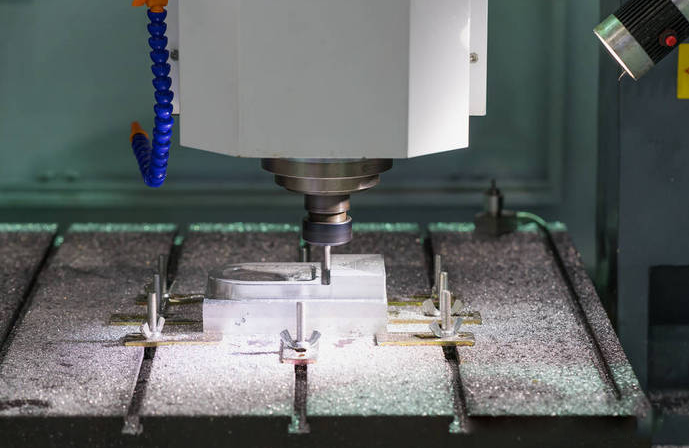

CNC machining refers to the processing method of machining parts on CNC machine tools. Generally speaking, the process flow of CNC machining and traditional machine tool machining is the same, but significant changes have also taken place. The processing method of using digital information to control the displacement of parts and tools. CNC machining is an effective way to solve the problems of a large variety of parts, small batches, complex shapes, and high precision, and to achieve high-efficiency automatic machining.

Advantages of machining:

CNC machining is a process in which the control system issues instructions to make the tool make various movements that meet the requirements. The shape and size of the workpiece and the processing technology requirements and other technical requirements are expressed in the form of numbers and letters. CNC machining quality is stable, the surface texture of the finished product is clear, the metal texture is firm, smooth and flat, without scratches and corners, the heat dissipation coefficient of the raw material, CNC machining resistance is small, and will not change with CNC machining. The manufacturer can adjust the specific process to improve its heat dissipation performance. For example, oxidation, stretching, cooking, sandblasting and other processes can be carried out under CNC operation.

CNC machining integrates milling, boring, drilling, tapping, and thread cutting, so that it has a variety of processing techniques. The machining center is equipped with a tool magazine, which stores different quantities of various tools or inspection tools, which are automatically selected and replaced by programs during the machining process. CNC machining can automatically select and replace tools, automatically change the spindle speed, feed rate, tool relative to the workpiece motion path and other auxiliary functions, and complete multiple processes on several surfaces of the workpiece in sequence, with multiple tool replacements Or tool selection function.

CNC precision machining With the development of science and technology, machining center machines have become the main force of machining. More and more machining centers have become necessary equipment for production. The machining centers are not affected by humans, and the processing consistency is good, which reduces the labor of workers. Strength has become an effective tool for improving production efficiency and processing complex parts, so the machining accuracy of the machining center has become a common concern for everyone.

External factors that affect machining accuracy:

Screw clearance of machining center: The positioning accuracy of the machining center directly affects the machining accuracy of the workpiece, and the temperature has an important influence on the positioning accuracy. If there is no machine tool in the constant temperature workshop, the machine tool should be run dry before processing every day to make the machine tool The temperature and the outside temperature have been in the process of processing, we commonly call it a heat engine, and the backlash of the lead screw should be checked frequently.