In any system that relies on ropes, lines, or cables, from a high-performance racing yacht to an industrial crane, the smooth and controlled movement of those lines is essential. That's where fairleads and sheaves come into play. These simple yet critical components help guide and redirect ropes while minimizing friction, wear, and stress. When they're poorly designed or manufactured with low precision, even the strongest ropes can suffer from abrasion, misalignment, or premature failure.

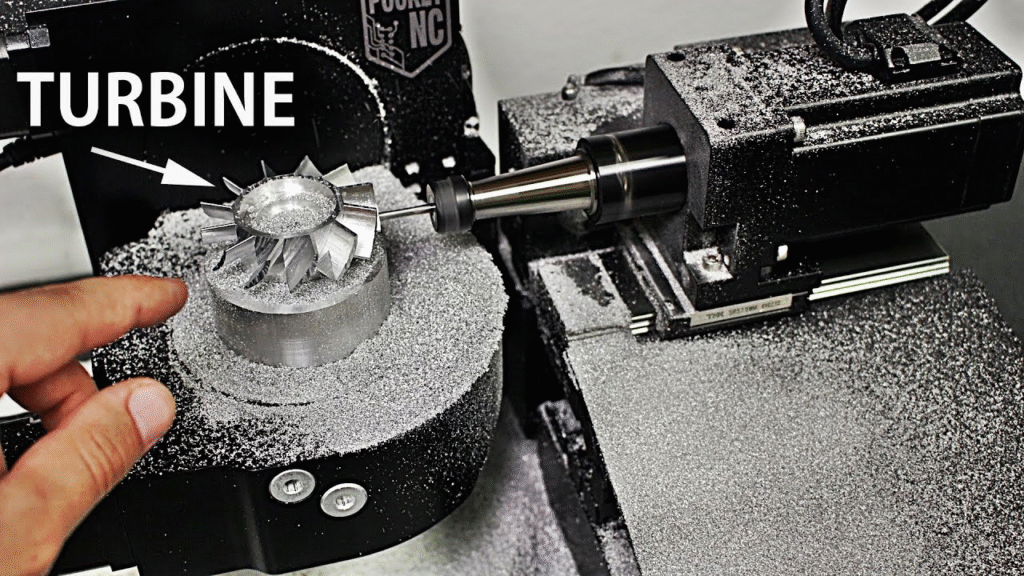

Over the years, CNC machining has transformed the way we produce these parts. With modern high-precision CNC methods, fairleads and sheaves can now be crafted with exact tolerances, finely tuned groove profiles, and incredibly smooth surface finishes. This not only improves performance under load but also significantly extends the life of ropes and the hardware itself. For rigging systems that operate under high tension or constant motion, this level of precision isn't just a bonus; it's essential.

In this article, I'll walk you through how CNC precision plays a critical role in enhancing rigging hardware.

The Importance of Smooth Surface Machining in Rope Longevity

In rigging systems, rope movement is constant. Whether you're trimming a sail, lifting a load, or adjusting tension under varying conditions, the rope is in frequent contact with sheaves and fairleads. Over time, this contact becomes a major factor in rope wear, especially if the hardware surfaces are rough, uneven, or poorly aligned. Even microscopic surface imperfections can start to act like sandpaper, slowly degrading the rope fibers with every pass.

This is where CNC machining steps in. Unlike traditional fabrication methods, high-precision CNC milling or turning can produce surfaces with tight control over roughness, roundness, and symmetry. And when you're dealing with high-load lines made from expensive synthetic fibers like Dyneema or Technora, even small improvements in surface finish can significantly extend rope life.

Let's break down exactly how smooth surface machining benefits rope longevity and what role CNC plays in making it possible.

How Surface Finish Affects Rope Wear

When rope runs through a fairlead or over a sheave, any irregularity in surface texture creates friction, and that friction translates directly to abrasion. The rougher the surface, the faster the fibers break down.

- Microscopic ridges on a poorly finished groove can catch and tear outer fibers.

- Non-uniform surfaces cause uneven pressure distribution, leading to hot spots and accelerated wear.

- Rough edges at transitions (such as groove edges or bearing interfaces) create snags and cuts.

In low-load or infrequent-use systems, this might not be immediately noticeable. But in high-cycle environments, such as competitive sailing, offshore mooring, or industrial lifting, this adds up quickly. The result? Frayed covers, core exposure, strength reduction, and more frequent replacement cycles.

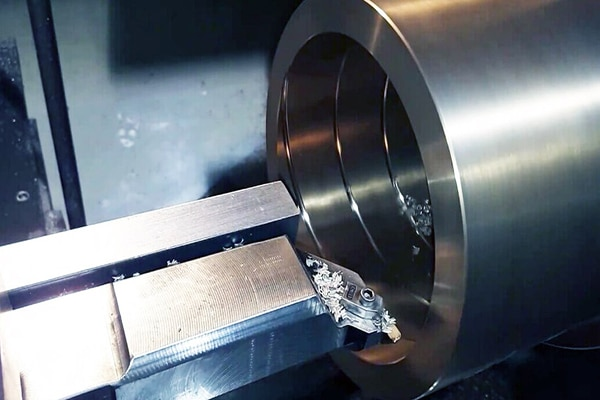

Role of CNC Machining in Achieving Consistent Smoothness

CNC machining offers consistent surface quality from part to part, thanks to programmable precision and repeatable cutting paths. Surface finishes can be fine-tuned by controlling cutting speed, tool sharpness, feed rates, and post-processing operations like polishing or anodizing.

- Consistent groove radius avoids point loading across the rope.

- Low Ra (Roughness Average) finishes help reduce friction and heat generation.

- Symmetrical machining ensures balanced movement and avoids excessive wear on one side of the rope.

More importantly, CNC allows for repeatability across batches. So whether you're machining ten sheaves or a thousand, each one can meet the same performance specs, essential for fleet-wide hardware consistency.

Impact on Rope Lifespan and Maintenance Costs

When hardware is precisely finished, rope doesn't just last longer; it performs better over that lifespan. This directly translates to cost savings.

- Fewer replacements: High-performance rope isn't cheap. Extending its life reduces recurring costs.

- Less downtime: Ropes that wear slowly mean fewer interruptions for re-rigging or inspection.

- Lower risk: Preventing unexpected rope failure reduces the chances of accidents, especially in critical load-handling operations.

In many professional setups, operators have tracked the differences. Some teams report 30–50% longer rope service intervals simply from switching to precision-machined fairleads and sheaves.

Examples of Improved Rope Performance

Real-world data from racing teams and offshore operators shows the tangible benefits of smoother surfaces:

- A commercial fishing fleet in the North Atlantic replaced its legacy sheaves with CNC-machined aluminum models with hard anodized finishes. The result: reduced mainline wear by 40% over the first six months.

- A competitive sailing team using high-modulus Dyneema halyards observed no measurable sheath damage after an entire race season, citing upgraded sheaves with Ra values under 0.4 μm as a key factor.

- Industrial crane systems upgraded their fairleads to CNC-cut units with Vesconite inserts. Rope inspection intervals doubled, with fewer replacement events logged.

CNC Grooving Accuracy and Its Effect on Load Distribution

When ropes pass over fairleads or sheaves, the groove profile is more than just a shape; it's a structural interface between synthetic fiber and metal. If the groove is too deep, too narrow, uneven, or off-center, it will concentrate force on specific parts of the rope instead of distributing it evenly. This imbalance is one of the most common causes of premature rope damage in rigging systems, especially when dealing with high-tension lines.

Precision grooving is critical, and it's exactly where CNC machining shines. Through computer-controlled machining processes, it becomes possible to define exact groove radii, depths, chamfers, and tolerances that are otherwise difficult (or impossible) to achieve manually. This not only improves mechanical performance but drastically reduces wear and the risk of rope failure due to stress concentration.

Let's explore how CNC grooving impacts load distribution and why it makes such a difference in real-world rigging.

What Is Grooving and Why It Matters

A groove is the recessed channel in a fairlead or sheave where the rope rests. Its shape determines how the rope sits, moves, and reacts under tension. A properly designed groove provides support to the rope without pinching or flattening it.

When grooves are inaccurately formed, several problems arise:

- The rope may ride unevenly or shift during operation

- The load is not spread evenly across the rope's diameter

- Fibers in contact with sharper surfaces receive more stress

- In dynamic systems, lateral movement may increase, creating internal heat

Poor groove design essentially turns a fairlead or sheave into a cutting tool over time.

How Precision Grooving Balances Load Across Rope Fibers

Rope fibers, whether braided or twisted, are designed to share load uniformly. The groove should mimic that intention. CNC machining allows grooves to be cut to exact specifications that support this balance.

Key characteristics of a well-cut groove include:

- Correct groove radius: Matches the rope diameter without flattening or compressing fibers

- Consistent depth: Ensures full rope contact and avoids stress concentration at the edges

- Smooth entry and exit angles: Reduce chafing during direction changes

- Centered profile: Prevents side-loading or uneven wear

By maintaining these dimensions within tight tolerances (often under ±0.05 mm), CNC-machined grooves ensure that each fiber in the rope carries its share of the load, instead of relying on just a few outer strands.

Effects of Groove Tolerances on Rope Stress

The slightest variation in groove profile can multiply stress on certain fibers, especially under heavy or fluctuating loads. When a groove is even slightly too narrow, for example, the rope is pinched. This introduces higher pressure points, especially at the outer fibers, and results in:

- Increased internal friction within the rope

- Uneven load paths, accelerating wear in specific areas

- Localized heating, especially in synthetic ropes under high-speed movement

CNC allows for tight tolerance control, making it ideal for sheaves used in safety-critical or performance-focused systems such as racing yachts, cranes, or offshore lifting rigs.

CNC Capabilities for Tight Tolerance Groove Production

Modern CNC lathes and mills can produce precision grooves that meet the most stringent dimensional requirements. This includes:

- Multi-axis machining for complex groove geometries

- Tool path simulation to verify groove accuracy before production

- Automated inspection using probe-based verification or optical measurement

- Post-machining finishing (e.g., polishing, anodizing) to further smooth surfaces without altering the groove's critical dimensions

In some high-specification applications, groove tolerances may be held to within ±0.01 mm, particularly when working with ropes that are expected to operate in cyclic high-load conditions.

Case Studies and Practical Examples

To better understand the real-world implications of CNC grooving, let's look at a few examples:

- Racing Yachts: A carbon rigging manufacturer replaced hand-filed aluminum sheaves with CNC-machined versions featuring matched groove radii for different halyards. Result: 30% reduction in halyard wear and a measurable improvement in line tension consistency.

- Industrial Lifting Systems: In a port crane setup, engineers observed frequent damage to load lines until the steel sheaves were remachined with CNC-defined grooves and edge rounding. Line failure rate dropped by 60%, and maintenance intervals nearly doubled.

- Mooring Systems: Offshore mooring fairleads equipped with CNC-cut grooves in Vesconite showed improved wear patterns on fiber hawsers over 12 months, with minimal abrasion at contact points.

Material Innovations in Fairleads & Sheaves

Material selection is just as critical as machining precision when it comes to the performance and durability of rigging components. Fairleads and sheaves are constantly exposed to mechanical loads, rope friction, UV, saltwater, and temperature fluctuations, a harsh cocktail of wear factors. Traditionally, these components were machined from stainless steel or bronze for strength and corrosion resistance. But today's performance demands have pushed engineers and builders to explore advanced materials that offer lower friction, lighter weight, and better machinability, all without compromising strength.

Modern CNC machining has made it possible to work with a broader range of materials and precisely combine them for targeted performance improvements. In this section, I'll walk through how traditional materials compare to newer options like Vesconite and Torlon, and how these innovations directly contribute to friction reduction, rope longevity, and extended hardware life.

From Metal to Composite: A Shift in Performance Priorities

Historically, marine and industrial sheaves were made from:

- 316 stainless steel: excellent corrosion resistance, but heavy and higher friction

- Bronze: solid wear properties, but requires regular lubrication

- Aluminum: lightweight and corrosion-resistant, but prone to galling without proper finishing

While these materials are still in use, they come with limitations, especially in terms of surface smoothness, weight, and how they behave under dynamic loading with synthetic rope.

Enter composite polymers and hybrid material assemblies. These materials offer performance benefits that were hard to achieve with metals alone, including:

- Lower coefficient of friction

- Self-lubricating properties

- Better noise damping

- Resistance to swelling or seizing in wet conditions

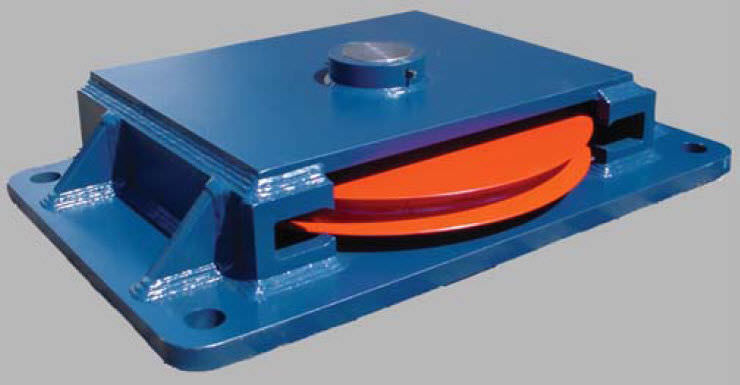

Vesconite: A High-Performance Polymer for Low-Friction Contact

Vesconite is a self-lubricating, high-load polymer developed specifically for applications that require low wear and minimal swelling in water-exposed conditions. Its properties make it a standout material for CNC-machined sheave inserts and standalone fairleads.

Key advantages of Vesconite include:

- Low friction coefficient: significantly less abrasive on ropes than metal

- Dimensional stability: unlike nylon or acetal, Vesconite doesn't absorb water and swell

- Self-lubricating: eliminates the need for greasing

- Long wear life: ideal for high-load or high-cycle applications

CNC machining of Vesconite is straightforward. It machines cleanly, holds tight tolerances, and does not require post-processing for lubrication. Many manufacturers are now using Vesconite inserts inside aluminum or stainless steel housings, combining metal strength with polymer contact surfaces.

In marine environments, Vesconite also resists barnacle growth and biofouling better than metals, making it well-suited for long-term immersion.

Torlon Inserts in Aluminum Housings: Strength Meets Smoothness

Torlon (polyamide-imide) is another high-performance engineering plastic with impressive thermal and mechanical properties. Though more expensive than Vesconite, it's used in premium applications where load and heat resistance are critical, such as racing yachts or aerospace-grade rigging hardware.

Benefits of Torlon sheave inserts:

- Exceptional strength-to-weight ratio

- Extreme temperature tolerance (up to 275°C)

- Excellent wear and creep resistance

- Compatible with high-speed, high-load rope movement

When paired with a CNC-machined aluminum body, Torlon inserts create a hybrid assembly that's both rigid and forgiving. The aluminum frame offers structure and mounting strength, while the Torlon groove surface provides a rope-friendly contact area that doesn't cut or burn the fibers under load.

How Material Combinations Reduce Friction and Increase Lifespan

The strategic combination of hard and soft materials in CNC-assembled fairleads and sheaves allows designers to fine-tune performance characteristics. Instead of a one-material compromise, you get a two-material solution, each optimized for its specific role.

For example:

- Aluminum body for strength and lightweight installation

- Vesconite or Torlon insert for smooth, low-friction contact with rope

- Optional sealed bearing interface for reduced rotation resistance

Benefits of this approach include:

- Dramatically reduced rope glazing and fiber burn

- Minimal friction under load, even when wet

- Lower thermal buildup during high-speed operations

- Increased hardware service life due to material wear resistance

Material Comparison: Traditional vs. Advanced Assemblies

Here's a quick performance comparison between common material choices for sheaves and fairleads:

| Material/Combo | Friction | Corrosion Resistance | Weight | Rope Wear |

| 316 Stainless Steel | High | Excellent | Heavy | Moderate–High |

| Aluminum Only | Medium | Good (with anodizing) | Light | Moderate |

| Bronze | Medium | Excellent | Heavy | Moderate |

| Aluminum + Vesconite | Low | Excellent | Light | Low |

| Aluminum + Torlon | Very Low | Excellent | Light | Very Low |

As shown, advanced assemblies using CNC-compatible polymers offer a strong return in both performance and durability. While initial material costs may be higher, the savings on rope replacements, labor, and operational reliability often make up the difference, especially in commercial or performance settings.

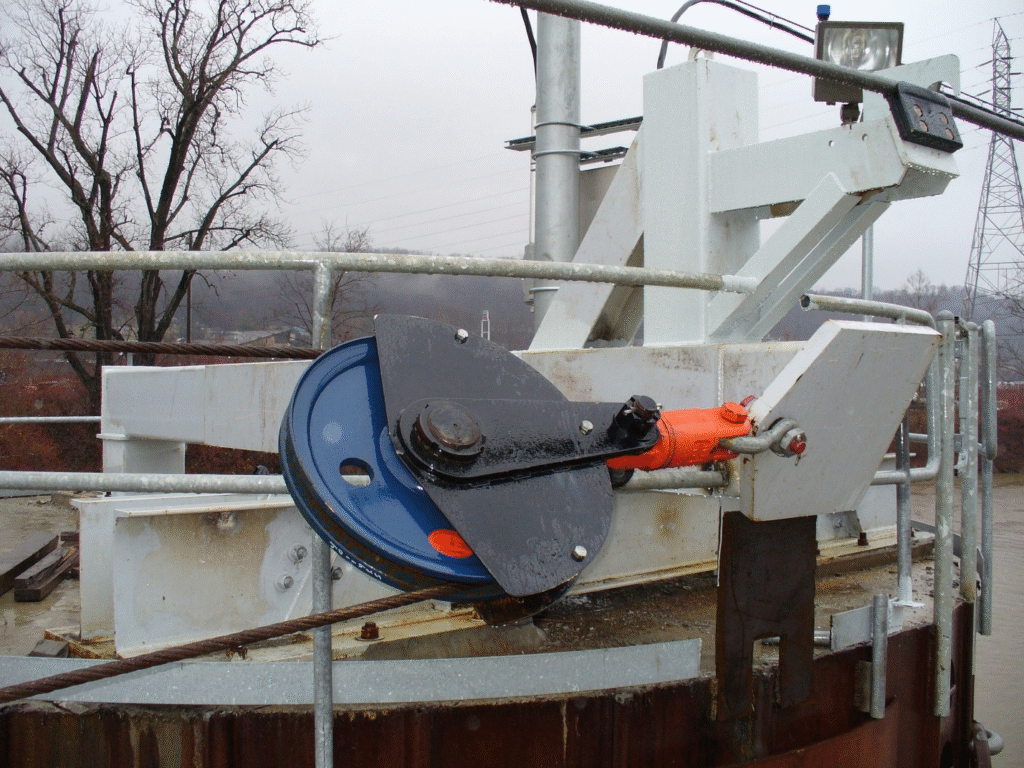

Integration of Sealed Bearings via CNC Pocket Machining

As rigging systems evolve toward higher performance and lower maintenance, bearings have become a central component of modern sheave design. They allow smoother rotation, reduce friction, and minimize the energy lost in mechanical movement. But not all bearings are created equal, and how they're integrated into the hardware matters just as much as the bearing itself.

In environments where reliability is non-negotiable, such as ocean racing, offshore platforms, or industrial cranes, sealed bearings offer distinct advantages over open or shielded types. They're protected against saltwater, dirt, and lubrication loss, allowing sheaves to keep spinning smoothly even after months of exposure.

Integrating these bearings with precision requires careful engineering. CNC pocket machining enables the exact tolerances and alignment needed to ensure bearing performance isn't compromised during installation or operation. Let's take a closer look at why bearing integration matters, how CNC machining supports it, and what benefits it brings to rigging systems.

Why Bearings Matter in Rigging Systems

Fairleads generally provide passive rope guidance, but sheaves are active components, designed to rotate under load as rope moves through the system. Without bearings, the sheave would rely on direct surface-to-surface contact, leading to high friction, heat, and rapid wear.

Bearings reduce these problems by:

- Allowing smooth rotation with minimal resistance

- Lowering the effort needed to move lines under load

- Preventing metal-on-metal or polymer wear

- Reducing the risk of rope chafing due to uneven motion

In high-load applications, even a minor friction reduction translates to easier handling and less mechanical strain on the rigging system as a whole.

Why Sealed Bearings Are Preferred for Harsh Environments

Open bearings may be suitable for dry, clean settings, but in marine or heavy-duty industrial conditions, they degrade quickly. Water, salt, sand, and debris can enter the bearing track and erode both the balls and raceways. Lubricants get flushed out, and failure follows.

Sealed bearings offer a much higher level of durability, as they:

- Contain built-in seals or shields to block contaminants

- Come pre-lubricated and often require zero maintenance

- Withstand immersion and fluctuating weather conditions

- Retain performance for longer operating intervals

These characteristics make sealed bearings the default choice for modern sheave systems used in offshore sailing, fishing fleets, rigging cranes, and lifting equipment exposed to the elements.

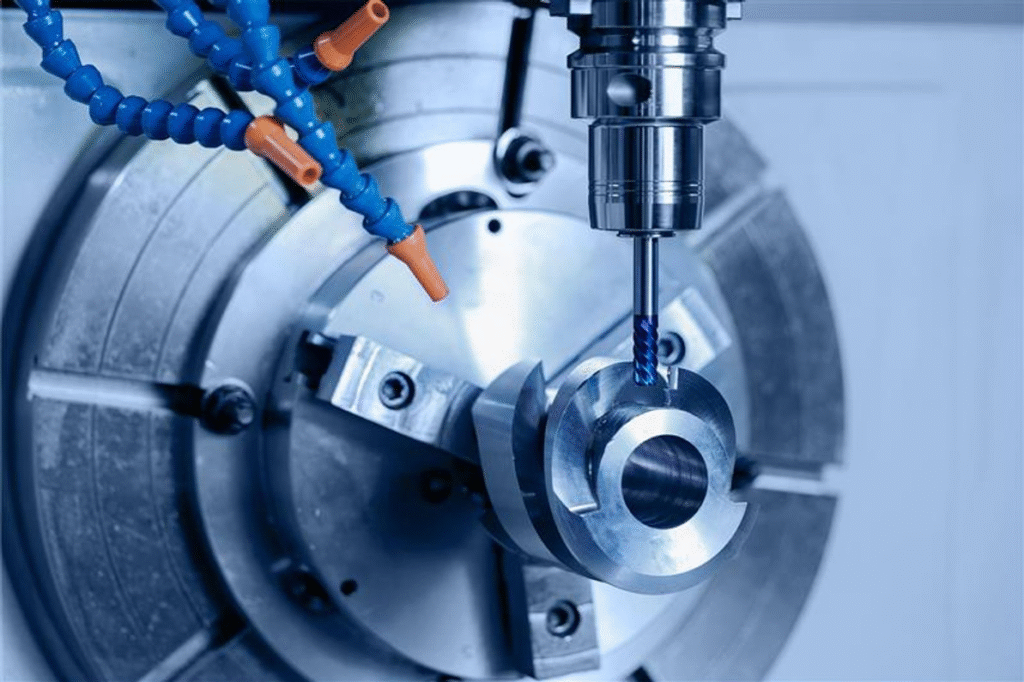

CNC Pocket Machining: Ensuring Proper Bearing Fit and Alignment

Installing a bearing isn't as simple as dropping it into place. For optimal performance, the bearing pocket, the cavity in which the bearing sits, must be machined to exact tolerances. Any looseness causes misalignment, while overtight fits can deform the bearing and cause early failure.

CNC machining provides the level of accuracy needed to create precision bearing pockets. This includes:

- Diameter tolerances as tight as ±0.01 mm

- Perfect circularity to ensure even radial load support

- Axial alignment for smooth rotation and uniform load transfer

- Consistent depth and face-flatness, which are critical for load-bearing performance

Modern CNC mills and lathes can use in-process probing to check pocket dimensions before final cuts, reducing error even further.

Some systems even use stepped pockets to accommodate dual-row or hybrid bearing setups, where a sealed bearing is combined with a polymer thrust washer or spacer ring to isolate loads.

Real Benefits of CNC-Machined Bearing Integration

When bearings are installed into CNC-machined pockets, the result is a sheave that performs smoothly, lasts longer, and requires less attention from the user. These advantages ripple through the system.

Performance improvements include:

- Reduced rotational resistance, especially under full load

- Minimized rope bounce or chatter during dynamic motion

- Less wear on bearing surfaces, thanks to proper seating

- Stable alignment, which protects both the sheave and the rope

Maintenance-related advantages:

- No need for frequent re-greasing or flushing

- Sealed system stays cleaner for longer

- Fewer bearing replacements over the equipment's life

When combined with self-lubricating materials like Vesconite or Torlon and protected in anodized aluminum housings, the result is a truly low-maintenance sheave system that performs under pressure without constant intervention.

Examples of Bearing Integration in the Field

- Sailing Winch Blocks: A racing yacht retrofitted all halyard sheaves with sealed ball bearings in CNC-machined pockets. Not only did line handling become easier under tension, but mid-season inspection showed zero salt ingress and no rotational stiffness.

- Industrial Crane Pulley Systems: A gantry crane system in a coastal shipyard upgraded to polymer-lined sheaves with precision bearing seats. Load movement became smoother, and wear on ropes decreased significantly. Engineers reported 50% fewer maintenance shutdowns over a year.

- Commercial Fishing Gear: Tuna vessels using fiber line nets replaced bronze bushings with sealed stainless bearings in CNC pockets. Result: lower drag in deployment, faster retrieval cycles, and longer rope life due to smoother rotation under strain.

Practical Benefits and Applications

High-precision CNC fairleads and sheaves are more than just premium hardware upgrades; they directly affect how rigging systems perform, last, and protect the equipment they serve. Whether on a sailboat, crane, or offshore rig, reducing friction, wear, and inefficiency has real operational consequences. These precision-machined components might seem small in size, but their impact is disproportionately large when viewed across the life cycle of a vessel or machine.

The advantages are felt not only by engineers and riggers but also by operators, maintenance crews, and even financial planners trying to stretch budgets and minimize downtime. Let's explore some of the most significant real-world benefits and where these technologies are making a difference today.

Enhanced Rigging Efficiency and Reduced Manual Effort

One of the most immediate effects of precision-machined sheaves is reduced effort. When a rope glides smoothly through a sheave or fairlead, there's less resistance, less strain, and far less energy wasted in overcoming friction. This translates to:

- Easier line handling, especially under load

- Smoother mechanical operation in automated systems

- Faster response in dynamic settings like racing, hoisting, or mooring

For manual systems, such as hand-operated winches, halyards, or block-and-tackle gear, this can make a substantial difference. Crew fatigue drops, and precision control improves. In automated systems, motors don't have to work as hard to overcome drag, which helps extend their life as well.

In essence, smoother rigging leads to smoother operations.

Cost Savings from Extended Rope and Component Lifespans

Modern synthetic ropes are engineered for strength and durability, but they still depend heavily on what they run through. Even the best rope will degrade quickly if it's subjected to a rough groove, poor alignment, or misfitted bearing.

By integrating precision-machined components:

- Rope lifespan increases significantly, often by 30–70%

- Replacement frequency drops, saving money and labor

- Downtime is reduced, especially in commercial or industrial settings

Over time, the initial investment in CNC components is often recouped simply through reduced rope purchases and fewer emergency rigging repairs.

Consider a vessel that replaces a set of high-modulus halyards every season. By upgrading to low-friction sheaves with CNC-machined grooves and sealed bearings, that replacement cycle might stretch to two or even three seasons, without compromising performance.

Improved Safety Through Reliable Load Handling

Safety is a top concern in any rigging application, whether it's hoisting a mainsail or lifting a multi-ton load on a dockside crane. When components seize, slip, or fail under stress, the risk to both personnel and equipment skyrockets.

Precision machining helps reduce these risks by:

- Eliminating unpredictable friction spikes

- Ensuring smooth, predictable movement under load

- Reducing rope slippage or shock-loading caused by resistance

- Enhancing structural integrity through accurate fits and tolerances

Sealed bearings, smooth groove radii, and self-lubricating materials all contribute to safer load handling. Operators can trust the system to respond consistently, which is crucial when working near moving loads or during sudden weather changes at sea.

Reduced System Fatigue and Wear on Supporting Structures

Another often overlooked advantage of precision-engineered fairleads and sheaves is the reduced mechanical strain they place on surrounding components. When a sheave runs roughly or binds under partial load, that resistance is transferred elsewhere, to mounting bolts, brackets, housings, and even the frame or mast of the structure it's installed on.

CNC-machined components, with optimized groove profiles and bearing alignment, ensure that the rope or line moves in sync with the system instead of fighting against it. This minimizes:

- Unwanted lateral forces that can cause metal fatigue or cracking in brackets

- Distortion or flexing in the support housing due to uneven load distribution

- Misalignment of adjacent pulleys, which often leads to rope tracking issues

- Vibration or chatter, which accelerates long-term wear across the structure

This benefit becomes especially important in high-load, continuous-use systems, such as cranes or industrial lifting rigs, where even small inefficiencies can multiply over thousands of cycles. With precise CNC machining, the entire rigging assembly stays mechanically aligned, reducing the chance of early structural failure or fatigue-based breakdowns.

Versatile Applications Across Marine and Industrial Sectors

CNC-machined fairleads and sheaves aren't just for yachts or cranes. Their use spans multiple industries and environments, each with its own unique demands. What ties them all together is the need for low-friction, high-reliability rope handling in compact hardware systems.

Some of the most common and impactful applications include:

- Sailing Vessels

Racing yachts, cruising sailboats, and commercial fishing boats all benefit from smoother halyards, furling systems, and spinnaker gear. Reduced wear means fewer failures mid-race or offshore.

- Cranes and Lifting Equipment

Overhead gantries, dockside cranes, and mobile hoisting systems use sheaves to redirect lifting cables. CNC-machined components ensure aligned loads and reduced friction for safer lifting.

- Winch Systems

Both manual and electric winches rely on sheaves to guide lines during payout and retraction. Precision grooves help maintain tension and prevent misalignment under load.

- Offshore Oil and Gas

Mooring systems and cable management platforms in offshore environments rely on sealed bearing sheaves that resist corrosion and wear, keeping critical equipment in place under extreme conditions.

- Architectural and Theatrical Rigging

In stage design or high-rise window cleaning systems, rope movement must be smooth, quiet, and reliable. CNC parts reduce noise and ensure safe operation during repeated cycling.

- Rescue and Military Applications

High-load sheaves are used in helicopter hoists, rappel gear, and tactical rigging setups. These demand reliability under the most unforgiving conditions, where failure is not an option.

Conclusion

Rigging systems rely on precision, not just in the rope, but in every component that touches it. Fairleads and sheaves may seem like minor parts, but as we've seen throughout this article, they carry a significant load when it comes to performance, safety, and longevity. When these components are manufactured using high-precision CNC machining, the result is a noticeable reduction in friction, wear, and system inefficiency.

From ultra-smooth surface finishes that preserve expensive synthetic ropes, to groove profiles that distribute load evenly across every fiber, the impact of tight machining tolerances is measurable and immediate. Advanced material pairings, such as aluminum bodies with Vesconite or Torlon inserts, further reduce abrasion while extending service life. And by integrating sealed bearings through CNC-machined pockets, hardware becomes more resistant to environmental stress and requires far less maintenance.

The practical outcomes speak for themselves: lower rope replacement costs, smoother manual and powered operation, improved safety margins, and reduced fatigue on supporting structures. Whether used on a racing yacht, an offshore crane, or a high-rise lift system, precision-machined fairleads and sheaves help ensure that the system runs cleaner, longer, and more reliably.

Looking ahead, the future of rigging technology is likely to lean even more heavily on CNC advancements, from automated groove validation to AI-optimized material layouts. For those designing, selecting, or maintaining modern rigging systems, investing in precision hardware is no longer just a performance choice; it's a strategic one.