What is Magnetic Finishing?

Magnetic finishing is also referred to as magnetic field-assisted finishing, and is a precision surface treatment technique that applies a controlled magnetic field to induce abrasives to strike a workpiece. Unlike conventional grinding or polishing, which has rigid tool elements and hence cannot adapt to complex geometries, magnetic finishing uses flexible, controllable, abrasive tools that take different configurations as required. The tool is not a solid wheel or belt but rather a dynamic medium using magnetic particles and abrasives that are aligned as if there were a magnetic field, customizing the configuration to achieve the machine tool path.

Process variants

Magnetic finishing is not a separate process but a group of processes that utilize the same simple principle of using a magnetic field to handle abrasive action, and has been shaped into different forms as appropriate. Here are descriptions of the major process variations.

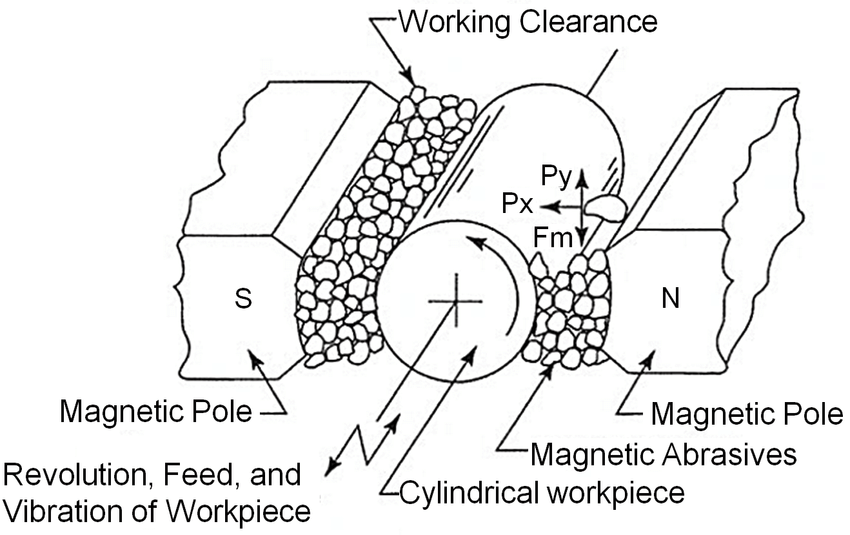

MAF (Magnetic Abrasive Finishing)

MAF generates a flexible magnetic-particle "brush" that aligns ferromagnetic abrasives under controlled local magnetic field conditions. The brush will adapt to edges, outside and inside bores, and even gently curved freeform surfaces, allowing for uniform micro-cutting and polishing action beyond the capabilities of rigid tools. The flexibility and practical contact force present in the MAF brush scale with magnetic flux and working gap, or separation, allow it to be tuned from delicate deburring to fine finishing, although representing the combined forces with regards to predicting material removal is an active area of inquiry with resources related to MAF technology. MAF is broadly used for the infrequent cases with limited access internal to additive or in precision remanufactured components, where there are involved passageways in general.

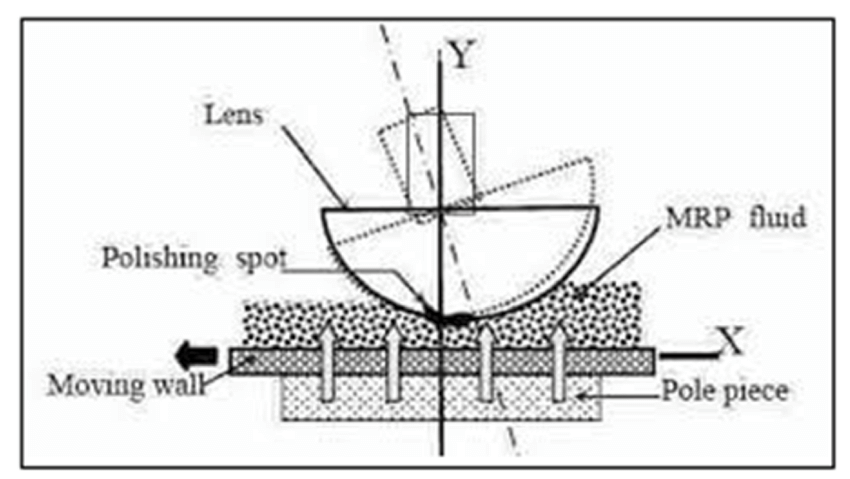

MRF (Magnetorheological Finishing)

MRF is a deterministic sub-aperture polishing process where a ribbon or spot of magnetorheological (MR) fluid (carbonyl-iron particles and non-magnetic abrasives in a carrier) is stiffened by a local magnetic field and then shears material removal tightly confining it. As a result, predictable function on optical-quality surfaces with nm-level roughness is achieved on flats, convex/concave lenses, and mirrors, which enables effective finishing. MRF is a mainstay of the precision optics and other brittle material processes, as it offers controllability (via flux), heat and debris transport, and the capability to vary the finishing area by varying the flux to achieve a specific geometry. On at least, shapes with more complex 3D form, ball-end MRF (BEMRF) finishes and fluid are shaped into a stable "ball" at a rotating tool tip, taking the idea of sub-aperture to freeform parts and the more complex 3D forms.

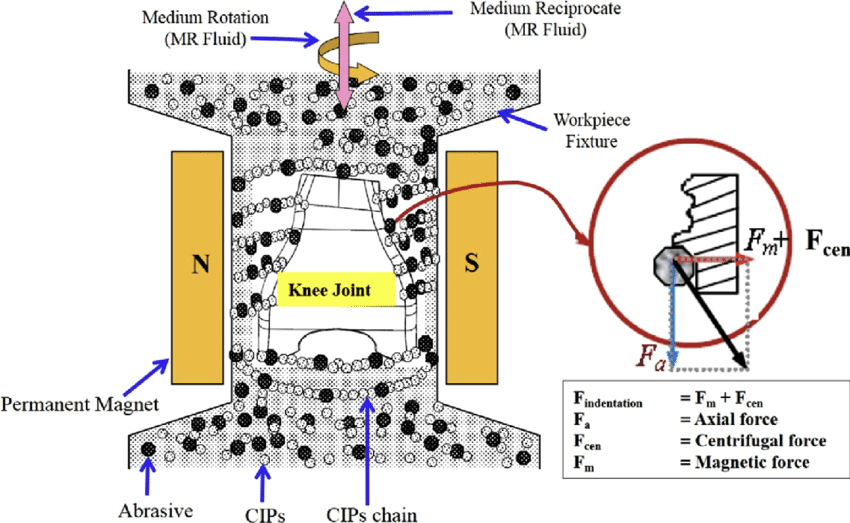

MRAFF / R-MRAFF (Hybrid of AFM + MRF)

Magnetorheological Abrasive Flow Finishing (MRAFF) offers hybrid access to abrasive-flow-machining (AFM) media-controlled flow to media wherein rheology is controlled with a sourced magnetic field. A reciprocating, magnetically stiffened MR medium passes over the openings of paths, affording greater control of the forces of engagement than AFM (although it is still present). When MRF is further combined with workpiece rotation under the sub-aperture of magnetorheological abrasive flow finishing- R-MRAFF- the remaining flux gap variation across the freeform part is smoothed, and the finishing rate and uniformity across differential surfaces were improved - again in a demonstration with what may be implant-like components, average finishing rates were nearly 2x faster than MAFF style approaches.

Other variants/hybrids of note

- BEMRF (Ball-End MRF): Engenders a magnetically-supported "ball" of MR fluid at the tool tip, allowing it to perform localized polishing processes upon complex 3D shapes; typically best suited for ferromagnetic materials due to the favorable field lines at the contact.

- MRJF (Magnetorheological Jet Finishing): Projects MR fluid in a free jet/spot; while MR jet removal physics shares the same mechanisms that are commonplace in MRF, MR-jet provides better access for localized or recessed features. Unify MRF with MR-jet into the removal models that have been proposed for optical systems.

- MRAH (Magnetorheological Abrasive Honing): In essence, a modified form of conventional honing with the ability to magnetically tune the abrasive action in order to address complex bores and non-magnetic materials. Reports indicate better roughness when field-stiffened chains form within the media.

- Ultrasonic-/chemical-assisted MRF/MAF: Combines either superimposed vibrations or reactive chemistry, in order to increase material-removal rate (MRR) while reducing subsurface damage. Ultrasonic-assisted MRF increases the relative particle velocity and forces that arise at the asperities, which ultimately results in a greater removal rate relative to the baseline MRF/MAF.

Equipment & media

Magnets: permanent vs. electromagnets

The magnetic field makes these processes possible. Permanent magnets, notably high-energy neodymium–iron–boron (NdFeB) magnets, offer a very small, efficient flux source that may be used in many industrial applications. The downside is that you cannot vary them once they are made. Electromagnets impart controllability of the flux density that is applied, which allows for more precision from polishing forces and spot geometries. High precision of magnetic field adjustment offers opportunities in optics and other advanced manufacturing processes, which are more easily challenged in maintenance, specifically, coil heating, which then renders the viscosity behavior of the MR fluids needs thermal management.

Magnetorheological fluid

Every magnetorheological finishing system is centered around a "smart fluid," which stiffens in a magnetic field. MR fluid typically consists of carbonyl iron particles (CIP) to provide the magnetic reactivity and abrasive grains (alumina, ceria, or diamond) for material removal, and a carrier medium (normally silicone oil, mineral oil, or water). To increase viscosity stability and prevent settlement, additional additives are mixed in (such as thixotropic additives, anti-wear, or anti-corrosion additives). This promotes MR fluid to turn from a liquid to a semi-solid polishing ribbon or brush state instantaneously, then returns to a liquid state when the magnetic field is removed.

Motion systems

It's possible to determine the interaction of the tool and workpiece based on controlled motion. Typical configurations for using MR finishing processes include rotating either a wheel or a small spot, in which the MR fluid becomes a stiffened polishing area; reciprocating flow systems, typically useful in abrasive flow-type hybrids for internal passages; and rotating workpieces, which often provide more consistent and greater rates of removal potential on cylindrical or freeform designs. Additionally, with adjustable motion and features, the manufacturers can finely tune both the rate of removal and finish with adjustable stiffness of the media.

Materials

Magnetic finishing processes are very flexible; however, the responses of materials depend on both their magnetic properties and their mechanical properties.

Most suitable: Ferromagnetic and relatively hard materials like steels and aluminum alloys are generally suitable materials for magnetic abrasive finishing. In optics, brittle ceramics like fused silica, BK7 glass, and single-crystal silicon are excellent materials for magnetorheological finishing and produce defect-free surfaces with nanometer-scale roughness.

Least suitable: Soft polymers and some non-ferrous metals (like copper and brass) are difficult materials to process because their low magnetic permeability means the strength of the abrasive tool formed in the field does not provide enough force. Polymers risk experiencing plowing instead of clean material removal, and precision may limit achievable tolerances.

Process Parameters.

Typical process parameters for processing to a consistent nano-finish are as follows.

- Magnetic flux density – this determines the stiffness of the tool, which applies polishing pressure.

- Carbonyl iron particle (CIP) and abrasive concentration & size – with greater concentrations of the abrasive, the removal rate (MRR) increases; however, too much loading causes the CIP to lose stability in the medium.

- Working gap – the distance between the magnet and the workpiece; the smaller the gap, the stronger the magnetic brush, but localized forces may increase.

- Relative motion – either rotational motion, reciprocating motion, or a combination thereof- establishes shear action on the surface.

- Processing time – if cycles are longer, the finish is improved, but throughput is reduced; therefore, optimization is vital for processing scales for production.

Advantages

- Accurate force control enables polishing to nanometer-level roughness with little subsurface damage.

- Adaptive conformance of the magnetic brush or MR fluid ribbon will enable finishing of complex shapes, freeform surfaces, and internal passages.

- Heat and debris management is inherently improved as the fluid medium is able to remove heat and loose particles, reducing thermal stresses and defects on the surface.

Disadvantages

- The slow removal rates on very hard materials limit competitiveness where significant stock removal is needed.

- The MR fluid is uniquely challenging in that there are issues such as sedimentation, stability, and additives that will complicate long-term operation.

- On non-ferrous and diamagnetic materials, the MR fluid has reduced effectiveness compared to. Reverse or poor magnetic interaction.

- The heating of the electromagnet will undermine the properties of the MR fluid and may require active cooling or a transition to a permanent magnet.

Applications.

Optics – polishing of lenses and mirrors and corrective figure control for high-performance optical systems.

Biomedical implants – finishing prosthetic joints, stents, and other free-form medical parts that require reduced wear and better biocompatibility.

Precision engineering – surface finishing applications for gears, fuel injectors, micro-nozzles, and hydraulic components; as well as post-processing of metal additive manufacturing parts where smooth internal channels are critical.