Custom CNC-Machined Spreaders: Balancing Strength and Weight

In this blog, we will explore what CNC-machined spreaders are, why the strength-to-weight ratio matters, their key design factors, manufacturing challenges, and more. So, keep reading!

Drawing from our 20+ years of precision machining experience, we share practical insights to help you overcome technical challenges in complex parts manufacturing. From material selection to process optimization, we empower your procurement decisions with professional expertise and confidence.

In this blog, we will explore what CNC-machined spreaders are, why the strength-to-weight ratio matters, their key design factors, manufacturing challenges, and more. So, keep reading!

Effective welding defect repair requires systematic assessment, appropriate method selection, and rigorous quality verification. By understanding defect characteristics and repair impacts, manufacturing engineers can restore component integrity while minimizing costs and production delays.

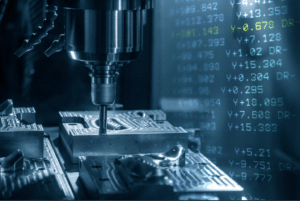

Recognizing G-Code basics is essential for fast and safe CNC machining. All feed commands (F, G94, G95), spindle command (S, M3, M4, M5), and tool change commands (T, M6, G43) application is directly related to surface finish, tool-life, and safety in machining.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.