We all know how brutal the ocean can be — saltwater, pressure, and constant motion are continuously hitting your equipment. If you’ve dealt with parts that are too expensive to repair, fit incorrectly, or require constant maintenance, you’re not alone.

In this article, we’ll detail the reasons why CNC Machined parts are the better choice compared to cast and welded parts, and look at why they’re the better choice to help avoid downtime, reduce costs, and keep your operations smooth, no matter how harsh the ocean gets. So, keep reading!

1) The Demands of the Marine Environment

You know machined parts are exposed to the harsh saltwater environment and all of its harsh additives, constant pressure, and extreme temperatures. We can say they experience some of the world's toughest conditions alongside rust. It constantly faces corrosion, material fatigue, and weak parts.

Unlike land machinery, marine machinery has no breaks and is exposed to a constant threat of corrosion. Every component of a boat, ship, or offshore platform requires immense strength. They not only have the ability to sustain extreme pressure alongside constant vibrations, but can be relied on to maintain durability during rough weather.

At this stage, cast and welded components have two specific flaws. Casting can and often does leave behind voids, or tiny holes, within the metal known as porosity. While not externally visible, these can compromise the integrity of the part from within.

Through welded components, the joints can exhibit uneven stress distribution. Additionally, the heat from welding can introduce additional weak zones, making the component prone to failure in the long term, especially in saline environments.

To be hoenst, sea don’t forgive eev minor mistakes. A part failure while at sea can be expensive to fix, lead to safety concerns, or worse. Because of this, ensuring the correct method of production is imperative. The right components are pivotal; the environment demands durability, precision, and reliability. But all these demands can be fulfilled by CNC machined parts. Let’s have a look in the next section.

2) CNC Machining: What Makes It Different?

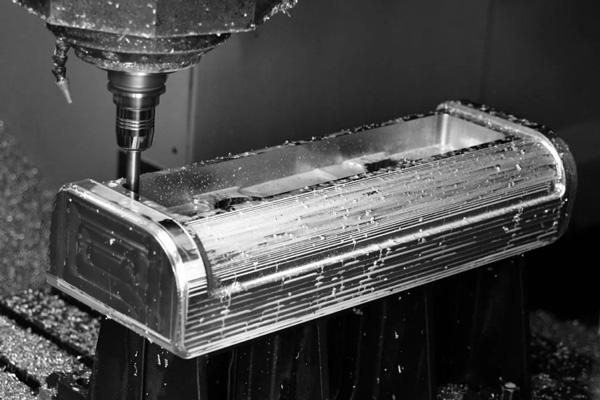

From other types of machining, CNC is different in a particular way: the amount of control it has over the manufacturing process. Yes, every cut, every angle, every curve, each of them is done in the utmost precision and is preprogrammed.

Therefore, parts are always precise and do not need to be estimated, unlike the previous versions, no afterwork done, no uneven edges that are uneven and no changes between different parts.

So, this is especially true for marine boat parts because they require components to be 100% compatible straight out of the box with absolutely no extra grinding, reshaping, or adjustments. CNC machining does guarantee this, since there is no need for luck or manual work to follow precise blueprints.

In addition, CNC does not require pouring metallic materials into preset molds as done in casting or welding. These two approaches normally pose risks for weak points, uneven contours, or superficial defects. Because parts are cut from solid materials, they have fewer weak spots and greater strength.

Apart from this, CNC machined parts are better withstand pressure, vibrations, or corrosion, which are crucial in the marine world. Now, let’s discuss in detail that what makes CNC machined parts win over casted or welded components.

3) Better Precision = Better Performance

Precision is critical in marine applications. Parts made from CNC machining are manufactured with exact dimensions, and thus will not require extra work in the form of adjustments. The accuracy of this level helps eliminate common problems such as leaks, misalignment, and vibration, which can create significant damage over time.

In addition, CNC machining guarantees every piece is manufactured uniformly with no deviation. This level of consistency guarantees fewer breakdowns and smoother performance. Each piece provides a tight and secure fit, which is important to withstand stress and movement.

Moreover, this also reduces damage to your system in the long run. Accurate parts fit helps to sustain proper alignment, enhancing efficiency and equipment longevity. CNC components, even in high vibration or shifting environments, remain securely anchored.

In contrast, cast and welded components lack precision. Casting may result in shrinkage and uneven surfaces, while welding can introduce heat-related distortion. Such inaccuracies necessitate time-consuming, costly corrections and still may not offer the CNC-grade precision.

If you are constructing a marine structure, precise CNC machining is a necessity. Such parts are intended to endure harsh seawater conditions where accuracy is crucial.

4) Stronger and More Reliable Components

To be honest, CNC machined components are significantly stronger and more reliable since they are carved from a solid block of metal. With no seams, joints, or hollow regions, the component is a single, dense piece which enhances its robustness and reliability. This is especially critical in high-pressure environments, such as marine contexts.

On the other hand, welded assemblies join components by welding techniques. Although this may work in certain cases, it tends to form weak joints at the portions where the molten metal solidified and fused. Such ‘heat-affected zones’ tend to be more brittle and more likely to crack under pressure, especially if there is constant movement or vibration.

Additionally, there are also risks with parts that are cast. As the metal cools and solidifies, it tends to form microcracks, shrinkage defects, or cavities called blowholes. Although these are not readily visible, they may result in catastrophic failure at a later time.

And, with CNC machining, there is no casting and no welding, so there is no internal stress buildup. This translates to fewer structural weaknesses and more uniform strength throughout the part. It also allows the use of stronger materials, like certain alloys that are challenging to cast. CNC machining also allows their use, which is ideal for applications at sea.

5) Longer Lifespan in Harsh Conditions

It is obvious that marine equipment is constantly subject to saltwater, humidity, and ever-changing temperatures, all of which accelerate corrosion and fatigue. Under these conditions, CNC machined parts have a distinct advantage, particularly if they are formed from high-grade, corrosion-resistant alloys. These materials are tailored to withstand harsh environments.

More importantly, CNC machining also helps eliminate excess friction and wear by achieving uniform surface finishing as well as smooth edges. There are no rough patches or uneven joins that can entrap salt or moisture—the primary culprits for corrosion or material degradation.

In comparison, parts that are cast and welded tend to have a shorter lifespan. Welded joints that are exposed to saltwater are vulnerable to corrosion if they are not treated adequately, and cast parts containing internal voids are also susceptible to saltwater exposure. These traits are detrimental as they lead to the development of cracks, pits, or complete failure.

CNC parts also demonstrate superior shape retention under stress, thus increasing resistance to long-term fatigue. Yes, parts that have undergone proper machining remain dependable even after years of servicing. For those wanting longevity in marine components, CNC machining is the solution as it provides the rigidity and reliability demanded.

6) Faster Prototyping and Low-Volume Flexibility

CNC machining is the best option when you need custom marine parts or have small production runs because of the quick movement from design to finished part. There is no need for a complex setup or expensive molds. So, this is a great option when you are replacing a single component or testing new ideas.

Juts update digital files, and you can rerun machines. There is no need to remake molds, and no manual work is required, which reduces costs and time. Well, this is another reason why changes become easier with CNC.

In comparison, casting must have custom molds, which are preposterously slow and expensive. Therefore, this is not ideal for small production runs. Welding differs as it relies on skilled labor, and the finished piece is very dependent on the person doing the work, making it very inconsistent.

Excitingly, CNC gives you speed, flexibility, and repeatability. Whether you are replacing parts or building something new, you are sure to get precision quickly. You don’t get the unresponsive service due to long lead times associated with casting or outsourced fabrication.

Moreover, prototypes can be fabricated in hours rather than weeks. This saves time in testing, refining designs, and greatly decreases the time to market. CNC will address the responsiveness and control needed to stay ahead for marine equipment manufacturers that respond to constantly shifting demands.

7) Reduced Failures and Downtime

Parts created using CNC engineering are less likely to fail mechanically with time. When the right CNC components are installed, their performance and the stress on the entire system decrease. Therefore, CNC reduces unplanned downtime, enhances system uptime, and optimises performance overall.

Regular maintenance in marine applications is often difficult and time-consuming. Therefore, using parts that require infrequent adjustments or replacements is advantageous. CNC parts hold their shape and fit better; therefore, less fine-tuning or replacement is needed.

Parts that are cast or welded tend to be structurally weak. Because of these underlying problems, cast and welded parts can require more frequent stop time for inspections, repairs, or replacement of parts due to uneven wear.

If you opt for CNC machined boat parts, you are quite literally a cut above your competitors because you can save time on automation, save cost on unplanned repairs, and allocate your attention to the parts of the operation that truly require it.

In this context, the machine is not a lifeless object; it is a colleague that performs tasks cheaper and without the need for a coffee break – if programmed correctly and supplied with the right components, the machine will keep “working” without disruption.

8) Environmental and Efficiency Benefits

Another area where the CNC machine shines is its environmental dimension. Waste is reduced to the very minimum. You know all parts are ‘carved out’ and a certain volume of raw material is processed. While this sustains and cost-efficiently ensures the material is not wasted.

It is particularly interesting to note that the precision cuts that CNC employs mean it uses only the exact amount of raw material. Moreover, as we discueed, the CNC machine is devoid of the bulky and one-off molds that are required as a prerequisite for casting or welding. Hence, it eliminates the need for heavy, tedious physical labour as well as exuberant energy.

Another area that can be termed as excess is the proliferation and proliferation of energy. Each piece is produced from a digital manifestation of the object, ensuring there is no likelihood of material variance or abundant changes. In simple terms, it greatly reduces the chances of human error.

Moreover, CNC machines practice to an impressive level the practices of the ‘Reduce, Reuse and Recycle’ rule. Practically, these activities, along with avoiding excess and cutting down on waste during and post-production, lead to astounding effects in terms of a cleaner, reduced waste. Overall, it thoroughly improves the design of a manufacturing system.

9) Cost Comparison Over Time

It might appear at first that welded and cast components are less expensive than CNC parts. It is, however, only over time that the real value comes to light. This is because cast and welded components do last, but not without needing constant maintenance.

Moreover, they are also not as reliable and don't perform to the standard required of components needed to be used in crucial parts, thus needing constant repairs. During rework, these parts are inevitably going to fail, which makes repairs and routine fixes costly. Sculpting parts to needs and reshaping is not going to be versatile.

CNC parts, in contrast, do not experience these issues; thus, fewer parts need to be replaced, and no constant fixes are required. The parts last longer, reducing maintenance costs, avoiding costs that easily add up in CNC boat kits. This is why it is much better to rely on cast and welded CNC parts, as they are going to be efficient with time, while also having the constant reliability to not fail and break.

10) Conclusion

In a nutshell, components created by CNC machining provide the exacting strength and peace of mind that are critical in marine applications. They are far more enduring and precise than any cast or welded parts. And, this leads to reduced failures and provides improved durability, which translates into fewer repairs, lower maintenance costs, and an extended service life.

If enduring performance and CNC precision are what you need, machined components are the answer. For custom builds or critical systems, it delivers consistent results you can count on.

When the ocean tests your equipment, CNC keeps you safe.