Rudder stocks are essential to performance sailing, as they connect the rudder blade to the steering system, impacting control and responsiveness. In high-performance sailing, the choice between CNC-machined and cast rudder stocks can make a significant difference. CNC machining offers greater precision, durability, and performance under stress, making it the preferred choice for many sailors.

Marine Upper Rudder Stock with Flange

This article explores why CNC-machined rudder stocks outperform cast versions, focusing on stress loads, material choices, surface finishes, and machining precision. We'll explain how CNC machining enhances performance and extends the lifespan of rudder systems, making it the optimal choice for competitive sailors.

Stress Loads During Rough Sailing Conditions

In high-performance sailing, rudder stocks endure extreme forces. Whether navigating choppy seas, racing at high speeds, or executing tight maneuvers, the rudder is under constant load, both from the water's resistance and the mechanical forces of steering input. The integrity of the rudder stock plays a key role in maintaining control and preventing catastrophic failure in these high-stress moments.

Rudder Stock, Quadrant Stress Test

Unlike cruising yachts, where loads are moderate and predictable, performance sailboats operate in dynamic conditions. Sudden wave impacts, rapid course corrections, and prolonged strain during races put immense pressure on rudder stocks. This is where the construction method becomes critical.

Types of Stress on Rudder Stocks

Rudder stocks are exposed to various mechanical loads during rough sailing, including:

- Torsional stress occurs as the rudder twists against hydrodynamic forces during turns.

- Bending loads – from uneven wave pressure on the rudder blade.

- Axial compression – when downward force is exerted through the tiller or steering mechanism.

- Shock loads – especially during sudden impacts like grounding or wave slamming.

These stresses don't act in isolation. They often combine, increasing the complexity of the load profile and the importance of uniform structural strength.

Effects of Rough Conditions on Structural Integrity

In turbulent seas, these stress loads intensify. The rudder can slam side to side, flex under pressure, or absorb sudden jolts. Over time, this weakens materials, especially if there are internal flaws or inconsistencies.

Cast rudder stocks, by nature, are more susceptible to:

- Micro-porosity and trapped air bubbles from the casting process

- Internal inconsistencies that act as stress risers

- Surface flaws that propagate cracks under fatigue

These flaws can reduce overall fatigue life and increase the chance of structural failure under repeated high-load conditions.

Stress Distribution: CNC Machined vs Cast Rudder Stocks

The way stress travels through the rudder stock is directly affected by how the part is made.

- CNC Machined Rudder Stocks:

- Uniform grain structure and material density

- Predictable stress distribution across the shaft

- Reduced weak points due to precision cutting from billet or forged stock

- Cast Rudder Stocks:

- Potential for uneven grain flow and density variations

- Hidden voids or inclusions that can initiate cracks

- Higher variability in mechanical performance

CNC machining ensures that stress is distributed more evenly, allowing the component to absorb higher loads without deformation or fatigue failure.

Why CNC Machining Excels Under High Stress

CNC machining offers mechanical and structural advantages that make it ideal for high-load applications like rudder stocks:

- Precision geometry – Every curve, shoulder, and taper can be optimized to manage load paths and reduce stress concentrations.

- Consistent material quality – No inclusions, voids, or porosity.

- Better fatigue resistance – CNC-machined parts handle cyclic stress over time without weakening.

- Optimized design tolerances – Tighter tolerances ensure a better fit in bearings and couplings, minimizing unwanted movement and wear.

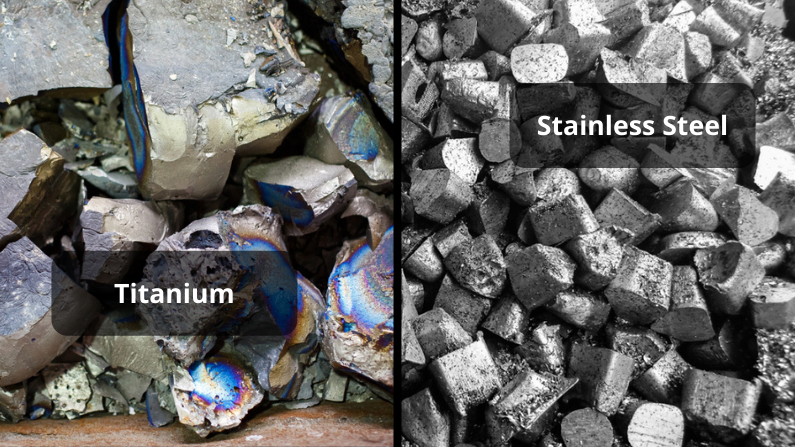

Materials: Titanium and Duplex Stainless Steel

In the world of performance sailing, material selection is critical to the effectiveness of rudder stocks. While cast rudder stocks are traditionally made from materials like bronze or cast stainless steel, CNC machining opens the door to using advanced, high-performance materials like titanium and duplex stainless steel. These materials not only provide superior strength and durability but also ensure that the rudder stocks can withstand the rigors of high-stress sailing conditions.

Titanium and duplex stainless steel are known for their outstanding mechanical properties, particularly in demanding environments like marine applications.

- Titanium: Lightweight, strong, and exceptionally resistant to corrosion, especially in saltwater.

- Duplex Stainless Steel: A hybrid material combining both austenitic and ferritic structures for enhanced strength, resistance to fatigue, and stress corrosion cracking.

Both materials are ideal for CNC machining, allowing for more precise design and tailoring to specific performance needs. Their properties make them especially effective for components that must endure extreme forces, as is the case with rudder stocks in high-performance sailing.

Benefits of Titanium

Titanium is widely considered one of the best materials for marine hardware due to its unique properties:

- Strength-to-Weight Ratio: Titanium is significantly stronger than many steels but much lighter. This makes it ideal for performance sailing, where weight reduction can directly impact speed and maneuverability.

- Corrosion Resistance: One of titanium's standout characteristics is its exceptional resistance to corrosion. It naturally forms a thin, protective oxide layer that prevents the metal from reacting with seawater, making it an ideal choice for harsh marine environments.

- Fatigue Resistance: Titanium maintains its structural integrity even under repeated stress, meaning it can handle high-stress loads over a long lifespan without failure.

Advantages of Duplex Stainless Steel

Duplex stainless steel combines the best properties of both austenitic and ferritic steels, offering a unique set of advantages:

- Durability: Duplex stainless steel is incredibly durable, with higher resistance to wear and tear compared to traditional materials. This is crucial for parts like rudder stocks that undergo constant stress.

- Resistance to Fatigue: The combined microstructure of duplex stainless steel gives it enhanced resistance to fatigue and cracking, ensuring longer service life in demanding conditions.

- Cost-Effectiveness: While titanium is costly, duplex stainless steel provides a more affordable alternative with excellent performance, particularly in terms of strength and resistance to corrosion.

Comparison with Traditional Cast Materials

- Cast materials, such as bronze or cast stainless steel, have long been the standard in rudder stock manufacturing. However, they present several limitations:

- Porosity and Inconsistencies: Cast materials often have micro-porosity or uneven grain structures, which can lead to weak spots under stress.

- Lower Corrosion Resistance: While stainless steel offers decent corrosion resistance, it doesn't match the longevity or performance of titanium or duplex stainless steel in marine environments.

- Heavier Weight: Cast materials are generally heavier, which may hinder the performance of racing yachts where every ounce matters.

Compared to these traditional materials, titanium and duplex stainless steel are far superior, offering lighter, stronger, and more corrosion-resistant solutions for high-performance rudder stocks.

How CNC Machining Enhances Material Precision

The ability to CNC machine materials like titanium and duplex stainless steel allows for:

- More Accurate Material Utilization: CNC machining minimizes waste and maximizes the use of high-performance materials, ensuring that every part is made with precision.

- Tailored Designs: CNC machining allows engineers to fine-tune dimensions and features of rudder stocks, optimizing them for specific sailing conditions. This includes adjustments in weight, strength, and corrosion resistance where needed.

- Consistent Quality: CNC machines can produce parts with extremely tight tolerances, ensuring consistency across multiple parts and reducing the likelihood of material defects or weaknesses that might arise from casting.

Titanium and duplex stainless steel provide significant advantages over traditional cast materials, and CNC machining allows these materials to be utilized to their full potential. Whether for strength, weight, or corrosion resistance, these materials ensure the performance and longevity of rudder stocks in high-performance sailing.

Finishes: Mirror Polish vs Bead Blast for Drag Reduction

The finish of a rudder stock plays a critical role in reducing drag and optimizing performance. In performance sailing, even the smallest improvement in drag can result in significant differences in speed and handling, especially in competitive environments. The smoothness of the rudder's surface affects how efficiently it moves through the water, and the right finish can drastically improve overall performance.

Significance of Surface Finishes in Performance Sailing

A rudder stock's surface finish directly influences how the rudder interacts with the water. The smoother the surface, the less friction is created as the rudder moves, which translates into reduced drag. The type of finish applied can either improve or hinder a rudder's hydrodynamic properties, making it an essential consideration for high-performance sailing.

- Hydrodynamic Efficiency: The smoother the surface, the more efficiently water flows over it, reducing turbulence and drag.

- Durability vs Performance Trade-Off: Some finishes, like bead blasting, focus more on durability and corrosion resistance, while others, like mirror polishing, prioritize reducing drag for speed.

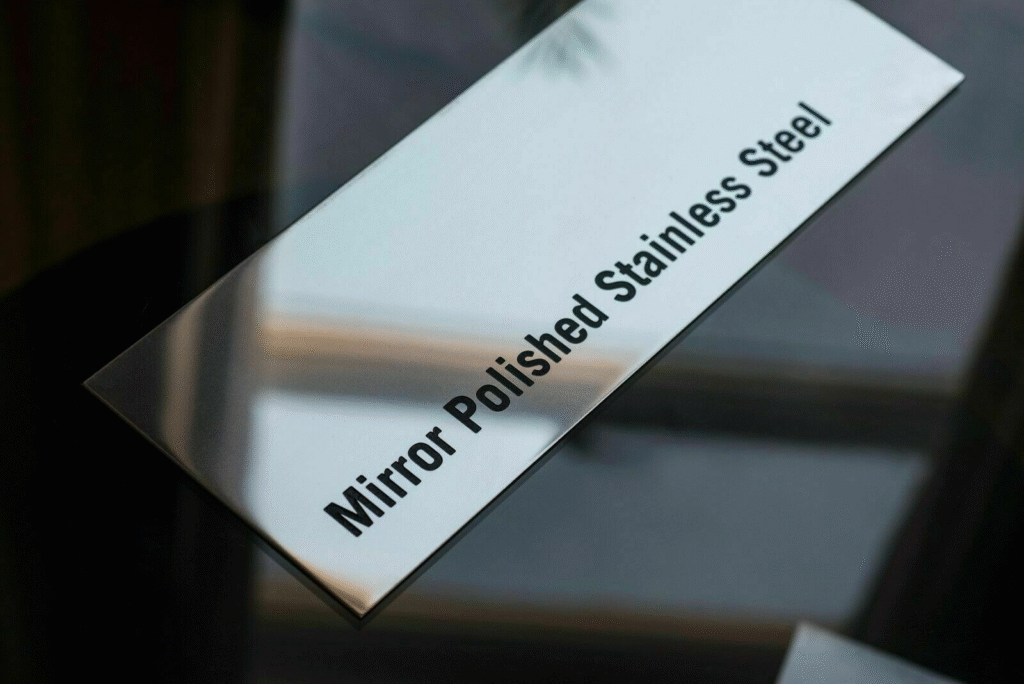

Mirror Polish: Enhanced Smoothness, Lower Drag, Higher Performance

Mirror Finish on Stainless Steel

A mirror polish finish is often the go-to choice for optimizing hydrodynamic efficiency. Polishing the rudder stock to a near-glass smooth surface minimizes surface roughness and allows for smooth water flow.

- Enhanced Smoothness: The polished surface creates an almost flawless barrier for water, significantly reducing drag.

- Lower Drag: Lower drag means less resistance when the rudder is in use, which translates into faster speeds, particularly important in racing or high-performance situations.

- Higher Performance: The reduced friction not only improves the boat's top speed but also enhances its responsiveness to rudder inputs, making maneuvers more precise and efficient.

A mirror-polished rudder stock, however, comes with one caveat: it is more susceptible to scratches and abrasions, especially in harsh marine environments, which can diminish its performance over time.

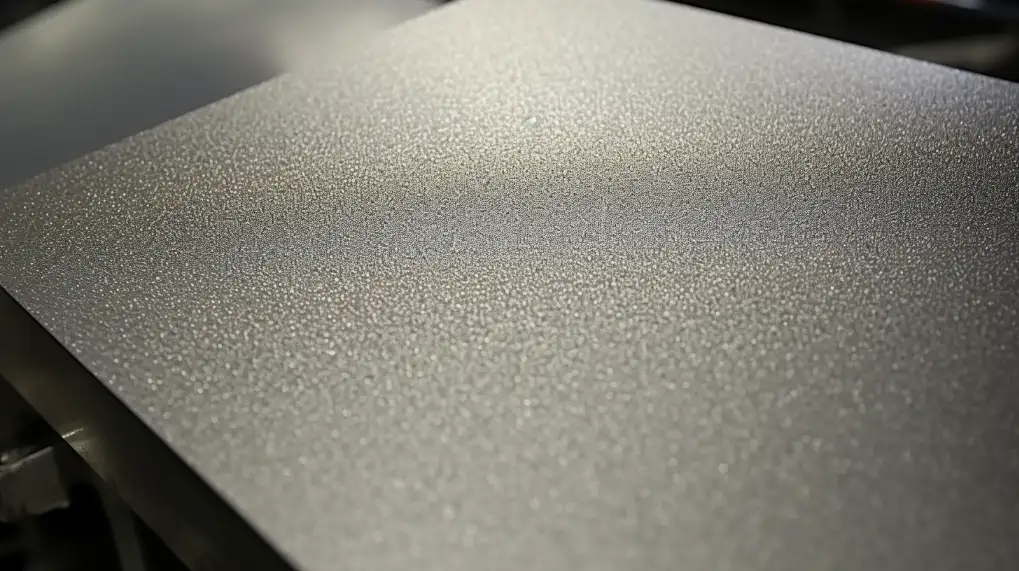

Bead Blast: Improved Durability, Balance Between Smoothness and Grip

On the other hand, a bead blast finish strikes a balance between smoothness and durability. This finish involves blasting the metal surface with tiny glass beads to create a slightly textured, matte surface.

- Improved Durability: The bead-blasted finish is more resistant to scratches and wear than a mirror-polished surface. This makes it better suited for everyday sailing or environments with high amounts of debris, reducing maintenance.

- Balanced Smoothness and Grip: While it may not be as smooth as a mirror polish, bead blasting provides a more balanced surface that still minimizes drag but offers better grip in turbulent water conditions.

- Corrosion Resistance: The finish also promotes better corrosion resistance compared to polished surfaces, making it an excellent choice for long-term durability in saltwater environments.

While bead blasting may slightly increase drag compared to a mirror polish, it ensures that the rudder stock remains resilient to environmental factors, offering a good trade-off between performance and longevity.

Comparison of Drag Reduction: CNC Machined vs Cast Rudder Stocks

When comparing CNC-machined rudder stocks to cast versions, the difference in drag reduction is stark. CNC machining allows for a higher degree of control over surface finishes, enabling more precise, smoother finishes than traditional casting processes.

- CNC Machined Rudder Stocks:

- CNC machining allows for a flawless, mirror-polished surface or a finely tuned bead blast finish, achieving greater consistency across all units.

- The precision of CNC machining minimizes surface imperfections, leading to more effective drag reduction, especially when paired with a mirror polish.

- Cast Rudder Stocks:

- Cast parts may have inherent surface imperfections from the casting process, such as rough spots or variations in texture, which can hinder drag reduction.

- While cast rudder stocks can be polished, achieving the same level of smoothness and consistency as CNC machining is more challenging. This can lead to higher drag and lower performance efficiency.

In terms of drag reduction, CNC machined rudder stocks hold a clear advantage, providing smoother surfaces with fewer imperfections that contribute to reduced resistance in the water.

CNC Machining and Refined Finish Choices for Optimal Drag Reduction

One of the major benefits of CNC machining is the ability to precisely control the finish of the rudder stock. Unlike casting, which is limited by the mold and material flow, CNC machining can create:

- Customized Finishes: CNC machining allows for the exact surface texture to be tailored to the specific needs of the sailor. Whether opting for a mirror polish for maximum smoothness or a bead blast for durability, CNC machining ensures that the finish is optimized for performance.

- High-Quality Consistency: Every CNC-machined rudder stock can be finished to the same high standard, ensuring that the drag-reducing properties are consistent across all parts, which is especially important in racing and high-performance contexts.

- No Surface Defects: CNC machining eliminates the risk of casting defects like porosity or irregular texture that can negatively affect drag.

Ultimately, CNC machining allows for more refined finish choices that balance hydrodynamics, performance, and durability, optimizing the rudder stock for long-term high-speed sailing.

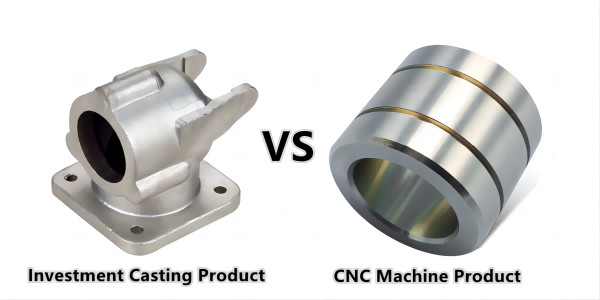

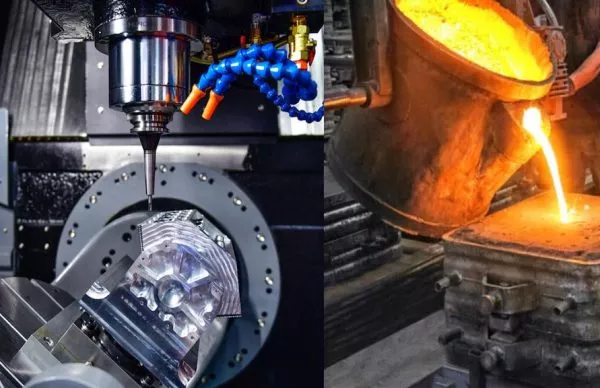

CNC Machining vs Casting: Performance, Precision, and Durability

When selecting manufacturing methods for rudder stocks, sailboat manufacturers must consider not only the cost but also the long-term performance and precision of the components. CNC machining offers significant advantages over traditional casting techniques in terms of precision, consistency, and durability. Below, we'll delve into the key differences between CNC machining and casting, highlighting why CNC machining is the superior choice for producing high-performance rudder stocks.

Precision of CNC Machining vs Casting

One of the primary benefits of CNC machining is its ability to achieve extremely tight tolerances and high precision, which are critical in the production of rudder stocks that must fit perfectly within the rudder system.

- CNC Machining:

- Tight Tolerances: CNC machines can achieve tolerances as low as 0.001 mm, ensuring that every rudder stock is produced to the exact specifications. This precision ensures that each part fits perfectly into the vessel's rudder system, minimizing the potential for misalignments or poor fits that could lead to wear and failure.

- Consistency: With CNC machining, manufacturers can produce identical parts with uniform precision. This reduces variability in quality, ensuring that every rudder stock, regardless of batch size, meets the same high standards.

- Casting:

- Looser Tolerances: The casting process typically has broader tolerances, with part dimensions varying more significantly due to the molding and cooling processes. This can lead to parts that don't fit as precisely, potentially compromising performance and increasing the need for post-production adjustments.

- Inconsistent Quality: Casting involves molten material poured into molds, which can lead to inconsistencies in the final product due to material flow, cooling rates, and mold imperfections. This results in a higher risk of defects like porosity, warping, or uneven thickness, which can affect performance.

Dimensional Accuracy and Reduced Tolerances

Dimensional accuracy is paramount in high-performance sailing components. CNC machining allows for the creation of parts with superior dimensional accuracy compared to casting methods.

- CNC Machining:

- Control Over Dimensions: With CNC machining, every part is carved from solid material, allowing manufacturers to control every aspect of the part's geometry. This level of control ensures that the dimensions remain consistent across all units, which is critical for parts like rudder stocks that must interact precisely with other systems on the boat.

- Minimized Tolerances: CNC machines can reduce tolerances significantly, meaning that parts are less likely to have gaps or uneven surfaces that could cause friction or wear. This reduces the likelihood of component failure due to poor fit.

- Casting:

- Inherent Dimensional Variability: During casting, the cooling and solidification process often leads to parts that have slight dimensional variations. These variations are not always easily controlled and can affect the performance of the rudder stock, particularly in areas where tight tolerances are necessary.

By ensuring tighter tolerances and precise dimensional control, CNC machining eliminates many of the issues associated with dimensional inaccuracies found in cast parts.

Durability of CNC-Machined vs Cast Rudder Stocks Under Varying Sailing Conditions

The long-term durability of rudder stocks is a key consideration for sailboat manufacturers. Rudder stocks are subjected to constant mechanical stress, corrosion, and fatigue, especially in high-performance sailing. CNC machining provides superior durability due to its material utilization and the precise manufacturing process.

- CNC Machining:

- Material Integrity: CNC machining works with high-quality, solid billets or forgings, ensuring that the material maintains its full structural integrity. There are no internal flaws, voids, or inconsistencies, which are common in cast parts. This enhances the fatigue resistance of the rudder stock.

- Consistent Performance: CNC-machined parts are less likely to experience performance degradation over time. The consistent quality ensures that the part will perform optimally across many sailing conditions, whether under high-stress or low-stress scenarios.

- Casting:

- Material Defects: Cast rudder stocks are more prone to defects such as porosity, internal cracks, or weak spots that can develop over time, particularly under repeated stress. These issues can lead to premature failure or reduced performance.

- Wear Resistance: Cast parts may show signs of wear sooner than CNC-machined parts, particularly in areas exposed to high mechanical stress. This results in more frequent maintenance and potential failure.

In comparison, CNC machining results in a more durable and reliable rudder stock, which can withstand the harsh marine environment over the long term with fewer signs of wear and tear.

Long-Term Benefits of CNC-Machined Rudder Stocks in Performance Sailing

The long-term advantages of CNC machining extend beyond immediate performance gains. By choosing CNC machining, sailboat manufacturers can ensure that their rudder stocks remain top-tier throughout their lifecycle.

- Reduced Maintenance Costs: CNC-machined rudder stocks, due to their superior durability and precision, typically require less maintenance and have a longer service life than cast versions. This reduces the long-term operational costs for sailboat owners and manufacturers.

- Enhanced Performance Over Time: The consistent high quality of CNC-machined parts ensures that performance doesn't degrade over time, unlike cast parts, which may experience issues with wear, corrosion, or structural damage.

- Customization and Adaptability: CNC machining allows for greater flexibility in design, enabling manufacturers to quickly adapt to changing performance requirements. This is crucial for the evolving demands of high-performance sailing, where component optimization is often key to gaining an edge.

By investing in CNC machining for rudder stocks, manufacturers ensure that their components not only meet but exceed the expectations of performance sailors, providing them with reliable, high-quality parts that enhance both the safety and efficiency of the vessel.

Conclusion

In summary, CNC-machined rudder stocks offer significant advantages over their cast counterparts, especially in high-performance sailing applications. The precision, dimensional accuracy, and material integrity provided by CNC machining ensure that rudder stocks can withstand the intense stress loads and harsh conditions of competitive sailing. Additionally, the ability to optimize finishes, select high-performance materials like titanium and duplex stainless steel, and achieve superior durability makes CNC machining the clear choice for manufacturers looking to deliver top-quality products.

When compared to traditional casting methods, CNC machining excels in providing consistent, high-quality components with superior performance and longevity. Manufacturers can rely on CNC-machined rudder stocks for reduced maintenance costs, increased durability, and the ability to tailor parts to specific design requirements, making them ideal for the demanding environments of competitive sailing.

For sailboat manufacturers aiming to stay ahead of the curve in both performance and reliability, investing in CNC machining for rudder stocks is a forward-thinking decision that will benefit both the manufacturer and the end-user in the long run.