Pre-processing procedures are used on materials and components prior to machining or final finishing. It reduces internal tensions, enhances dimensional stability, and guarantees reliable performance throughout service.

In large-scale structural components, the residual stresses impact the dimensional stability and operating longevity of precision machine tools. The parts longevity and service life are significantly influenced by residual stresses. The residual stresses in the material part are developed by processes including heating, machining, mechanical treatment, and even the actual manufacturing process.

These stresses cause dimensional drift, faster fatigue-corrosion synergy, and machining errors, among other multi-axis deterioration mechanisms. So, It's very necessary to eliminate this stress in pre-processing to avoid any kind of failure during processing and machining.

Pre-processing techniques are necessary for current precision manufacturing to produce high-quality, reliable, and effective manufacturing outcomes. In this blog, we will let you know how pre-processing techniques can reduce the material internal stress. So are you ready? Let's begin.

1. Fundamentals of Residual/Internal Stress in Manufacturing

Residual stresses can have a significant impact on the technical characteristics of materials and structural elements, including fatigue life, distortion, dimensional stability, corrosion resistance, and brittle fracture. They originate in a variety of sources and can be found in raw materials that haven't been treated, injected during the production process, or result from loading while the product is in use.

The source of residual tensions could be categorized as follows:

- Phase changes with volume changes,

- Differential cooling rates, and

- Differential plastic flow, among other things.

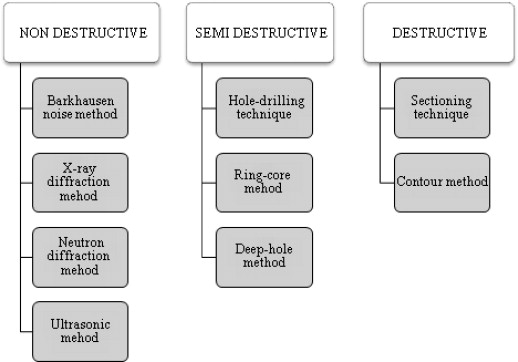

Tensile residual stresses in a part or structural element are generally detrimental since they can lead to fatigue failure and stress corrosion cracking, and they are frequently the primary cause of these conditions. It is generally advantageous to have compressive residual stresses created in the (sub)surface layers of material by various methods since they enhance wear and corrosion resistance and stop fatigue cracks from originating and spreading. It is possible to categorize residual pressures as either non-destructive, semi-destructive, or destructive, as demonstrated

Measuring techniques of residual stress

The following determines the residual stresses' distribution and magnitude:

- Material characteristics (transformation behavior, yield strength, and thermal expansion)

- Geometry (section changes, thickness, and symmetry)

- Processing parameters (cutting forces, distortion mode, heat input, and cooling rate)

Considering these stresses is crucial because residual stresses might combine with machining or service loads to generate unforeseen deformation or decreased performance. Thus, to stabilize the material and enhance dimensional accuracy, pre-processing stress-relieving methods (thermal, mechanical, cryogenic, isostatic, or vibratory) are frequently used prior to finish machining.

2. Impact of Internal Stress on Machining Accuracy

Residual stresses as one of the primary elements influencing component qualities, which may have an impact on the component's performance. The component's life is eventually impacted by residual stresses, which are specifically found to have an effect on fatigue strength, corrosion strength, structural strength, etc. Throughout the component's service life, their impacts can be gradually seen even though they are not readily apparent.

The material's fatigue strength is enhanced by either a higher compressive residual stress or a lower tensile residual stress. To put it simply, compression results in a decrease in an object's length whereas tension causes it to rise. The majority of production procedures, including metal forming, machining, heat treatment, and grinding, leave behind residual tensions.

There are ways to purposefully create residual stress into the components using techniques like peening, or even remove the ones that are already there using stress-relieving techniques like heat-treatment, cryogenic treating, etc., depending on the kind and form of residual stress.

It is important to note that, in light of all these observations about the nature and consequences of residual stresses, it is imperative that they be measured precisely. This is the duty of researchers and practitioners to determine both the beneficial and detrimental effects of these stresses so that they can be avoided or used to their fullest potential.

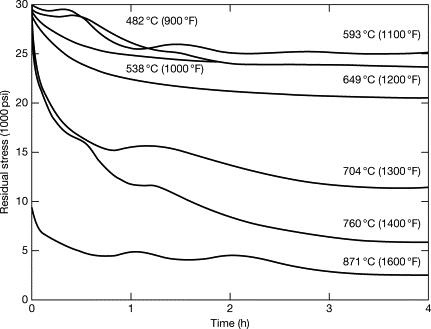

3. Pre-Processing Strategy: Thermal Stress Relief Methods

One of the most popular pre-processing methods to lessen residual stresses that develop during manufacturing operations like welding, casting, forging, machining, and heat treatment is thermal stress relief, or TSR.

In order to redistribute and minimize internal tensions, thermal stress relief mostly involves heating the component to a temperature below its transformation or recrystallization range, maintaining it there for a certain period.

TSR uses a high/low temperature cycle in materials to induce stress relaxation or creep, which results in changes in mechanical properties such as the yield limit and elastic modulus.

It lowers residual stress by transforming the material's internal elastic strain energy into plastic strain energy.

High energy consumption and low efficiency are the drawbacks of this kind of approach, although its benefits include a good overall stress regulation impact and uniform stress distribution.

Thermal stress relief, for instance, helps preserve shape stability, reduces distortion during finish machining, and increases fatigue life in precision machined parts, large castings, welded pressure vessels, and aerospace structures.

TSR influences the microstructure and mechanical characteristics of materials in addition to lowering residual stress. 6061 aluminum alloy components' residual stress-induced deformation is reduced by 60% but their tensile strength is decreased by 20% following a one-hour heat aging treatment at 340 °C.

Thermal stress relief does have certain drawbacks, though. It could be challenging to fit large structures within furnaces, and certain heat-sensitive materials might experience unfavorable microstructural changes.

Furthermore, in complex or extremely thick geometries with widely fluctuating stress gradients, thermal stress reduction might not be effective. Considering its repeatability, predictability, and solid metallurgical basis, thermal stress release is yet a common and safe technique in spite of these limitations.

4. Pre-Processing Strategy: Mechanical & Vibratory Treatments

Prior to final machining or assembly, mechanical and vibratory stress relief (VSR) procedures are frequently employed to reduce or redistribute residual stresses in components.

The mechanical and vibratory techniques utilize regulated cyclic forces to the material to create localized plastic deformation in highly stressed places, allowing internal stresses to rebalance more uniformly than thermal stress release, which depends on heating.

Mechanical Treatments:

Providing controlled mechanical loading to the part—such as stretching, compression, peening, or surface rolling—relieves mechanical stress. Mechanical techniques purposefully add compressive residual stresses to the surface layers, which enhance wear performance, fatigue strength, and crack resistance. Such as

- Shots Peening

- Roller Burnishing

- Mechanical Forming and Stretching

These procedures purposefully cause surface layers to experience compressive residual stresses. The advantages of compressive stress are as follows:

- increases the strength of tiredness

- increases resistance against corrosion and wear.

- prevents the start and spread of cracks

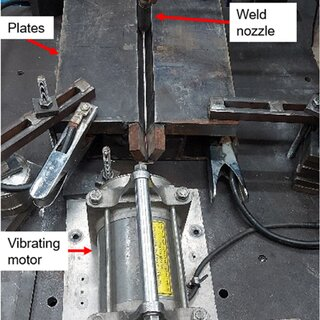

Vibratory Stress Relief (VSR) Treatment:

The effectiveness, portability, convenience of use, and quick processing time of VSR treatment make it a technique that eliminates residual stress. It is seen as a long-term approach of removing lingering stress.

When a workpiece is subjected to mechanical vibrations, VSR technology causes slight plastic deformations when the total stress produced by the vibrations plus the residual stress from welding surpasses the yield limit of the material. By doing this, residual stress is reduced and material qualities are enhanced.

In situations when heat treatment may not be feasible because of size, expense, or distortion risk, vibratory stress relief is especially useful for big welded fabrications, machine frames, molds, and castings.

Welding dissimilar steels, variables including phase transitions, carbon migration, and structural displacement restricts naturally result in uneven residual stress in the welded area and its vicinity because each material has different physical and chemical properties. This unequal residual stress greatly impacts the structural integrity and performance of different steel welded components

Therefore, a highly concentrated area in the application of welded structural components and a hot research topic in the welding sector right now is the release of residual stress and the optimization of performance in dissimilar steel welded connections.

When a workpiece is subjected to mechanical vibrations, VSR technology causes slight plastic deformations when the total stress produced by the vibrations plus the residual stress from welding surpasses the yield limit of the material. By doing this, residual stress is reduced and material qualities are enhanced.

Researchers found that VSR could lower stress levels while simultaneously improving the material's mechanical qualities. Among the main benefits of VSR are:

- Suitable for big and intricate geometries

- No alteration in hardness or microstructure

- economical and energy-efficient

- can be carried out on-site, even following assembly.

5. Pre-Processing Strategy: Pressure & Isostatic Treatments

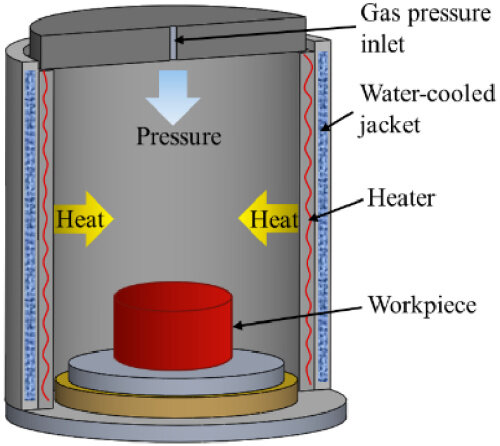

Hot Isostatic Pressing (HIP) and Cold Isostatic Pressing (CIP) are two pressure-based stress relief procedures that are frequently used to decrease residual stresses. It homogenizes microstructure, and reduces internal flaws in metallic and composite components prior to final machining.

By applying pressure consistently from all directions, these techniques guarantee that internal voids and microstructural irregularities are minimized without causing distortion.

HIP is particularly crucial for high-performance tool steels, castings, and additive manufacturing (AM) components because layered deposition or rapid solidification have a tendency to trap micro-voids and produce high tensile residual stresses. Following HIP, the parts show:

- Porosity reduction frequently approaches 0%.

- A more consistent grain structure

- Reduced likelihood of fractures developing while in service

Materials with complex geometries and near-net shapes that are challenging to process can be produced using laser powder-bed fusion (LPBF). Even with a high preheating temperature, components made of LPBF-produced tool steels frequently exhibit high residual stresses, residual porosity, and cracks.

Components can undergo microstructure modification and densification through the use of hot isostatic pressing (HIP). Furthermore, quick cooling inside the HIP vessel helps reduce thermal stresses, warping, or breaking during quenching as opposed to traditional heat treatment at ambient pressure.

Cold Isostatic Pressing (CIP)

CIP uses a flexible mold inside a fluid chamber with high pressure and runs at room temperature. It

- creates homogeneous density,

- homogeneous green (pre-sintering) compacts

- reduces areas of stress concentration prior to additional processing or sintering

- is mostly employed in ceramics, refractory materials, and powder metallurgy.

6. Pre-Processing Strategy: Cryogenic, Aging & Surface Methods

Cryogenic Treatment: The aim of cryogenic treatment is to alter the microstructures of metallic materials at extremely low temperatures in order to enhance their characteristics. The material is cooled at extremely low temperatures—typically below -150 °C or lower—for a while before bringing them back to normal temperature. This can reduce residual stresses or enhance dimensional stability by refining the microstructure (for instance, by encouraging finer precipitates, decreasing dislocations, or changing retained austenite in steels).

Aging: In the aging process, precipitates are formed (for example, in alloys of nickel or aluminum), components are aged at a moderately high temperature following initial solution treatment or quenching. By stabilizing the microstructure and relaxing internal tensions, this precipitate formation lessens residual stress and deformation.

Surface Treatment: There are some surface methods such as surface blasting, burnishing, laser peening, shot peening, surface finishing, polishing, and other techniques used to the part surface (without complete section heating/pressure). These surface treatments alter the topology of the surface, create compressive stresses there, increase fatigue life, and aid in reducing residual stress close to the surface, which frequently regulates the onset of failure.

Mechanism:

Cryogenic Treatment: Internal stresses caused by remaining retained phases or dislocations can be reduced by drastically lowering the temperature during cryogenic treatment. This is possible when growth takes place, microstructure improves, and thermal contraction redistributes tensions. For instance, an Al alloy's residual stress was reduced by about 64% after cryogenic treatment and aging.

Aging:

As a material ages, it can relax and internal strains can even out, allowing for the diffusion and development of fine precipitates that relieve internal tensions. In an aluminum casting investigation, for instance, residual-stress relaxation rose as the aging temperature and time increased.

Surface Treatment: Surface treatments: Tensile residual stresses, which are detrimental for fatigue/crack initiation, are mitigated by applying compressive residual stress to the surface (shot peening, laser peening, and burnishing). Additionally, altering the surface's smoothness or roughness might alter the local stress state, which in turn can alter the behavior of residual stress generally.

7. Material- and Geometry-Based Technique Selection

The geometry of the component being treated and the material qualities have a significant influence on the choice of residual stress reduction technique. The method that may be used safely and successfully depends on the part's size, thickness, and structural complexity. Different materials react differently to heat, pressure, vibration, or surface treatments.

Considerations Based on Materials

- Metals having Phase Transformation Behavior (e.g., steels):

Phase transformation can stabilize the microstructure and relieve internal stress, which makes heat treatment and cryogenic processing successful.

- Precipitation-Hardening Alloys (e.g., Al- and Ni-based alloys):

Aging treatments are chosen to refine precipitates and minimize internal strain without distorting the part.

- Ceramic or brittle materials:

Preventing cracking requires careful control of thermal stress alleviation; surface polishing or isostatic pressing are better options.

- Materials Made via Powder Metallurgy and Additive Manufacturing (AM):

Hot Isostatic Pressing (HIP) is a common technique for sealing interior pores and lowering component stress.

Geometry-Based Aspects

- Thick and massive structures:

Vibratory Stress Relief (VSR) is a practical and economical solution for thick, massive structures where furnace stress-relief is challenging due to size.

- Thin-walled or lightweight parts:

Surface techniques (shot peening, laser peening, and burnishing) reduce distortion and increase fatigue strength in thin-walled or lightweight parts.

- Complex lattice or hollow components, particularly AM parts:

HIP densifies areas that are inaccessible to other techniques and relieves interior flaws.

- High-precision machined parts:

Low-temperature or cryogenic aging processes enhance dimensional stability for parts that must meet strict tolerance specifications.

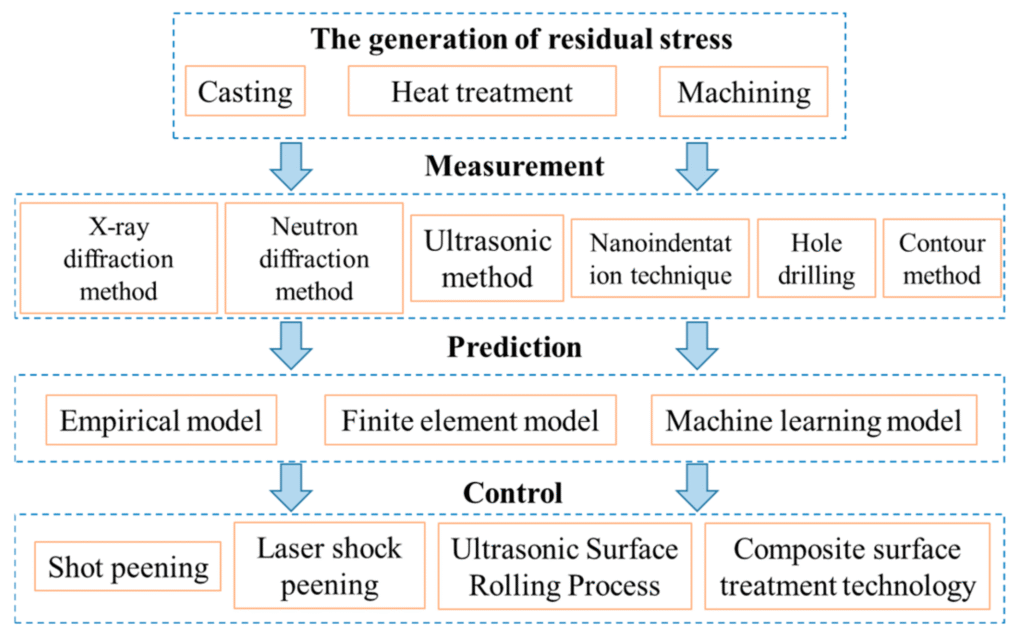

8. Measurement & Validation of Stress Relief Effectiveness

To verify the efficacy of a stress-relief technique, residual stresses must be measured both before and after treatment to determine the component's stability and level of stress reduction.

The part size, material, intended depth, and permitted destructive testing all influence the measuring technique selection.

1. Diffraction of X-rays (XRD)

Principle: Quantifies how internal tension alters the atomic lattice spacing.

Use Case: Ideal for residual stress at the surface level.

Benefits: Nondestructive and highly accurate.

Limitation: Usually less than 10 μm of penetration depth.

2. Method of Hole Drilling (ASTM E837)

Principle: The component is drilled with a tiny hole, and strain gauges record deformation to determine stress.

Use Case: Measuring depth from near the surface to medium.

Benefits: extensively applicable and semi-destructive.

Limitation: needs precise calibration and access to the surface.

3. Neutron Diffraction

Principle: Measures internal lattice strain over whole cross-sections via neutron scattering.

Use Case: Measuring residual stress in significant components in bulk.

Benefits: Very accurate and deep penetration.

Limitation: Needs specialist facilities for study.

4. Ultrasonic Assessment of Stress

Principle: Elastic wave velocity through a medium is influenced by stress.

Use Case: Examining significant structures and fields.

Benefits include portability and nondestructiveness.

Limitation: The precision is lower than with diffraction methods.

9. Case Studies Demonstrating Improved Machining Accuracy

The best way to demonstrate the efficacy of residual stress management techniques is to use actual manufacturing case studies. The examples provided demonstrate how choosing the right stress-relief technique can greatly enhance part stability, tool life, surface polish, and dimensional accuracy during machining.

Case Study 1: Enhancing Dimensional Stability via Thermal Stress Relief in Alloy Steel

- Thermal stress relief at 650–700°C prior to final machining produced the following results when AISI 4140 steel shafts were machined:

- Reduced residual tensile stresses by 42 percent.

- An increase of 25% in dimensional stability.

- less distortion when twisting and grinding.

Case Study 2: Vibratory Stress Relief for Welded Frames Minimizes Post Machining Distortion

During milling, internal tensions cause large welded machine frames to bend often. Applying a vibratory stress relief (VSR) treatment for 45 to 90 minutes at a resonant frequency produced the following results:

- Reduction of weld-induced stress concentration substantially.

- Compared to frames that were not treated, the dimensional deviation dropped by about 30 to 60%.

10. Implementation Checklist for Engineering Teams

- Determine the Components at High Risk

Identify the components that are susceptible to internal stress-induced deformation, including thick sections that are cast or machined, welded assemblies, heat-treated tool steels, and metals that are additively created.

2. Choose the Best Technique for Relieving Stress

Adapt the technique to the material, size, tolerance, and budgetary constraints:

Thermal Stress Relief: For alloys and steels that need to maintain their dimensions.

Vibratory Stress Relief (VSR): When heating is not an option for massive weldments.

Cryogenic + aging: Tool steels can benefit from cryogenic + aging to enhance wear resistance and carbide dispersion.

Hot Isostatic Pressing (HIP): To lessen internal voids and stress in AM titanium/nickel alloys.

3. Establish Processing Parameters

Depending on the material specifications, published standards, or supplier data sheets, set the temperature, cooling rate, vibration frequency, time duration, or pressure.

4. Execute the Stress-Reduction Procedure

Avoid fixturing, which could reintroduce deformation, and make sure the process is operated in a controlled and consistent environment.

5. Check for Stress Reduction Before and After Testing

Utilize the proper measurement methods according to the part size and level of accuracy needed:

- For surface stress, XRD

- Hole drilling for gradients close to the surface

- Internal bulk stresses using neutron diffraction or ultrasonic

6. Verify Dimensional Stability

To evaluate distortion behavior, do a trial machining cut, a CMM measurement, or a flatness check.

7. Standardize lessons learned and document parameters.

To guarantee repeatability and lower rework in subsequent machining operations, record all process parameters (temperature, time, frequency, and pressure) and update work instructions.

Conclusion:

Internal or residual stresses have a major impact on the long-term performance, dimensional stability, and machining precision of manufactured parts. The pre-processing techniques demonstrate that, focusing on the geometry, material composition, and functional requirements, each approach has unique advantages.

The right technique must be chosen, processing parameters must be carefully controlled, and the results must be confirmed using trustworthy stress measurement techniques such as neutron diffraction, hole drilling, X-ray diffraction, or ultrasonic analysis.

Case studies show how using the right stress relief technique can improve surface quality, decrease machining distortion, and increase manufacturing efficiency overall. Therefore, to guarantee repeatable and quantifiable gains, a systematic decision framework and standardized validation procedures are crucial.

Engineering teams can improve product dependability, precision, and rejection rates by incorporating stress-relief techniques into early manufacturing planning.