The maritime industry struggles with heavy hardware that slows vessel performance and increases fuel consumption. Outdated manufacturing processes create sailboat components that are needlessly bulky, compromising speed and efficiency on the water.

Optimized CNC machining strategies for sailboat hardware combine lightweight material selection with advanced multi-axis techniques. Modern approaches utilize marine-grade aluminum alloys, titanium, or high-performance polymers machined with sophisticated toolpaths that maintain structural integrity while reducing weight by up to 30%.

CNC-machined lightweight sailboat hardware

In our factory, we've witnessed firsthand how proper machining strategies transform sailboat performance. One client reported that after switching to our lightweight cleats and blocks, their racing yacht shaved valuable seconds off their competition times. Let me share what we've learned about optimizing these critical components.

What Materials Best Balance Weight and Corrosion Resistance in Marine Hardware?

Sailors face a frustrating dilemma: lightweight components corrode quickly in saltwater, while corrosion-resistant options add unwanted weight. This compromise undermines performance and increases long-term maintenance costs.

The optimal materials for lightweight marine hardware include 6061-T6 and 7075 aluminum alloys with anodized finishes, marine-grade stainless steel (316L), titanium alloys, and engineered composites like carbon fiber-reinforced polymers. These materials offer excellent strength-to-weight ratios while withstanding harsh marine environments.

Marine-grade materials for sailboat components

In our machining facility, material selection is the foundation of lightweight marine hardware production. We've developed specific expertise working with these specialized materials to maximize their potential in marine applications. From my experience, each material presents unique machining challenges and opportunities.

Marine-grade aluminum alloys like 6061-T6 and 7075 offer excellent machinability while providing a superior strength-to-weight ratio. We typically use these for larger cleats and blocks where weight savings are most significant. The key to success with aluminum is proper surface treatment post-machining - we implement a multi-stage anodizing process that creates a hard, corrosion-resistant outer layer without adding appreciable weight.

Titanium alloys, while more expensive, provide unmatched corrosion resistance and strength at approximately 40% less weight than stainless steel. Our specialized tooling and cutting parameters for titanium (slower speeds, constant coolant flow, and rigid fixturing) enable us to machine complex geometries that would be impossible with conventional approaches.

For components with complex internal features, we've had excellent results with engineered composites, particularly carbon fiber-reinforced polymers. These materials require specific cutting strategies to prevent delamination, but the weight savings can reach up to 70% compared to metal alternatives.

| Material | Weight Reduction | Corrosion Resistance | Cost Factor | Best Applications |

|---|---|---|---|---|

| 6061-T6 Aluminum | 65% vs steel | Good (with anodizing) | $$ | General hardware, larger blocks |

| 7075 Aluminum | 65% vs steel | Moderate (with anodizing) | $$$ | High-stress components |

| 316L Stainless | Baseline | Excellent | $$$ | Critical load-bearing parts |

| Titanium alloys | 40% vs steel | Exceptional | $$$$$ | Racing hardware, premium components |

| Carbon composites | 70% vs steel | Excellent | $$$$ | Complex shapes, extreme weight reduction |

Which CNC Machining Techniques Effectively Reduce Weight in Sailboat Cleats?

Traditional sailboat cleats are overbuilt, with unnecessarily thick walls and solid sections. This outdated design approach adds weight where it isn't needed, reducing sailing performance and efficiency.

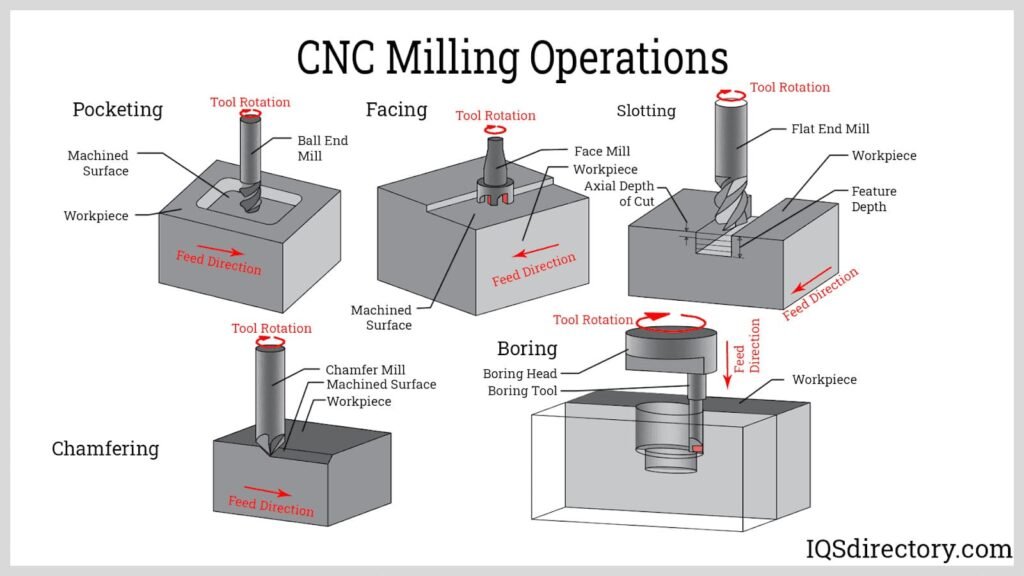

Advanced weight reduction techniques for sailboat cleats include pocket machining, strategic material removal in non-load-bearing areas, honeycomb internal structures, and topology optimization using FEA analysis. Modern CNC programming allows for precise wall thickness control as thin as 1.2mm while maintaining structural integrity.

CNC pocket machining for weight reduction

The art of creating lightweight yet strong sailboat cleats requires specialized CNC programming approaches. In our shop, we've refined these techniques through years of marine hardware production, finding the perfect balance between weight savings and durability.

Pocket machining represents our most frequently used weight reduction strategy. This technique removes material from non-critical areas while maintaining structural support where forces are concentrated. Using 5-axis machining, we can create complex pocket geometries that follow the natural load paths within the component. Our programmers utilize specialized CAM strategies that maintain consistent tool engagement, allowing for thin walls (typically 1.2-2.5mm) without deflection or chatter during machining.

We've also pioneered the implementation of biomimetic structures in sailboat hardware. These nature-inspired designs, such as internal honeycomb or lattice patterns, provide remarkable strength with minimal material. Creating these structures requires sophisticated machining approaches - we typically use small-diameter end mills (1-3mm) with high-speed, light-cutting passes to achieve the necessary detail.

Topology optimization has transformed our approach to clear design. Using finite element analysis (FEA), we identify exactly where material is needed to withstand expected loads and remove it everywhere else. This computational approach has yielded weight reductions of 25-35% compared to traditional designs, without sacrificing strength or durability.

| Weight Reduction Technique | Potential Weight Savings | Complexity Level | Best Applications |

|---|---|---|---|

| Pocket machining | 15-25% | Medium | Most cleats and blocks |

| Variable wall thickness | 10-20% | High | Larger components |

| Internal ribbing | 20-30% | Medium-High | Load-bearing cleats |

| Honeycomb/lattice structures | 25-40% | Very High | Premium racing hardware |

| Topology optimization | 25-35% | High (design phase) | Custom components |

How Do Multi-Axis CNC Systems Improve Efficiency in Producing Complex Marine Components?

Marine manufacturers struggle with inefficient production processes that require multiple setups, increasing labor costs, and error potential. Traditional 3-axis machining can't effectively produce the complex geometries needed for high-performance marine hardware.

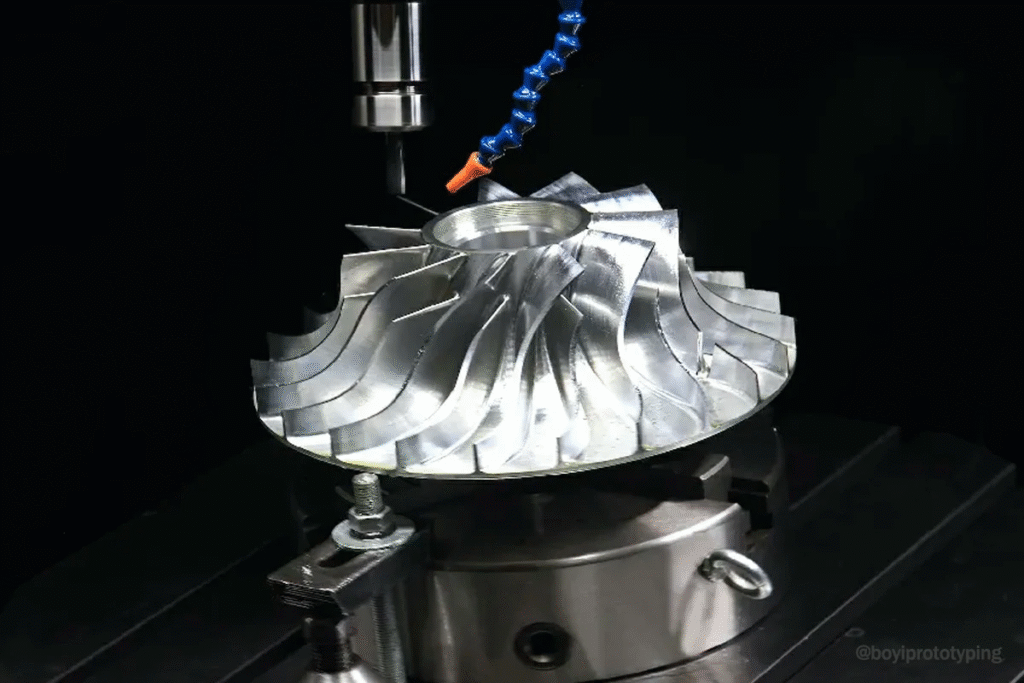

Multi-axis CNC systems dramatically improve marine hardware production by reducing setups (from 6+ to often just 1-2), enabling complex organic shapes impossible with conventional machining, and achieving better surface finishes that reduce post-processing. 5-axis simultaneous machining allows for optimized tool angles that extend tool life and improve part quality.

Multi-axis CNC machining of marine components

Our investment in advanced multi-axis CNC systems has revolutionized how we approach marine component manufacturing. The benefits extend far beyond simple production efficiency – they enable entirely new design possibilities for our sailing clients.

With our 5-axis simultaneous machining centers, we can maintain optimal tool orientation throughout the cutting process. This capability is particularly valuable when machining the complex curved surfaces common in marine hardware. By keeping the tool perpendicular to the surface being cut, we achieve superior surface finishes (often under Ra 0.8μm) directly from the machine, significantly reducing secondary finishing operations that add cost and time.

Setup reduction represents another major advantage. Components that once required 6-8 individual setups can now be completed in just 1-2 operations. This not only accelerates production but dramatically improves accuracy by eliminating cumulative positioning errors. For our marine clients, this translates to hardware with better fit, function, and consistency.

The most exciting advantage is design freedom. Multi-axis machining allows us to create organic, flowing geometries that optimize hydrodynamics and ergonomics simultaneously. Features like variable-radius fillets, complex undercuts, and compound curves – all challenging or impossible with conventional machining – become straightforward with our 5-axis capabilities. One recent project involved cleats with integrated fairleads featuring smooth transitions and internal channels that would have required extensive EDM work with traditional methods.

| Multi-Axis Advantage | Impact on Production | Client Benefit |

|---|---|---|

| Single-setup machining | 40-60% reduction in production time | Faster delivery, lower costs |

| Optimal tool orientation | Extended tool life, better finishes | Higher quality, reduced post-processing |

| Complex geometry capability | Enables advanced designs | Improved performance, distinctive products |

| Consistent accuracy | Reduced scrap rate (typically <2%) | Reliable fit and function |

| Simultaneous 5-axis movements | Ability to machine "impossible" features | Design freedom, competitive advantage |

What Quality Control Measures Ensure Marine-Grade Performance in Lightweight Hardware?

Lightweight marine hardware often fails prematurely due to inadequate quality control processes. Manufacturers who focus solely on weight reduction without rigorous testing create products that corrode, crack, or fail under real-world marine conditions.

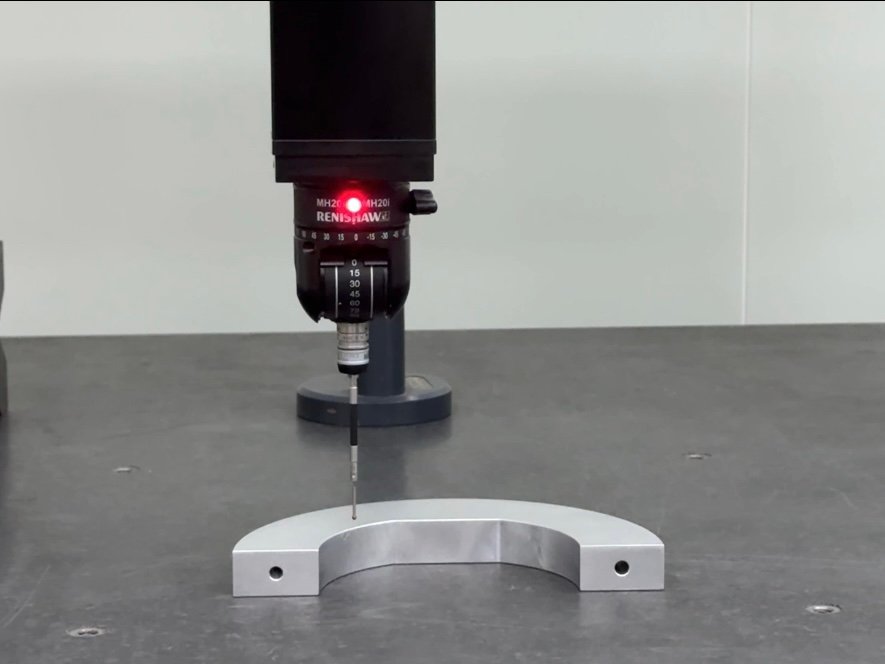

Effective quality control for marine hardware combines advanced metrology (CMM verification to ±0.01mm tolerances), material certification tracking, salt spray testing (500+ hours), load testing to 150% of rated capacity, and anodizing thickness verification (typically 20-25 microns for marine applications). This multi-faceted approach ensures components remain functional in harsh maritime environments.

Marine hardware quality control inspection

Quality control isn't an afterthought in our marine hardware production – it's integrated into every step of our manufacturing process. Our comprehensive approach combines high-precision measurement with real-world performance testing to ensure lightweight components withstand demanding marine conditions.

Our quality assurance begins with material verification. Every batch of raw material undergoes XRF (X-ray fluorescence) analysis to confirm its chemical composition matches specifications. For critical components, we maintain complete material traceability from the mill certificate through final inspection, ensuring every part meets its intended grade and temper.

Dimensional verification employs both contact and non-contact measurement techniques. Our climate-controlled metrology lab houses a Zeiss coordinate measuring machine (CMM) capable of measuring features to ±0.01mm accuracy. For complex organic surfaces, we utilize laser scanning to create digital comparisons between the designed and actual geometries. This dual approach catches deviations invisible to conventional measurement techniques.

Beyond dimensions, we validate performance through application-specific testing. Our in-house protocols include cyclic load testing that simulates years of use in compressed timeframes. Components undergo saltwater immersion followed by load testing to verify their structural integrity remains uncompromised by corrosion. For anodized aluminum parts, coating thickness measurements ensure proper protection (typically 20-25 microns for marine applications).

What truly distinguishes our quality approach is our environmental simulation testing. We've developed specialized fixtures that simultaneously apply UV exposure, salt spray, and cyclic loading – replicating the combined stresses hardware experiences at sea. This comprehensive testing has helped us refine our manufacturing processes to address failure modes that simpler testing might miss.

| Quality Control Measure | Testing Method | Acceptance Criteria |

|---|---|---|

| Dimensional accuracy | CMM measurement | ±0.01mm for critical features |

| Material composition | XRF analysis | Within ASTM specifications |

| Anodize quality | Thickness testing & salt spray | 20-25μm depth, 500+ hour salt spray resistance |

| Structural integrity | Load testing to 150% | No deformation or cracking |

| Environmental resilience | Combined UV/salt/load cycling | Performance retention after 500 hours |

How Can Custom CNC Solutions Reduce Production Costs for Marine Hardware Manufacturers?

Marine hardware manufacturers face skyrocketing production costs from inefficient processes, excessive material waste, and extensive finishing requirements. Without optimization, these costs must be passed to customers or absorbed at the expense of profitability.

Custom CNC solutions reduce production costs through optimized toolpaths that minimize machining time (typically 30-40% reduction), specialized fixtures that enable batch processing, near-net-shape manufacturing that reduces material waste, and automated finishing processes. These improvements lower per-unit costs while maintaining or improving component quality.

Efficient CNC setup for marine hardware production

Cost optimization in marine hardware manufacturing has been one of our core focuses for clients seeking to balance performance with affordability. Through thoughtful process engineering and strategic automation, we've developed custom CNC solutions that deliver significant cost advantages without quality compromises.

Material utilization represents one of our most effective cost-reduction strategies. We employ advanced nesting algorithms to maximize the number of components from each raw material blank, typically achieving 15-25% better material utilization than conventional approaches. For expensive materials like titanium, these savings directly impact final component costs. We've also developed specialized fixturing that allows for "waterline" machining – processing parts from multiple sides before completely separating them from the stock, which maintains stability while minimizing waste.

Our toolpath optimization strategies focus on both machine time and tool longevity. By analyzing cutting forces and adjusting parameters based on specific material characteristics, we've achieved cycle time reductions of 30-40% compared to standard CAM outputs. These optimized toolpaths maintain constant tool engagement, which extends tool life by 50-100% in many applications. For marine hardware produced in moderate volumes, these combined savings significantly reduce per-unit costs.

We've also implemented semi-automated finishing processes specifically designed for marine components. Traditional hand finishing is labor-intensive and inconsistent, particularly for complex geometries. Our mechanical finishing cells combine specialized tumbling equipment with controlled media and compounds formulated for specific materials. This approach delivers consistent results at approximately 30% of the cost of manual finishing, while also improving surface consistency critical for corrosion resistance.

For our marine manufacturing clients, perhaps the most valuable cost reduction comes from our design-for-manufacturing (DFM) collaboration. By engaging early in the product development process, we identify features that drive unnecessary costs and suggest alternatives that maintain functionality while reducing machining complexity. This collaborative approach typically yields 15-25% cost savings compared to manufacturing designs created without machining input.

| Cost Reduction Strategy | Typical Savings | Implementation Complexity |

|---|---|---|

| Optimized toolpaths | 30-40% machine time | Medium |

| Multi-part fixturing | 20-30% setup time | Medium-High |

| Material nesting optimization | 15-25% material savings | Low-Medium |

| Semi-automated finishing | 60-70% finishing cost | High |

| Design-for-manufacturing | 15-25% overall cost | Low (requires early involvement) |

Conclusion

Optimizing lightweight marine hardware production requires specialized materials, advanced multi-axis machining techniques, and rigorous quality control. By implementing these strategies, manufacturers can achieve significant weight reduction without sacrificing durability or performance in harsh marine environments.