Thin-walled parts constantly warp and vibrate during machining, causing headaches for our production team. The delicate nature of these components means even slight cutting forces can lead to costly rejects and wasted materials.

Support techniques are specialized methods that stabilize thin-walled workpieces during CNC machining by countering cutting forces and preventing deformation. Effective supports include customized fixtures, low-melting point alloys, backing materials, and optimized toolpaths—all working together to maintain dimensional accuracy throughout the machining process.

Thin-walled CNC machining with support techniques

In our factory, we've seen firsthand how proper support techniques can transform thin-walled machining results. When we first started machining vacuum chamber components with walls under 1mm thick, our reject rate was frustratingly high. By implementing the right support strategies, we've managed to achieve consistent quality even on our most challenging thin-walled projects.

What Are the Main Challenges in Thin-Walled Part Machining?

Thin-walled parts flex and vibrate with even the slightest cutting pressure, creating a nightmare for maintaining tight tolerances. When these components deform during machining, scrap rates climb and production costs spiral out of control.

The main challenges include workpiece deflection under cutting forces, vibration and chatter during machining, heat distortion from cutting operations, and maintaining dimensional stability throughout the process. These issues are especially pronounced when wall thickness falls below 1mm, requiring specialized support strategies tailored to the specific component geometry and material properties.

Challenges in thin-walled machining

Thin-walled machining problems stem from the fundamental physics of material behavior under stress. When cutting forces are applied to thin sections, the material lacks inherent rigidity to resist deformation. This creates a complex challenge requiring a multi-faceted approach to support.

The severity of these challenges varies significantly by material. Aluminum thin-walled components, common in aerospace applications, tend to deflect easily but are less prone to work-hardening. Stainless steel thin sections, which we frequently machine for medical equipment, resist deflection better but generate more heat during cutting, creating thermal distortion issues.

Material type also influences vibration characteristics. Titanium, which we use in high-performance marine components, has a higher elastic modulus than aluminum but lower thermal conductivity, creating unique support requirements. Materials with low stiffness-to-weight ratios require more robust support strategies to prevent deformation during machining operations.

Our approach to these challenges involves careful analysis of the specific thin-walled part geometry, material properties, and required tolerances. We've developed a decision matrix that helps us select the most appropriate support technique based on these factors, significantly reducing our trial-and-error time and improving first-time quality rates.

Which External Support Methods Work Best for Different Materials?

Our machinists struggled with constant vibration when cutting thin titanium parts, leading to poor surface finish and dimensional issues. Traditional fixtures weren't holding the workpiece firmly enough, and we needed a better solution fast.

External supports include backing materials (wax, polymers, or resins), sacrificial supports that are machined away with the part, vacuum fixtures that hold workpieces through suction, and magnetic workholding for ferrous materials. Each method has specific advantages depending on the material being machined, with backing materials excelling for aluminum, sacrificial supports for stainless steel, and magnetic systems for low carbon steel components.

External support methods for thin-walled machining

The effectiveness of external support methods varies dramatically across different materials, requiring a tailored approach based on material properties. Through our experience working with diverse clients across industries, we've developed specific support strategies for common thin-walled materials.

For aluminum thin-walled parts, which make up about 40% of our precision components, we've found that polymer backing materials provide exceptional results. The backing material fills internal cavities and provides support during machining, then is easily removed using heat or solvents. This approach works particularly well for aerospace components with complex internal geometries and wall thicknesses down to 0.5mm.

Stainless steel thin-walled parts respond better to sacrificial support structures. We design these supports as extensions of the final part that provide rigidity during machining but are removed in the final operations. This approach has proven effective for medical device components with walls as thin as 0.7mm, where dimensional accuracy is critical.

For titanium components, which present unique challenges due to their poor thermal conductivity and tendency to work-harden, we've had success with specialized vacuum fixtures combined with cryogenic cooling. The vacuum securely holds the workpiece while the cooling minimizes thermal deformation.

Here's a comparison of external support methods across common materials:

| Material | Recommended Support Method | Key Advantage | Typical Application |

|---|---|---|---|

| Aluminum | Polymer backing materials | Easy removal with heat | Aerospace components |

| Stainless Steel | Sacrificial supports | Low-melting-point metal backing | Medical devices |

| Titanium | Vacuum fixtures with cryogenic cooling | Minimizes thermal distortion | Marine components |

| Copper alloys | Low-melting point metal backing | Excellent thermal conductivity | Heat exchangers |

| Plastics | Freezing fixtures | Temporarily increases rigidity | Electronic housings |

How Do Low-Melting-Point Alloy Supports Compare to Traditional Methods?

We were struggling with complex thin-walled aluminum vacuum chambers that kept warping during machining. Traditional fixtures couldn't reach internal surfaces, leading to unacceptable deformation and high scrap rates.

Low-melting-point alloys (LMPAs) like Wood's metal or Cerrobend can be melted at relatively low temperatures (70-150°C), poured around or inside thin-walled parts to provide complete support during machining, then melted away afterward. Compared to traditional methods, LMPAs offer superior support for complex geometries, are reusable, and provide uniform pressure distribution across the entire workpiece surface.

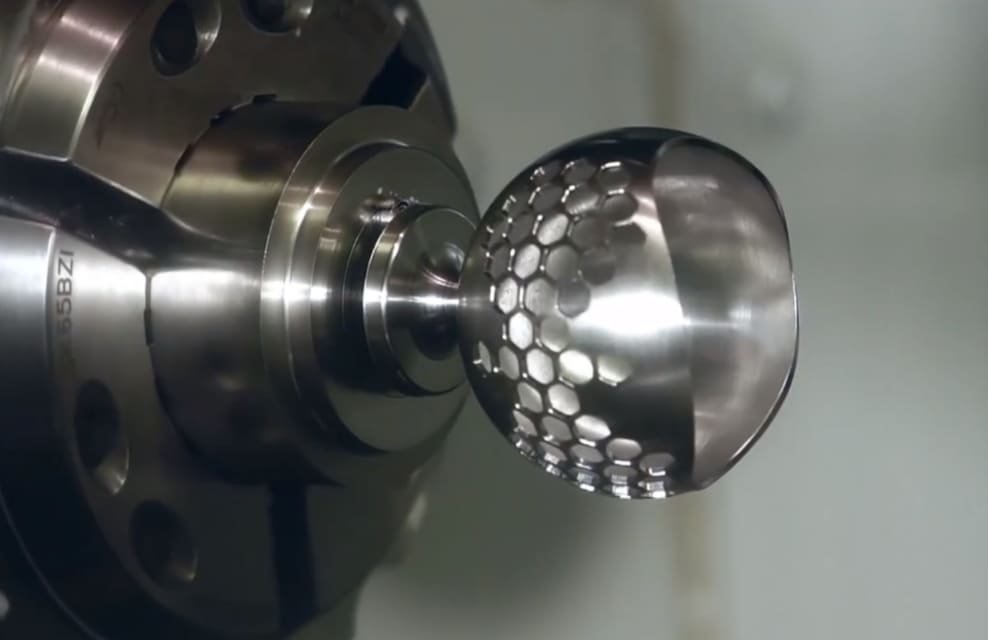

Low-melting-point alloy support in action

Low-melting-point alloy (LMPA) supports represent one of the most significant advancements in thin-walled machining technology we've implemented in our shop. These specialized alloys, typically composed of bismuth, lead, tin, and cadmium, melt at temperatures between 70°C and 150°C, making them easy to apply and remove without damaging even the most delicate workpieces.

The primary advantage of LMPA supports over traditional methods is their ability to conform perfectly to complex part geometries. When we machine intricate vacuum chamber components with internal features, LMPAs can be poured into cavities where conventional fixtures cannot reach. The alloy solidifies to form a perfect supporting structure that contacts 100% of the surface area, virtually eliminating localized deformation.

From a cost perspective, LMPAs initially require greater investment than conventional fixtures but offer exceptional value over time. The alloy is fully reusable – after machining, we simply melt it again for the next application. For a recent project involving semiconductor vacuum components with 0.6mm walls, we calculated a 40% reduction in total support costs over the production run compared to custom fixtures.

LMPAs also significantly reduce setup time for complex parts. Rather than designing and manufacturing custom fixtures that might take weeks, we can implement LMPA support in hours. This has allowed us to respond more quickly to urgent customer requests, particularly in the medical equipment sector, where lead times are often critical.

However, LMPAs do have limitations. They require careful temperature control during application and removal, and additional cleaning steps to remove any residue. They're also less suitable for materials with very high thermal conductivity, like copper, as rapid heat dissipation can cause uneven solidification of the alloy.

What Role Does Fixture Design Play in Thin-Walled Machining Stability?

Our standard vises and clamps were causing visible deformation when we tightened them on a batch of thin-walled marine components. The parts would measure perfectly while fixtured, but spring back out of tolerance once released.

Well-designed fixtures are critical for thin-walled machining success, as they must secure the workpiece without causing deformation. Advanced fixtures incorporate distributed clamping pressure, minimize vibration through damping materials, and utilize CAE-optimized contact points. Modern designs often integrate in-process measurement systems to monitor and compensate for any movement during machining.

Advanced fixture design for thin-walled machining

Fixture design represents the foundation of successful thin-walled machining operations. In our Kunshan facility, we've invested heavily in developing specialized fixturing systems that address the unique challenges of holding delicate components without distortion.

The core principle of effective thin-walled fixturing lies in distributing holding forces evenly across the workpiece. Traditional fixturing methods often concentrate pressure at specific points, causing localized deformation. Our advanced fixtures utilize multiple low-pressure contact points strategically positioned to maintain part geometry while providing sufficient holding force to resist cutting forces.

Computer-aided engineering (CAE) has revolutionized our approach to fixture design. Using finite element analysis (FEA), we can now simulate the behavior of thin-walled parts under various clamping configurations before manufacturing a single fixture component. This virtual testing allows us to identify potential deformation issues and optimize contact points, clamping pressures, and support locations.

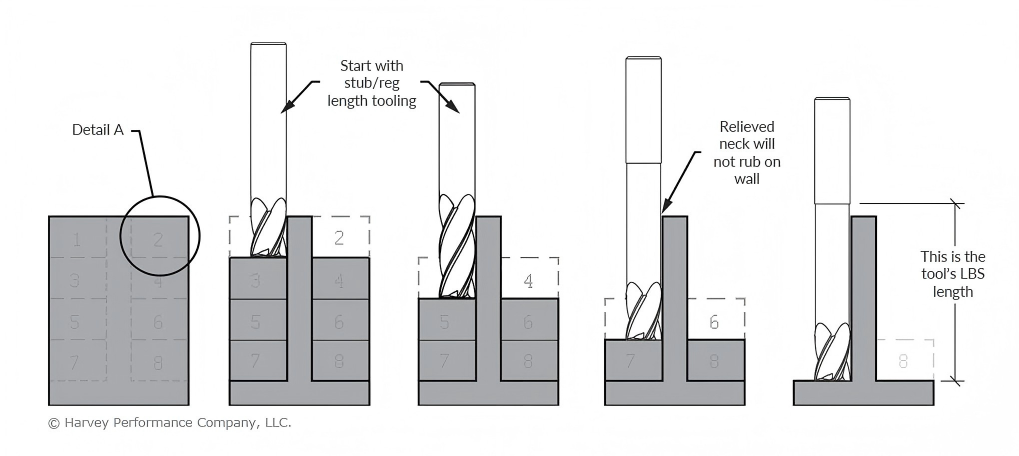

For a recent aerospace project involving titanium components with wall thicknesses of just 0.8mm, we developed a hybrid fixture system that combines:

- Primary vacuum workholding for gentle, distributed holding force

- Secondary mechanical locators with precisely controlled clamping pressure

- Tertiary damping elements to minimize vibration

- Integrated cooling channels to maintain thermal stability

The fixture also incorporated in-process measurement capability, using compact sensors to monitor workpiece position during machining operations. This system could detect minute movements or deflections and automatically adjust machining parameters to compensate, resulting in unprecedented dimensional accuracy.

Material selection for fixtures themselves plays a crucial role in thin-walled machining success. We often utilize composite materials with high damping characteristics for fixture bodies, which absorb vibration more effectively than traditional steel fixtures. For particularly challenging applications, we've even developed fixtures with active damping systems that counteract harmonics that could cause resonance in thin-walled sections.

Conclusion

Successful thin-walled machining requires a comprehensive approach to support techniques. By carefully selecting the right support methods for your specific material and application, you can achieve exceptional quality while minimizing scrap rates and production costs.