Are you struggling with finding the right manufacturing solution for your complex parts? The overwhelming number of CNC machining options can leave even experienced engineers confused about which process best fits their specific requirements.

CNC machining services encompass multiple processes including milling, turning, drilling, and grinding - each offering unique advantages for different applications. The right process depends on your part geometry, material choice, tolerance requirements, and production volume, ensuring optimal performance while maintaining cost efficiency.

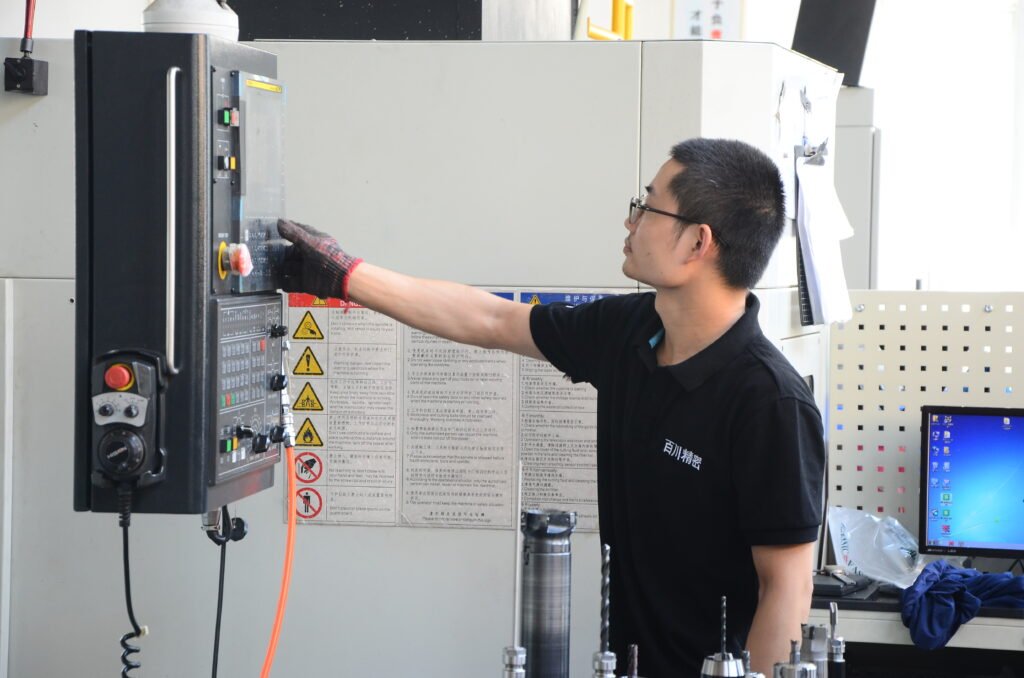

Modern CNC machining center in operation

At our machining facility, we've helped countless clients navigate these choices. I remember working with an automotive client who came to us with a complex transmission component that required both high precision and durability. By analyzing their specific needs, we were able to recommend a multi-axis milling1 approach that delivered the exact specifications they needed while keeping costs reasonable. This is just one example of how understanding the full spectrum of CNC processes can make all the difference in manufacturing success.

How Does Material Selection Impact Machining Performance?

Have you ever wondered why some materials are nearly impossible to machine while others cut like butter? Material properties can mean the difference between a successful production run and a costly failure with damaged tools and scrapped parts.

Material selection directly affects cutting speeds, tool wear, surface finish, and overall machining efficiency. Metals like aluminum are typically easy to machine, while titanium and hardened steels require specialized tooling and reduced cutting speeds to achieve optimal results without excessive tool wear.

Different materials used in CNC machining

In our years of CNC machining experience, we've worked with virtually every material type imaginable. The relationship between material properties and machining parameters is critical for successful outcomes. When selecting materials for your project, it's important to consider not just the end-use requirements but also the manufacturability.

Material Categories and Their Machining Characteristics

Different materials exhibit varying degrees of machinability2 based on their physical and chemical properties. Here's a breakdown of common material categories and their machining characteristics:

| Material Type | Machinability | Tool Requirements | Typical Applications |

|---|---|---|---|

| Aluminum Alloys | Excellent | Standard carbide tools | Aerospace components, consumer electronics |

| Mild Steel | Good | Standard carbide tools | Structural components, fixtures |

| Stainless Steel | Fair to Difficult | Cobalt or carbide tools with specific geometries | Medical devices, food processing equipment |

| Titanium | Difficult | Special carbide tools with unique geometries | Aerospace, medical implants |

| Plastics | Varies widely | Sharp cutting tools with specific rake angles | Consumer products, medical devices |

I recall a challenging project involving a vacuum chamber component made from a specialized stainless steel alloy. The material's work-hardening properties made conventional machining approaches ineffective. By carefully analyzing the material properties, we developed a custom tooling strategy3 with specialized coatings and adjusted our cutting parameters to maintain low cutting temperatures. This approach prevented work hardening and delivered the high-precision components the client needed for their semiconductor equipment.

Material selection isn't just about the end-use properties; it's equally about understanding how those materials will behave during the manufacturing process. This knowledge allows us to recommend the most cost-effective material that meets both your performance requirements and manufacturability constraints.

Which CNC Process Is Ideal for Your Product Requirements?

Are you confused by the array of machining processes available for your project? Many clients come to us uncertain whether milling1, turning4, or another process will deliver the best results for their specific part geometry and requirements.

The ideal CNC process depends on part geometry, feature complexity, tolerance requirements, and production volume. Milling excels for complex 3D geometries, turning is optimal for cylindrical parts, and multi-axis machining centers can combine operations to minimize setups and improve accuracy.

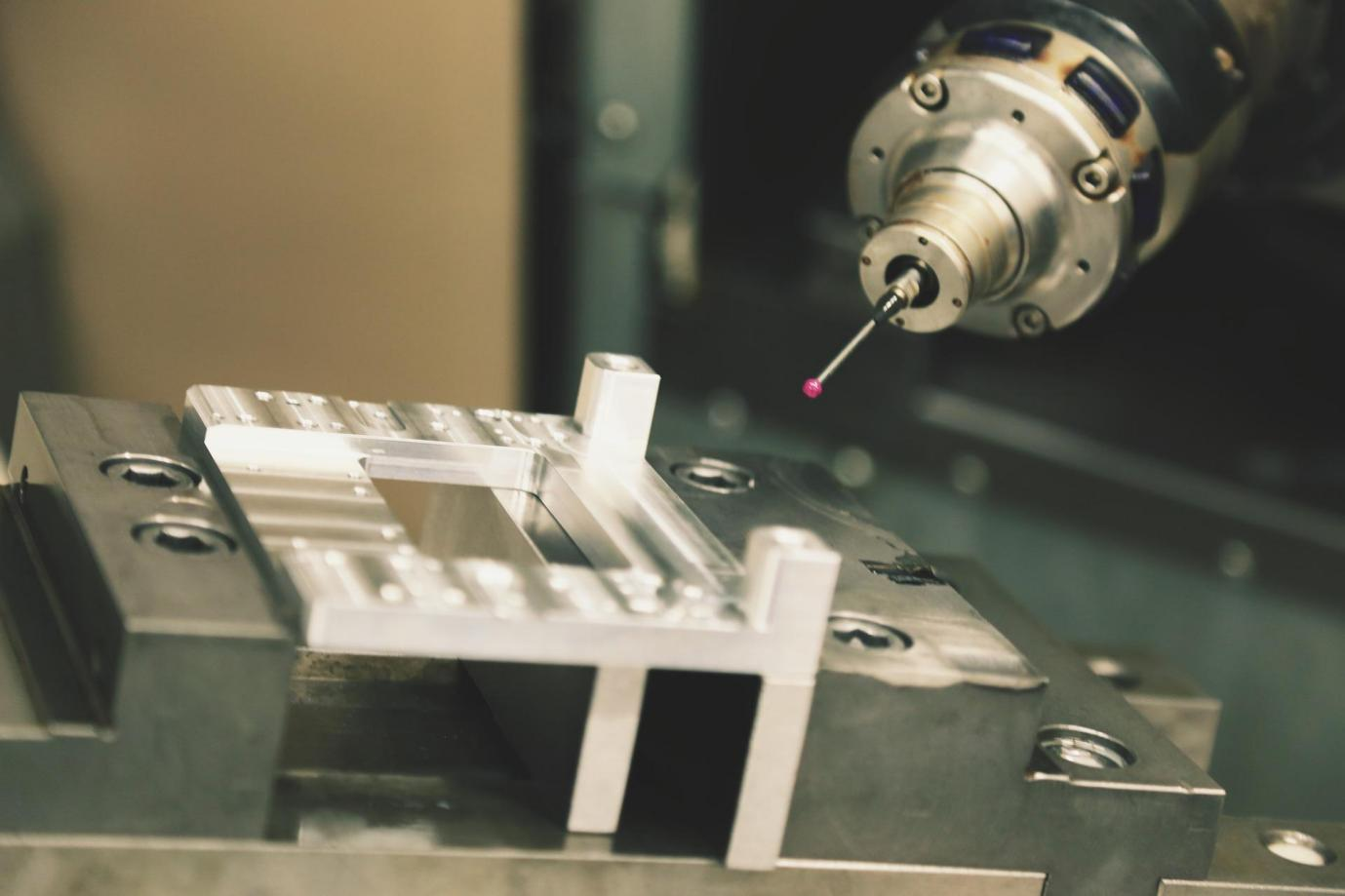

5-axis CNC machining center creating complex components

Selecting the right CNC process involves careful analysis of your product requirements and manufacturing constraints. Each machining process offers distinct advantages and limitations that directly impact your part's quality, cost, and production timeline. Understanding these nuances is crucial for making informed manufacturing decisions.

Comparing CNC Machining Processes

When evaluating which CNC process is right for your project, consider how each approach aligns with your specific requirements:

| Process | Best For | Typical Tolerances | Cost Factors | Limitations |

|---|---|---|---|---|

| CNC Milling | Complex 3D shapes, pockets, slots | ±0.025mm-0.1mm | Setup time, programming complexity | Limited for deep internal features |

| CNC Turning | Cylindrical parts, threads | ±0.025mm-0.075mm | Simple setup for basic parts | Limited to rotationally symmetric parts |

| Swiss-Type Turning | Small, precise cylindrical parts | ±0.005mm-0.025mm | Higher hourly rates, specialized tooling | Part diameter restrictions |

| 5-Axis Milling | Complex geometries, undercuts | ±0.025mm-0.075mm | Programming complexity, specialized fixturing | Higher cost for simpler parts |

| Grinding | Super-precise surfaces, hardened materials | ±0.005mm-0.010mm | Slow material removal rates | Limited to surface operations |

I recently worked with a marine equipment manufacturer who needed complex sailboat hardware components with intricate internal passages. Initially, they assumed 3-axis milling would be sufficient. After analyzing their designs, I recommended our 5-axis machining center instead. This approach allowed us to reach all the required features in a single setup, improving accuracy while reducing production time by nearly 40%. The ability to approach the workpiece from virtually any angle eliminated the need for multiple setups and specialized fixturing.

Understanding the capabilities and limitations of different CNC processes allows us to recommend the most efficient manufacturing approach for your specific requirements. Sometimes, this might even involve combining multiple processes to achieve the optimal balance of quality, cost, and lead time.

How Do We Ensure Quality in Custom CNC Parts?

Are you worried about receiving parts that don't meet your specifications? Quality concerns keep many engineers and procurement professionals awake at night, especially when working with custom components critical to your product's success.

Quality assurance in CNC machining involves a comprehensive approach including proper machine calibration, in-process inspections, and final verification using precision measurement equipment like CMMs. Our rigorous quality system ensures parts consistently meet or exceed your tolerances and specifications.

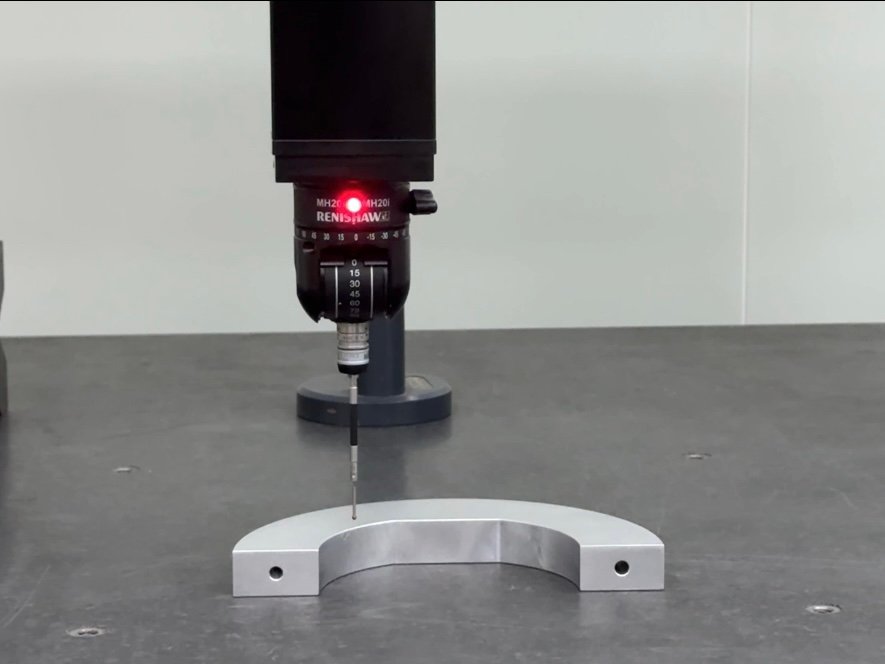

Coordinate Measuring Machine (CMM) inspection of precision machined component

Quality doesn't happen by accident—it's built into every step of our manufacturing process. From the moment we receive your design files to the final inspection before shipping, multiple quality checkpoints ensure your parts meet every specification. This systematic approach to quality has been refined through decades of experience serving industries with demanding requirements.

Our Multi-Layered Quality Assurance System

Ensuring consistent quality in custom CNC machining requires a structured approach with verification at multiple stages of production:

| Quality Stage | Key Activities | Tools/Methods | Benefits |

|---|---|---|---|

| Pre-Production | Design for manufacturability review, tolerance stack analysis | CAD/CAM simulation, manufacturing expertise | Prevents design-related quality issues before production begins |

| Setup Verification | First article inspection, tool offset verification | Precision measuring instruments, CMM | Catches setup errors before full production run |

| In-Process Controls | Statistical process control, tool wear monitoring | Automated measurement systems, operator inspections | Identifies drift in process parameters in real-time |

| Final Inspection | Comprehensive dimensional verification, surface finish analysis | CMM, surface roughness testers, optical comparators | Ensures all specifications are met before parts are approved |

| Documentation | Quality reports, material certifications, inspection records | Digital quality management system | Provides traceability and verification for regulatory compliance |

I recently led a project for a medical device manufacturer requiring components with extremely tight tolerances of ±0.005mm. To meet these demanding requirements, we implemented an enhanced quality protocol that included temperature-controlled inspection, multiple verification methods, and 100% part inspection rather than statistical sampling. This rigorous approach ensured that every single component met the client's exacting standards, which were essential for patient safety in their final application.

Quality assurance isn't just about catching defects—it's about preventing them through systematic processes and continuous improvement. Our quality management system has evolved through decades of experience and is tailored to meet the specific requirements of industries ranging from automotive to aerospace to medical device manufacturing.

How Do Post-Processing Treatments Enhance Component Performance?

Are your machined parts underperforming despite meeting dimensional specifications? Many engineers overlook the critical role that post-processing treatments play in achieving optimal component performance and longevity.

Post-processing treatments like heat treatment, surface finishing, and coating applications can dramatically improve a component's mechanical properties, corrosion resistance, and aesthetic appearance. These secondary operations transform a geometrically correct part into one that fully meets your functional requirements.

Post-machining surface treatment process

The final performance of a machined component often depends as much on its post-processing treatments5 as on the initial machining operations. These secondary processes can be the difference between a part that merely looks right and one that performs optimally throughout its service life. Our comprehensive approach includes recommending and executing the appropriate post-processing treatments based on your specific application requirements.

Common Post-Processing Treatments and Their Benefits

Selecting the right post-processing treatments requires understanding how each option affects your component's performance characteristics:

| Post-Process | Primary Benefits | Typical Applications | Considerations |

|---|---|---|---|

| Heat Treatment | Improved hardness, strength, or ductility | Gears, shafts, structural components | This may cause dimensional changes requiring final machining |

| Anodizing | Enhanced corrosion resistance, wear resistance, electrical insulation | Aerospace components, consumer electronics | Color options available, slight dimensional change |

| Passivation | Improved corrosion resistance without dimensional change | Medical devices, food processing equipment | Primarily for stainless steel components |

| Electropolishing | Smooth surface finish, improved cleanliness, reduced microscopic defects | Medical implants, semiconductor components | Removes a small amount of material |

| Powder Coating | Durable protective finish, aesthetic appearance | Outdoor equipment, architectural components | Requires proper surface preparation |

| Plating (Nickel, Chrome, etc.) | Wear resistance, corrosion protection, appearance | Automotive components, consumer products | It may affect tolerances, and requires careful process control |

I recently collaborated with a client in the marine industry who was experiencing premature corrosion on their machined stainless steel components despite using "marine-grade" materials. After analyzing their application environment, we recommended an electropolishing6 process followed by a specialized passivation treatment. This combination dramatically improved the components' corrosion resistance7 by removing free iron from the surface and enhancing the natural oxide layer. The client reported that the treated parts showed no signs of corrosion after a full season of use in saltwater conditions, while their previous untreated parts had begun corroding within weeks.

The right post-processing treatments shouldn't be an afterthought—they should be an integral part of your manufacturing strategy from the design phase onward. By considering these treatments early in the product development process, we can help you optimize both performance and cost-effectiveness.

Conclusion

Selecting the right CNC machining processes involves careful consideration of materials, methods, quality systems, and post-processing treatments. By partnering with an experienced manufacturer like us, you'll benefit from our expertise in delivering precision parts that perform exactly as required in your specific application.

- Learn about CNC milling, its processes, and how it can be applied to create complex parts efficiently. ↩ ↩

- Learn about the factors that influence machinability and how they impact your manufacturing process. ↩

- Discover the importance of a custom tooling strategy for optimizing machining processes and outcomes. ↩

- Discover the CNC turning process and its advantages for producing cylindrical parts with precision. ↩

- Explore various post-processing treatments and how they enhance the performance of machined components. ↩

- Find out how electropolishing enhances the cleanliness and corrosion resistance of machined parts. ↩

- Learn about methods to enhance corrosion resistance in machined components for better longevity. ↩