Superalloys have become essential in industries where components must withstand extreme heat, high loads, and corrosive environments. Aerospace engines, power generation systems, and advanced medical devices rely on these materials because they retain mechanical strength even at elevated temperatures. Although their performance advantages are significant, these same characteristics make them demanding to machine. Every cut generates intense heat, chips behave unpredictably, and tool wear becomes rapid if parameters are not controlled carefully.

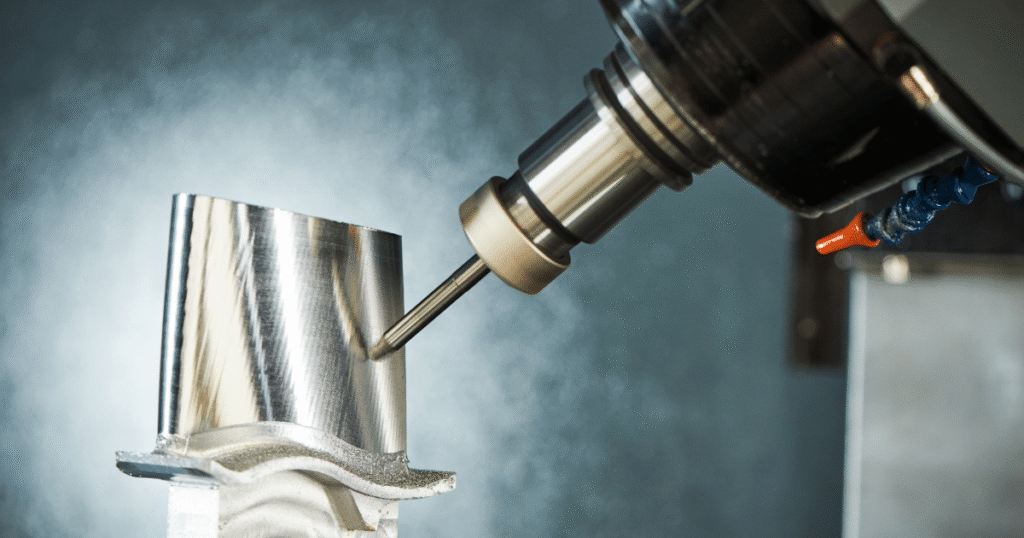

This article explores how to machine superalloys with accuracy and consistency by focusing on the fundamentals that matter most. It breaks down process parameters, tooling selection, heat management, finishing requirements, and the strategies that help maintain both productivity and surface integrity. When the right techniques are applied, CNC machining of superalloys becomes reliable, predictable, and capable of meeting the strict standards required in modern manufacturing.

Understanding Superalloys and Their Machining Challenges

Superalloys behave very differently from common engineering materials, which is why machining them demands far more control and planning. Their strength at high temperatures, resistance to deformation, and complex microstructures create continuous stress on cutting tools. Heat stays concentrated at the cutting edge, chips do not break easily, and even small mistakes in cutting conditions can lead to rapid tool failure. When a machinist understands how these materials respond under load, selecting the right strategy becomes much easier.

These characteristics influence every stage of machining, from roughing to finishing. They affect chip formation, cutting forces, vibration levels, and even the final surface quality. Before exploring process parameters and tooling requirements, it is important to understand the inherent behavior of superalloys during cutting.

Key Properties That Affect Machining

Superalloys share several characteristics that influence the stability and efficiency of machining operations. These properties determine how tools wear, how heat moves through the cutting zone, and how the material responds to aggressive or conservative parameters.

Key properties include:

- High strength at elevated temperatures, which increases cutting forces

- Low thermal conductivity that traps heat near the tool

- A strong tendency to work-harden if chip load drops

- Abrasive microstructures that accelerate flank wear and edge rounding

Each of these properties affects tool life and requires a machining strategy that prioritizes continuous cutting, sharp tooling, and controlled heat management.

Material-Specific Requirements

Different superalloys behave uniquely, and each one demands specific strategies to maintain tool life and surface quality. Even small differences in composition can influence heat generation, chip formation, and engagement stability.

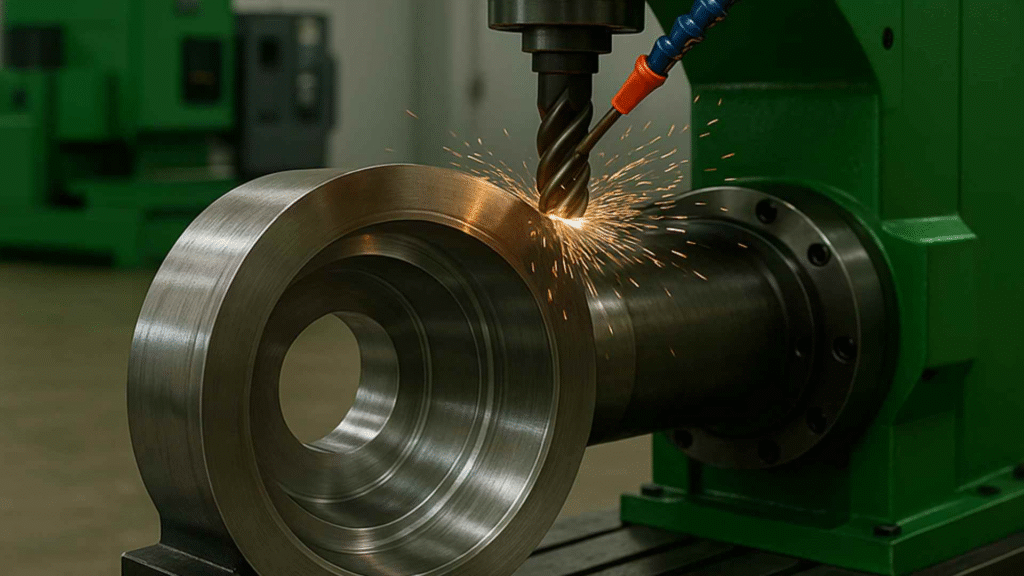

CNC Turning for Inconel, Monel & Superalloys

Below are the main considerations for common superalloys used in CNC machining.

Inconel

Inconel is one of the most challenging materials to machine because it strengthens rapidly under pressure and heat. This behavior increases resistance to cutting and often leads to unstable tool engagement.

Key problems include:

- Rapid work-hardening occurs when the chip load fluctuates

- High cutting forces that strain the tool

- Heat concentration at the cutting edge due to poor thermal conductivity

Hastelloy

Hastelloy offers corrosion resistance and mechanical stability, but these benefits come with machining difficulties. Its structure creates high shear strength that requires a rigid setup and precise parameters.

Typical concerns include:

- Strong tendency for built-up edge when using worn tools

- High shear strength increases the power needed for cutting

- A need for controlled heat input and sharp tooling to avoid smearing

Titanium Alloys

Titanium behaves differently from nickel-based alloys but is equally challenging. Its low thermal conductivity traps heat in the cutting zone, while its elastic nature increases the risk of deflection.

Key challenges include:

- Poor thermal conductivity that overheats tools

- A higher risk of chatter due to material flexibility

- Chemical reactivity at high temperatures that promotes tool adhesion

Process Parameters for Stability and Accuracy

Superalloys respond very sensitively to cutting parameters, which means even small deviations can affect heat levels, chip formation, and tool stability. Selecting parameters is not only about reaching a target productivity rate. It is about protecting the cutting edge, preventing work-hardening, and maintaining a stable chip load throughout the cut. If feeds, speeds, or engagement are incorrect, the alloy can harden instantly, causing heavy wear or chatter that compromises surface integrity.

Well-chosen parameters help distribute heat, maintain consistent cutting pressure, and reduce the risk of rubbing. Each superalloy has its own preferred range, but the principles for stable machining remain similar across nickel and titanium-based materials.

Cutting Speeds and Feed Rates

Cutting speed directly influences heat generation. High speeds can lead to thermal softening of the tool, flank wear, and loss of edge sharpness. Superalloys generally require lower surface speeds than steels because they trap heat near the cutting zone. Feed rate also needs careful adjustment because too light a feed promotes rubbing and work-hardening.

General considerations include:

- Using conservative cutting speeds to manage heat

- Maintaining feed rates high enough to form proper chips

- Balancing surface integrity with tool life to avoid excessive wear

Excessive cutting speed shortens tool life rapidly, while overly slow feed rates increase the risk of material hardening. Stability comes from finding the right combination for the specific alloy and tool type.

Depth of Cut and Radial Engagement

Depth of cut affects chip thickness, which influences cutting pressure and heat. When machining superalloys, inconsistent chip thickness can cause the tool to rub against the workpiece. This creates localized hardening and increases cutting resistance on the next pass. Radial engagement also requires control because high engagement generates excessive heat, while low engagement can cause vibration.

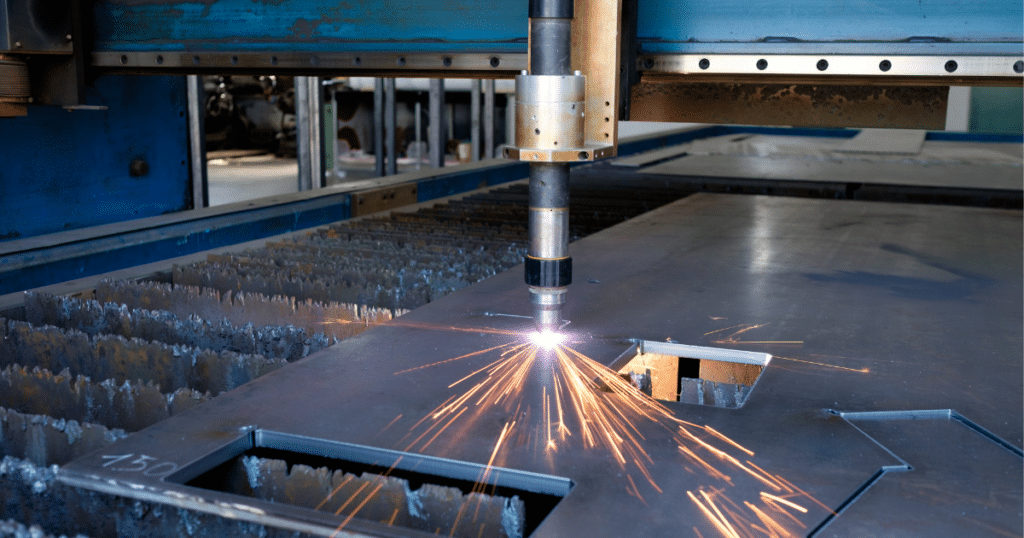

Mastering the Art of Machining Superalloys

Effective strategies involve:

- Choosing a depth of cut that maintains proper chip thickness

- Avoiding shallow passes that cause rubbing

- Adjusting roughing and finishing parameters to match tool rigidity and machine power

Roughing typically uses moderate to heavy engagement with strong chip evacuation. Finishing uses lighter, controlled cuts to protect the final surface integrity.

Coolant Use and Heat Control

Heat is one of the main problems when machining superalloys, and improper cooling leads to tool wear and microcracks. Coolant selection and delivery method determine how effectively heat is removed from the cutting zone. High-pressure systems generally perform better because they push chips away and prevent them from recutting.

Important factors include:

- Choosing between standard flood cooling and high-pressure coolant

- Considering the risks of thermal cracking in dry machining

- Ensuring strong chip evacuation to prevent trapped heat

Reliable temperature control helps maintain stable tool performance and reduces material damage during long machining cycles.

Spindle Power, Torque, and Machine Rigidity

Superalloys demand a rigid machine structure because cutting forces remain high throughout the operation. Flex or vibration in the spindle or fixturing leads to poor finish and inconsistent tool wear. Machine power also dictates the maximum allowable engagement and type of roughing strategies that can be used.

Key considerations include:

- Ensuring machine stiffness to improve tool life and surface quality

- Confirming that spindle power and torque are sufficient for heavy cuts

- Reducing vibration through stable toolpaths and proper clamping

A rigid machine and stable power delivery allow more aggressive parameters without sacrificing accuracy or finish.

Tooling Selection and Optimization

Tooling plays the most influential role in how superalloys respond during machining. Even with the best parameters and coolant strategy, poor tool selection results in rapid wear, inconsistent chip formation, and surface defects. Superalloys place intense mechanical and thermal stress on cutting tools, so the choice of material, geometry, and coating directly determines stability and tool life. A well-designed tool reduces heat concentration, promotes clean shearing, and protects the cutting edge from abrasion.

Another important aspect is how tools behave over time. Wear tends to accelerate once the cutting edge loses its sharpness, which affects chip flow and increases cutting forces. Monitoring tool condition and selecting geometries that delay wear helps maintain predictable performance throughout long machining cycles.

Tool Material and Coating Choices

The materials used for cutting tools must withstand high temperatures and abrasive wear. Carbide remains the most common choice because it balances hardness with toughness, but grade selection matters. Fine-grain carbides usually perform better in superalloys since they resist edge chipping and maintain strength at elevated temperatures.

After understanding this, several coating considerations come into play:

- CVD vs PVD coatings

CVD coatings offer strong wear resistance, but PVD coatings adhere better to sharp cutting edges and minimize thermal cracking. The choice depends on whether the priority is maximum durability or edge stability.

- Ceramic and CBN tools

These materials excel in very high temperature environments and allow much faster cutting speeds during specialized operations. They are often used for finishing hard nickel-based alloys, although they require rigid setups and consistent engagement to prevent edge failure.

Choosing the correct tool and coating combination improves tool life and helps maintain a predictable cutting environment.

Tool Geometry for Superalloys

Geometry influences how the tool enters the cut, forms the chip, and distributes heat. Superalloys respond better to positive cutting action, where the tool slices through the material instead of pushing against it. A polished flute or smooth chip evacuation path also helps control heat and reduces friction.

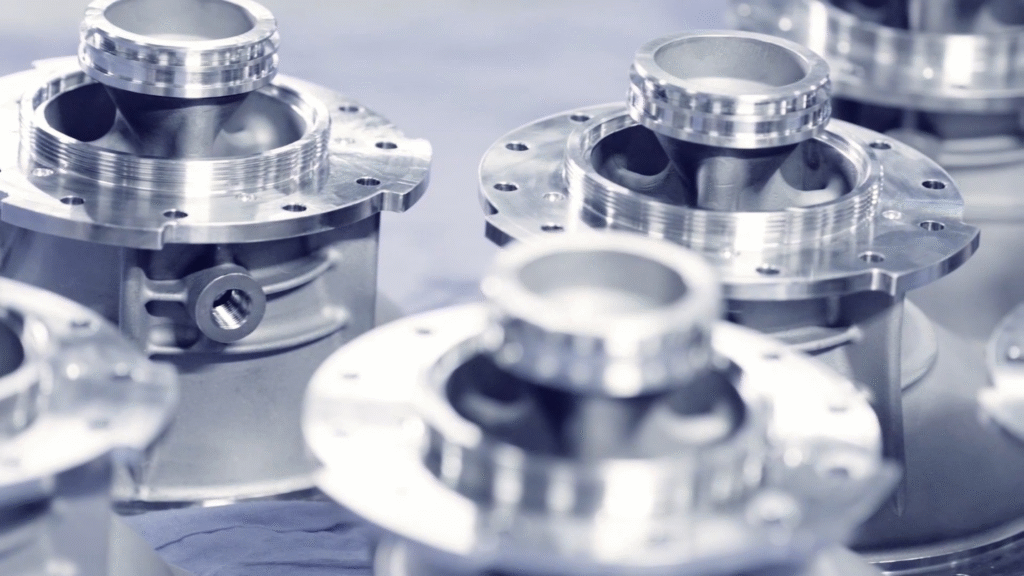

Machining for High-Temperature Aerospace Applications

Once these principles are understood, geometry choices become clearer:

- Positive rake angles

These reduce cutting forces and promote cleaner shearing.

- Edge prep and honed edges

Very sharp edges reduce rubbing but may chip quickly. A slight hone adds strength while maintaining cutting efficiency.

- Corner radius selection

A correct radius reduces stress concentration at the tool tip and improves surface finish. Too large a radius increases cutting forces, while too small a radius increases the risk of edge wear.

These geometric features help balance chip control, tool stability, and surface quality.

Toolpath Strategies

Toolpaths have a major influence on heat generation, chip thickness, and overall tool load. Superalloys require smooth, consistent engagement to avoid sudden spikes in temperature or force. Abrupt direction changes or heavy entry cuts can damage the tool and degrade surface integrity.

After establishing the need for stable engagement, several strategies become important:

- Climb milling over conventional milling

Climb milling reduces the amount of heat absorbed by the tool and improves chip flow.

- High efficiency milling

This method maintains a constant chip load with low radial engagement, allowing higher feed rates and lower tool temperatures.

- Adaptive toolpaths

These maintain consistent cutter engagement in complex geometries, which prevents load spikes and preserves tool life.

- Smooth entry and exit patterns

Gradual ramping or helical entry reduces shock loading at the start of the cut.

Optimizing toolpaths improves accuracy, reduces wear, and shortens machining time.

Tool Life Monitoring

Tool wear happens quickly when machining superalloys, so monitoring becomes essential for both quality and cost control. Wear patterns vary depending on the alloy, cutting conditions, and coating, but they usually start at the flank or nose radius. Early detection prevents surface damage and reduces scrap.

Several methods help track tool condition more effectively:

- Recognizing wear patterns typical to each alloy

Inconel often shows crater wear, while titanium tends to cause notching at the depth of the cut line.

- Predictive monitoring

Using historical data helps determine standard tool change intervals before wear becomes critical.

- Sensors and machine diagnostics

Modern CNC machines can track spindle load, vibration, and acoustic signals to identify when a tool is nearing failure.

Proper monitoring ensures consistent quality and reduces downtime.

Workholding, Fixturing, and Machine Setup

Superalloys are unforgiving when the setup is weak. Their high cutting forces, poor thermal conductivity, and tendency to deflect under stress make it important to secure the workpiece with maximum stability. Even minor vibration can damage the cutting edge, create chatter marks, or reduce accuracy. A rigid setup allows the tool to maintain a consistent path, prevents micro movement during heavy cuts, and reduces the heat generated from tool rubbing.

Another critical aspect is how the workpiece reacts to heat during machining. Superalloys expand more aggressively than common steels, and this movement affects dimensional accuracy. Good fixturing and pre-processing practices help control these effects and ensure the part maintains its geometry through multiple passes.

Fixturing for High-Strength Alloys

Because these materials resist cutting and generate strong forces, fixturing must eliminate unnecessary movement. Rigid clamps, solid supports, and stable contact surfaces help distribute loads evenly. The goal is to keep the workpiece locked in position without distortion.

Important considerations include:

- Using rigid clamps and supports that can withstand high cutting forces

- Positioning the part to minimize potential vibration pathways

- Ensuring uniform clamping pressure to avoid bending thin sections

A stable foundation directly improves tool life and surface quality.

Managing Heat Expansion in Workpieces

Heat expansion is unavoidable when machining superalloys, and ignoring it leads to out-of-tolerance parts, especially in tight-tolerance aerospace and medical components. Machines must compensate for thermal growth to maintain final accuracy.

Effective techniques include:

- Using probing routines to measure dimensional changes during machining

- Allowing fixturing designs that let the material expand in a controlled direction

- Reducing long continuous cuts that build excessive heat

Compensation ensures the part stays true even as temperature changes throughout the machining cycle.

Pre-Processing Considerations

Pre-processing helps improve consistency and reduces the risk of unexpected deformation or internal stress during machining. Many superalloys retain residual stresses from forging or heat treatment, which may release unpredictably once material is removed.

Key practices include:

- Applying stress relief heat treatment before machining for stability

- Verifying material certification to ensure correct composition and microstructure

- Inspecting the stock for surface defects that may affect the cutting process

Good preparation avoids dimensional shifts and ensures the alloy behaves predictably during cutting.

Common Mistakes and How to Avoid Them

Machining superalloys demands precision, and even small mistakes can lead to rapid tool failure, poor surface quality, or dimensional errors. Many of these issues come from overlooking how sensitive these materials are to heat, chip load, and tool engagement. Understanding the most frequent errors helps prevent unnecessary scrap and ensures stable machining over long production runs.

Mastering the Art of Machining Superalloys

These mistakes often appear when machinists rely on parameters suited for steels or aluminum. Superalloys behave very differently, and they punish any inconsistency in cutting conditions. With proper planning and controlled execution, most of these issues can be avoided.

Typical Problems to Watch Out For

- Running excessive speeds that cause thermal damage

High cutting speeds trap heat near the cutting edge because these alloys conduct heat poorly. The tool reaches critical temperature quickly, which accelerates flank wear and can cause microcracks on the workpiece surface. Keeping surface speed conservative and focusing on stable chip load reduces this risk.

- Using incorrect coatings that fail under heat and abrasion

Coatings designed for general-purpose machining may not survive the heat generated by nickel or titanium-based alloys. Inappropriate coatings can peel, crack, or promote built-up edge. Choosing coatings compatible with high temperatures and abrasive microstructures maintains better tool integrity.

- Poor chip evacuation leading to a built-up edge and vibration

Superalloys produce tough, stringy chips that tend to wrap around the tool or recut if evacuation is weak. This increases cutting forces and causes unpredictable tool loading. High-pressure coolant or chip breakers help maintain clean chip flow and prevent tool rubbing.

- Skipping toolpath optimization

Standard toolpaths often create uneven engagement, sudden load spikes, or aggressive plunge moves. These conditions raise the chance of chatter and premature wear. Adaptive and high-efficiency toolpaths maintain consistent pressure and prevent the alloy from work hardening.

- Incorrect fixturing that contributes to chatter and poor accuracy

Weak setups allow the part to vibrate or flex during cutting. Even slight movement reduces surface quality and increases tool wear. Rigid clamps, balanced supports, and strategic part orientation eliminate vibration pathways and stabilize the cut.

Conclusion

CNC machining of superalloys requires far more control and planning than machining conventional materials. Their high strength, low thermal conductivity, and tendency to work harden create an environment where heat, tool wear, and stability must be managed with precision. Successful machining depends on selecting the right tool materials, choosing effective coatings, setting optimized parameters, and maintaining a rigid setup that minimizes vibration and thermal distortion. When these elements align, the cutting process becomes predictable and capable of meeting the demanding standards found in aerospace, energy, and medical applications.

Achieving consistent quality also relies on careful attention to toolpath strategies, chip evacuation, and process monitoring. With the correct balance of cutting forces, temperature control, and finishing parameters, manufacturers can produce parts with excellent surface integrity and dimensional accuracy while avoiding unnecessary cycle time. Although superalloys present significant challenges, a thoughtful approach and disciplined machining strategy allow teams to reach high productivity without compromising the performance or reliability of the final component.