances found in manual fabrication.

When applied to anodized aluminum, CNC machining produces fittings with exact tolerances. Whether it's a winch base that must align seamlessly with the deck curvature or a shackle that must lock securely without play, CNC ensures dimensional accuracy to within fractions of a millimeter. This precision reduces wear, eliminates fitting issues, and enhances safety during high-load maneuvers.

Custom Fittings for Enhanced Performance

Every sailboat is different; hull shape, rigging setup, and sailing conditions all vary. Off-the-shelf hardware often doesn't meet specific needs. CNC machining solves this by enabling tailored designs for critical components. Boat owners and builders can request custom-fitted winch pads, blocks optimized for unusual angles, or shackles with unique load requirements.

Anodized Aluminum Sailboat: Performance and Comfort

Customizing fittings allows for better load distribution and improved sailing performance. For example, a lightweight CNC-machined fairlead designed specifically for a racing yacht can reduce friction on control lines, leading to smoother handling and reduced crew fatigue. These seemingly small optimizations contribute to both speed and control, vital advantages in both cruising and competitive sailing.

Optimized Design Capabilities

CNC also makes it possible to manufacture fittings with complex geometries that would be difficult or impossible with traditional methods. Weight-reducing pockets, smooth curves for stress distribution, and integrated features like drainage channels or recessed bolt holes can all be implemented with precision.

This design freedom leads to stronger yet lighter parts. For example, a CNC-machined winch base can be hollowed internally to reduce weight without sacrificing structural integrity. Likewise, a block designed with reinforced load paths and minimal material waste can outperform heavier alternatives, crucial when every gram matters aboard performance sailboats.

Material Efficiency

CNC machining is not only about accuracy but also about smart material use. With precise control over cutting paths, machinists can reduce excess waste during production. This is especially important when working with high-quality anodized aluminum stock, where every cut must count.

Efficient use of material lowers production costs and supports sustainable manufacturing. It also ensures consistency in wall thicknesses and material distribution, which is critical in high-stress applications like boom vang brackets, spinnaker pole fittings, or backstay adjusters.

Consistency and Reproducibility

One of CNC's most valuable advantages is repeatability. Once a design is finalized, it can be reproduced identically across multiple units. This means replacement parts can be ordered with full confidence that they will fit and perform exactly like the original.

This consistency is particularly useful for fleet maintenance or production boats, where uniformity ensures predictable performance. It also simplifies logistics and reduces downtime when repairs are needed, especially in remote sailing locations where improvisation isn't an option.

Additional Advantages of Anodized Aluminum for Sailboat Fittings

Lightweight Strength

Aluminum's greatest strength lies in its strength-to-weight ratio, and anodizing only improves its marine suitability. Anodized aluminum maintains its low weight while gaining a hardened, protective surface. For sailboat fittings, this means hardware that is strong under load but doesn't add unnecessary weight.

A few welds from an anodized aluminum soft top for a boat

Reducing weight aloft, especially on the mast or rigging, improves boat stability and sail performance. Whether it's a lightweight gooseneck bracket or an optimized halyard block, every ounce matters. Anodized aluminum fittings help minimize total displacement without compromising structural reliability, a balance few materials achieve so effectively.

Aesthetic Appeal and Finish Options

Functionality aside, anodized aluminum offers a refined, professional appearance. The anodizing process allows for a uniform matte or gloss finish and can be dyed in various colors, from classic black to bold red or blue. These finishes are not just cosmetic; they're UV-stable, meaning they won't fade or discolor under sun exposure.

Sailboat builders and owners often select colored anodized fittings to match the vessel's branding or aesthetic design. Beyond appearance, the smooth finish also resists chalking, staining, and fingerprint marks, helping the hardware retain its clean, modern look with minimal upkeep.

Eco-Friendly and Sustainable

Anodizing is a clean, water-based process that doesn't rely on heavy metals or harmful volatile organic compounds. Unlike paint or plating, it produces minimal toxic waste and generates no hazardous fumes. This makes it a more environmentally responsible choice, especially for manufacturers focused on reducing their ecological impact.

Additionally, aluminum is fully recyclable. Anodized components, even at end of life, can be melted down and reused without degradation in quality. This contributes to a circular materials economy, aligning well with the increasing demand for sustainable marine manufacturing practices.

Electrical Insulation

In certain installations, electrical isolation is crucial to prevent galvanic corrosion or signal interference. The anodized layer on aluminum acts as a natural electrical insulator. This is particularly useful in areas where fittings are mounted near sensitive instruments or mixed-metal assemblies.

By breaking the conductive path between dissimilar metals, anodized fittings reduce the risk of galvanic reactions, a common issue in saltwater where stray currents can accelerate corrosion. This insulation is especially valuable in modern sailboats equipped with GPS, radar, and autopilot systems, where signal integrity is critical.

Low Maintenance Requirements

One of anodized aluminum's overlooked advantages is how little attention it demands. Unlike stainless steel, which can tea-stain or pit without polishing, anodized surfaces only require occasional rinsing. They don't rust, flake, or require repainting. This makes them ideal for boat owners who prioritize reliability with minimal effort.

Maintenance of Anodized Aluminum

In summary, anodized aluminum doesn't just solve corrosion problems; it brings a suite of practical, aesthetic, and environmental benefits that make it the top choice for modern sailboat fittings.

Maintenance Tips for Keeping Anodized Surfaces Clean and Intact

Anodized aluminum is low-maintenance by design, but no marine hardware is fully immune to the cumulative effects of salt, UV, friction, and mechanical stress. Proper care helps preserve both function and appearance, ensuring fittings perform at their best season after season.

Keeping Anodized Surfaces Clean and Intact

Routine Cleaning

Even with its corrosion resistance, anodized aluminum still benefits from regular rinsing. Salt crystals, airborne pollutants, and grime can settle on surfaces and slowly degrade the finish if left unchecked.

- Use mild soap and water: A soft cloth or sponge with pH-neutral soap is ideal. Avoid alkaline or acidic cleaners, which can dull or etch the anodized layer.

- Rinse with fresh water: Especially after offshore passages or heavy spray, rinsing with freshwater removes salt deposits that may accelerate wear.

- Dry thoroughly: After cleaning, drying helps prevent water spots and streaks, especially on darker anodized finishes.

Avoid abrasive pads, scouring powders, or high-pressure washers. These can damage the surface, remove protective sealing, or introduce micro-scratches that dull the finish.

Surface Protection and Inspection

Even anodized surfaces can suffer localized wear, especially in high-friction areas like rotating shackles, winch drums, or boom fittings. Routine visual inspections help identify early signs of damage.

- Look for discoloration, chalking, or pitting: These could indicate loss of the anodized layer in localized spots.

- Check hardware movement zones: Areas with metal-on-metal contact may wear faster, especially if lubrication is insufficient.

- Touch up minor damage: While you can't "re-anodize" in the field, you can apply aluminum-compatible sealants or protective coatings to reduce exposure until proper maintenance is possible.

Protecting fittings with covers or keeping them out of direct sunlight when not in use extends both their aesthetic life and functional reliability.

Preventing Mechanical Damage

Scratches, dents, and abrasions don't just affect looks; they can breach the anodized layer and expose raw aluminum underneath.

- Store loose fittings carefully: Shackles, cleats, or removable hardware should be stored in padded containers to prevent metal-on-metal contact.

- Avoid dragging or scraping: Don't let fittings grind against non-marine surfaces during maintenance or transport.

- Use barrier materials when mounting: Installing anodized parts against rough fiberglass or carbon fiber? Add a plastic washer or gasket to reduce stress and friction.

Treat anodized hardware with the same care you'd give precision instruments. While durable, it performs best when shielded from unnecessary impact or abrasion.

Re-Anodizing and Restoration

Over time, even the best-maintained anodized fittings may show wear, especially in harsh sailing conditions or long-term UV exposure.

- Professional re-anodizing: When hardware loses its protective layer, it can be stripped and re-anodized by a specialist. This process fully restores corrosion resistance and finish.

- Interim protection: For components that can't be immediately restored, marine-grade waxes, sprays, or clear coats can provide temporary shielding.

Re-anodizing is particularly useful for expensive or custom CNC-machined parts that can't be easily replaced. Investing in restoration extends their lifecycle and reduces long-term costs.

Anodized Aluminum vs. Other Marine Materials

When selecting sailboat fittings, material choice is critical. While anodized aluminum has gained popularity, it's often compared with alternatives like stainless steel, titanium, and composites. Each has strengths and weaknesses, but in most marine applications, anodized aluminum offers the best combination of performance, cost, and practicality.

Weight Comparison

Weight is a top concern, especially in performance sailing, where every gram matters.

- Anodized Aluminum: Extremely lightweight, about one-third the density of stainless steel. Ideal for masthead fittings, rigging blocks, and anything above deck where reduced mass improves stability and sail efficiency.

- Stainless Steel (316): Strong but heavy. Suitable for high-load anchors or structural hardware, but adds unnecessary weight for most deck fittings.

- Titanium: Lighter than steel and highly corrosion-resistant, but costly and often over-engineered for sailboat hardware.

- Composites (e.g., carbon fiber): Lightest option, but limited in load-bearing fittings. Prone to UV degradation and costly to repair or replace.

In terms of balance between weight and strength, anodized aluminum outperforms steel in non-structural applications and is far more cost-effective than titanium.

Corrosion Resistance in Marine Environments

Saltwater is unforgiving, and corrosion is the silent killer of metal hardware.

- Anodized Aluminum: The anodic oxide layer protects against both salt and UV exposure. Resistant to pitting and general corrosion, especially when sealed properly.

- Stainless Steel: 316 marine-grade steel offers solid corrosion resistance but can develop tea-staining or localized pitting, especially in poorly ventilated areas.

- Titanium: Outstanding corrosion resistance, virtually immune in marine environments. However, this performance often exceeds practical needs and comes with a high price tag.

- Composites: Don't corrode but may delaminate or degrade under UV or chemical exposure.

Anodized aluminum strikes the right balance, offering protection against corrosion while avoiding the drawbacks of weight or cost.

Fabrication and Customization

Precision matters, especially for fittings under repeated load.

- Anodized Aluminum: Easily machined with CNC tools. Allows for complex designs, lightweight optimization, and tight tolerances. The anodizing process follows fabrication, so it protects even finely detailed components.

- Stainless Steel: More difficult to machine, especially in custom applications. Requires a higher cutting force and more wear on tools.

- Titanium: Very difficult to machine and weld. Limited customization unless working with high-end manufacturing.

- Composites: Custom shapes are possible via molding, but once set, they cannot be easily modified. Not suitable for small, high-tolerance hardware.

For builders, designers, or sailors needing tailored parts, anodized aluminum offers unmatched design freedom and repeatability.

Cost and Availability

- Anodized Aluminum: Widely available, competitively priced, and easy to source in both raw and pre-anodized stock. Costs less than both stainless and titanium in most marine markets.

- Stainless Steel: Mid-range cost, with high durability but added weight.

- Titanium: Expensive, with limited suppliers for marine-grade stock.

- Composites: High material and labor costs, especially for short production runs.

Unless extremely high strength or exotic performance is required, anodized aluminum provides excellent value without compromising quality.

Real-World Applications and Case Examples

The advantages of anodized aluminum aren't just theoretical; they're proven daily in real-world marine settings. From competitive racing to offshore cruising and modern refits, anodized fittings have become the standard for performance, reliability, and longevity.

Performance Sailing: Lightweight Efficiency at Sea

In racing yachts, weight reduction is critical. Every gram saved aloft translates to better righting moment and improved sail control. Anodized aluminum fittings dominate in this space, particularly for:

- Masthead sheaves and halyard blocks: Lightweight yet strong, allowing higher rig tension without excessive mast compression.

- Boom vang brackets and traveler cars: Precision-machined and anodized to reduce weight while withstanding high loads and repeated use.

- Custom deck hardware: Teams often commission CNC-anodized fittings tailored to unique rigging layouts, minimizing friction and maximizing sail trim efficiency.

Professional racing crews choose anodized aluminum not only for its mechanical benefits but also for its consistent performance under stress and exposure.

Cruising Sailboats: Durability and Low Maintenance

Anodized Aluminium blue water cruising explorer yacht

Long-distance cruisers prioritize reliability and ease of maintenance. Anodized aluminum delivers on both fronts.

- Chainplates, stanchion bases, and cleats are commonly made from anodized stock. These components must resist UV, salt spray, and mechanical strain for years with minimal upkeep.

- Winch bases and toe rails often use anodized aluminum to combine strength with corrosion resistance, especially in tropical climates where sun exposure is constant.

Cruising sailors often favor hardware that doesn't require polishing or sealing every few weeks. Anodized fittings stay intact and presentable with little more than routine rinsing.

Yacht Refits and Custom Projects

For boat owners updating older vessels, anodized aluminum offers a modern alternative to heavy or corroded original parts.

- Replacing steel shackles and blocks with anodized aluminum versions reduces deck weight and eliminates tea-staining.

- Upgrading rigging hardware with CNC-machined, anodized components allows a clean, precise retrofit without compromising aesthetics or strength.

- Color-matching custom parts, such as mast tracks, rails, or fairleads, is made possible through dyed anodizing, adding visual cohesion to the updated deck layout.

Custom builders and DIY sailors alike appreciate anodized aluminum for its machinability, finish options, and long-term performance in all climates.

Fleet and Charter Boats: Consistency and Serviceability

In commercial fleets, standardization and easy servicing are key. Anodized aluminum components are favored because:

- They can be produced in volume with consistent dimensions, simplifying stocking and replacement.

- Their resistance to wear reduces downtime between charters or regattas.

- Surface durability prevents fittings from looking prematurely worn, an important factor in client-facing operations.

Whether managing a training fleet or outfitting a coastal charter company, operators value how anodized aluminum reduces maintenance while preserving functionality.

Conclusion

In the demanding world of marine hardware, anodized aluminum has proven itself as a superior material, not by marketing claims, but through decades of real-world application. Its unmatched balance of strength, lightness, corrosion resistance, and design flexibility makes it a natural choice for sailboat fittings, whether you're racing offshore, cruising long-term, or refitting a classic hull.

The anodizing process transforms standard aluminum into a surface that withstands salt, sun, abrasion, and time. With proper maintenance, these fittings outlast expectations, reducing replacement costs and enhancing onboard reliability. And thanks to CNC machining, boat owners and builders can now access custom, precisely engineered parts that meet the specific needs of modern sailing.

Compared to stainless steel, titanium, or composite alternatives, anodized aluminum consistently delivers the best performance-to-cost ratio, especially when weight, customization, and visual appeal matter.

From high-load rigging hardware to cleanly styled deck components, anodized aluminum continues to define the standard for quality marine fittings. For those who demand durability, efficiency, and long-term value on the water, it remains not just a good choice, but the best one.