Are you struggling with component failures after delivery? Rejected parts due to microscopic leaks are costing you money and damaging client relationships. Ultrasonic leak detection could be your solution.

Ultrasonic leak detection uses high-frequency sound waves to identify microscopic leaks in machined components that visual inspection can't catch. This technology helps manufacturers ensure airtight and watertight integrity in critical components before they reach customers, dramatically reducing failure rates and warranty claims.

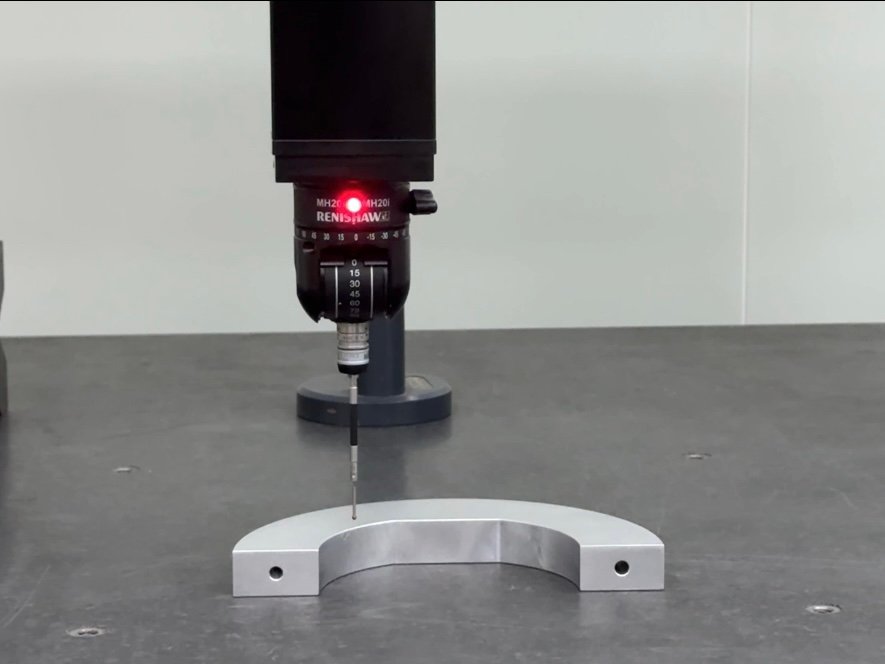

Ultrasonic leak detection in action

In our factory, we've seen firsthand how implementing advanced quality control technologies can transform manufacturing outcomes. As competition in the precision machining industry intensifies, the ability to guarantee component integrity becomes a key differentiator. Let's explore how ultrasonic leak detection is changing the game for CNC manufacturers like us.

What is ultrasonic leak detection?

Do you know that gas or liquid leaks emit sound waves beyond human hearing? These undetected leaks might be silently compromising your machine parts while passing traditional inspection methods.

Ultrasonic leak detection is a non-destructive testing method that captures high-frequency sound waves (usually 25-100 kHz) created when gases or liquids escape through tiny openings in components. The technology translates these sounds into audible signals or visual readings that technicians can interpret to locate and assess leak severity.

Modern ultrasonic leak detection equipment

Ultrasonic leak detection works on a fascinating principle that gives it unique advantages in precision manufacturing. When pressurized gases or liquids escape through even microscopic gaps, they create turbulence that produces high-frequency ultrasonic sound waves. These sound waves are consistent regardless of the type of gas or liquid, making the technology extremely versatile.

Modern ultrasonic detectors typically consist of specialized sensors that pick up these high-frequency sounds, convert them to lower frequencies audible to humans, and display the intensity on meters. Some advanced systems even create visual maps showing leak locations and severity. The technology is particularly valuable because it works in noisy factory environments where other methods fail, as ultrasonic frequencies stand out clearly from typical machinery noise.

The sensitivity of these systems is remarkable – capable of detecting leaks as small as 0.005 mm in diameter or flow rates of less than 1×10^-3 cc/sec. For our vacuum chamber customers, this means we can verify that components will maintain proper vacuum integrity before installation, preventing costly system failures down the line.

Why are leak detection systems critical for high-precision CNC-machined parts?

Have you ever calculated the true cost of component failure in the field? Beyond replacement parts, consider downtime, reputation damage, and potential safety risks when precision-machined components leak unexpectedly.

Leak detection systems are essential because high-precision parts often serve in critical applications where failures can be catastrophic. For components used in medical devices, automotive systems, or aerospace applications, even microscopic leaks can lead to system failures, contamination issues, or safety hazards that compromise entire assemblies.

Quality control for precision-machined parts

The importance of leak detection systems for high-precision CNC-machined parts cannot be overstated, especially as manufacturing tolerances continue to tighten across industries. When we produce components for semiconductor vacuum chambers, for instance, we're working with specifications that demand near-perfect sealing integrity. A single undetected microscopic leak could contaminate an entire semiconductor production batch worth millions.

The criticality becomes even clearer when examining industry-specific requirements. In automotive manufacturing, fuel system components must maintain perfect seals to prevent dangerous leaks and meet emissions standards. Medical device components that house sensitive electronics or biological materials must maintain sterile environments. Aerospace components are subject to extreme pressure differentials and temperature fluctuations that can amplify even tiny manufacturing defects.

Traditional quality control methods like visual inspection, dimensional verification, and even pressure testing have significant blind spots when it comes to detecting these subtle defects. Visual inspection, even with microscopes, cannot detect internal passageway leaks. Dimensional verification might confirm that a part meets size specifications, but it cannot verify functional sealing performance. Basic pressure testing might identify catastrophic leaks but miss slow leaks that will cause problems over time.

Our implementation of ultrasonic leak detection has allowed us to validate complex internal channels in hydraulic manifolds, verify sealing surfaces on medical device housings, and confirm the integrity of cooling passages in automotive components – capabilities that have significantly enhanced our quality assurance program and reduced customer returns by over 30%.

How can ultrasonic technology identify microscopic defects in critical machined components?

Is your quality control process missing hidden defects? Microscopic cracks, porosity issues, and sealing surface imperfections often escape traditional inspection but eventually lead to component failure.

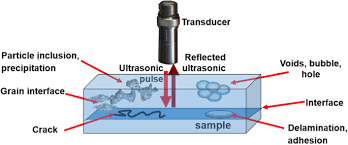

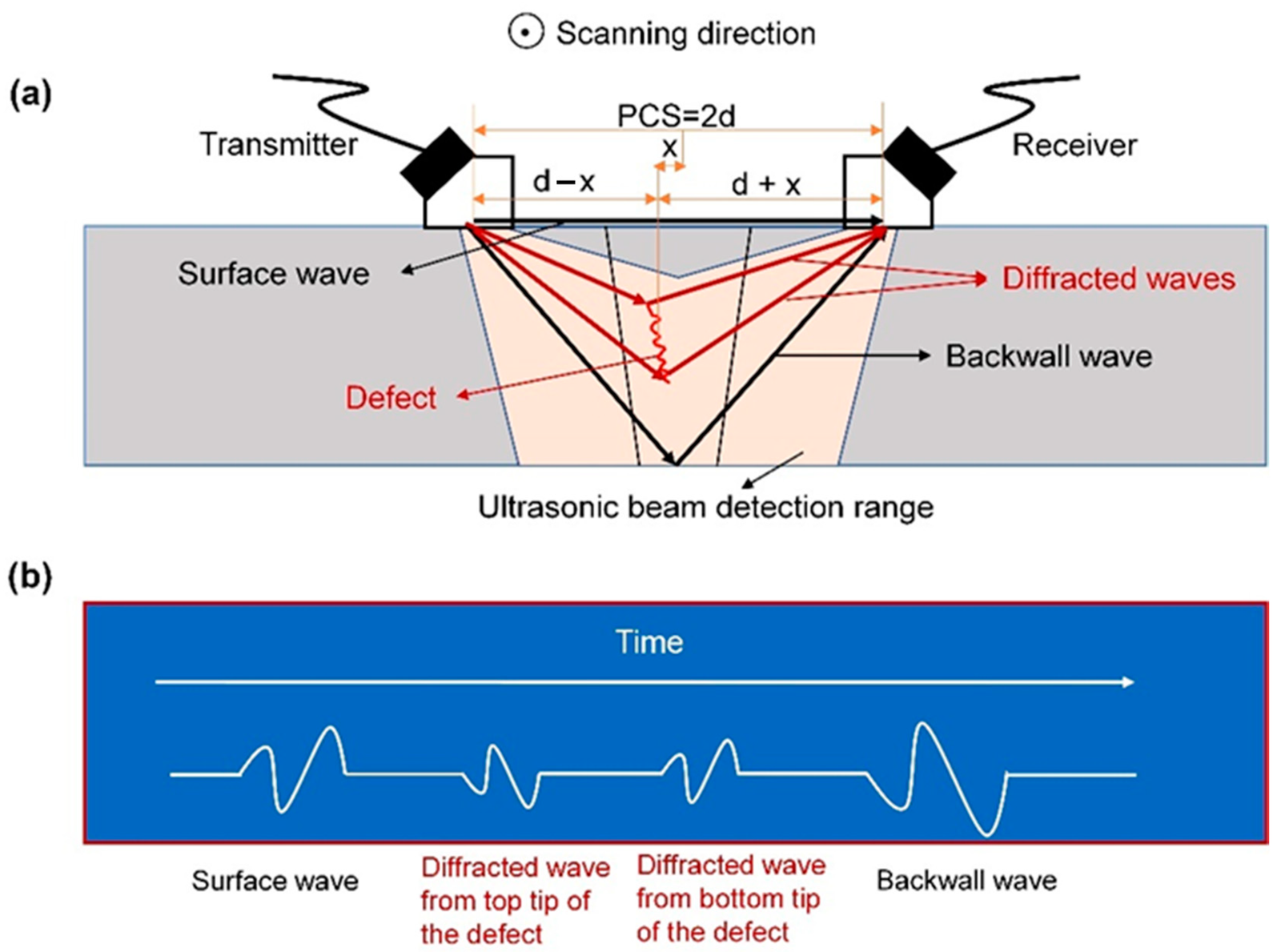

Ultrasonic technology detects microscopic defects by measuring sound wave behavior as it travels through the material. When sound waves encounter defects like cracks, voids, or porosity, they create distinctive echo patterns. By analyzing these patterns, technicians can locate, size, and characterize defects invisible to the naked eye, ensuring component integrity.

Microscopic defect detection using ultrasonic technology

Ultrasonic technology's ability to identify microscopic defects represents one of the most significant advances in modern quality control for precision manufacturing. The technology works through two primary approaches in machining quality control: active testing and passive monitoring, each offering unique advantages for different applications.

In active ultrasonic testing, we introduce controlled sound waves into the machined component and analyze how these waves travel through and reflect within the material. This approach is particularly valuable for identifying internal defects that no surface inspection could reveal. When sound waves encounter discontinuities like cracks, voids, or material inconsistencies, they reflect back at different rates and intensities. Our sophisticated equipment captures these reflection patterns and creates detailed maps of the component's internal structure.

For example, when testing a critical sailboat fitting, our active ultrasonic testing revealed a subsurface porosity cluster that would have eventually led to stress failure. This defect was completely invisible from the surface and would have passed all conventional inspections. By identifying and rejecting this part before delivery, we prevented a potential failure at sea.

Passive ultrasonic leak detection, meanwhile, listens for the distinctive high-frequency sounds created when pressurized gases or liquids escape through microscopic openings. This approach is particularly valuable for testing sealed components or assemblies. We've used this method to verify the integrity of sealed chambers where even microscopic leaks could compromise functionality.

The technology's sensitivity is remarkable – capable of detecting defects as small as 0.1mm in many materials. For our automotive customers requiring components with internal cooling channels, this capability ensures that no microscopic cracks will lead to fluid leaks that could cause engine failures or performance issues down the line.

What ROI can manufacturers expect when implementing ultrasonic testing in QC processes?

Are the costs of implementing new testing technologies holding you back? Many manufacturers hesitate to invest in advanced QC equipment, not realizing the significant financial benefits that follow.

Implementing ultrasonic testing typically delivers ROI within 6-18 months through reduced warranty claims, fewer field failures, and decreased rework costs. Manufacturers report rejection rate reductions of 15-30% after implementation, while customer satisfaction metrics improve as products demonstrate better reliability and longevity in real-world applications.

ROI analysis of ultrasonic testing implementation

The return on investment for implementing ultrasonic testing in quality control processes is compelling when analyzed comprehensively. While the initial capital expenditure for quality ultrasonic testing equipment typically ranges from $15,000 to $75,000, depending on sophistication, the financial benefits quickly accumulate across multiple business dimensions.

First, there are the direct savings from reduced warranty claims and field failures. In our own operation, after implementing ultrasonic testing for critical components, we documented a 27% reduction in warranty-related expenses within the first year. For high-value components like vacuum chambers or complex automotive parts, preventing even a small number of failures can justify the entire equipment investment.

The second ROI factor comes from production efficiency improvements. With earlier defect detection, manufacturing processes can be adjusted before significant material or labor is wasted on non-conforming parts. One of our automotive customers reported that early detection of a recurring porosity issue saved approximately $120,000 in material and processing costs that would have been spent on parts that ultimately would have failed final testing.

Training requirements represent a consideration in the ROI calculation. While basic ultrasonic testing can be taught relatively quickly, developing true expertise typically requires about 80 hours of training per technician. However, this investment creates valuable in-house capability that continues to deliver returns through improved quality outcomes.

The technology also opens doors to new business opportunities. After implementing advanced ultrasonic testing, we were able to qualify for more demanding contracts in the medical device and aerospace sectors, where stringent quality requirements previously presented barriers to entry. These higher-margin contracts significantly contributed to our ROI calculation.

Most manufacturers implementing comprehensive ultrasonic testing programs report breakeven periods of 6-18 months, with ongoing benefits continuing to accumulate thereafter. In our experience, the question isn't whether you can afford to implement ultrasonic testing, but whether you can afford not to in today's competitive manufacturing landscape.

Conclusion

Ultrasonic leak detection represents a game-changing quality control advancement for precision CNC manufacturing. By implementing this technology, we've reduced defects, won new business, and established ourselves as a trusted partner for demanding industries. The investment pays for itself while elevating manufacturing capabilities.