High-speed CNC machining has become the backbone of modern manufacturing, delivering higher productivity and tighter tolerances than ever before. As spindle speeds climb and material removal rates increase, the stresses on both tools and workpieces rise dramatically. With this push for speed and precision comes a greater challenge: managing heat, friction, and chip flow in a way that preserves tool life and ensures consistent part quality.

Coolant plays a decisive role in meeting these challenges. More than just a liquid to keep the cutting zone wet, it is a critical factor in heat dissipation, lubrication, chip evacuation, and surface finish. In high-speed operations, where conventional cooling practices often fall short, an optimized coolant strategy can mean the difference between profitable production and costly downtime.

This article explores how to manage coolant effectively in high-speed CNC machining. From choosing the right type of coolant to optimizing flow and temperature to understanding its impact on tool wear and part finish, we will cover practical strategies backed by industry practices. The goal is straightforward: to equip machinists and engineers with actionable insights that enhance efficiency, extend tool life, and improve overall machining quality.

Role of Coolant in CNC Machining

Coolant is one of the most overlooked yet most influential factors in CNC machining. When high spindle speeds and aggressive cutting parameters are applied, the cutting zone quickly builds up heat and stress. Without effective coolant management, tools dull faster, surfaces degrade, and chips accumulate in ways that compromise both precision and safety. Understanding what coolant does inside the machine is the first step to managing it effectively.

Heat Dissipation

The most immediate function of coolant is to remove heat from the cutting zone. When a tool contacts material at high speed, friction generates localized temperatures that can exceed several hundred degrees Celsius. If heat is not carried away, tools lose hardness, coatings break down, and the workpiece may suffer thermal distortion. Coolant absorbs this heat and transfers it away into the circulation system, helping stabilize both tool and part.

- In aluminum machining, rapid heat conduction makes coolant essential to prevent built-up edge formation.

- In titanium and nickel alloys, where poor thermal conductivity traps heat at the cutting edge, high-pressure coolant ensures temperatures remain within safe ranges.

By controlling heat, coolant also minimizes dimensional errors, keeping tolerances tight even on long production runs.

Lubrication

Friction between the tool and material is another major factor influencing tool wear. A well-formulated coolant provides a lubricating film that reduces direct contact between the cutting edge and the chip. This lowers cutting forces, decreases wear, and prevents premature tool breakage.

Lubrication is especially critical in high-speed drilling and tapping, where deep tool engagement creates high sidewall friction. The right lubricant balance not only prolongs tool life but also reduces spindle load and vibration, leading to smoother cutting conditions.

Chip Evacuation

Coolant also acts as a transport medium for chips. When chips remain in the cutting zone, they are recut by the tool, causing edge chipping, surface scratches, or even catastrophic tool failure. Properly directed coolant lifts chips away from the toolpath and flushes them into filtration systems.

- In pocket milling, coolant helps prevent chip packing that can trap heat and damage cutting edges.

- In through-hole drilling, high-pressure coolant channels are vital for pushing chips out of deep cavities.

Efficient chip removal keeps the toolpath clear and reduces the risk of tool clogging, particularly in high-speed operations where chip volume increases dramatically.

Surface Finish Improvement

Coolant directly influences the quality of the machined surface. A steady flow of coolant stabilizes the cutting edge, reduces chatter, and minimizes micro-welding between the tool and the workpiece. This leads to a smoother surface finish and fewer secondary operations.

Poor coolant management often shows up as rough finishes, discoloration, or even surface burns. In contrast, when coolant parameters are optimized, parts exhibit a more uniform finish and improved accuracy in geometrical features. This is especially important in industries like aerospace and medical, where surface quality impacts both performance and compliance with standards.

Importance of High-Speed vs Conventional Machining

In conventional machining, moderate speeds generate manageable heat and chip loads, making coolant less critical in some cases. However, in high-speed CNC machining, the energy input is significantly higher. The role of coolant becomes central because:

- Heat builds up much faster and in larger volumes.

- Chips are smaller but more numerous, requiring stronger flushing action.

- Tool coatings and carbide substrates are more sensitive to temperature swings.

This difference explains why strategies that may work in standard machining often fail under high-speed conditions. Coolant in high-speed CNC machining is not optional support but an integral part of the cutting process.

Types of Coolant Used in Industry

Different coolant formulations are available, each with distinct benefits and trade-offs. The main categories are:

- Water-based coolants: Common for general machining, offering strong cooling capacity but requiring additives to prevent corrosion and microbial growth.

- Oil-based coolants: Provide superior lubrication, used in operations like grinding or tapping, though they tend to run hotter and can be more difficult to manage.

- Synthetic coolants: Contain no mineral oils, delivering excellent heat transfer and cleanliness, often favored in high-speed applications.

- Semi-synthetic coolants: Combine the lubrication benefits of oils with the cooling properties of water, making them versatile for mixed-material shops.

Choosing the right type depends not only on the operation but also on shop priorities like tool life, cost, environmental impact, and ease of maintenance.

Choosing the Right Coolant

Selecting the correct coolant is not a one-size-fits-all decision. The wrong choice can shorten tool life, degrade surface quality, and increase operational costs. The right choice, on the other hand, matches the workpiece material, cutting parameters, and machining environment. Careful evaluation of coolant properties ensures that the balance between cooling, lubrication, and chip evacuation is maintained throughout production.

Influence of Material on Coolant Selection

Different materials respond differently to heat and friction, which makes coolant compatibility essential.

- Aluminum: Prone to built-up edge formation. Requires coolants with strong lubricity and anti-weld additives to prevent chip adhesion.

- Steel and hardened alloys: Generate significant cutting heat. Water-soluble coolants with stable thermal control are preferred to minimize tool wear.

- Titanium and nickel-based alloys: Poor thermal conductivity traps heat at the cutting edge. High-pressure synthetic coolants are ideal for maintaining manageable temperatures.

- Cast iron: Produces abrasive dust-like chips that can contaminate coolant. Straight oils or well-filtered water-based coolants help reduce wear and maintain fluid cleanliness.

Understanding material behavior helps prevent issues such as corrosion, staining, or excessive foaming, all of which can be linked to coolant incompatibility.

Machining Speed and Depth of Cut

High spindle speeds and deep engagements increase thermal loads. In these conditions, the coolant must absorb heat rapidly and maintain its stability under pressure.

- At higher cutting speeds, water-based and semi-synthetic coolants perform well because of their heat transfer efficiency.

- For heavy cuts with high loads, oil-rich coolants provide extra lubrication to prevent edge chipping.

Balancing cooling versus lubrication becomes more critical as speeds rise. Overemphasis on one aspect may compromise the other, leading to inefficient machining.

Operation-Specific Considerations

Different machining operations demand different coolant properties.

- Milling: Continuous chip generation requires fluids with good flushing action and moderate lubrication.

- Turning: Surface contact is larger, making consistent cooling important to prevent thermal expansion.

- Drilling and tapping: Deep cavities trap heat and chips. High-pressure coolants with strong lubricity are best to ensure chip evacuation and prevent tool jamming.

- Grinding: Requires stable cooling with fine filtration, as coolant must remove microscopic debris while preventing wheel glazing.

Matching coolant to the operation type reduces tool failures and enhances consistency in results.

Pros and Cons of Coolant Types

Every coolant category brings advantages and trade-offs. Understanding these helps shops choose the most cost-effective option.

- Water-based coolants: Excellent cooling, relatively inexpensive, but susceptible to corrosion and bacterial growth if not monitored.

- Straight oils: Superior lubrication and surface finish, but higher risk of smoke, mist, and higher operating costs.

- Synthetics: Clean running, excellent heat control, environmentally safer, but may lack lubricity in heavy-duty cutting.

- Semi-synthetics: Balanced performance, suitable for mixed-material shops, though may still require frequent concentration checks.

Selecting the right fluid requires aligning coolant strengths with operational goals rather than defaulting to a single solution.

Cost-Effectiveness and Environmental Factors

Coolant cost extends far beyond purchase price. Disposal, recycling, and maintenance must be considered. A cheaper coolant that requires frequent replacement may ultimately be more expensive than a premium fluid that lasts longer and protects tooling better.

Environmental impact is also a growing concern. Many facilities adopt coolants with low toxicity, biodegradable additives, and reduced misting to comply with safety standards and reduce waste management costs. In some industries, customer requirements now mandate the use of environmentally responsible coolants.

Optimizing Coolant Flow

Coolant flow is more than just the amount of liquid entering the cutting zone. It is about delivering the right volume, at the right pressure, and from the right direction. In high-speed CNC machining, poor flow management can lead to heat accumulation, chip recutting, and unstable cutting conditions. Optimizing coolant delivery ensures that heat is carried away efficiently, chips are flushed out, and the tool edge remains sharp for longer cycles.

Recommended Flow Rates for High-Speed Operations

The volume of coolant supplied must match the speed and aggressiveness of the cut. At higher spindle speeds, the contact time between tool and coolant decreases, which means more fluid is required to achieve the same cooling effect.

- For aluminum at high speeds, higher flow rates help reduce built-up edge and chip welding.

- For titanium, concentrated streams with sufficient pressure are needed to penetrate the cutting zone and remove heat efficiently.

- For steels, balanced flow rates prevent excessive turbulence, which could trap chips instead of carrying them away.

Flow rate guidelines are typically expressed in liters per minute per millimeter of tool diameter. Adjusting within these ranges according to material and depth of cut helps maintain consistent machining performance.

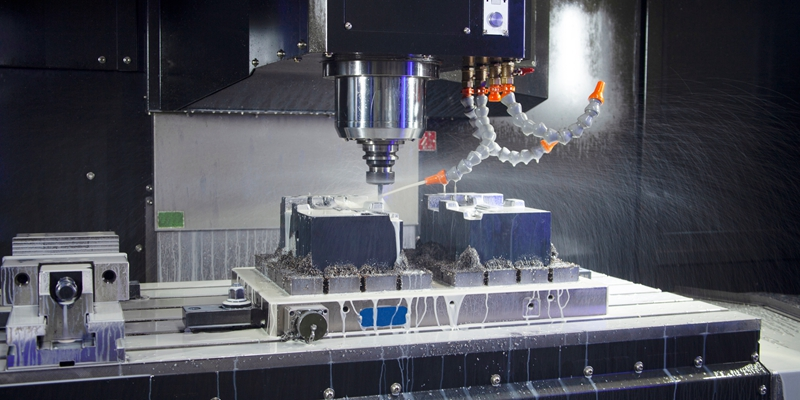

Delivery Methods: Direct, Flood, and Mist

Coolant can be applied in different ways, each with distinct advantages.

- Direct high-pressure delivery: Channels coolant through the spindle or tool body directly to the cutting edge. Most effective for deep drilling and high-speed milling, as it targets heat at its source.

- Flood cooling: Uses large volumes of fluid to submerge the cutting zone. It is simple and reliable, but less precise compared to high-pressure systems.

- Mist cooling: Delivers atomized coolant mixed with air. Useful for operations requiring minimal fluid, but less effective at removing large amounts of heat.

The choice depends on part geometry, machine capability, and the type of operation. Often, shops combine methods for complex jobs.

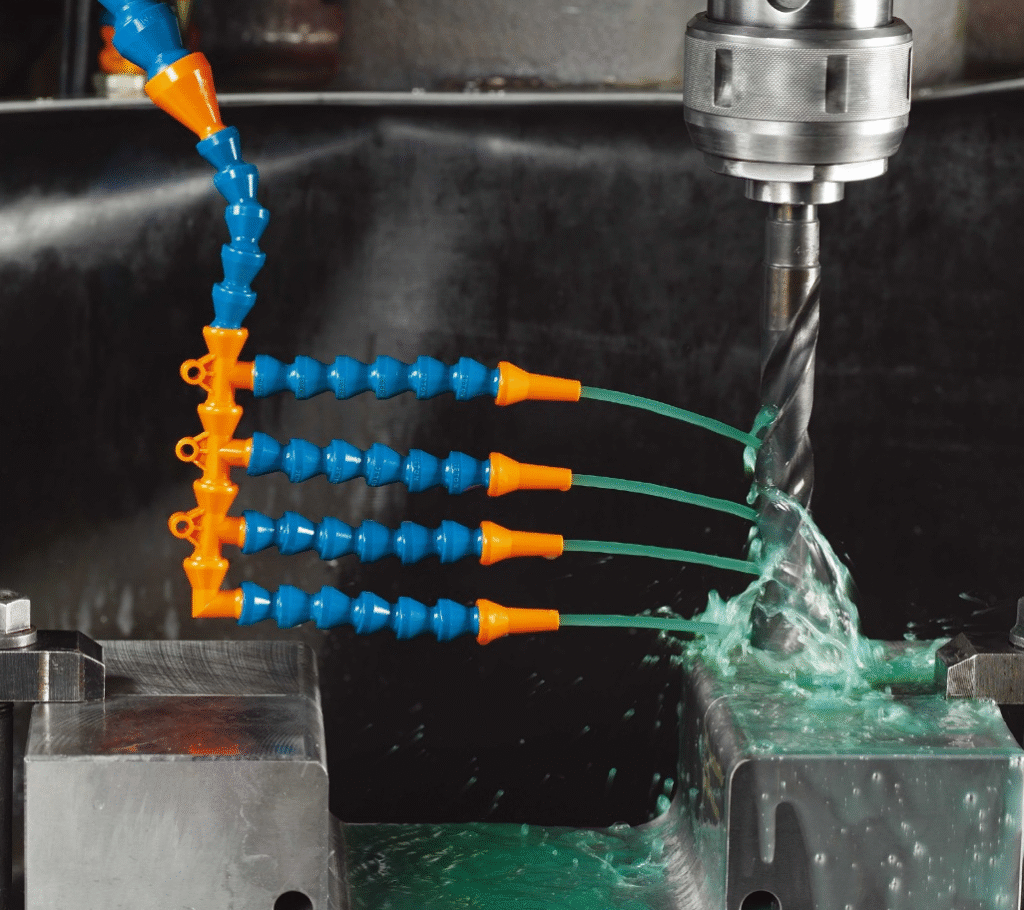

Nozzle Positioning for Effective Cooling

Even with sufficient flow, poor nozzle placement can make coolant ineffective. The fluid must reach the tool-chip interface directly, not just the tool shank or surrounding area.

- Positioning nozzles slightly ahead of the cutting edge allows coolant to be pulled into the cut by chip movement.

- Multi-nozzle setups provide coverage for wide cutters or multi-flute tools.

- Adjustable nozzles help adapt the flow to different operations without major machine changes.

Incorrect positioning can lead to dry spots, where the tool overheats and wears prematurely.

Flow and Chip Evacuation

Chip control depends heavily on how the coolant interacts with the cutting zone. Without sufficient flushing action, chips remain in the toolpath, causing recutting and tool edge chipping.

- In slot milling, a strong directed flow prevents chips from packing into the slot.

- In drilling, coolant must not only cool but also push chips upward through flutes or downward through exit holes.

- In high-volume machining, filtration systems must work in sync with the flow to prevent chips from recirculating back into the cut.

Flow that is too weak fails to clear chips, while flow that is too turbulent may scatter chips around the enclosure instead of removing them.

Impact of Flow on Tool Life

Consistent coolant flow directly extends tool life by controlling temperature, reducing friction, and preventing chip adhesion. Variations in flow, such as blocked nozzles or pressure drops, create sudden tool stresses that lead to premature breakage. Monitoring pressure levels and checking for obstructions in delivery lines should be part of routine maintenance.

Tools designed with internal coolant channels often achieve longer life spans compared to tools relying only on external flood systems. The reason is simple: coolant delivered through the tool reaches the edge more reliably, especially at high spindle speeds where centrifugal forces repel external fluid.

Controlling Coolant Temperature

Coolant temperature is one of the most decisive factors in ensuring process stability during high-speed CNC machining. While flow and type of coolant determine how effectively heat is removed, temperature management dictates whether dimensional accuracy and surface integrity can be consistently achieved. Even slight fluctuations can cause thermal expansion in both tool and workpiece, leading to deviations that affect part quality. Managing coolant temperature is, therefore, as important as selecting the fluid itself.

CNC Coolant For Aluminum Milling

Ideal Temperature Ranges for Materials and Operations

Different materials demand different coolant temperatures for optimal machining performance.

- Aluminum: Best results are achieved with coolant near ambient shop temperature. Too cold a fluid can create thermal shock, while too warm a fluid can promote built-up edge.

- Titanium and nickel alloys: Require cooler fluids to counteract poor thermal conductivity and prevent tool tip softening. Maintaining temperatures between 18–22°C helps balance cutting stability with tool life.

- Steel and hardened alloys: Moderate temperature control is sufficient. Stable coolant between 20–25°C minimizes distortion while still dissipating heat effectively.

Consistency matters more than extreme cooling. Sudden drops or rises in coolant temperature create uneven expansion across the workpiece, which compromises tolerances.

Cooling Systems: Chilled vs Ambient Coolant

Shops typically manage coolant temperature through one of two methods: relying on ambient shop temperature or using active chilling systems.

- Chilled coolant systems: Use refrigeration units to maintain coolant within narrow temperature bands. Effective for aerospace, medical, and precision industries where tolerances are extremely tight.

- Ambient-cooled systems: Depend on natural shop conditions, sometimes supported with large tanks that allow heat dissipation. While more cost-effective, they are vulnerable to seasonal temperature swings and inconsistent accuracy.

Choosing between chilled and ambient cooling depends on tolerance requirements and the value of parts being produced.

Effects of Temperature Fluctuations on Accuracy and Finish

Coolant temperature directly impacts both part quality and tool performance.

- Dimensional accuracy: Even small changes in coolant temperature cause expansion in the workpiece. A fluctuation of just 1°C in steel can result in microns of size variation, which becomes critical in tight-tolerance machining.

- Surface finish: Stable coolant temperatures reduce the risk of thermal cracking, chatter, and uneven tool wear. Inconsistent temperature often shows up as visible waviness or roughness on the part surface.

- Tool coatings: Coatings such as TiAlN or DLC are sensitive to excessive thermal cycling. Stable coolant temperature helps preserve coating integrity, improving tool life.

By reducing fluctuation, coolant management ensures repeatable results across multiple parts in a batch.

Monitoring and Maintaining Stability

Temperature control requires active monitoring systems rather than assumptions.

- Sensors and probes: Installed in the coolant tank or delivery line, these provide real-time data on fluid conditions.

- Coolant chillers with feedback loops: Automatically adjust cooling intensity to hold the fluid within set limits.

- Insulated tanks and lines: Reduce heat absorption from shop environments and machine enclosures.

Routine checks should confirm that coolant remains within the specified range for the material and operation. Adjustments can then be made before deviations affect production.

Effects on Tool Life

Tooling represents one of the largest ongoing costs in CNC machining, and its performance is directly influenced by coolant management. At high speeds, cutting edges are subjected to intense heat, rapid wear, and sudden stress variations. Coolant acts as a protective factor, allowing tools to operate longer, cut cleaner, and withstand aggressive machining parameters. When coolant is poorly managed, tools dull faster, coatings fail prematurely, and unexpected breakages disrupt production.

The Role of Coolant in Tool Longevity

Reduction of Tool Wear

The primary way coolant extends tool life is by reducing wear at the cutting edge. Excessive heat accelerates diffusion and adhesion wear, which gradually erodes tool geometry. Coolant reduces the temperature at the tool–chip interface, slowing down this degradation.

- In carbide tools, heat management prevents loss of hardness that otherwise occurs when edges overheat.

- In coated tools, stable coolant conditions protect thin films like TiAlN from flaking or softening.

- In drills and reamers, coolant reduces sidewall friction, limiting abrasive wear that can shorten tool lifespan.

Even a small improvement in wear resistance results in significantly longer tool cycles across high-volume production.

Prevention of Heat-Related Damage

Uncontrolled heat not only dulls the tool but also causes structural problems such as thermal cracking. Coolant mitigates these risks by distributing temperature more evenly across the tool body.

- Sudden entry into a hot zone without coolant can cause micro-fractures on the tool edge.

- High-pressure coolant streams stabilize thermal conditions, reducing stress concentrations.

- In operations with continuous engagement, like high-speed milling, consistent cooling ensures tools do not alternate between extreme hot and cold, which leads to fatigue damage.

By preventing sharp thermal gradients, the coolant keeps the tool structurally intact even under harsh operating conditions.

Minimizing Tool Breakage

At high spindle speeds, even minor fluctuations in temperature or chip removal can cause mechanical failures. Proper coolant delivery reduces friction, prevents chip jamming, and lowers cutting forces. The result is a smoother load distribution on the cutting edge.

- In deep-hole drilling, coolant ensures chips are expelled, reducing torque spikes that snap drills.

- In threading, lubrication prevents galling that can seize and fracture taps.

- In CNC turning, a steady stream of coolant reduces vibration and chatter that otherwise destabilize inserts.

These protective effects are most visible in tools with smaller diameters, where even slight increases in load can cause breakage.

Examples of Tool Life Improvements

Shops that implement optimized coolant management often report significant gains in tool performance. Case studies highlight improvements such as:

- Doubling of tool life in titanium milling when high-pressure synthetic coolant replaced conventional flood coolant.

- Reduction in insert consumption during steel turning by maintaining stable coolant concentration and temperature.

- Extended drill life in aluminum machining through precise through-tool coolant delivery that eliminated chip packing.

These improvements do not just reduce tooling costs but also minimize downtime, improve schedule reliability, and increase overall equipment efficiency.

Effects on Surface Finish

Surface finish is one of the most visible indicators of machining quality, and coolant management directly determines whether a part meets specifications or requires rework. At high speeds, the cutting edge interacts with the workpiece under extreme heat and pressure. Without proper coolant application, surfaces can show burns, roughness, or irregular patterns. With controlled coolant delivery, however, the tool cuts smoothly, friction is minimized, and surfaces achieve the required finish with fewer secondary processes.

Surface Finish in Manufacturing

Influence of Coolant on Surface Roughness

Coolant helps reduce the micro-friction between the tool and workpiece, which has a direct effect on roughness values. Lower friction stabilizes the tool path, ensuring the cutting edge shears material cleanly rather than tearing it.

- In CNC milling, consistent coolant flow reduces the chance of burr formation along edges.

- In CNC turning, a stable lubricant film prevents micro-welding between the insert and the part surface.

- In drilling, coolant prevents smearing that often leaves rough or torn hole walls.

By keeping the interface clean and cool, coolant supports smoother surfaces and better dimensional consistency.

Prevention of Surface Defects

When coolant management is poor, several common surface problems appear.

- Thermal damage: Overheated zones cause discoloration or burns on the workpiece surface.

- Built-up edge marks: Without proper lubrication, chips weld to the cutting edge and transfer onto the part, leaving irregular patterns.

- Scratches and chatter marks: Inadequate chip evacuation allows fragments to drag across the surface.

These defects increase rejection rates and force additional polishing or grinding, which adds cost and time to production.

Industry Examples of Improvement

Practical evidence shows that correct coolant management consistently enhances surface quality.

- In aerospace aluminum machining, using high-pressure through-spindle coolant reduced surface waviness and eliminated built-up edge defects.

- In medical stainless steel components, maintaining coolant concentration within tight limits achieved mirror-like finishes that met biocompatibility standards.

- In automotive cylinder head machining, improved nozzle positioning reduced tool vibration, resulting in smoother bore finishes without secondary honing.

These examples highlight how coolant not only protects tools but also elevates the visible and functional quality of finished parts.

Relationship Between Finish and Dimensional Accuracy

Surface finish and dimensional accuracy are closely linked. When coolant temperature and flow are well controlled, the cutting tool moves with less resistance and lower thermal distortion. This reduces variation in both form and finish, ensuring parts meet specifications without additional correction steps.

Stable coolant conditions also improve repeatability across large production runs, where even minor inconsistencies in finish can lead to significant downstream issues.

Best Practices for Coolant Management

Coolant management is not limited to selecting the right fluid or setting the correct flow rates. It requires continuous monitoring, preventive maintenance, and adherence to safe handling standards. A systematic approach ensures that coolant maintains its effectiveness throughout its service life and consistently supports machining performance.

Coolant management best practices

Regular Monitoring of Coolant Quality and Concentration

Coolant concentration directly influences its cooling, lubricating, and anti-corrosion properties. If the concentration drifts too low, the fluid loses strength, leading to rust, bacterial growth, and poor surface quality. If it is too high, foaming, staining, and unnecessary costs occur.

- Use refractometers or digital sensors to measure concentration daily in high-volume shops.

- Record readings and adjust with water or additives to maintain stability.

- Monitor pH levels, as an imbalance can signal contamination or degradation.

By tracking concentration and pH, shops prevent costly fluid breakdowns that shorten tool life and harm part quality.

Filtration and Contamination Control

Clean coolant is as important as the correct type or mix. Chips, tramp oil, and fine abrasive particles gradually contaminate the fluid, reducing its efficiency and creating health hazards.

- Install filtration units to capture chips before they circulate back into the cutting zone.

- Use oil skimmers to remove tramp oil, which supports bacterial growth and weakens coolant performance.

- Schedule tank cleaning at intervals based on usage and material type.

Filtration not only extends coolant life but also protects pumps, seals, and delivery systems from premature wear.

Adjusting Parameters Based on Tool and Material

Coolant strategies should not remain static. Different tools and materials require different flow rates, nozzle placements, and pressure settings.

- Carbide tools with coatings may require stronger cooling to protect thin films.

- High-speed drilling needs through-tool coolant for chip evacuation.

- Soft materials like aluminum benefit more from lubrication additives than from extreme cooling.

Making adjustments for each setup ensures coolant always supports the machining objective rather than being a generic solution.

Safety and Environmental Guidelines

Coolant is a workplace hazard if mishandled. Prolonged skin contact can cause irritation, and mist inhalation may create health issues. Shops must follow safety practices to protect operators.

- Provide proper ventilation in enclosed machines to reduce mist exposure.

- Supply gloves and protective gear for operators who handle coolant directly.

- Dispose of used coolant responsibly by following local regulations or using recycling services.

Environmental concerns also make it important to choose fluids with biodegradable additives and reduced toxicity. Compliance protects both workers and the company from long-term risks.

Training Operators and Standardizing Procedures

Even the best coolant system is ineffective without skilled handling. Operators must understand how to check, maintain, and adjust coolant on a daily basis.

- Train staff on using refractometers, testing pH, and recognizing early signs of fluid degradation.

- Establish standard operating procedures for adding concentrates, cleaning filters, and checking levels.

- Encourage feedback from operators, as they often detect problems like unusual odors, foaming, or inconsistent finishes before sensors indicate issues.

Standardized training ensures consistency across shifts and reduces mistakes that shorten coolant life or compromise part quality.

Conclusion

Coolant management is central to achieving precision, efficiency, and reliability in high-speed CNC machining. The choice of coolant, its flow, temperature stability, and concentration all determine how well tools perform and how consistently parts meet specifications. Properly managed coolant extends tool life, improves surface finish, and reduces the risk of thermal damage or dimensional errors.

Key practices such as monitoring concentration, controlling contamination, adjusting parameters to suit tools and materials, maintaining stable temperatures, and training operators ensure the coolant delivers its full potential. By treating coolant as a critical part of the machining process rather than a secondary element, manufacturers can lower costs, reduce downtime, and sustain high-quality output.

Effective coolant management is not only a technical requirement but also a strategic advantage. It enables shops to run faster, maintain accuracy, and deliver reliable results across every production cycle.