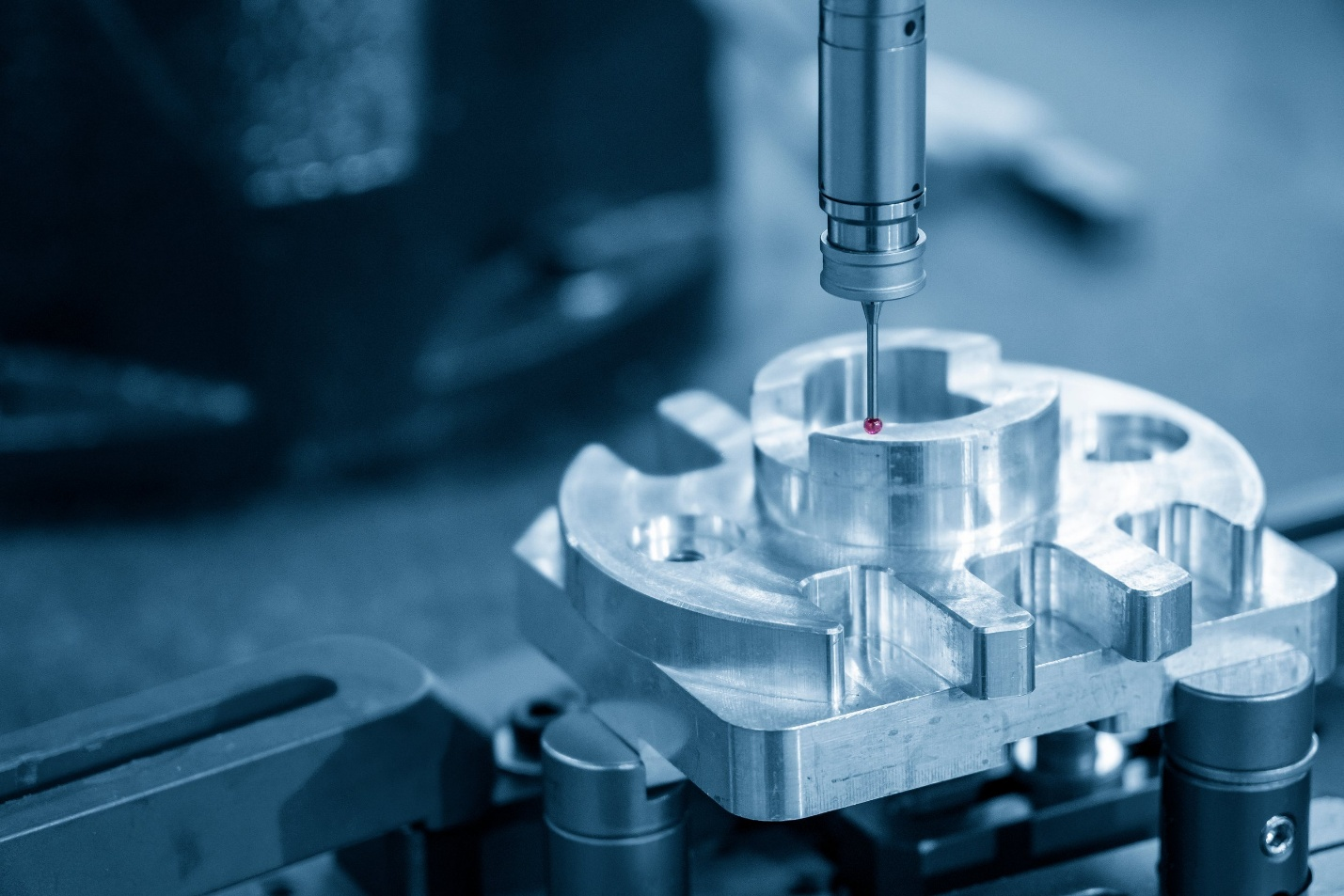

Turning digital sketches into real, precision parts can seem impossible for many businesses. But custom CNC machining makes it clear, fast, and repeatable—even for the most complex shapes.

Custom CNC machining services use computer-guided milling and turning to transform 3D models into accurate metal or plastic parts1. This process allows for unmatched precision, fast turnaround, and consistency from prototype to full production.

Every industry needs reliable parts at demanding speeds and tight tolerances. I work with designers and entrepreneurs who ask: How exactly does a digital file become a flawless piece of hardware? This post will walk you through the tools, material choices, quality checks, and new technologies that make it possible. Whether you're ordering the first prototype or preparing to scale up, it helps to understand what happens behind the scenes—and how to pick the right shop for your next project.

What Core Capabilities Define Modern CNC Milling and Turning?

Precision can make or break a part—especially in aerospace, medical, and automotive projects. Many fear production will not match digital intent, or that shops won't have the right equipment for complex features.

Modern CNC milling and turning centers use multi-axis machines2, high-speed spindles3, and live tooling4 to replicate digital designs down to the micron. Shops succeed by combining skilled programmers, advanced machines, and strict process control.

Let’s break down what really matters. For milling, shops now use 3-axis, 4-axis, and 5-axis machines. More axes allow single-setup machining for undercuts and sculpted surfaces, leading to fewer errors and faster cycles. Tolerances can reach ±0.01 mm with careful toolpath planning and calibration. Turning centers with live tooling4 handle shafts, threads, and complex profiles without secondary operations. Key factors include spindle power, tool magazine size, and the ability to switch quickly between set-ups or materials. Here’s a simple comparison:

| Capability | Typical Details | Impact |

|---|---|---|

| 3-Axis Milling | Simple prismatic shapes | Cost-effective, fast |

| 4/5-Axis Milling | Complex freeform surfaces, fewer setups | Higher accuracy, flexibility |

| CNC Turning | Cylindrical parts, live tooling4, sub-spindle | Threads, grooves in one pass |

| Tolerance Control | ±0.005–0.02 mm (application-dependent) | Reliable, repeatable results |

Shops that invest in programmable fixturing5, tool presetters, and simulation software6 deliver higher quality with less lead time. When you see "multi-axis" and "in-process probing" on a shop’s spec sheet, it means they can meet both prototyping and scaled production needs.

Which Materials Are Best for CNC Machining Across Industries?

Material mistakes can delay production and raise costs. Customers want to know if their chosen metal or plastic will machine well, hold tight tolerances, and survive in tough environments.

The best CNC machining materials depend on use: aluminum is fast and affordable7; stainless steel resists corrosion8; titanium offers strength with less weight9; engineering plastics handle heat and chemicals. Each serves different industries, from aerospace to robotics.

I see the choices every week: an aerospace engineer needs a strong but light bracket, while a medical-device startup needs inert, biocompatible housings. Let’s look at common choices:

| Material | Properties | Applications |

|---|---|---|

| Aluminum (6061/7075) | Lightweight, strong, easy to machine | Aircraft, enclosures, fixtures |

| Stainless Steel (304/316) | Corrosion-resistant, tough | Medical, food, marine |

| Titanium | High strength, light, biocompatible | Aerospace, implants |

| Brass/Copper | Good conductivity, easy to finish | Electronics, connectors |

| Engineering Plastics (POM, PEEK, PC) | Chemical-resistant, strong | Medical, automotive, robotics |

Aluminum is the go-to for prototypes and high-speed machining. Stainless holds up in harsh environments. PEEK and PC find use in medical or electrical insulators, where metal won’t do. Custom shops can advise on cost, machining time, and post-processing for each. Choosing wisely saves money and ensures your part works on the first try.

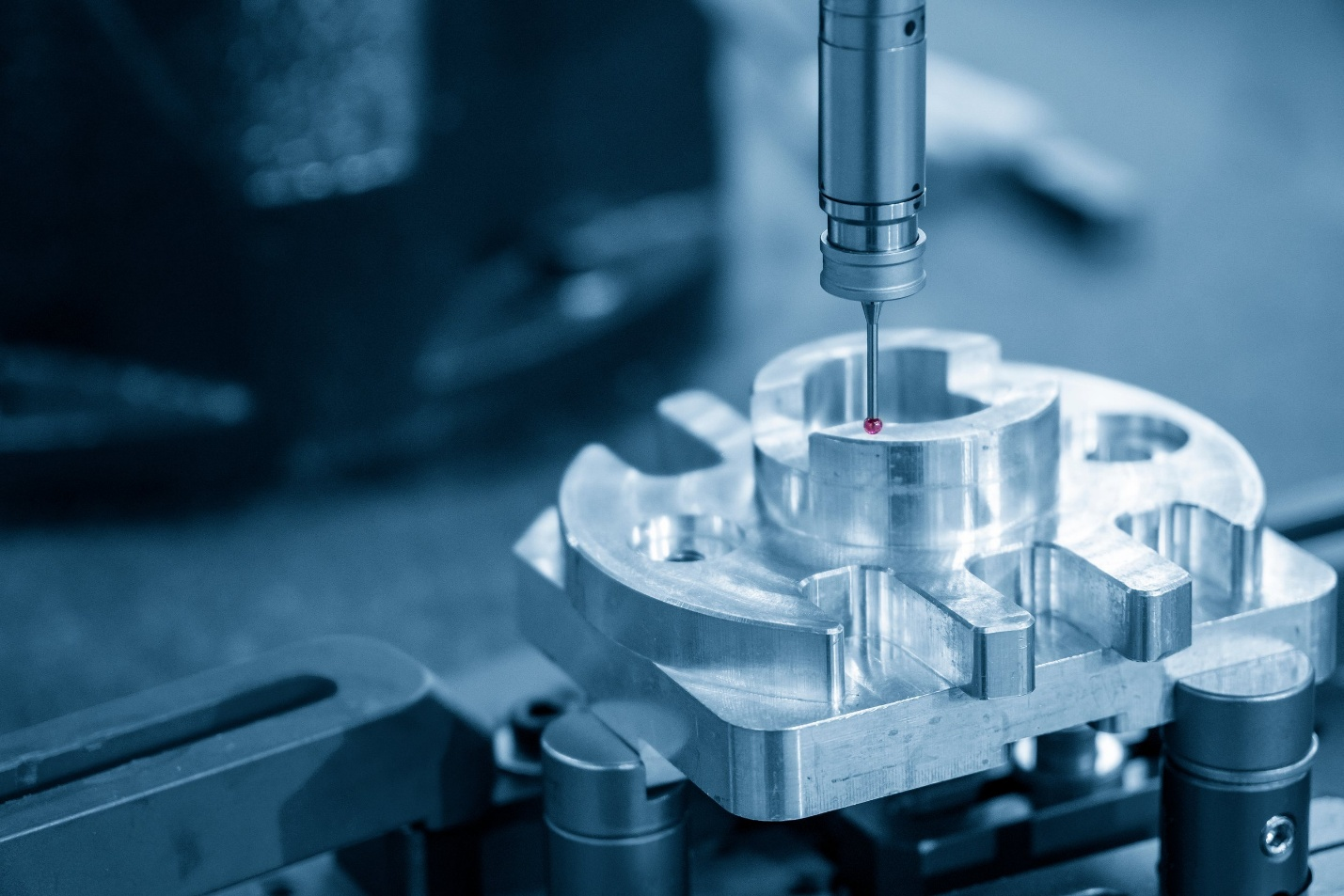

How Do Shops Maintain Tight Tolerances and Reliable Quality?

Many projects fail when a single tolerance stacks up or a dimension drifts outside spec. Buyers worry about hidden quality problems or unreliable inspections.

Shops achieve tight tolerances with calibrated tools10, climate-controlled environments11, regular quality checks with CMMs, and detailed process control records. In-process and final inspections catch errors before shipment.

I’ve seen cases where one missed inspection led to rework or even recalls. To avoid this, the best shops use the following workflow:

| Step | Tools and Methods | Result |

|---|---|---|

| Tool/Fixture Calibration | Laser tool setters, touch probes | Consistent setup, repeatability |

| In-Process Checks | Machine probing, SPC sampling | Trends spotted before scrap occurs |

| Final Inspection | CMM, vision systems, surface testers | Documented, verified dimensions |

| Traceability Records | Batch/serial number, inspection reports | Accountability, fast recalls |

Real-time SPC lets operators react before things go wrong. With digital reports and photos, buyers can check every step. I provide these to my customers—especially for safety-critical industries—because one missing micron can mean project failure.

What Advanced Technologies and Automation Improve Efficiency?

Machining time and costs add up quickly. Many ask if new technology can speed up orders, handle more complex jobs, or lower manual intervention.

Advanced shops use simultaneous 5-axis machines12, robot loading arms13, automatic tool changers, and in-line metrology to boost output, reduce errors, and predict downtime before it happens.

I watched our factory transform with the introduction of robot loaders. These machines run lights-out, swapping parts even during night shifts. Here’s what matters:

| Tech Upgrade | Benefit | Example Use |

|---|---|---|

| 5-Axis Machining | Fewer setups, complex geometries | Aerospace impellers, molds |

| Robotic Loading | Continuous production, less human error | High-volume, short-cycle runs |

| Smart Tool Management | Optimized life, fewer crashes | Unattended shifts, tool wear alerts |

| In-line Inspection | Fast feedback, instant correction | First-off/last-off part checks |

Smart factories now link all machines to a central dashboard, showing OEE (overall equipment effectiveness), tool wear, and scheduled maintenance. The result: shorter lead times, consistent pricing, and more parts shipped per day.

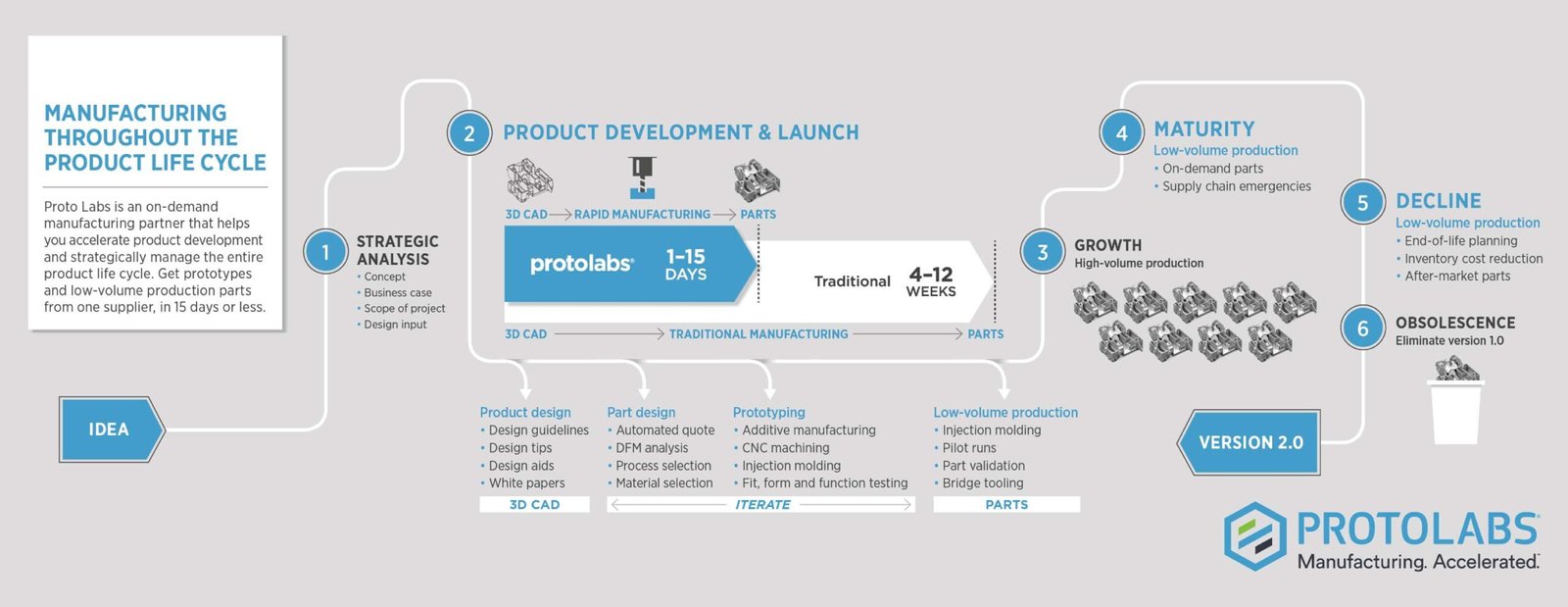

How Can You Move Seamlessly from Prototyping to Production?

It’s common to get a prototype fast, only to face delays or big surprises when scaling up for mass production. People fear that early designs will not work in real-world manufacturing.

A seamless transition comes from design-for-manufacturing (DFM) support14, flexible equipment, and a process built for both single parts and thousands—without costly redesigns or slips in quality.

My team often starts with a single prototype, then helps the customer tweak dimensions, wall thickness, or features for lower overall cost. Here’s how a smooth hand-off works:

| Stage | Key Actions | Customer Benefit |

|---|---|---|

| Design Consultation | DFM review, tolerance analysis | Flawless prototypes, cost down |

| Pilot Run | Bridge tooling, short-batch test | Validate manufacturing, spot issues |

| Mass Production | Optimized workflows, SPC, safety stock | Fast, reliable delivery, less risk |

| Change Management | Agile updates, clear communication | Quick adapts, avoid delays |

Picking a shop with integrated prototyping and production15—plus clear feedback and engineering help—saves money and time. I always recommend investing in DFM at the start, which can pay for itself in the first production run.

Conclusion

Custom CNC machining bridges digital ideas and final hardware—thanks to advanced machines, material expertise, tight quality control, automation, and smart workflows from prototype to mass production.

-

Learn how CNC machining turns your 3D models into precise parts, ensuring high accuracy and quality. ↩

-

Discover how multi-axis machines enhance CNC machining by allowing complex shapes and reducing errors. ↩

-

Explore the role of high-speed spindles in achieving faster and more precise CNC machining results. ↩

-

Understand how live tooling in CNC turning enables complex part creation without secondary operations. ↩ ↩ ↩

-

Learn how programmable fixturing enhances precision and reduces lead times in CNC machining. ↩

-

Simulation software helps predict machining outcomes, reducing errors and improving efficiency. ↩

-

Aluminum's properties make it a popular choice for cost-effective and quick CNC machining projects. ↩

-

Stainless steel's corrosion resistance makes it ideal for durable parts in harsh environments. ↩

-

Titanium's strength and lightweight properties make it perfect for aerospace and medical applications. ↩

-

Calibrated tools are essential for maintaining tight tolerances and high-quality CNC machined parts. ↩

-

Climate control ensures consistent machining conditions, crucial for precision and quality. ↩

-

Simultaneous 5-axis machines allow for complex geometries and reduce the need for multiple setups. ↩

-

Robot loading arms increase production efficiency by reducing manual intervention and errors. ↩

-

DFM support ensures that designs are optimized for manufacturing, reducing costs and improving quality. ↩

-

Integrated prototyping and production streamline the process, saving time and reducing errors. ↩